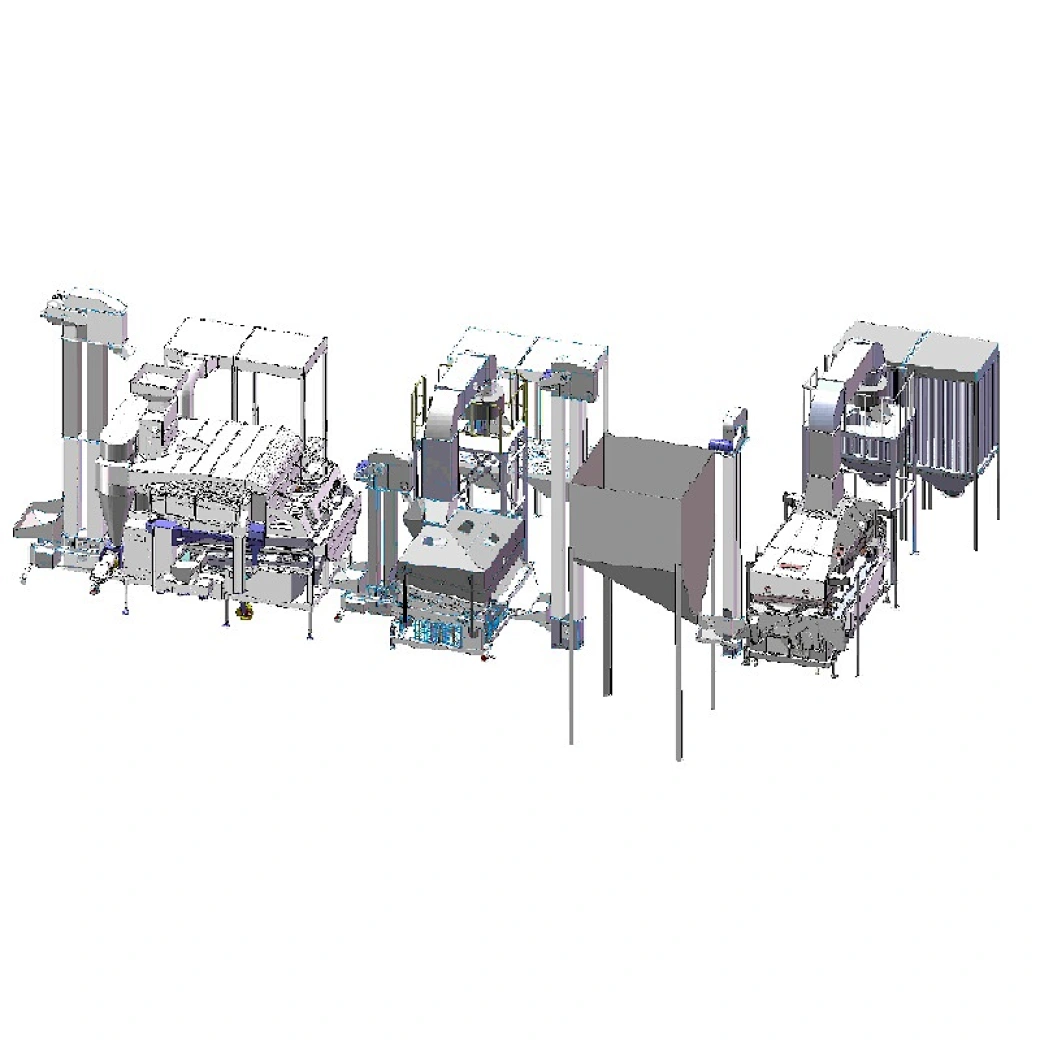

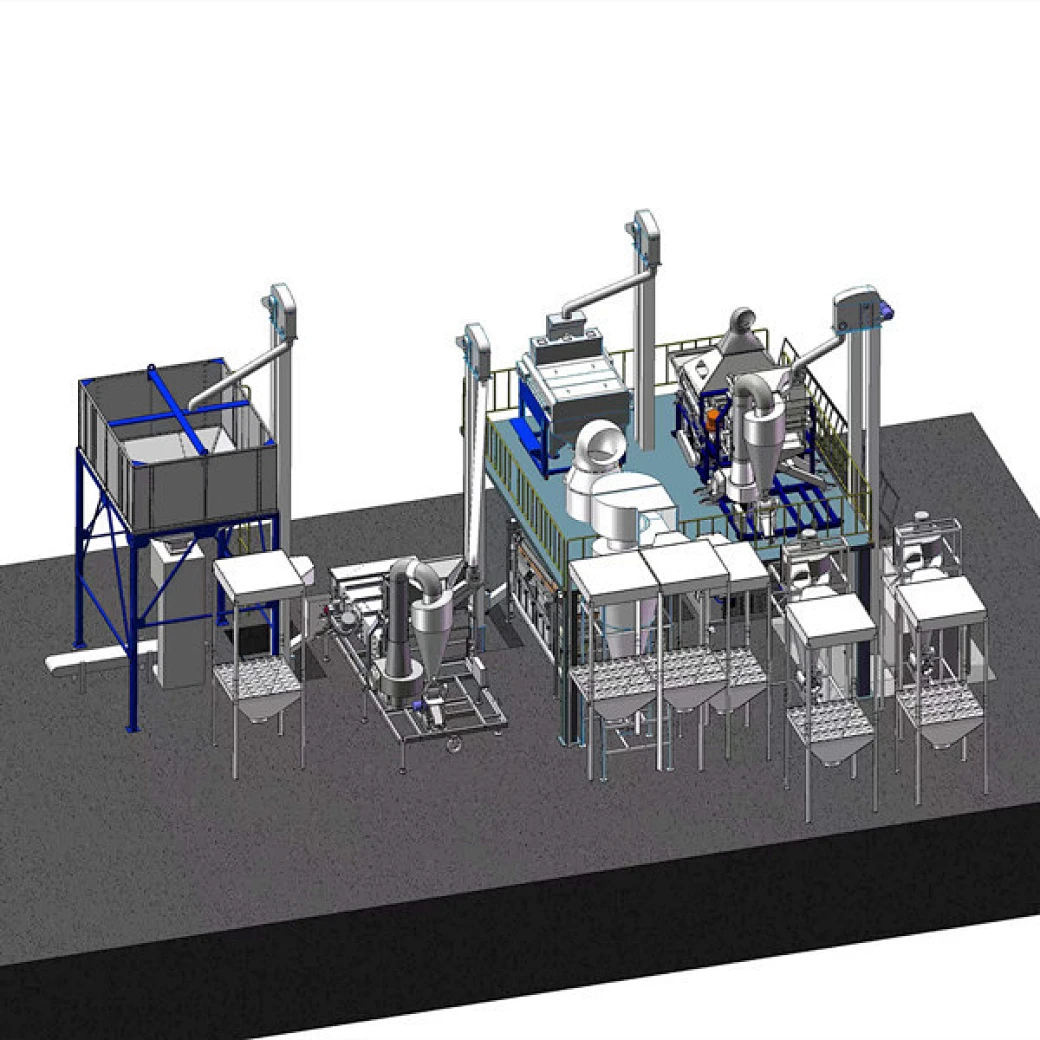

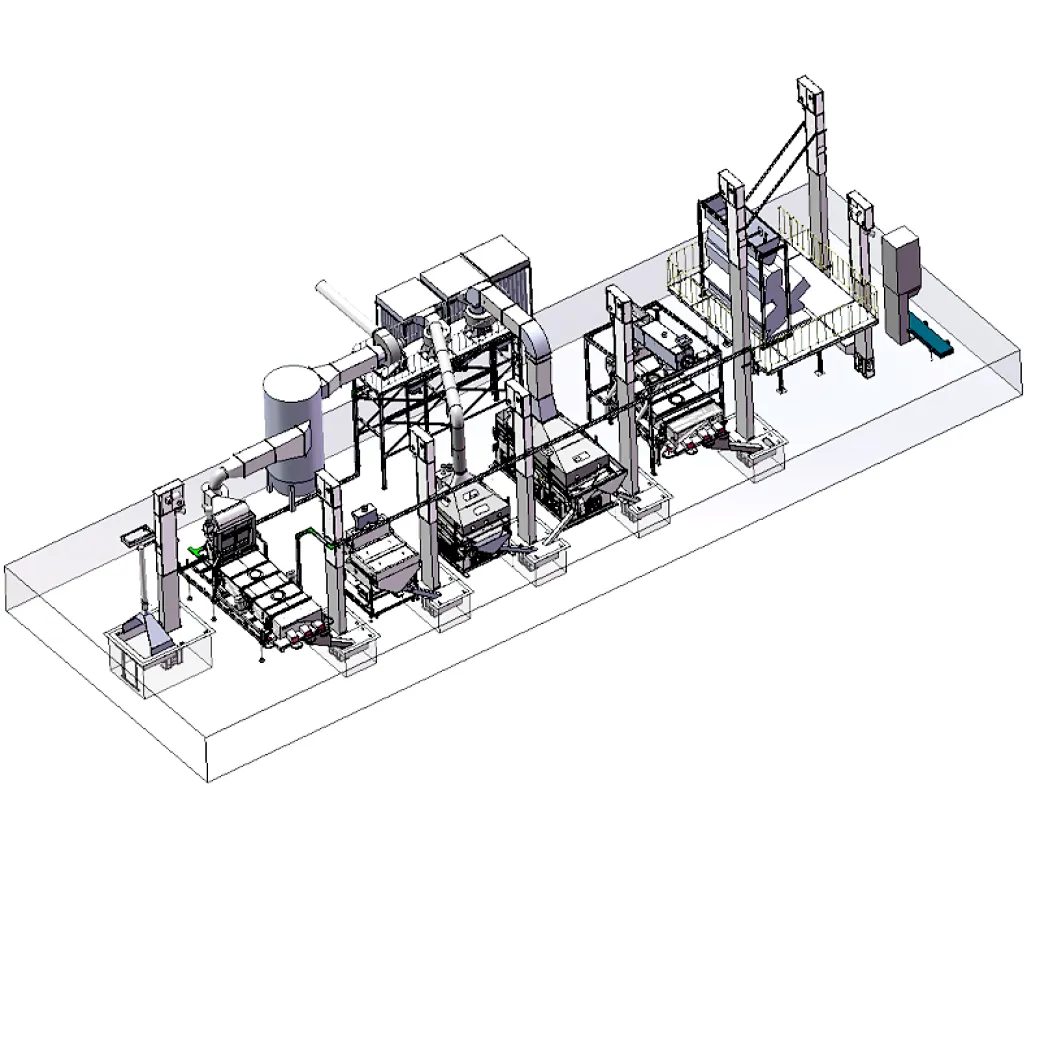

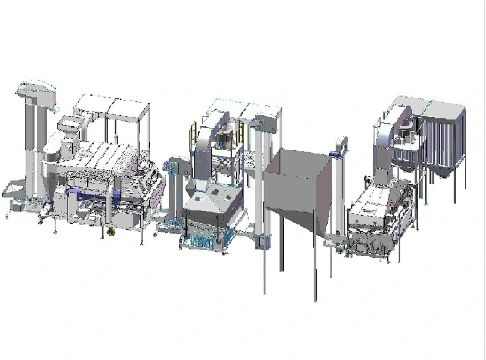

The cleaning process in food and agricultural product handling typically involves seven key steps to ensure the removal of impurities and prepare materials for further processing. These steps are designed to improve product quality, safety, and efficiency:

-

Pre-Cleaning: This initial step removes large impurities such as straw, leaves, and large stones. Machines like rotary sifters or vibrating screens are used to separate oversized debris.

-

Sieving or Screening: Products pass through mesh screens or sieves of varying sizes to separate smaller impurities like dust, dirt clumps, and broken grains from the main product.

-

Aspirating: Air flow is used to blow away light impurities such as dust, chaff, and husks. Aspirators help in improving product purity by removing lightweight contaminants.

-

Magnetic Separation: Magnets are employed to extract metal particles or ferrous contaminants that may damage equipment or compromise product safety.

-

Destoning: Specialized equipment separates stones and heavy impurities from the product based on weight and density differences, ensuring that heavier foreign materials are removed.

-

Gravity Separation: This step uses gravity separators to classify products by density, removing impurities or broken grains that differ in weight from the desired product.

-

Final Grading: The cleaned product is sorted by size or quality to ensure uniformity and meet processing or market standards.

Together, these seven steps form a comprehensive cleaning process that effectively removes physical and metallic contaminants, ensuring high-quality, safe, and uniform products ready for further processing or packaging.

Beibu Machinery