- Introduction to Automatic Peanut Shelling Machines

- Technical Advantages and Innovations in Automatic Groundnut Shelling

- Comparative Analysis of Leading Manufacturers

- Tailored Solutions for Production Scale and Requirements

- Real-World Applications and Success Stories

- Maintenance, Operation, and Troubleshooting Insights

- Conclusion: Elevate Your Processing with an Automatic Peanut Shelling Machine

(automatic peanut shelling machine)

Introduction to Automatic Peanut Shelling Machine: Revolutionizing Peanut Processing

Across the global agricultural sector, the adoption of automatic peanut shelling machine

s is transforming traditional groundnut processing. Mechanization has become imperative as peanut demand is rising, driven by the processed snack market and the growing consumption in food manufacturing—particularly peanut oil and peanut butter products. By 2023, the global peanut market was valued at over USD 67 billion, with processed forms such as peanut butter experiencing a year-over-year growth rate of 5.8% (Statista/MarketWatch).

Manual shelling methods can only yield around 6-8 kg/hour and have a breakage rate of up to 20%. In contrast, top-tier automated shellers process between 300-800 kg/hour with less than 2% breakage and improve kernel recovery rates. Integrating automatic shelling offers not just time savings but operational consistency, safety improvements, and minimized labor demands—optimally suited for small-scale processors and industrial facilities alike.

