Susam Soyma Makinesi

- Ev

- Ürünler

- Susam Soyma Makinesi Hattı

- Susam Soyma Makinesi

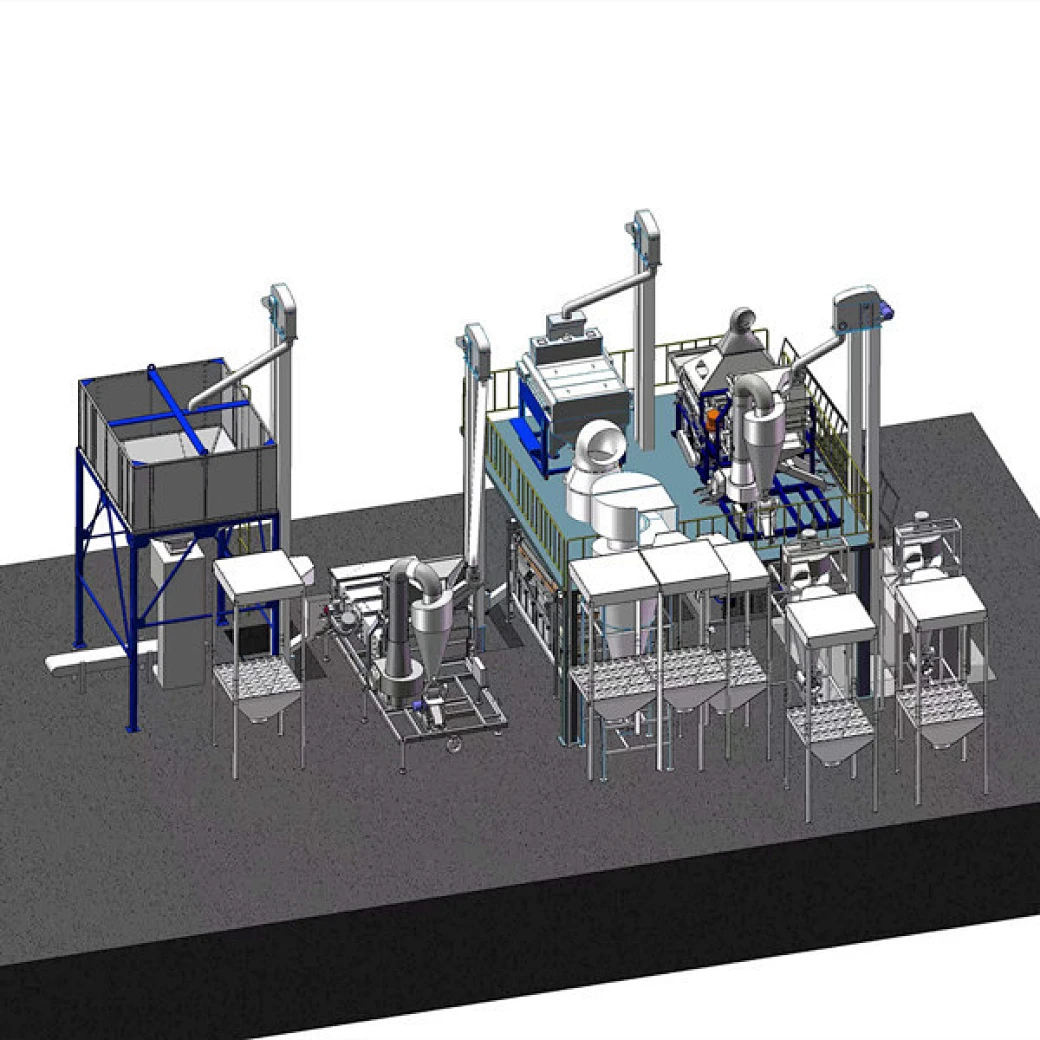

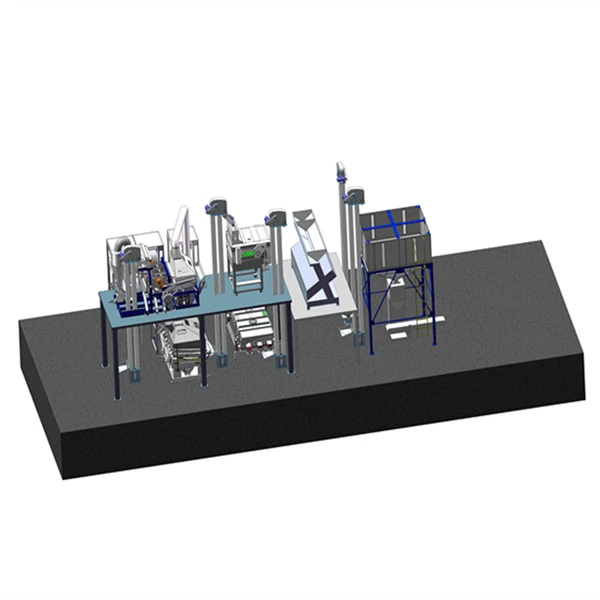

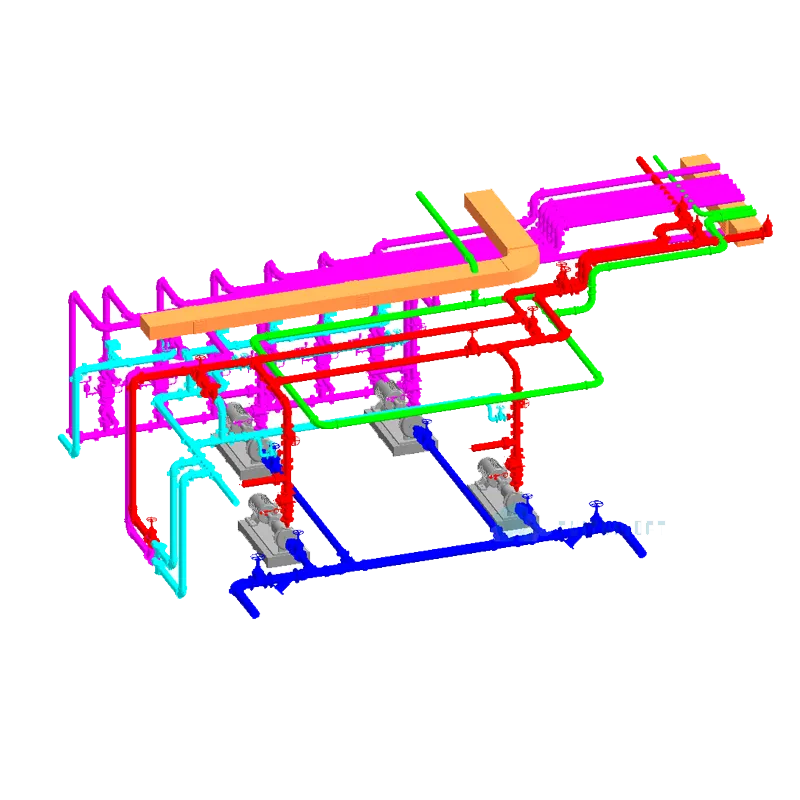

Susam soyma makinemiz Çin'deki çeşitli yerli firmaların olgun ve ileri teknolojilerini bir araya getirerek çözümleri entegre ediyor.

Susam temizleme makinesi, susam soyma makinesi, susam boyama makinesi, renk ayırma ve paketleme makinesi gibi tam donanımlı işleme makinelerine sahiptir.

