Pabrik Pengolahan Pembersihan Wijen

- Rumah

- Produk

- Lini Pengolahan Pembersihan Gandum & Benih

- Pabrik Pengolahan Pembersihan Wijen

Dapat membersihkan biji wijen, kacang-kacangan, biji kopi.

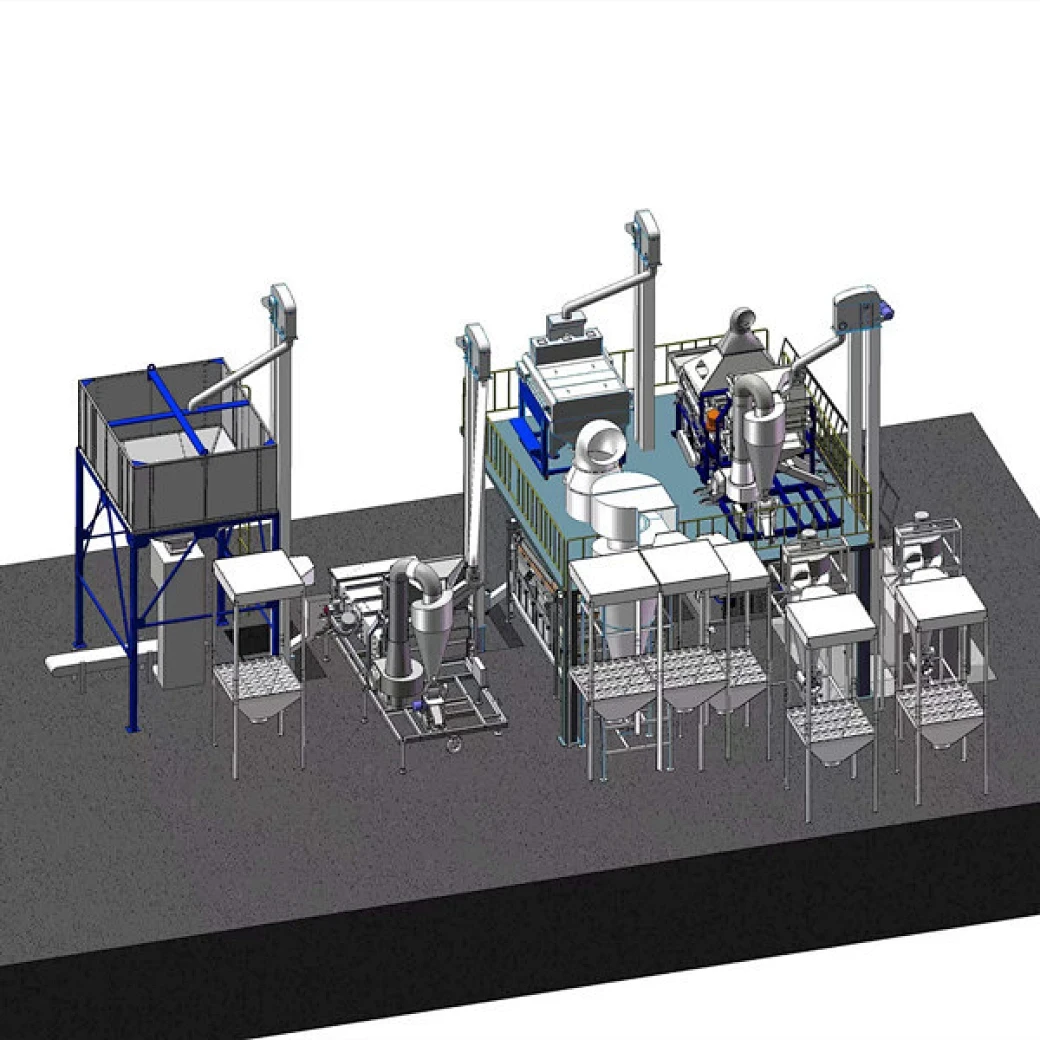

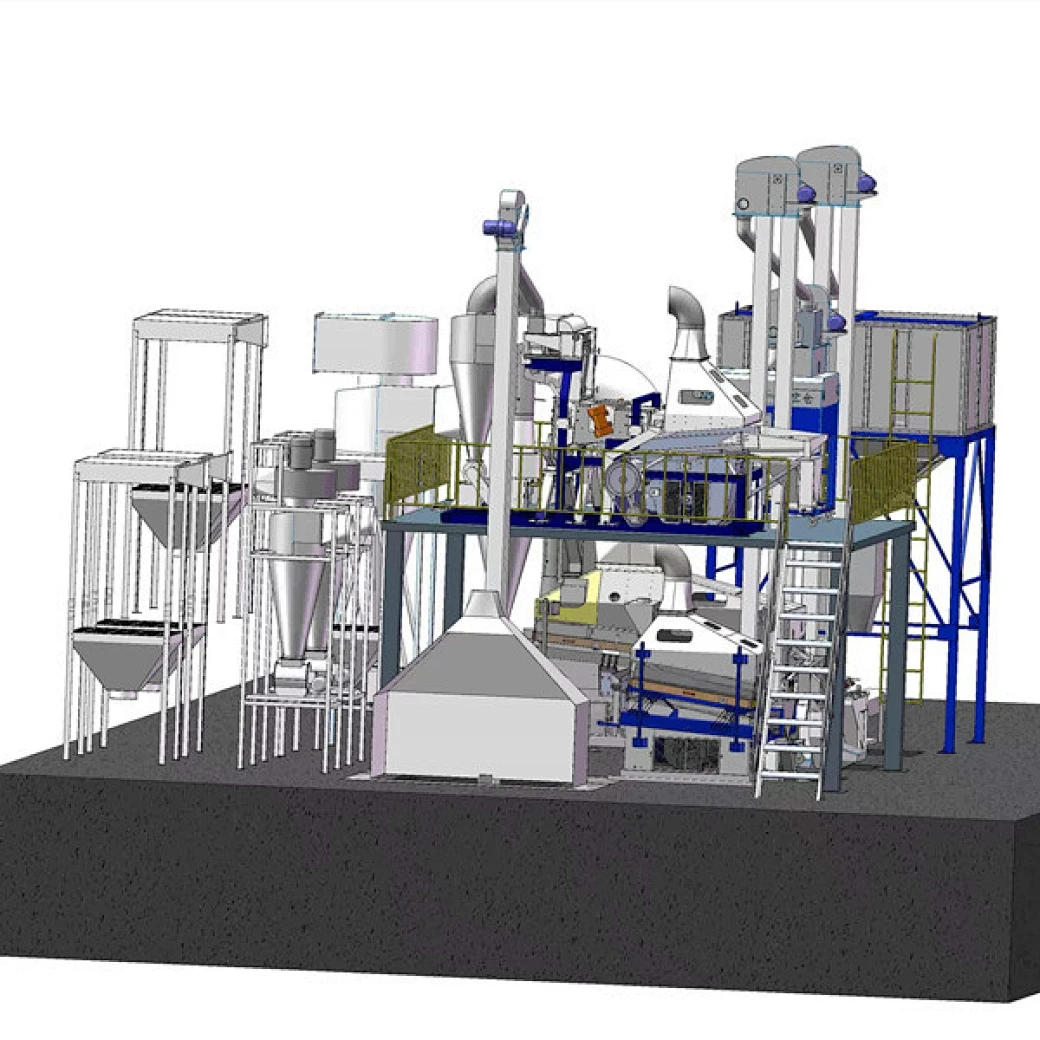

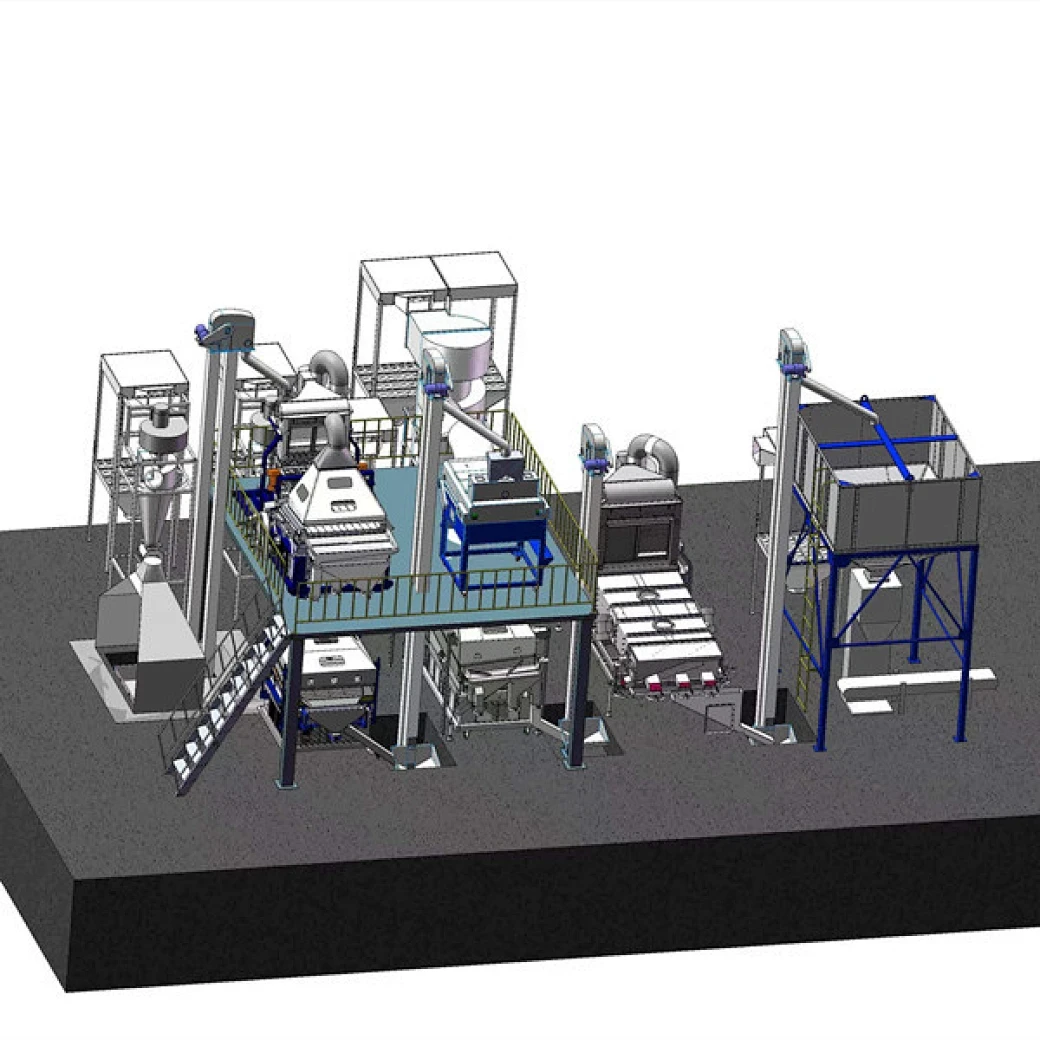

