Uygun asansör nasıl seçilir?

Tahıl tohumu temizleme ve işleme alanında, tahıl tohumu kırılması sıklıkla meydana gelir. Uygun bir asansör seçmek, iş verimliliğini artırmak, maliyetleri düşürmek ve ürün kalitesini sağlamak için çok önemlidir.

Piyasada çok çeşitli asansör ürünleri varken, fabrikanızın ihtiyaçlarına en uygun olanı nasıl seçebilirsiniz? Bu makale sizi tahıl satın almanın temel noktaları hakkında derinlemesine bir anlayışa götürecektir asansörler ve akıllıca bir seçim yapmanıza yardımcı olur.

BÖLÜM 1 İhtiyaçlarınızı belirleyin

Öncelikle, işlenmesi gereken malzemenin türü, saatlik kaldırma hacmi, kırma oranı gereksinimleri, kaldırma yüksekliği, çalışma ortamının alan kısıtlamaları, taşınması gerekip gerekmediği vb. dahil olmak üzere özel ihtiyaçlarınızı netleştirmeniz gerekir.

BÖLÜM2 Güvenlik

Güvenlik de önemli bir husustur. İdeal vinç, halat dolanmasını önleyen bir yapıya, ayrıca tork korumasına, ters kilitlemeye ve hız izleme işlevlerine sahip olmalı ve operasyonel riskleri en aza indirmeli, operatörlerin ve ekipmanın kişisel güvenliğini hasardan korumalıdır.

BÖLÜM3 İstikrarlı ve güvenilir

Makul bir vinç üretmek ve tasarlamak için yüksek kaliteli motorlar, rulmanlar, çelik malzemeler vb. seçmek, verimli ve istikrarlı çalışmasını sağlamanın anahtarıdır. Yüksek kaliteli hammaddeler, makinenin uzun vadeli istikrarını sağlarken, otomatik yağlama ve zincir temizleme işlevleri gibi dikkatli tasarım, bakım sürecini basitleştirir ve verimliliği artırır.

KISIM 4 Maliyet tüketimi

Ekipman tedarikinin ilk maliyetine dikkat etmenin yanı sıra, işleme süreci sırasında vincin neden olabileceği malzeme kaybı da dikkate alınmalıdır. Malzeme kırılmasını en aza indiren asansörler seçilerek, genel işleme maliyetleri önemli ölçüde azaltılabilir.

