5XFJ tebranish greyderi

- Uy

- Mahsulotlar

- Vibratsiyali greyder

- 5XFJ tebranish greyderi

Quvvat: 1,5KVt (ikki tebranish motori)

Imkoniyat: 10t/soat

Ishlab chiqarish vaqti: 7 ish kuni

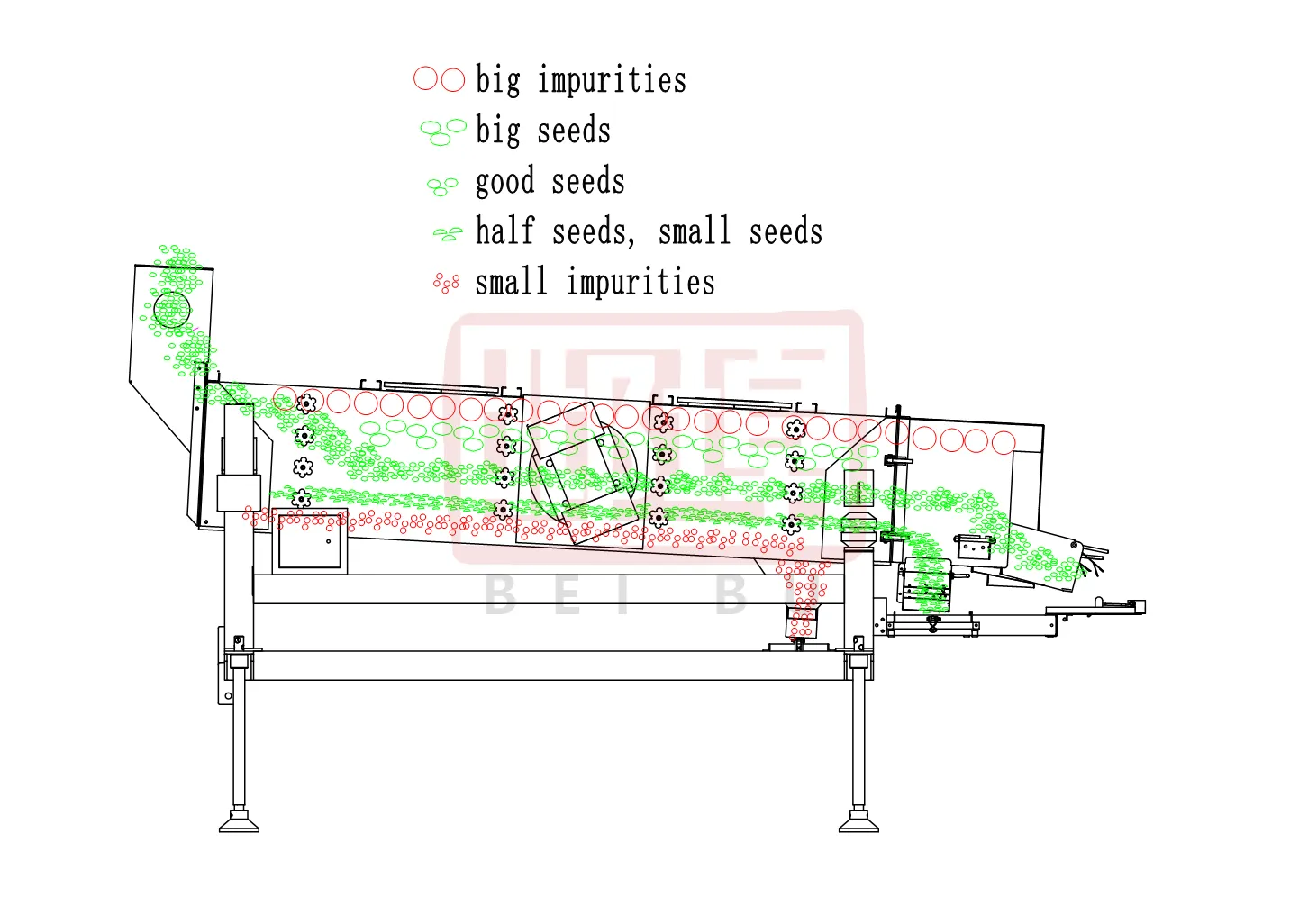

The 5XFJ Series Vibration Grader based on the different capacity have different capacity. The output of the machine varies according to the width of the screen. At the same time, the inclination angle of the machine also has a great influence on the output. The larger the inclination angle, the greater the output, but the screening rate will be reduced.

