5XFS-7.5BC Double Air Screen Cleaner

- အိမ်

- ထုတ်ကုန်များ

- ကြိုတင်ရှင်းလင်းပါ။

- 5XFS-7.5BC Double Air Screen Cleaner

သန့်ရှင်းမှု 98.5%

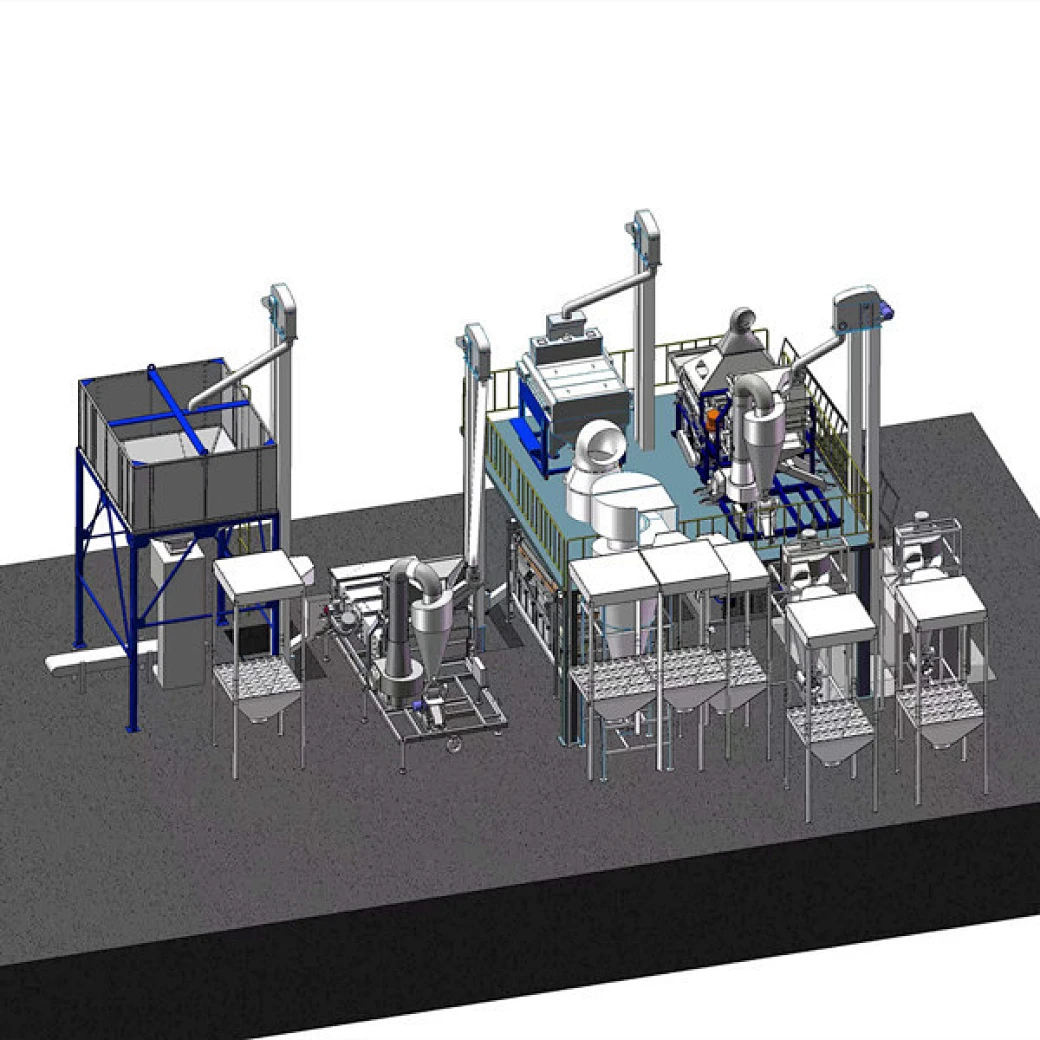

Double Air Screen Cleaner

ဓာတ်အား: 9.9KW

အလေးချိန်: 2000 ကီလိုဂရမ်

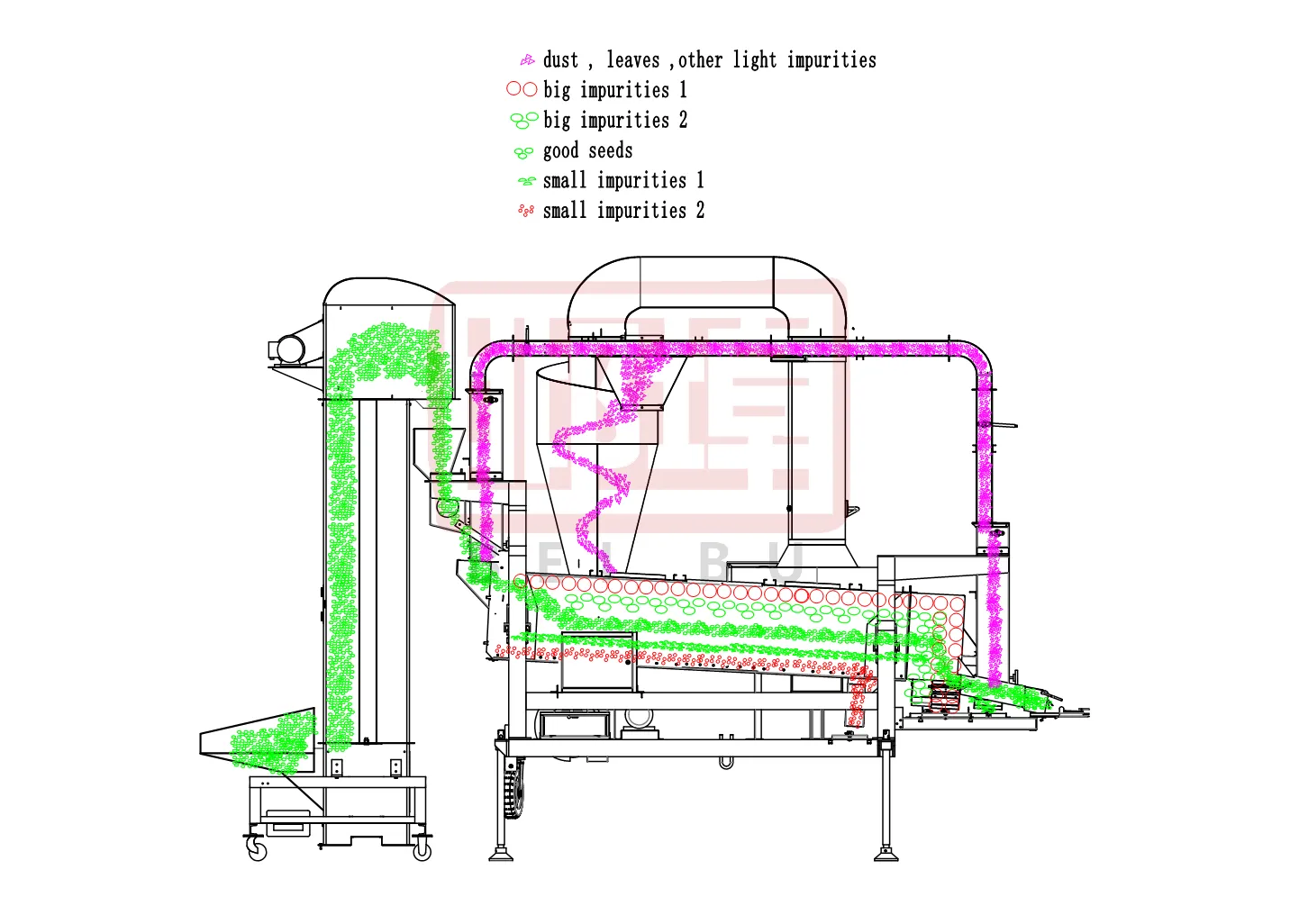

5XFS-7.5BC Double Air Screen Cleaner include the two times air screen part can remove the dust and light impurities out well,with four layers sieves which can remove the bigger and smaller impurities well;

This is a machine with a long history. As early as 2010, when this machine was first launched, it has been widely praised by major sesame exporters.Its advantages are very obvious:

Simple operation.

The operation process of this machine is very simple, which is the secret of its popularity in various countries.

