01

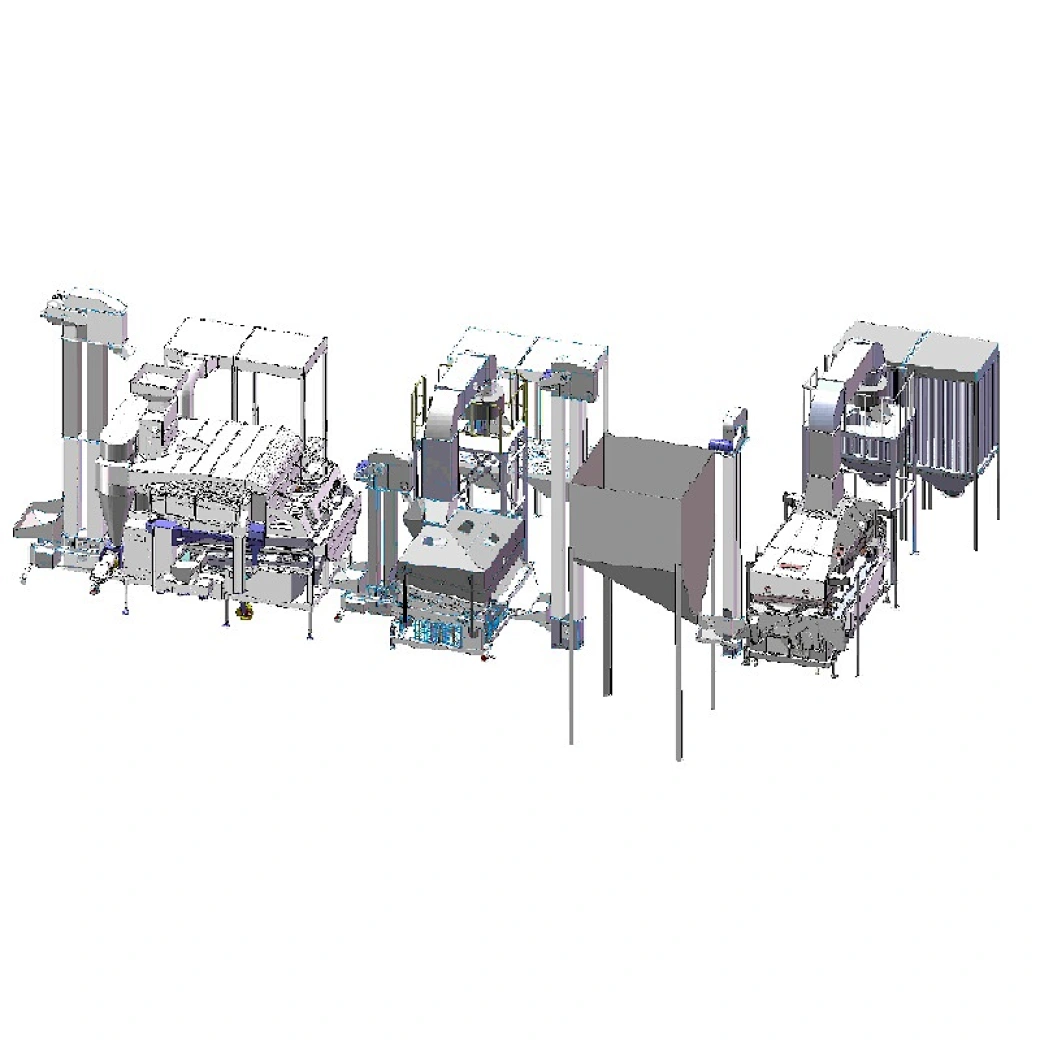

Advanced Cassia Tora Cleaning Line for Export to Nigeria – High Efficiency & Premium Quality

Complete Processing Solution for Superior Cassia Tora Seeds

We proudly present our high-performance Cassia Tora cleaning production line, specially designed to meet the rigorous demands of Nigerian processors and exporters. With Nigeria being a key supplier of Cassia Tora seeds to China, ensuring high purity, uniformity, and visual appeal is essential for maximizing market value. Our fully automated line delivers 4-5 tons per hour of impeccably cleaned, polished, and graded seeds, perfectly suited for export to China and other international markets.

