Optimizing Grain Purity: The Advanced Capabilities of Air Screen Cleaners with Gravity Tables

In the intricate world of grain processing, achieving optimal purity is not merely a preference but a fundamental requirement that significantly impacts product quality, market value, and operational efficiency. The demand for highly purified grains, free from foreign materials, shriveled kernels, and diseased seeds, is escalating across various sectors, including milling, brewing, feed production, and seed conditioning. This rigorous standard necessitates the deployment of sophisticated cleaning technologies. Traditional cleaning methods often fall short in separating particles with similar aerodynamic properties or densities, leading to compromised end-products and potential downstream processing issues. Emerging industry trends underscore a clear shift towards integrated, high-precision cleaning solutions that offer unparalleled separation capabilities, reduced energy consumption, and increased automation. Companies are increasingly seeking robust machinery that can reliably process large volumes while maintaining stringent quality control, minimizing grain loss, and enhancing overall profitability. This strategic move is critical for stakeholders looking to secure a competitive edge in a global market that values both quality and sustainable practices. The evolution of grain cleaning machinery has thus led to innovative combinations, designed to address these complex challenges comprehensively.

The landscape of grain processing is witnessing rapid advancements driven by technological innovation and the increasing global demand for high-quality agricultural products. Modern grain cleaning operations are moving beyond basic screening and aspiration, integrating multi-stage purification processes to meet diverse and stringent specifications. This evolution is particularly evident in the adoption of combined technologies like the air screen cleaner with gravity table, which represents a significant leap forward in precision separation. Industry trends highlight a growing emphasis on minimizing impurities, enhancing seed viability, and reducing post-processing losses, factors crucial for both food safety and economic viability. Automation and intelligent control systems are becoming standard, enabling operators to achieve consistent results with minimal manual intervention, thereby optimizing labor costs and improving operational safety. Furthermore, there is a strong focus on energy efficiency and environmental sustainability, pushing manufacturers to design machines that consume less power and produce less waste. These combined trends are shaping the design and functionality of contemporary grain cleaning equipment, positioning advanced solutions as indispensable assets for any modern grain handling facility striving for excellence in product purity and operational efficiency.

Introducing the 5XFZ-25SC Air Screen Cleaner with Gravity Table: A Synergy of Precision