Put the materials into the hopper of elevator . The no crushing elevator will send the materials into the machine . At first , it will go through the back air screen , or someone called air separator . Here the air will take out the light impurities such as dust , small leaves , shells , strew, etc .

Then , the materials will go through the vibration grader . the vibration grader have 4 layer sieves with different size of holes . it will remove the big and small impurities .

After that , the materials will go through another air screen again to remove the light impurities .

To use this machine , you only need to adjusting the air handle for the two air screen . So it is very easy to operate .

That is why people want to use it .

Suitable for all kinds of light materials.

For example, sesame, sunflower seeds, quinoa, chia seeds, alfalfa seeds, etc. Later, we developed more spices. For example, cumin, fennel seeds, thyme, hibiscus flowers, etc.

Since it go through the air screen two times , so it will separate the light impurities very well .

We sell more than 100 machines of this model every year. Over the years, our customers have spread across various countries, including Nigeria, Burkina Faso, Tanzania, Sudan, Egypt, Kazakhstan and other countries.

| မော်ဒယ် | 5XFS-7.5BC |

| ပါဝါ | 9.9KW |

| ဆန်ခါအရွယ်အစား | လေးလွှာတွင် 1250*1200mm |

| စွမ်းရည် | 7.5t/h (ဂျုံအပေါ်အခြေခံ၍) |

| အလေးချိန် | 2000 ကီလိုဂရမ် |

| စုစုပေါင်းအရွယ်အစား | 4000*2500*3400mm |

| ဓာတ်အား | 380V၊ 50HZ၊ အဆင့်သုံးဆင့် |

စက် ဗီဒီယို

-

5XFS-7.5BC Double Air Screen Cleaner ၏ အဓိကလုပ်ဆောင်ချက်ကား အဘယ်နည်း။

5XFS-7.5BC သည် အစေ့အဆန်များ၊ ပဲများနှင့် ဆီထွက်သီးနှံများကဲ့သို့သော စိုက်ပျိုးရေးထွက်ကုန်များကို ကြိုတင်သန့်ရှင်းရေးနှင့် ကောင်းစွာသန့်စင်ရန်အတွက် ဒီဇိုင်းထုတ်ထားသည်။ ၎င်းသည် လေနှစ်ဆခွဲထုတ်ခြင်းနှင့် တုန်ခါမှုစခရင်များကို ပေါင်းစပ်အသုံးပြု၍ ဖုန်မှုန့်များ၊ အလင်းအညစ်အကြေးများ၊ အခွံခွာထားသော အစေ့များနှင့် နိုင်ငံခြားပစ္စည်းများကို ထိရောက်စွာ ဖယ်ရှားပေးပါသည်။ -

ဒီစက်ရဲ့ လုပ်ဆောင်ချက်စွမ်းရည်က ဘယ်လောက်လဲ။

စက်သည် ပစ္စည်း၏ အမျိုးအစားနှင့် အခြေအနေပေါ်မူတည်၍ တစ်နာရီလျှင် 5 တန်မှ 7.5 တန်အထိ လုပ်ဆောင်နိုင်စွမ်းရှိသည်။ အလတ်စား လယ်ယာများ၊ မျိုးစေ့ထုတ် ယူနစ်များနှင့် စပါး ကိုင်တွယ်သည့် စက်ရုံများအတွက် စံပြဖြစ်သည်။ -

Double air screen စနစ်ရဲ့ အားသာချက်တွေက ဘာတွေလဲ။

Dual Air Cleaning System သည် လေကို ခွဲထုတ်ခြင်း အဆင့်နှစ်ဆင့်ကို ပံ့ပိုးပေးပါသည်။ ပထမအဆင့်သည် ဖုန်မှုန့်နှင့် စပါးခွံကဲ့သို့ ပေါ့ပါးသော အညစ်အကြေးများကို ဖယ်ရှားပေးကာ ဒုတိယအဆင့်တွင် အခေါင်းပေါက်နှင့် အစေ့အဆန်များကို ခွဲထုတ်သည်။ ၎င်းသည် ပိုမိုသန့်ရှင်းတိကျမှုနှင့် ထုတ်ကုန်သန့်ရှင်းမှုကို ဖြစ်ပေါ်စေသည်။ -

