We,Hebei Beibu Machinery Technology Co.,LTD which can supplier all kinds of different grain and seeds cleaning machine like pre-cleaning machine,destoner,gravity separaor,magnetic separator,which is for cleaning wheat,maize,sesame,soybean,sorghum,cassia tora,sunflower seeds etc.

We only offer the right machine not the expensive machine.

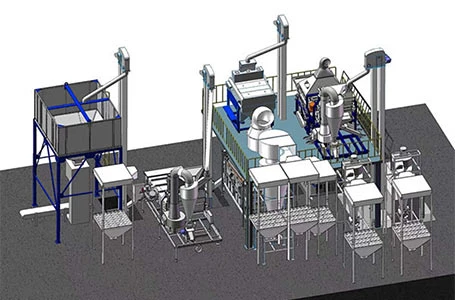

A grain cleaner is an essential agricultural machine designed to improve the quality and value of harvested grain by removing unwanted materials. It works through a series of mechanical processes that separate clean grain from impurities such as dust, straw, chaff, stones, weed seeds, and damaged kernels. The process begins with feeding the harvested grain into the machine. The first stage often involves a set of vibrating screens or sieves that separate particles based on size. Large impurities like sticks and clumps are removed by coarse screens, while smaller unwanted particles pass through finer screens.

Next, the grain moves into the aspiration system. This uses a controlled airflow to lift and remove lighter materials, such as dust, husks, or dried leaves, which are blown away and collected separately. After aspiration, gravity separation may be applied. In this step, grains pass over inclined vibrating surfaces or air-based gravity tables that help distinguish heavier, healthier kernels from lighter, damaged ones.

Some advanced grain cleaners also use magnetic separators to remove metal particles or optical sensors to detect and remove discolored or moldy grains. The end result is a batch of clean, uniform grain that is better suited for storage, milling, or sale. Grain cleaning enhances food safety, prolongs shelf life, and helps meet market or export standards.