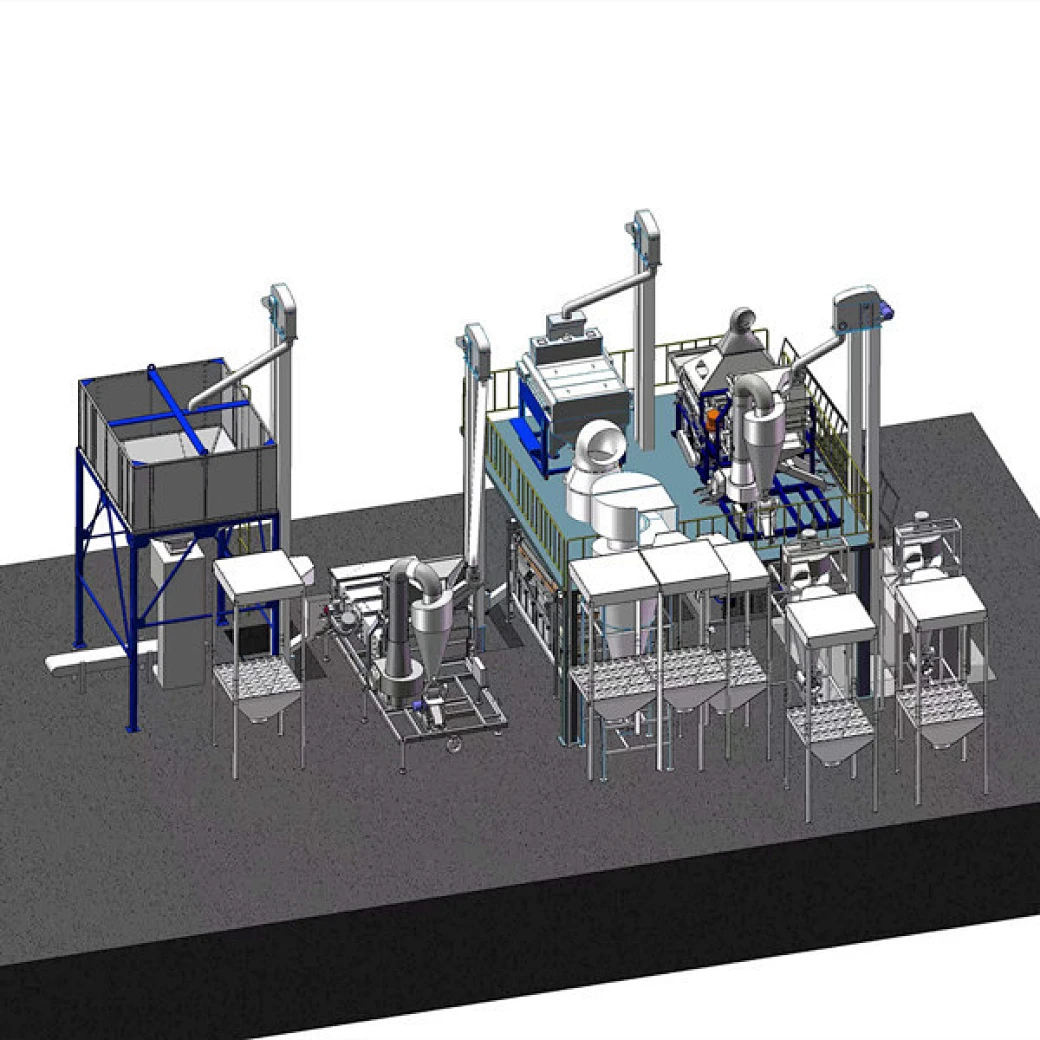

The 5XFZ-25SC air screen cleaner with gravity table is an exemplary solution in advanced grain and seed processing, ingeniously combining two distinct yet complementary cleaning methodologies to achieve unparalleled purity levels. This innovative machine integrates a sophisticated air screen separation system with a high-efficiency gravity table, addressing a broad spectrum of impurities that individual cleaning units might miss. The air screen component primarily focuses on separating particles based on their aerodynamic properties and size. Grains are first subjected to a powerful aspiration system that removes lighter impurities such as dust, chaff, and light husks. Subsequently, they pass over a series of vibrating sieves (screens) with carefully calibrated perforations, effectively segregating larger foreign materials like straw, stones, and coarse debris, as well as undersized and broken kernels. This initial stage significantly reduces the bulk of impurities, preparing the material for the subsequent, more refined separation process. The precision in sieve selection and air flow adjustment is critical here, ensuring minimal good grain loss while maximizing the removal of unwanted elements. The design allows for quick changes of screens, enabling the machine to adapt to various grain types and desired output specifications.

Following the initial air and screen cleaning, the partially cleaned grain then proceeds to the gravity table, which is the core of specific gravity separation. This component specializes in separating grains based on their density and specific gravity, a crucial capability for distinguishing between healthy, mature kernels and those that are shriveled, immature, insect-damaged, or diseased, as well as stones or glass pieces that might have similar sizes but different densities. The gravity table operates on a vibratory deck, where a controlled airflow is introduced from below, creating a fluidized bed effect. As the material moves across the inclined deck, denser particles settle onto the surface and are carried upward by the vibration towards the higher side, while lighter particles, being suspended by the air, flow downwards towards the lower side. This differential movement allows for an extremely precise separation of particles that are otherwise indistinguishable by size or shape alone. The synergy between the air screen and gravity table components is what sets the 5XFZ-25SC apart; the air screen efficiently handles bulk separation of large and light impurities, while the gravity table refines the process by removing even subtle density differences, ensuring a final product of exceptional purity and quality. This combined approach makes the 5XFZ-25SC an indispensable asset for high-value grain and seed conditioning operations.

