Understanding the Modern Sesame Peeling Machine: An Industry Overview

The global demand for sesame products, ranging from tahini and sesame oil to bakery ingredients, continues its upward trajectory, propelling innovation in the processing industry. At the heart of this advancement lies the sesame peeling machine, a pivotal piece of equipment designed to efficiently remove the hull from sesame seeds. This process, known as dehulling, is crucial for improving the taste, nutritional value, and digestibility of sesame, while also extending its shelf life by reducing bitterness. Modern peeling machines are engineered for high throughput, minimal breakage, and superior hygiene, meeting the stringent quality standards of today’s food industry. They represent a significant leap from traditional methods, offering unparalleled precision and operational efficiency for manufacturers worldwide.

Industry trends indicate a strong shift towards automation and integration, with manufacturers increasingly seeking solutions that offer lower energy consumption and reduced water usage, alongside robust performance. The market for sesame processing equipment is driven by rising consumer awareness regarding healthy eating and the versatility of sesame seeds in various culinary applications. Companies specializing in this machinery are focusing on modular designs, allowing for easier scalability and customization to specific production needs. Furthermore, there's a growing emphasis on smart technologies, integrating sensors and PLC controls to optimize the peeling process, monitor parameters in real-time, and ensure consistent product quality, thus establishing new benchmarks for the entire sesame processing machine sector.

The Advanced Manufacturing Process of a Sesame Peeling Machine

The construction of a high-performance sesame peeling machine involves meticulous engineering and adherence to stringent quality controls to ensure durability, efficiency, and food safety. The primary material choice is food-grade stainless steel (e.g., SUS304 or SUS316L) for all parts that come into contact with the sesame seeds. This material is chosen for its excellent corrosion resistance, ease of cleaning, and inertness, preventing any contamination of the food product. Manufacturing processes include precision CNC machining for critical components like rollers and impellers, ensuring tight tolerances for optimal dehulling performance and minimal seed breakage. Laser cutting and automated welding techniques are employed for fabricating the machine's frame and tanks, guaranteeing structural integrity and leak-proof operation.

Each stage of manufacturing is subject to rigorous inspection and testing protocols. Components undergo material verification tests, dimensional checks, and surface roughness measurements to comply with industry standards such as ISO 9001 for quality management and ANSI standards for specific mechanical parts. Before assembly, all electrical components are tested for compliance with CE or UL standards, ensuring operational safety. The final assembled sesame seed peeling machine undergoes comprehensive functional testing, including trial runs with actual sesame seeds to verify peeling rate, breakage rate, water consumption, and energy efficiency. This exhaustive process ensures a service life typically exceeding 15 years, even under continuous industrial operation, providing a reliable solution for various food processing industries, including edible oil production, confectionery, and bakery. The design also emphasizes energy efficiency, contributing to lower operational costs for end-users.