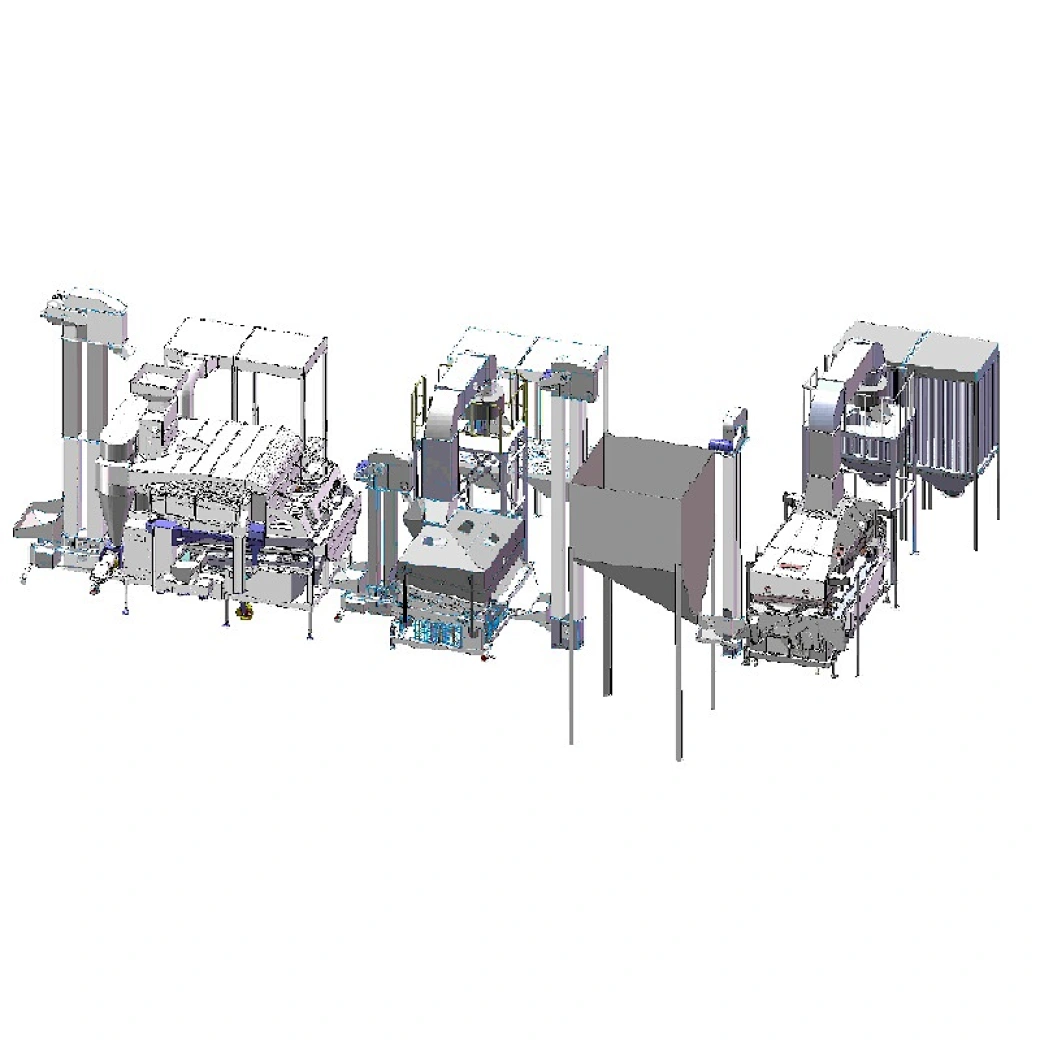

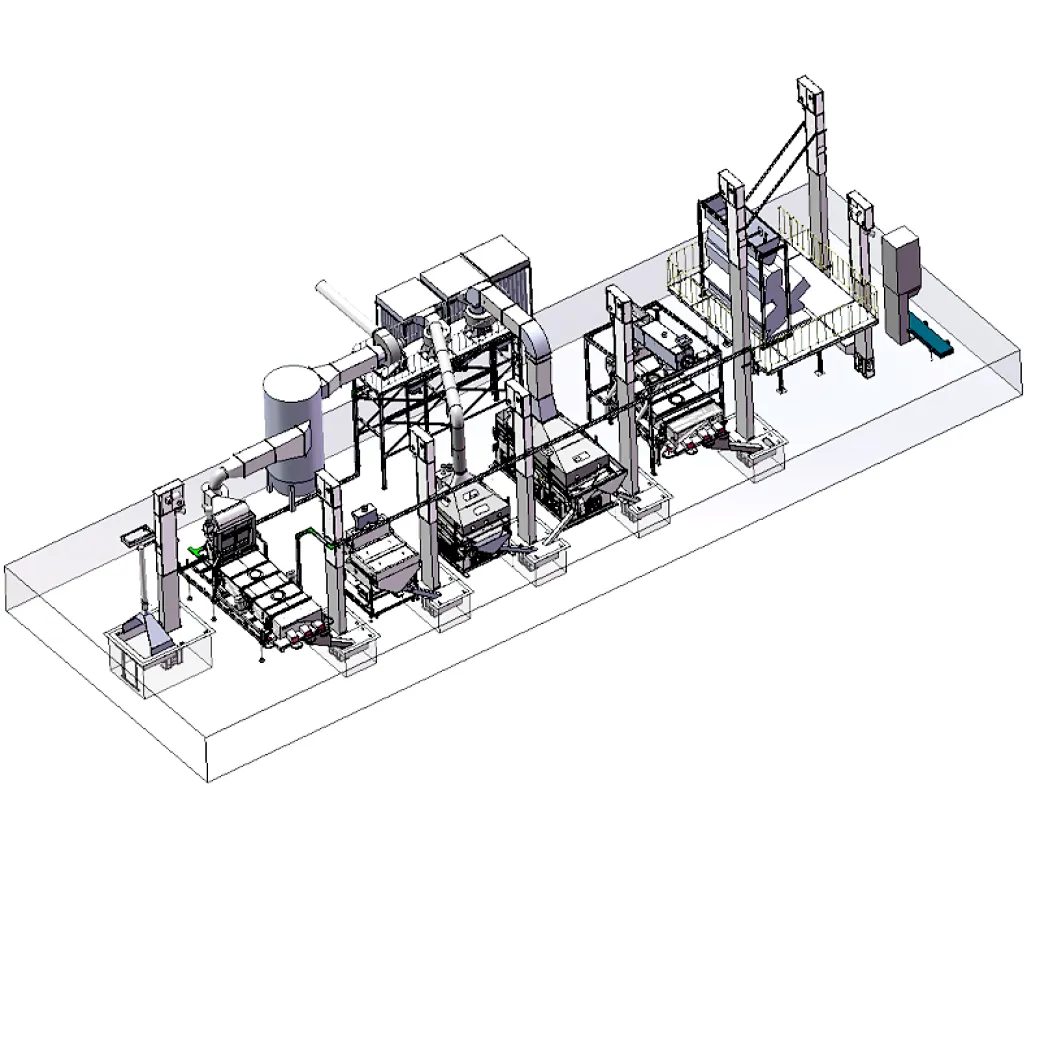

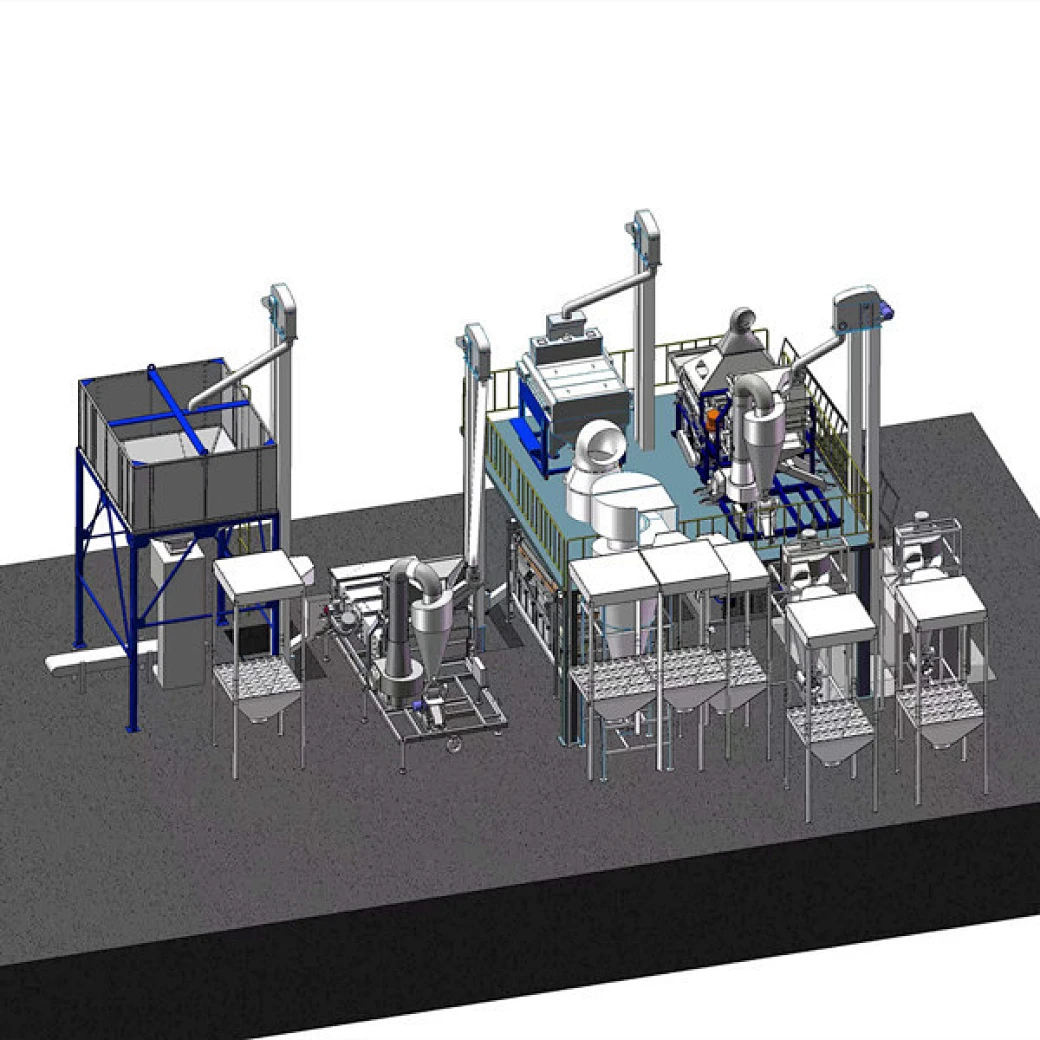

Lini pemrosesan meliputi mesin-mesin seperti di bawah ini. Pembersih saringan udara 5XFZ-25SC dengan meja gravitasi, de-stoner 5QSC-10, pemisah gravitasi 5XZ-8, Grader Getaran 5XFJ-10C, Mesin Pengemas dan elevator DTY-10M, juga sistem pengumpul debu.