Key Equipment & Benefits:

✔ Pre-Cleaner – Removes large impurities, dust, and foreign materials for a cleaner initial product.

✔ Destoner – Efficiently eliminates stones, mud clots, and heavy debris to protect downstream equipment.

✔ Gravity Separator – Precisely removes immature, damaged, or low-density seeds for superior quality control.

✔ Polishing Machine – Uniquely designed for Cassia Tora, enhancing surface smoothness and brightness to meet premium market standards.

✔ Vibration Grader – Accurately classifies seeds by size, ensuring consistency for export packaging.

Boost Your Cassia Tora Export Business Today!

Equip your processing plant with our state-of-the-art cleaning line to deliver premium-quality seeds with higher profitability.

Contact us now for a customized solution!

02

Premium Sesame Seed Cleaning Line for Nigeria – High Efficiency & Export Quality

Complete Sesame Processing Solution for Nigerian Exporters

We are proud to introduce our advanced sesame seed cleaning line, specially engineered for Nigeria's thriving sesame industry. With Nigeria producing over 500,000 tons of sesame annually - primarily exported to China - our 4-5 ton/hour processing line ensures your seeds meet the strictest international quality standards. Having successfully supplied numerous machines to Nigeria, we understand exactly what local processors need to compete in global markets.

Key Equipment & Outstanding Features:

✔ Multi-Functional Pre-Cleaner

Combines aspiration, screening & gravity separation

Removes dust, stalks, immature seeds & lightweight impurities

Proven performance in African sesame processing

✔ High-Efficiency Destoner

Eliminates stones, soil particles & heavy contaminants

Protects downstream equipment from damage

✔ Advanced Color Sorter

Boosts purity to 99.9%+ through AI-powered optical sorting

Removes discolored, damaged & foreign material seeds

Significantly increases product value

✔ Precision Packing Scale

Automated weighing with ±0.2% accuracy

Multiple bag size options from 25kg to 50kg

Integrated stitching for export-ready packaging

Why Nigerian Processors Choose Our Line?

✅ Proven Africa Experience - Dozens of successful installations in Nigeria

✅ Higher Profit Margins - Color sorting adds significant value to exports

✅ China Market Ready - Meets all Chinese import quality requirements

✅ Low Maintenance - Designed for Africa's operating conditions

Nigeria's Sesame Trade Potential

Top 5 global producer with increasing cultivation areas

80%+ exported to China for oil, tahini & confectionery use

Growing demand from food, cosmetic & pharmaceutical industries

03

High-Speed Packaging Scale for Export to Mexico – Ideal for Beans & Grains

Efficient, Accurate, and Fully Automated Packaging Solution

We are proud to introduce our high-performance packaging scale, designed specifically for exporters targeting the Mexican market. This advanced system is perfect for packaging beans, grains, and other granular products, offering a wide weighing range of 10kg to 100kg with an impressive output of 300 bags per hour. Built for durability and precision, our packaging scale ensures consistent weight accuracy, seamless operation, and minimal downtime—key factors for boosting your export productivity.

Key Features & Benefits:

✔ Wide Weighing Range (10kg–100kg) – Versatile enough to handle various bag sizes, catering to different market demands.

✔ High-Speed Operation (300 Bags/Hour) – Maximizes efficiency, reducing bottlenecks in your production line.

✔ Fully Automatic Sewing & Cutting System – Integrated auto-stitching and thread-cutting machine ensures secure, neat, and professional bag closures without manual intervention.

✔ Built-in Conveyor Belt – Smoothly transports filled bags to the sewing station, optimizing workflow and reducing labor costs.

✔ Durable & Low-Maintenance Design – Constructed with high-quality materials for long-term reliability in demanding environments.

✔ User-Friendly Controls – Intuitive interface allows easy adjustments for different packaging requirements.

Upgrade Your Packaging Line Today!

Boost your export efficiency with our high-speed, fully automated packaging scale—engineered for reliability, speed, and precision.

Contact us now for a customized solution tailored to your needs!