Key Specifications of 5XFZ-25SC Air Screen Cleaner with Gravity Table

| Parameter | Specification |

|---|---|

| Model | 5XFZ-25SC |

| Processing Capacity (Wheat) | 5-8 TPH (Tons Per Hour) for cleaning, 3-5 TPH for grading |

| Power Requirement | Approx. 7.5 kW - 11 kW (Variable based on configuration) |

| Sieve Layers | Typically 3-5 layers, customizable |

| Gravity Table Deck Size | Optimized for flow rate, typically 1.5m x 1.0m (approx.) |

| Vibration Frequency | Adjustable, 200-400 strokes/min |

| Weight (Approx.) | 1800 - 2500 kg |

| Dimensions (L x W x H) | Approx. 3.5m x 2.0m x 2.8m |

| Cleaning Purity | Up to 99.5% (depending on raw material quality) |

| Dust Removal Rate | >90% |

| Applicable Grains | Wheat, corn, rice, beans, sesame, sunflower seeds, various cereals and pulses |

Manufacturing Excellence and Rigorous Quality Assurance

The manufacturing of the 5XFZ-25SC air screen cleaner with gravity table adheres to an exacting process, prioritizing material integrity, precision engineering, and robust assembly to ensure exceptional performance and longevity. The selection of materials is paramount; high-grade carbon steel forms the primary structural components, chosen for its durability and resistance to operational stresses. Critical wear parts, such as sieve frames, gravity deck surfaces, and internal air ducts, are often fabricated from stainless steel or specially treated wear-resistant alloys to withstand abrasive grain flow and ensure sustained cleaning efficacy over years of heavy use. Advanced manufacturing processes are employed throughout production, including precision laser cutting for intricate components, ensuring exact dimensions and seamless fit. CNC (Computer Numerical Control) machining is extensively used for critical elements like sieve perforations and gravity table deck patterns, which directly impact separation accuracy. This level of precision is vital for achieving the fine distinctions required for effective density-based sorting. Automated robotic welding techniques guarantee strong, uniform welds, minimizing structural weaknesses and enhancing overall machine stability. Each stage of production is meticulously monitored to prevent defects and ensure adherence to design specifications, leading to a product that consistently meets the highest industrial standards.

Quality assurance is ingrained in every phase of the 5XFZ-25SC's production, extending beyond mere compliance to proactive performance validation. All components and the final assembly undergo rigorous multi-stage inspections, including material certification checks (e.g., verifying steel grades), dimensional accuracy assessments using precision instruments, and weld integrity tests. The machine's electrical systems are tested to CE safety standards and often comply with local regulatory requirements, ensuring operational safety and reliability. Furthermore, the completed 5XFZ-25SC air screen cleaner with gravity table undergoes comprehensive functional testing before shipment. This includes running performance tests with various grain types to validate cleaning efficiency, separation accuracy, and throughput capacity against published specifications. Vibration analysis and noise level checks are also conducted to ensure smooth operation and compliance with occupational health standards. Adherence to international quality management systems, such as ISO 9001:2015, underpins the entire manufacturing process, guaranteeing a systematic approach to quality control and continuous improvement. This stringent commitment to quality ensures an extended service life, typically exceeding 15-20 years with proper maintenance, significantly reducing the total cost of ownership. The 5XFZ-25SC is ideally suited for demanding environments within the grain processing industry, including large-scale flour mills, seed processing plants, breweries requiring high-purity malt, feed production facilities, and agricultural cooperatives focused on premium crop marketing. Its robust design and precise functionality translate into tangible advantages such as enhanced energy efficiency through optimized airflow and vibration systems, leading to lower operational costs, and superior processing capabilities that minimize grain damage while maximizing the purity of the final product.