Sesame cleaning production line is a production line with relatively large demand. Because China, India, Turkey and other countries consume a lot of sesame every year. This leads to the fact that these sesame exporting countries (Ethiopia, Tanzania, Mozambique, Nigeria, Sudan, Chad, Togo) need a lot of such machines.

The following is a standard set of machines.

Kapasitas: 4-5t/jam (kapasitas dapat disesuaikan) Kemurnian: Di atas 99,5%

Dapat membersihkan biji wijen, kacang-kacangan, biji kopi.

Lini pemrosesan meliputi mesin-mesin seperti di bawah ini. Pembersih saringan udara 5XFZ-25SC dengan meja gravitasi, de-stoner 5QSC-10, pemisah gravitasi 5XZ-8, Grader Getaran 5XFJ-10C, Mesin Pengemas dan elevator DTY-10M, juga sistem pengumpul debu.

The function of the machines is as below .

5XFZ-25SC Air Screen Cleaner with Gravity Table for removing the dust,light impurities,bigger and smaller impurities than sesame;

Pemisah Magnetik 5CX-5 untuk menghilangkan tanah keras dan gumpalan;

5QSC-10 De-stoner for removing stones;

Pemisah Gravity 5XZ-8 untuk memisahkan batang-batang kecil, wijen yang busuk, dan berjamur;

Pembersih Layar Udara 5XFS-10C untuk menghilangkan kembali debu dan kotoran ringan;

Mesin pengemas untuk mengemas wijen dalam karung 50kg.