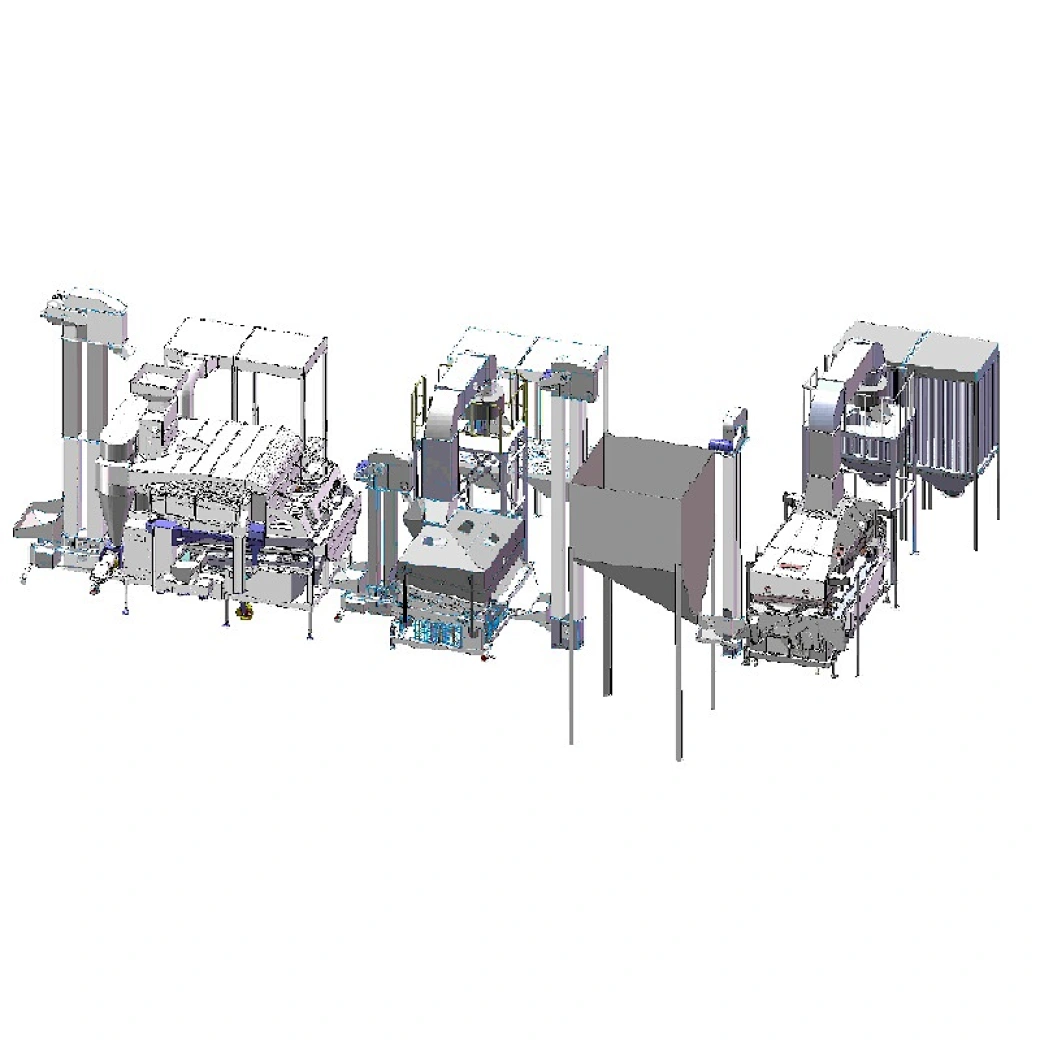

Beibu Makineleri on yıldan uzun süredir tahıl temizleme ve fiyatlandırma makinelerine kendini adamıştır ve tahıl işleme endüstrisindeki müşterilere profesyonel çözümler sunmaktadır. Ürün yelpazemiz çeşitli tahıl tohumlarının temizlenmesini ve işlenmesini kapsar! Bunların arasında, her biri farklı müşterilerin ihtiyaçlarını karşılamak için sıkı kalite kontrolünden geçmiş ultra düşük hızlı ezmeyen asansör serisi yer almaktadır.

DTY-10M ultra düşük hızlı ezmeyen asansör

Ürün avantajları:

1. Düşük kırma oranı:

Makine kendi ağırlığını boşaltma, düşük doğrusal hız, dökülen ve düşen malzemeler olmadan çalışır ve ezilmeyi önler;

2. Kolay kullanım:

Transmisyon kayışının gerginliğini ve ayarını kolaylaştırmak için makine tabanlı tahrikli tekerlek ayar cihazı ile donatılmıştır;

3. Çift namlulu yapı:

Namlu, ayrı üst ve alt malzemelere sahip çift namlulu bir yapıya sahiptir ve düşen tahılın tahrikli tekerleğe girmesini ve ekstrüzyona ve ezilmeye neden olmasını önlemek için bir tahıl bariyer yapısı ile tasarlanmıştır;

4. Çıkarılabilir kauçuk film:

Yapısal kafa tahrik tekerleği, yüksek sürtünme, uzun hizmet ömrü, iyi kendi kendini temizleme, iyi ısı dağılımı ve kolay kurulum ve bakım özelliklerine sahip çıkarılabilir bir kauçuk film yapısını benimser;

5. Sarma önleyici yapı:

Tahrikli tekerlek, plastik halat ve çuval ipi gibi sarma sorunlarının oluşmasını etkili bir şekilde önleyebilen ve günlük bakım işini azaltabilen anti-sargı yapı tasarımına sahiptir;

6. Kolay gözlem:

Namlu, beslenen ve geri dönen malzemelerin rahatça izlenebilmesi için ön ve arka gözlem portlarıyla donatılmıştır.