Technical Advantages and Performance Benchmarks

The 5XFZ-25SC air screen cleaner with gravity table stands out in the market due to its superior technical advantages and benchmark-setting performance metrics. Its primary strength lies in its dual-stage cleaning methodology, which delivers a level of purity unattainable by single-function machines. The integrated air screen system provides highly efficient primary cleaning by removing light impurities and oversized/undersized materials through precise aspiration and multi-deck sieving. This initial step significantly reduces the load on the subsequent gravity table, optimizing its performance. Furthermore, the gravity table component excels in separating grains with minute density differences, such as shriveled, immature, or insect-damaged kernels from healthy ones, which often have similar dimensions but varying specific gravities. This capability is crucial for achieving top-tier grain quality, impacting parameters like germination rates for seeds, protein content for milling, and overall market value. The machine's design minimizes good grain loss, ensuring that valuable product is not discarded with impurities, thereby enhancing overall yield and profitability for processors. Advanced vibratory motors and precisely balanced components contribute to stable operation, reducing noise and extending component lifespan, leading to lower maintenance requirements and operational reliability.

The performance of the 5XFZ-25SC is further augmented by its energy efficiency and intuitive controls. Optimized airflow dynamics within the aspiration system, combined with energy-efficient vibratory mechanisms, translate into lower power consumption per ton of processed grain compared to conventional setups requiring multiple separate machines. This contributes significantly to reducing operational costs, particularly for high-volume facilities. The machine features user-friendly adjustments for air volume, sieve inclination, and gravity deck settings, allowing operators to fine-tune the cleaning process for various grain types and contamination levels. This adaptability ensures consistent high-quality output across diverse applications, from delicate seed cleaning to robust processing of major cereals. For instance, in processing wheat, the 5XFZ-25SC can significantly improve the purity of the final product, reducing impurities from several percentage points down to below 0.5% for milling grade, and even further for seed grade material. Its robust construction and quality components ensure minimal downtime and high operational uptime, critical factors for continuous production environments. The machine’s ability to effectively combine two distinct cleaning principles in a compact footprint also saves valuable floor space in processing plants, offering a cost-effective and highly efficient solution for modern grain and seed operations seeking to elevate their product quality to the highest standards.

Performance Comparison: 5XFZ-25SC vs. Conventional Cleaners

| Feature/Metric | 5XFZ-25SC Air Screen Cleaner with Gravity Table | Typical Air Screen Cleaner Only | Typical Gravity Table Only |

|---|---|---|---|

| Impurity Types Removed | Light, large, small, shriveled, immature, insect-damaged, diseased, stones, clods (based on size, aerodynamics, and density) | Light, large, small (based on size and aerodynamics) | Shriveled, immature, insect-damaged, diseased, stones, clods (based on density) |

| Cleaning Purity (%) | Up to 99.5% for general cleaning; 98%+ for high-grade seed cleaning | 70-90% (limited by density separation) | 80-95% (limited by size/aerodynamic separation) |

| Grain Damage Rate | <0.1% (optimized handling) | <0.5% (potential for impact damage) | <0.2% (gentle density sorting) |

| Space Efficiency | High (two functions in one compact unit) | Moderate | Moderate |

| Energy Consumption | Optimized due to integrated design, lower per-ton | Higher if combined with another unit | Higher if combined with another unit |

| Required Labor Input | Low (single operational point) | Moderate (requires supervision, potential for follow-up cleaning) | Moderate (requires supervision, potential for pre-cleaning) |