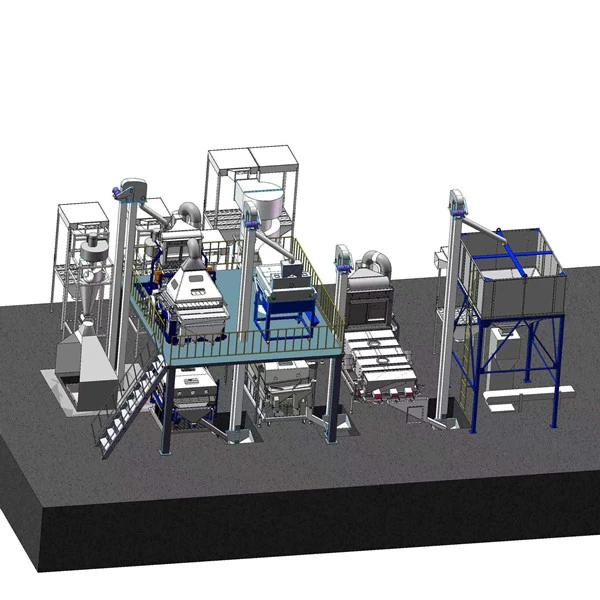

Such a sesame cleaning production line can basically remove almost all impurities from sesame. However, some customers have requirements for the color of sesame. In this case, we need to add another color sorter. At the same time, some customers need to clean a variety of materials, such as sesame, mung beans, soybeans, red beans, etc. We need to add additional sieves, tables, etc. for customers.

Although they are all cleaning sesame, customers who do not understand have different requirements. For example, some customers need more machines, some customers need different dust removal systems, and some customers need the platform of the machine designed according to his factory, etc. After fully communicating with customers, we will provide customers with the best sesame cleaning production line solution.

-

Apa kegunaan Pabrik Pengolahan Pembersihan Wijen?

Pabrik Pengolahan Pembersihan Wijen dirancang untuk membersihkan, memilah, dan menyiapkan biji wijen dengan menghilangkan kotoran seperti debu, batu, biji pecah, dan bahan asing untuk meningkatkan kualitas dan nilai pasar. -

Peralatan pembersih apa saja yang termasuk di pabrik?

Pabrik tersebut pada umumnya meliputi pembersih saringan udara, pemisah gravitasi, pemisah magnetik, penghilang batu, pemilah getaran, dan pemilah warna untuk memastikan pembersihan dan pemilahan biji wijen secara menyeluruh. -

Berapa kapasitas pengolahan pabrik pembersih wijen?

Tergantung pada model dan konfigurasinya, pabrik dapat memproses 1 hingga 15 ton per jam, cocok untuk operasi pemrosesan wijen skala kecil hingga besar. -

Apakah tanaman tersebut dapat tumbuh pada varietas biji wijen yang berbeda?

Ya. Mesin ini dapat disesuaikan dengan saringan dan pengaturan yang dapat diganti untuk mengakomodasi berbagai jenis dan ukuran biji wijen, sehingga menghasilkan hasil pembersihan yang optimal. -

Apakah Pabrik Pengolahan Pembersihan Wijen mudah dioperasikan dan dirawat?

Ya. Pabrik ini dirancang agar mudah dioperasikan dengan kontrol otomatis dan komponen modular yang memudahkan perawatan dan penyelesaian masalah dengan cepat.

17 Desember 2024

Lini produksi benih gandum Beibu Machinery terus menghasilkan

10 Juli 2024

peningkatan angkutan laut pada tahun 2024

18 Juli 2024

Kunjungan dari Afrika - Pengolahan wijen

30 Mei 2024

Pemasangan dan commissioning jalur produksi pengupasan wijen telah selesai - Beibu Machinery

27 Februari 2025

22 Agustus 2024

Mesin Pembersih Kacang Arab-Hebei Beibu Machinery

Mesin Beibu

Jika Anda tertarik dengan produk kami, Anda dapat memilih untuk meninggalkan informasi Anda di sini, dan kami akan segera menghubungi Anda.