Recently, our company launched an innovative seed processing trailer in collaboration with a European distributor. This project stemmed from the distributor's explicit request for a mobile seed cleaning system that could be flexibly moved long distances and easily accessed by various customer sites. This equipment would be primarily used for the primary processing and handling of seeds for common crops such as wheat, oats, and corn.

During the initial phase of the project, we conducted multiple rounds of in-depth discussions with distributors and end users to gain a comprehensive understanding of the real-world agricultural production scenarios and their specific pain points. Traditional fixed seed processing equipment not only has long installation cycles and high moving costs, but also struggles to meet the flexible, multi-location, and seasonal demands of operations. Based on this feedback, we proposed a solution combining an efficient seed processing system with a towable trailer, ultimately resulting in the development of this highly integrated, mobile, and all-in-one seed processing trailer.

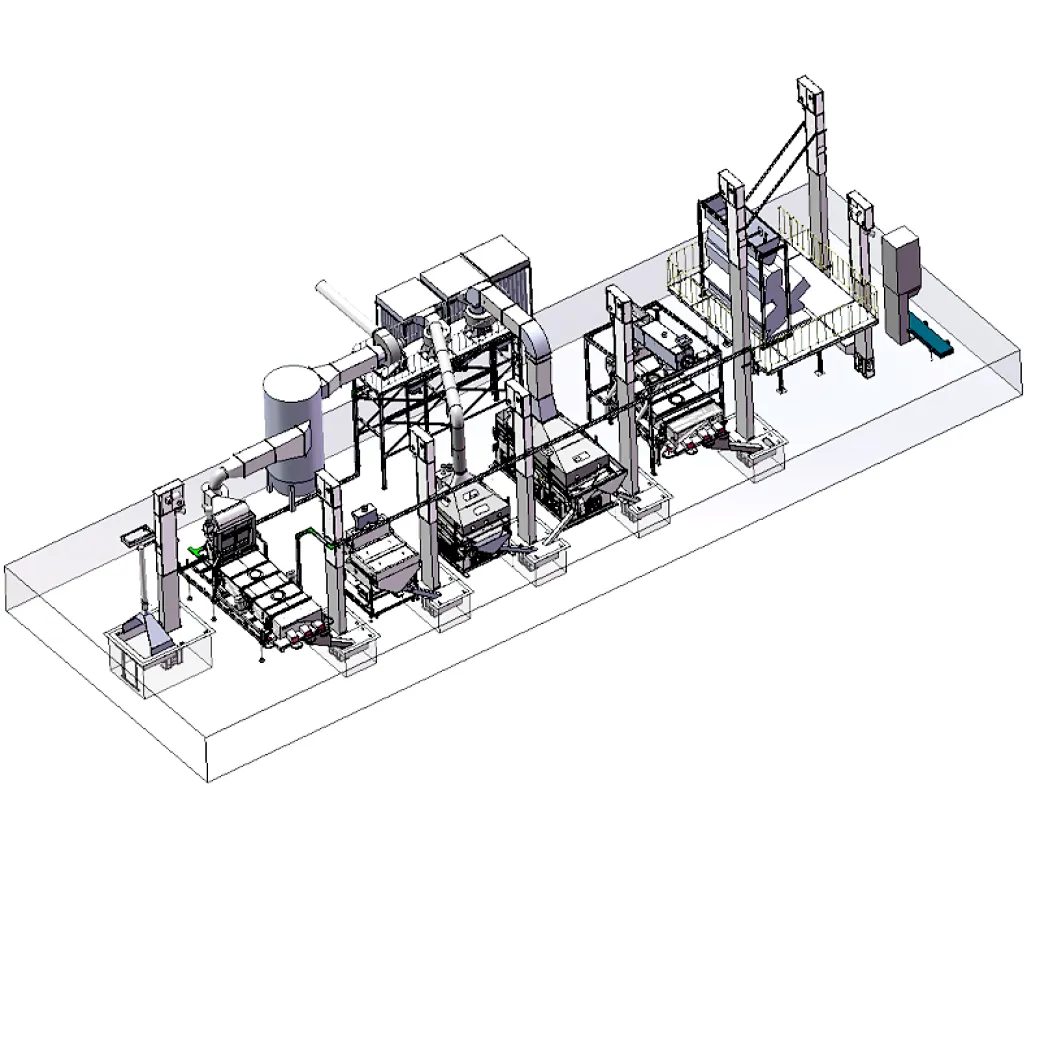

This equipment consists of two core components: a 5XFZ-25SC air-screening and gravity sorting machine, which efficiently screens and gradates seeds by size and density, effectively removing impurities and low-quality kernels; and a 5BY-5 seed coating machine, which precisely coats cleaned seeds to enhance disease resistance and germination rates. These two components are connected by a sturdy, integrated chassis, featuring a strategic layout and balanced weight distribution. The entire system is secured to a heavy-duty trailer, ensuring both structural safety during transport and maximum convenience and stability for on-site operations.

Taking into account the equipment's long-distance transport and diverse road conditions, we incorporated extensive special design considerations into the trailer structure and overall mounting. The chassis utilizes high-strength steel and a shock-absorbing structure to effectively mitigate vibration and shock during travel. Key components are secured with anti-loosening and redundant mounting. Hydraulic outriggers and a quick-connect system further enhance on-site installation efficiency. Before leaving the factory, each unit undergoes dozens of hours of rigorous testing, simulating various road conditions and continuous production operations, ensuring rapid and stable operation upon arrival at the customer's site.

In terms of performance, the equipment demonstrated excellent results in real-world testing, with an hourly processing capacity of 6-8 tons and a consistently high seed purity of over 99.3%, fully meeting and even exceeding European customers' expectations for mobile processing systems. Customer feedback indicates that this trailer significantly improves service mobility and responsiveness. By eliminating the need for redundant fixed equipment, a single vehicle can meet seasonal needs across multiple locations, significantly reducing operating costs.

This seed processing trailer represents more than just a mobile production line; it represents a new possibility for modern agricultural service models. It successfully brings the factory to the field, providing the European seed processing industry with a new, efficient, flexible, and cost-effective solution.

14 ga Satumba, 2024

Afrilu 08, 2024

Sabuwar Injin Tsabtace Sesame-Hebei Beibu Machinery Technology Co., LTD

19 ga Yuni, 2024

78 na'urorin tsabtace sesame sun jigilar-Mashinan Beibu

Afrilu 23, 2024

Injin Beibu ya halarci bikin baje kolin masana'antar ciyar da abinci ta kasar Sin na shekarar 2024

Mayu 20 ga Nuwamba, 2024

Kayan Kayan Hatsi na Hatsi-Hebei Beibu Machinery Technology Co., LTD

02 ga Yuli, 2024

Injin Beibu CNC na lankwasa na'ura da kuma ƙaddamar da na'ura

Injin Beibu

Idan kuna sha'awar samfuranmu, zaku iya zaɓar barin bayanin ku anan, kuma za mu tuntube ku nan ba da jimawa ba.