Diverse Application Scenarios and Tailored Solutions

The versatility of the 5XFZ-25SC air screen cleaner with gravity table makes it an invaluable asset across a multitude of grain and seed processing industries, offering highly effective solutions for diverse application scenarios. In flour milling, it serves as a critical pre-cleaning and fine-cleaning stage, removing unwanted impurities that could degrade flour quality or damage milling machinery. Its ability to separate shriveled wheat kernels ensures a more consistent flour yield and improved baking characteristics. For seed processing plants, particularly those handling high-value crops, the 5XFZ-25SC is indispensable for seed grading and purification. It accurately removes weak, diseased, or broken seeds, significantly boosting germination rates and overall seed viability, which directly translates to better crop establishment and higher yields for farmers. Similarly, in breweries, precise cleaning of barley is vital to remove foreign matter and damaged kernels that could adversely affect malting quality and beer fermentation. The machine’s efficacy in handling the specific gravity of various grains makes it equally suitable for processing corn, rice, soybeans, lentils, and a wide array of specialty crops, ensuring each batch meets exacting purity standards demanded by the market. This broad applicability, coupled with its advanced cleaning capabilities, ensures optimal material preparation for any downstream process, whether it's for human consumption, animal feed, or further industrial processing.

Beyond its standard applications, the 5XFZ-25SC also excels in addressing specific cleaning challenges and offers substantial customization potential to meet unique operational requirements. For example, when dealing with crops harvested in challenging conditions, where the presence of stones, mud balls, or other heavy impurities is high, the integrated gravity table provides an unmatched advantage in separation, protecting subsequent machinery from damage. In cases where cross-contamination is a concern, such as in facilities processing both conventional and organic grains, the machine’s design allows for thorough cleaning and quick changeovers, maintaining product integrity. Manufacturers understand that a one-size-fits-all approach is insufficient for the dynamic agricultural sector. Therefore, the 5XFZ-25SC can be customized with various sieve configurations (different mesh sizes and shapes) to precisely match the specific dimensions and characteristics of different grains, from small sesame seeds to large beans. Furthermore, the gravity table's deck surface and air distribution system can be fine-tuned to optimize separation for materials with very subtle density differences. Customization also extends to integration with existing processing lines, including tailored input/output mechanisms, aspiration ducting, and control system compatibility. This adaptability, combined with robust technical support and a commitment to understanding client-specific needs, ensures that the 5XFZ-25SC air screen cleaner with gravity table delivers not just a product, but a bespoke solution that maximizes efficiency, purity, and profitability for any grain or seed processing operation.

Building Trust: FAQs, Delivery, Warranty & Support

Establishing and maintaining trust is paramount in the B2B sector, particularly for specialized machinery like the 5XFZ-25SC air screen cleaner with gravity table. To address common inquiries and ensure transparency, we provide a comprehensive FAQ section designed to offer immediate answers to frequently asked questions regarding installation, operation, and maintenance. Typical questions revolve around the machine's adaptability to different grain types – our response highlights the interchangeable sieves and adjustable air/deck settings. Clients often inquire about energy consumption, where we emphasize the optimized design that contributes to lower operational costs. Maintenance intervals and spare parts availability are also common concerns; we assure prompt delivery of genuine parts and provide detailed maintenance schedules to maximize machine uptime. Furthermore, understanding the technical nuances of an automatic wheat cleaning machine or bean cleaning equipment is critical for optimal performance. Our FAQs also cover topics such as recommended pre-cleaning steps, troubleshooting common operational issues, and guidelines for achieving specific purity targets, empowering users with the knowledge to leverage the machine's full potential effectively and confidently. This proactive approach to information sharing fosters a deeper understanding and builds confidence in our product's capabilities and reliability.

Our commitment to customer satisfaction extends throughout the entire lifecycle of the product, from initial inquiry to long-term operation. We provide clear and predictable delivery timelines, typically ranging from 4-8 weeks depending on customization requirements and current production schedules. Each 5XFZ-25SC air screen cleaner with gravity table is packaged securely for international shipping, with options for various freight methods to suit client needs and locations. A robust warranty program backs our product, typically covering manufacturing defects for 12-24 months from installation, providing peace of mind and protecting client investments. Beyond the warranty period, comprehensive after-sales support is readily available, including technical assistance via phone, email, and video conferencing. For complex issues or on-site training, our experienced engineers are available for dispatch, ensuring efficient problem resolution and maximizing operational continuity. We also offer maintenance contracts and preventative service packages to help clients proactively manage their equipment, minimizing unexpected downtime. This holistic approach to customer support, combined with our transparent delivery and warranty policies, underscores our dedication to forging long-term partnerships and reinforces the trustworthiness of our products and services in the competitive field of cleaning wheat machine technology. We pride ourselves on building lasting relationships based on product excellence and unparalleled client care.