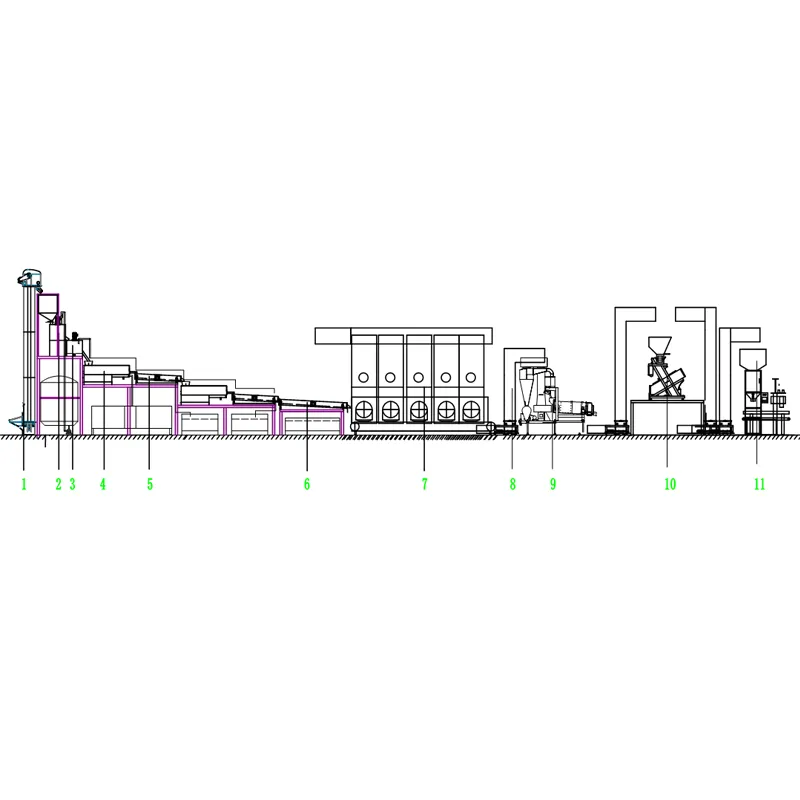

İşleme Adımı:

-

Susam Soyma Makinesi Ne İşe Yarar?

Susam Soyma Makinesi, susam tohumlarının dış kabuğunu veya zarını çıkarmak, nihai ürünün görünümünü, tadını ve kalitesini daha ileri işleme veya tüketime sunmak için tasarlanmıştır. -

Susam Soyma Makinasının kapasitesi nedir?

Modele bağlı olarak saatte 500 kg ile 3 ton arasında işleme kapasitesine sahip olan makine, küçükten büyüğe her türlü susam işleme operasyonuna uygundur. -

Susamın kabuklarını soyma işlemi zarar verir mi?

Hayır. Makine, tohumları çatlatmadan veya zarar vermeden kabuğu etkili bir şekilde soyan nazik aşındırıcı veya sürtünme yöntemleri kullanır. -

Makine farklı susam çeşitlerini işleyebilir mi?

Evet. Makine farklı tohum boyutlarına ve çeşitlerine uyum sağlayacak şekilde ayarlanabilir ve bu sayede çeşitli susam türlerinin etkili bir şekilde soyulmasını sağlar. -

Makinenin kullanımı ve temizliği kolay mı?

Evet. Susam Soyma Makinesi basit bir yapıya, kolay temizlenen bileşenlere ve basit bir çalışmaya sahiptir, bu da duruş süresini ve bakımı en aza indirir.

25 Mart 2024

Çok Tipli Tahıl Temizleme Makinesi-Hebei Beibu Makine Teknolojisi A.Ş.,LTD

26 Haziran 2024

Büyük Kapasiteli Kombine Soya Temizleme Makinesi-Hebei Beibu Makine Teknolojisi A.Ş.,LTD

20 Mayıs 2024

Tahıl Torbası Paketleme Makinesi-Hebei Beibu Makine Teknolojisi A.Ş.,LTD

10 Mayıs 2024

Nijeryalı müşterilerin Beibu Machinery'i ziyaret etmelerini içtenlikle bekliyoruz

Jun. 24, 2025

BEIBU'nun Mısır Gezisi: Tahıl ve Ot Temizleme Teknolojisinde Ufukların Genişletilmesi

07 Kasım 2024

Susam ve Fasulye Temizleme İşleme Hattı-Hebei Beibu Makine Teknolojisi A.Ş.,LTD

Beibu Makineleri

Ürünlerimizle ilgileniyorsanız, bilgilerinizi buraya bırakabilirsiniz; en kısa sürede sizinle iletişime geçeceğiz.