Technical Advantages and Innovations in Automatic Groundnut Shelling

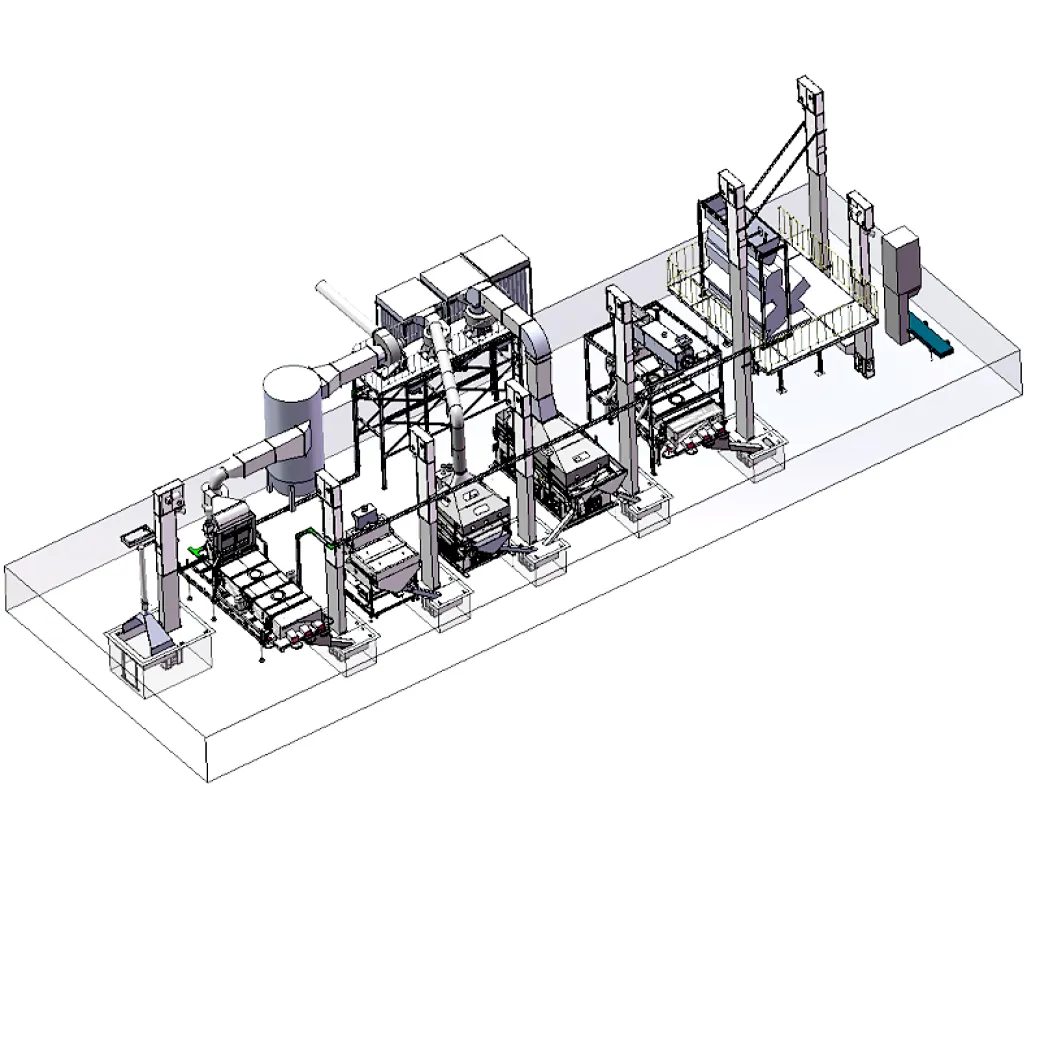

The latest automatic groundnut shelling machine models are equipped with advanced technological features designed to boost output, reduce downtime, and ensure a superior product. Some of these technical advancements include:

- Unique Adjustable Gap Systems: Enables adaptation to variable peanut sizes, maintaining kernel integrity and near-zero breakage.

- Integrated Dust & Husk Extraction: Built-in cyclone or aspiration systems remove husks efficiently, creating a cleaner, safer production environment and reducing post-processing time.

- Energy Efficiency & Output Metrics: Low power consumption while delivering up to 800 kg/hour production rates.

- Modular Design: Facilitates tool-less changeovers and easy maintenance, allowing rapid switching between peanut varieties or production lines.

Comparative Analysis of Leading Manufacturers

Selecting the right manufacturer for your automatic peanut or groundnut shelling needs requires an understanding of production capacities, final product quality, machine longevity, and after-sales service. Below is a comparative table of leading global suppliers specializing in automatic peanut shelling, groundnut shelling, and integrated peanut processing (including butter making).

| Manufacturer | Capacity (kg/hr) | Kernel Breakage Rate (%) | Power Consumption (kW) | Warranty | Integration Option (Peanut Butter) | After-Sales Support |

|---|---|---|---|---|---|---|

| AgriTech Pro | 600 | 2.1 | 3.2 | 24 Months | Available | Global, Online/Onsite |

| NutriShell Equipments | 450 | 2.5 | 2.8 | 18 Months | Optional | Asia, Onsite |

| GroundPro Mechanics | 800 | 1.9 | 4.0 | 24 Months | Integrated Line | Global, 24/7 Hotline |

| ShellMax Solutions | 300 | 2.8 | 2.6 | 12 Months | Separate Machine | Region Limited |

While all leading models perform well in core shelling tasks, distinguishing factors include the degree of kernel preservation, output flexibility, after-sales services, and the feasibility of system integration with automatic peanut butter making machines.

Tailored Solutions for Production Scale and Requirements

No two processing operations are exactly the same. Producers can select automatic peanut shelling solutions adjusted for volume, peanut varieties (Virginia, Spanish, Runner, Valencia), and line integration. For example:

- Small-Batch Farms: Compact, mobile shelling machines (150–300 kg/hour) that support seasonal harvests or cooperative processing, optimized for ease of transport and setup.

- Mid-Sized Enterprises: Flexible machines (300–600 kg/hour) offering scalability, suited for both groundnut and peanut butter output via side-by-side integration.

- Industrial-Scale Operations: High-throughput automated lines (up to 1000 kg/hour) that couple shellers directly with cleaning, grading, roasting, and automatic peanut butter making machines. These lines ensure streamlined, uninterrupted production for demanding commercial markets.

Real-World Applications and Success Stories

Companies across continents have adopted automatic groundnut shelling machine systems to tremendous effect:

- Indian Snack Producers: Leveraging shellers with integrated aspiration systems reduced labor needs by 58% and grew output by 430 kg/day, while also shrinking kernel losses by 70% compared to manual shelling.