04

High-Efficiency Magnetic Separator for Mexico – Ideal for Cleaning Beans & Pulses

Advanced Metal & Impurity Removal for Superior Product Quality

Boost your bean processing efficiency with our high-performance magnetic separator, specially designed to meet the demands of Mexico’s thriving agricultural sector. As Mexico is a major producer and exporter of beans, chickpeas, lentils, and other pulses, ensuring contaminant-free products is critical for both food safety and export compliance. Our stainless steel magnetic separator delivers powerful, reliable, and maintenance-free metal extraction, making it an essential machine for processors and exporters.

Key Features & Benefits:

✔ Ultra-Strong 18,000 Gauss Magnetic Force – Effectively captures even the smallest ferrous contaminants like iron, steel fragments, and rust particles.

✔ Stainless Steel Construction – Corrosion-resistant, durable, and easy to clean, ensuring long-term performance in demanding environments.

✔ Optimized for Mexican Bean Varieties – Perfect for removing metal impurities from black beans, pinto beans, chickpeas, and other pulses commonly grown in Mexico.

✔ Low Maintenance & Energy Efficient – No moving parts, reducing wear and operational costs while maintaining high efficiency.

✔ Easy Integration – Fits seamlessly into existing cleaning and sorting lines, enhancing workflow without disruptions.

Upgrade Your Cleaning Line Today!

With Mexico’s growing bean production and export demand, investing in a high-power magnetic separator is a smart choice for quality control and operational efficiency.

Contact us now for a customized solution tailored to your needs!

05

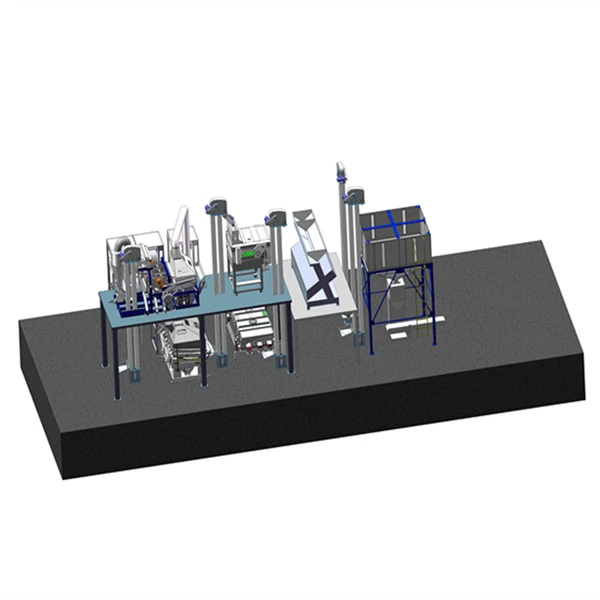

Whole Set Coffee Bean Cleaning Line for Export to Guinea

Enhance your coffee bean processing with our state-of-the-art cleaning production line, designed specifically for export-quality coffee beans to Guinea. This advanced system ensures superior cleanliness, consistency, and efficiency, meeting international standards for premium coffee exports.This whole coffee bean cleaning machine line exported to Guinea,and the whole line capacity can be 5t/h and purity is above 99.7%.

Key Equipment & Features:

1.Pre-Cleaning Machine – Removes large impurities, dust, and foreign materials for a cleaner initial product.

2.Destoner – Effectively separates stones, metals, and other heavy debris to protect downstream equipment.

3.Gravity Separator – Precisely sorts beans by density, eliminating defective or low-quality beans for uniform quality.

4.Vibration Grader – Classifies beans by size to ensure consistent grading and superior market appeal.

5.Packaging Machine – Delivers accurate weighing for efficient and professional bagging, optimizing logistics.

Why Choose Our Line?

✅ High Efficiency – Streamlined automation reduces labor costs and boosts output.

✅ Superior Quality – Delivers clean, uniform, and export-ready coffee beans.

✅ Durability & Reliability – Robust construction ensures long-term performance.

✅ Customizable – Adjustable settings to meet specific processing needs.

Ideal for coffee exporters targeting the Guinea market, our production line guarantees higher profitability and customer satisfaction.

Upgrade your coffee processing today—contact us for a tailored solution!

Beibu Machinery