Normally , the machine have four layers of sieves inside . some time we use them all , some times we use only 2 layer or 3 layer sieve . It will depends on the customers need and the material .

In some cases, in order to increase the capacity, we will use a special type of sieves. Its model is 5XFJ-20Y VIBRATION GRADER. This machine has 5 layers of sieves but the middle layer has no screen holes. In this way, the vibration grader box is divided into two spaces, upper and lower. In these two spaces, there are two layers of sieves respectively. When we produce and process, we use these two spaces separately, and we can have twice the output of ordinary grading screens.

Based on the need the vibration grader can work for grading in different sizes and removing the bigger and smaller impurities out; This depends mainly on the size of the mesh. We can customize the mesh size according to your requirements, including long holes and round holes. The size is accurate to 0.1mm.

Our sieves have a self-cleaning function. In each layer of the sieve, we place some elastic balls. During the vibration of the machine, the elastic balls bounce continuously and remove the materials that are blocked in the sieve holes.

About vibration. There is a kind of vibrating grading screen that relies on the motor to drive the eccentric wheel to vibrate, and then drives the machine to vibrate. This machine is relatively slow. However, our machine uses a double-sided vibration motor, which has a relatively fast vibration frequency. Therefore, the machine has a large product and a good screening effect.

| Ism | Turi | Qatlam | Elak hajmi | Imkoniyat | Og'irligi | Umumiy hajmi | Kuchlanishi |

| Vibratsiyali greyder | 5XFJ-5C | 4 | 1000 * 2400 mm | 5 t/soat | 1000kg | 3600 * 1850 * 1850 mm |

380V, 50HZ, uch fazali

|

| 5XFJ-7,5C | 4 | 1250 * 2400 mm | 7,5 t/soat | 1200 kg | 3600 * 2050 * 1850 mm | ||

| 5XFJ-10C | 4 | 1500 * 2400 mm | 10t/soat | 1400 kg | 3600 * 2300 * 1850 mm | ||

| 5XFJ-20Y | 5 | 1500 * 2400 mm | 20t/soat | 1500 kg | 3600 * 2300 * 2000 mm |

-

5XFJ Vibratsiyali Greyder nima uchun ishlatiladi?

5XFJ vibratsiyali greyder urug'lar yoki donalarni o'lchamlari bo'yicha tasniflash va tasniflash uchun ishlatiladi. U turli xil o'lchamdagi bir nechta tebranish ekranlari yordamida materiallarni 2 dan 4 gacha turli o'lchamdagi fraktsiyalarga ajratadi. -

Ushbu mashina bilan qanday ekinlarni navlarga ajratish mumkin?

Bu bug'doy, guruch, makkajo'xori, soya, kungaboqar urug'lari, no'xat va qadoqlash yoki keyingi qayta ishlash uchun bir xil o'lchamlarni talab qiladigan boshqa donador ekinlar uchun javob beradi. -

Baholash jarayoni qanday ishlaydi?

Material qatlamli tebranish ekranlariga teng ravishda taqsimlanadi. Mashina tebranayotganda, kichikroq zarralar yuqori ekranlardan o'tib, kattaroqlari qoladi, natijada aniq o'lchamga asoslangan bo'linadi. -

5XFJ ning baholash qobiliyati qanday?

Ekin turi va ekran konfiguratsiyasiga qarab, 5XFJ odatda soatiga 3 dan 8 tonnagacha ishlov beradi. -

Ekran qatlamlarini o'zgartirish yoki moslashtirish mumkinmi?

Ha. Mashina maxsus ekran to'r o'lchamlarini qo'llab-quvvatlaydi va ekranlar osongina almashtirilishi yoki turli xil ekin turlari va tasniflash talablariga mos ravishda sozlanishi mumkin.

may. 08, 2024 yil

kunjut tozalash zavodi ishlamoqda

2024 yil 25 dekabr

2024 yil 16 iyul

Soya tozalash mashinasi - Hebei Beibu Machinery Technology Co., LTD

03 dekabr, 2024 yil

Beibu Machinery Roselle tozalash ishlab chiqarish liniyasi Afrikaga jo'natilgan

2024 yil 14 mart

Sesame tozalash mashinasi uchun yangi yuklash - Hebei Beibu Machinery Technology Co., LTD

2025 yil 19 mart

Beibu Machinery

Agar siz bizning mahsulotlarimizga qiziqsangiz, ma'lumotingizni shu yerda qoldirishingiz mumkin va biz tez orada siz bilan bog'lanamiz.