Uygulama kapsamı:

Çoğu taneli tahıl tohumlarının kaldırılmasında uygulanabilir!

İletişim numarası: +8615564532062

23 Eylül 2024

Dört Set Susam Temizleme Makinesi Teslimatı-Hebei Beibu Makine Teknolojisi A.Ş.,LTD

Dört Set Susam Temizleme Makinesi Teslimatının ayrıntılarını mı bilmek istiyorsunuz? Beibu Machinery sizin için susam temizleme makinesi, susam fiyatı hakkında bilgi paylaşacaktır. Daha fazla bilgi edinmek için bağlantıya tıklayın.

20 Mayıs 2024

Cassia Tohum Temizleme Makinesi-Hebei Beibu Makine Teknolojisi A.Ş.,LTD

Cassia Tohum Temizleme Makinesinin ayrıntılarını mı bilmek istiyorsunuz? Beibu Machinery, cassia tohum temizleme makinesi, çekirdek ayırıcı hakkında bilgi paylaşacaktır. Daha fazla bilgi edinmek için bağlantıya tıklayın.

24 Şubat 2025

2025'in 1 numaralı belgesi ilk olarak "yeni kaliteli tarımsal verimlilik"ten bahsetti

2025'in ilk kez bahsedilen 1 numaralı belgesinin ayrıntılarını bilmek ister misiniz?

Jul. 23, 2025

Siemens Screen Control Intelligent Combined Cleaner-Hebei Beibu Machinery Technology Co.,LTD

Z310 PLC Control Intelligent Combined Cleaner

W,Hebei Beibu Machinery Technology Co.,

29 Nis 2024

Otlar için taş ayırıcının ayrıntılarını mı bilmek istiyorsunuz? Önde gelen tedarikçi - Hebei Beibu Machinery Technology Co.,LTD sizin için bilgi paylaşacaktır. Daha fazla bilgi edinmek için bağlantıya tıklayın.

24 Temmuz 2024

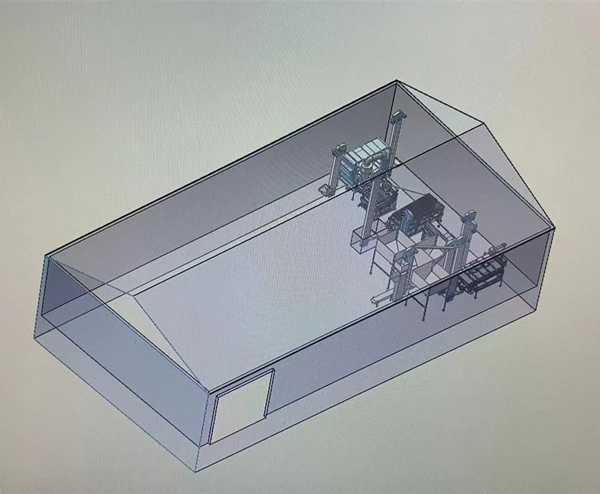

Beibu Makine-Fasulye üretim hattı kuruldu

Beibu Machinery-Bean üretim hattı kurulumunun ayrıntılarını mı bilmek istiyorsunuz? Önde gelen tedarikçi - Hebei Beibu Machinery Technology Co.,LTD sizin için bilgi paylaşacaktır. Daha fazla bilgi edinmek için bağlantıya tıklayın.

Beibu Makineleri

Pahalı ekipman seçmek değil, en uygun tahıl temizleme solüsyonunu seçmek

Ürünlerimizle ilgileniyorsanız, bilgilerinizi buraya bırakabilirsiniz; en kısa sürede sizinle iletişime geçeceğiz.

Mesajınızı Bırakın