- Nigerian Agro-Cooperatives: By connecting an inline shelling and grading plant, member incomes rose by 32% within one harvest cycle, and the plant achieved consistent shelling quality above 97%.

- U.S. Peanut Butter Manufacturers: Adoption of highly automated sheller-roaster-butter lines enabled continuous 24/7 operation, producing over 17 million jars annually and securing USFDA and EU certifications for food safety and traceability.

- European Organic Brands: Modular, easy-to-clean machines proved key for allergen control, allowing the rapid alternation of organic and non-organic runs with minimal contamination.

Maintenance, Operation, and Troubleshooting Insights

Ensuring longevity and consistent performance of an automatic peanut shelling machine lies in adherence to regular maintenance and operational best practices. Key insights include:

- Lubrication Protocols: Schedule greasing of bearings and moving parts every 200 operational hours to prevent excessive wear.

- Rotor and Screen Check: Inspect for debris or wear weekly; a worn shelling screen can increase breakage above 10% if not replaced.

- Calibration: Routine adjustment for different peanut grades to guarantee output uniformity.

- Downtime Reduction: Employ predictive maintenance systems or sensor alerts to catch issues such as blockages or electric faults before they escalate, helping some facilities achieve less than 3% annual unplanned downtime.

- Cleaning: End-of-shift cleaning routines with compressed air, and monthly deep cleans using food-grade detergents, ensure top hygienic performance.

Conclusion: Elevate Your Operations with an Automatic Peanut Shelling Machine

The integration of an automatic peanut shelling machine represents a milestone in efficiency and product quality for modern groundnut processing operations. Technological advances have enabled processors to achieve higher yields, lower breakage, and advanced food safety—while comparative analysis shows clear differentiation in capacity, modular design, and product integration potential. Whether you are seeking to upgrade a small farm, expand a midsize snack production plant, or streamline a full-scale peanut butter factory, tailored solutions are available to match those unique needs. With proper investment in maintenance and training, organizations can realize not only operational continuity but also substantial boosts in profitability and market competitiveness. Embrace the future of groundnut processing—unlock consistent, rapid, and reliable results with a state-of-the-art automatic peanut shelling machine.

(automatic peanut shelling machine)

FAQS on automatic peanut shelling machine

Q: What is an automatic peanut shelling machine?

A: An automatic peanut shelling machine is equipment designed to efficiently remove shells from peanuts without manual labor. It speeds up the process and increases productivity. This machine is ideal for large-scale peanut processing.

Q: How does an automatic groundnut shelling machine improve efficiency?

A: The automatic groundnut shelling machine uses mechanical and electrical systems to shell groundnuts quickly and with minimal wastage. It significantly reduces labor costs. This ensures a high throughput in peanut or groundnut processing plants.

Q: Can automatic peanut shelling machines handle different peanut sizes?

A: Yes, most automatic peanut shelling machines are adjustable to accommodate various peanut sizes. They usually come with configurable settings to ensure optimal shelling performance. This flexibility suits processors managing diverse peanut varieties.

Q: What is the difference between an automatic peanut shelling machine and an automatic peanut butter making machine?

A: An automatic peanut shelling machine removes shells from raw peanuts, while an automatic peanut butter making machine grinds shelled peanuts into butter. They serve different purposes in the peanut processing chain. Each is crucial for producing finished peanut products.

Q: How easy is it to maintain an automatic peanut shelling machine?

A: Most automatic peanut shelling machines are designed for easy cleaning and maintenance. Regular checks and lubrication ensure optimal performance. Simple maintenance helps extend the machine’s lifespan and reliability.

May. 20, 2024

Grain Bag Packing Machine-Hebei Beibu Machinery Technology Co.,LTD

Nov. 11, 2024

Beibu Machinery participate in the 2024 China International Import Expo!

Jul. 09, 2024

sesame and mung beans in Myanmar

Dec. 25, 2024

How to choose a high-quality grain seed cleaning machine - Beibu Machinery answers your questions

Mar. 20, 2024

Hand Sewing Machine for PP Bags-Hebei Beibu Machinery Technology Co.,LTD

Dec. 11, 2024

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.