စက်သည် လည်ပတ်ရန် လွယ်ကူပါသလား။

ဟုတ်ကဲ့။ စက်တွင် အလိုလိုသိနိုင်သော control panel နှင့် ချိန်ညှိနိုင်သော ဆက်တင်များ တပ်ဆင်ထားပါသည်။ လေ့ကျင့်မှုအနည်းဆုံးဖြင့်၊ အော်ပရေတာများသည် စက်ကို ထိထိရောက်ရောက် လည်ပတ်ထိန်းသိမ်းနိုင်သည်။ နေ့စဥ်ထိန်းသိမ်းမှုတွင် ဖန်သားပြင်များကို သန့်ရှင်းရေးလုပ်ပြီး လေပြွန်များကို ရှင်းရှင်းလင်းလင်းဖြစ်စေရန် ပါဝင်သည်။ -

ဂျုံ၊ ပဲပုပ်နှင့် နှမ်းကဲ့သို့သော သီးနှံအမျိုးမျိုးအတွက် စက်ကို ချိန်ညှိနိုင်ပါသလား။

မေးတာ။ 5XFS-7.5BC သည် မတူညီသော မျိုးစေ့အမျိုးအစားများနှင့် အရွယ်အစားများနှင့် ကိုက်ညီစေရန် လေစီးဆင်းမှု၊ မျက်နှာပြင်အမျိုးအစားနှင့် မျက်နှာပြင်ထောင့်ကို လွယ်ကူစွာ ချိန်ညှိနိုင်စေပါသည်။ ဂျုံ၊ ပြောင်း၊ ပဲ၊ နှမ်းနှင့် ပြောင်းဖူးအပါအဝင် သီးနှံမျိုးစုံအတွက် သင့်လျော်သည်။