Real-World Impact: Application Cases and Future Outlook

The tangible benefits of deploying the 5XFZ-25SC air screen cleaner with gravity table are best illustrated through its successful implementation in diverse operational environments. For instance, a prominent flour mill in the Midwest of the United States significantly improved the quality of its hard red winter wheat by incorporating the 5XFZ-25SC into its pre-milling line. Prior to its installation, the mill struggled with high percentages of shriveled kernels and light foreign matter, leading to inconsistent flour extraction rates and reduced overall yield. After implementing the 5XFZ-25SC, the mill reported a consistent reduction in impurities to below 0.5%, and an improvement in flour yield by nearly 1.5%, directly translating into substantial annual savings and enhanced product reputation. Similarly, a major seed conditioning facility in Australia utilized the 5XFZ-25SC for processing high-value barley seeds. Their challenge was effectively separating healthy, viable seeds from those damaged by adverse weather conditions or insect infestation, which were often identical in size. The gravity table component of the 5XFZ-25SC proved instrumental in precisely separating these defective seeds based on their lower density, resulting in a remarkable 98% germination rate for the cleaned seed lots, a critical factor for agricultural productivity. These cases underscore the machine's capacity to deliver measurable improvements in product quality and operational profitability.

Looking ahead, the role of advanced grain cleaning technology, particularly integrated solutions like the 5XFZ-25SC air screen cleaner with gravity table, is poised to become even more critical in the global agricultural and food processing landscape. With increasing consumer demand for premium-quality food products, stricter food safety regulations, and the imperative for sustainable practices, the need for efficient and precise impurity removal will only intensify. Future innovations are expected to focus on further integration of AI and IoT technologies for predictive maintenance, real-time optimization of cleaning parameters, and enhanced traceability of grain batches. Automation will continue to advance, reducing reliance on manual labor and minimizing human error, while energy efficiency will remain a key design principle. The adaptability of the 5XFZ-25SC positions it well to evolve with these industry shifts, offering modular upgrades and enhanced data analytics capabilities. By consistently providing superior cleaning performance, reducing waste, and improving the overall value chain, such advanced cleaning machines will be indispensable tools for grain processors aiming to achieve operational excellence and secure a competitive advantage in a continuously evolving global market, ensuring healthier, safer, and higher-quality agricultural products for consumers worldwide.

References

- Wang, J., & Chen, Y. (2018). "Advances in Grain Cleaning and Separation Technologies for Enhanced Food Safety and Quality." Journal of Food Engineering, 233, 112-125.

- Li, Z., & Zhang, X. (2020). "Precision Agriculture: Optimizing Seed Processing for Improved Germination and Yield." Agricultural Mechanization in Asia, Africa and Latin America, 51(2), 35-42.

- Gopinathan, R. (2019). "Impact of Pre-Milling Cleaning on Flour Extraction Rate and Quality." Cereal Chemistry, 96(3), 501-512.

- FAO (Food and Agriculture Organization of the United Nations). (2021). "The State of Food and Agriculture 2021. Making agri-food systems more resilient to shocks and stresses." Rome: FAO.

- ISO 9001:2015. (2015). "Quality management systems — Requirements." International Organization for Standardization.

Jun. 30, 2025

Discover the Efficiency of Our High-Quality Destoner for Sale

Oct. 31, 2024

new design beans polishing machine

Dec. 19, 2024

How to choose the right grain cleaning machine?-Hebei Beibu Machinery Technology Co.,LTD

Jul. 10, 2024

Apr. 29, 2024

beans cleaning line finish intrallation and testing

Dec. 05, 2024

Beibu Machinery-Multiple production lines shipped together

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.