ဧပြီလ 08 ရက် 2024 ခုနှစ်

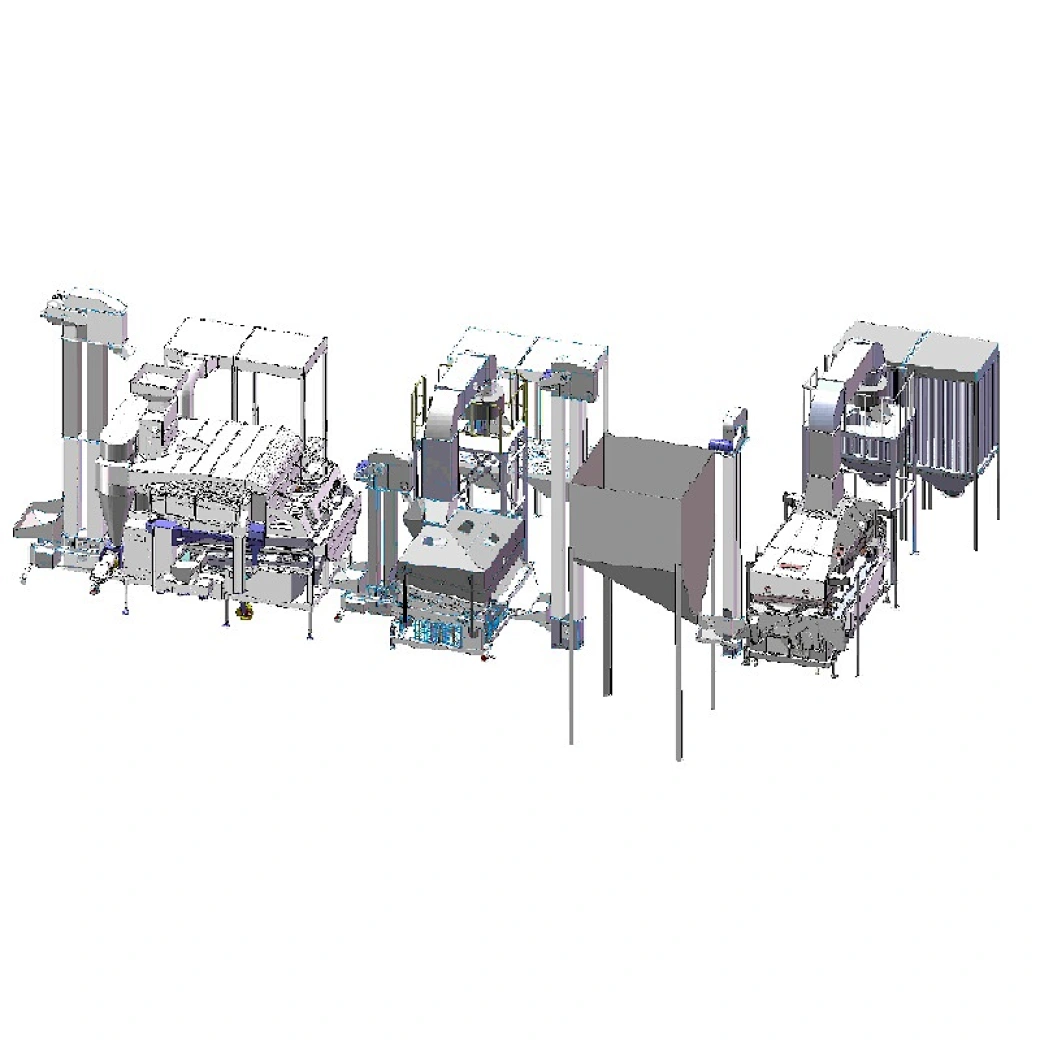

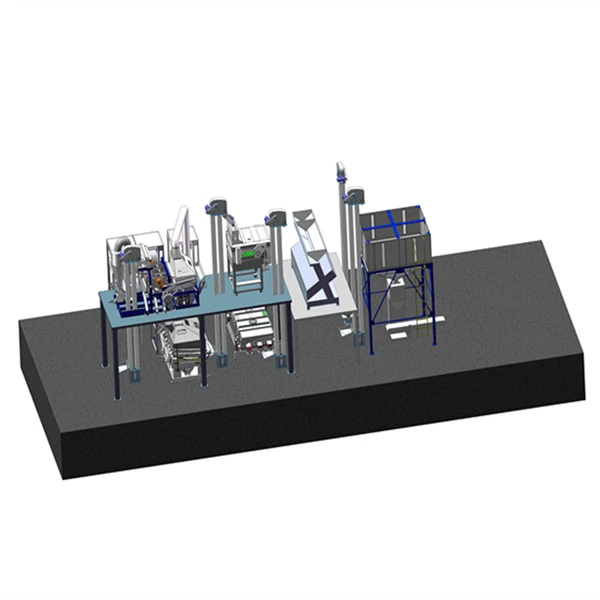

အသစ်တပ်ဆင်ထားသော နှမ်းသန့်စင်စက်-Hebei Beibu Machinery Technology Co.,LTD

နိုဝင်ဘာ ၀၇၊ ၂၀၂၄

နှမ်းနှင့် ပဲများ သန့်ရှင်းရေး ဆောင်ရွက်နေသည့် Line-Hebei Beibu Machinery Technology Co.,LTD

မတ် ၂၆၊ ၂၀၂၄

နှမ်းသန့်စင်စက် - Hebei Beibu Machinery Technology CO.,LTD

ဇန်နဝါရီ ၂၄၊ ၂၀၂၄

နိုင်ဂျီးရီးယားတွင် တပ်ဆင်ထားသော နှမ်းသန့်စင်စက်အသစ်

ဇန်နဝါရီ ၂၂၊ ၂၀၂၅

တရုတ်နှစ်သစ်ကူးနီး-Hebei Beibu Machinery Technology Co.,LTD

စက်တင်ဘာ ၁၃၊ ၂၀၂၄

China-Hebei Beibu Machinery Technology Co.,LTD ရှိ နှမ်းဈေးကွက်အခြေအနေ

Beibu စက်ယန္တရား

အကယ်၍ သင်သည် ကျွန်ုပ်တို့၏ထုတ်ကုန်များကို စိတ်ဝင်စားပါက၊ သင့်အချက်အလက်များကို ဤနေရာတွင်ထားခဲ့ရန် သင်ရွေးချယ်နိုင်ပြီး၊ ကျွန်ုပ်တို့သည် သင့်အား မကြာမီ ဆက်သွယ်ပေးမည်ဖြစ်ပါသည်။