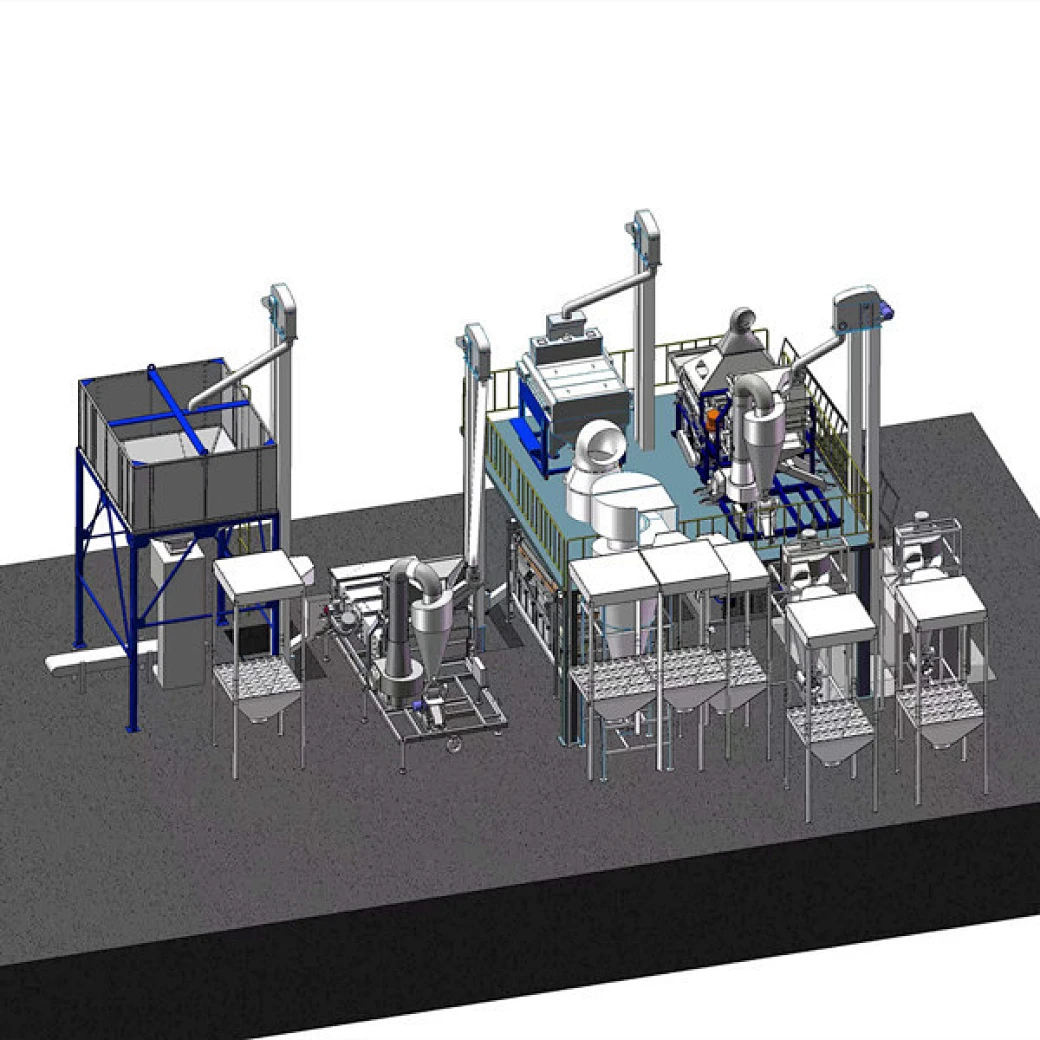

Figure 1: Automated sesame peeling machine designed for high efficiency and hygienic operation.

Technical Parameters and Performance Benchmarks

Selecting the appropriate sesame seed peeling machine requires a thorough understanding of its technical specifications and performance capabilities. Key parameters include processing capacity, power consumption, dimensions, and critical performance indicators such as the dehulling rate and the breakage rate. Modern machines typically boast a dehulling rate exceeding 98% and a breakage rate below 2%, reflecting advanced design and precision manufacturing. Water consumption, an important consideration for operational costs and environmental impact, has also been significantly optimized in recent models, with efficient water recycling systems often integrated. These technical parameters directly translate into operational efficiency, cost-effectiveness, and the quality of the final peeled sesame product.

Below is a comparative table detailing common technical specifications for different models of sesame hulling machines, showcasing the range of capacities and the associated resource requirements. These figures are derived from extensive testing and real-world application data, providing a reliable reference for potential buyers. Such data is vital for project planning, enabling businesses to size their equipment accurately based on production volume targets and available utilities. Understanding these benchmarks allows for informed decision-making, ensuring that the chosen sesame hulling machine aligns perfectly with operational demands and long-term business goals, contributing to overall profitability and product quality.

| Parameter | Small Scale Model | Medium Scale Model | Large Scale Model |

|---|---|---|---|

| Capacity (kg/h) | 100-200 | 300-800 | 1000-2500+ |

| Total Power (kW) | 5-8 | 12-25 | 30-60+ |

| Dehulling Rate (%) | >97 | >98 | >98.5 |

| Breakage Rate (%) | <2.5 | <2.0 | <1.5 |

| Water Consumption (L/h) | 150-300 | 500-1200 | 1500-3000+ |

| Dimensions (L×W×H, mm) | ~2000×1000×2500 | ~3500×1500×3000 | ~5000×2000×3500 |

Application Scenarios and Strategic Advantages

The versatility of the sesame peeling machine makes it indispensable across a spectrum of food processing sectors. Its primary application is in the production of tahini and sesame paste, where a clean, hull-free seed is paramount for achieving the desired creamy texture and mild flavor. Furthermore, it's widely used in the edible oil industry for producing high-quality sesame oil, as peeled seeds yield a purer oil with less bitterness and longer shelf life. Bakeries, confectioneries, and snack food manufacturers also rely on these machines to prepare sesame seeds for toppings, ingredients in various baked goods, and healthy snack mixes, ensuring consumer appeal and food safety. The ability to process both white and black sesame seeds with high efficiency further broadens its utility in diverse culinary traditions.

The strategic advantages of investing in a high-quality sesame processing machine extend beyond mere operational efficiency. Key benefits include significant improvements in product quality due to the precise removal of hulls, which eliminates bitter flavors and enhances visual appeal. This leads to higher market value for finished products and greater consumer satisfaction. Energy efficiency and optimized water usage reduce operational costs, contributing to a more sustainable production model. Moreover, the robust construction, often featuring food-grade stainless steel and sanitary design, ensures easy cleaning and maintenance, reducing downtime and adhering to strict food safety regulations like FDA compliance for food contact materials. This technological edge provides a competitive advantage in a demanding global market.

Manufacturer Comparison and Custom Solutions

When evaluating suppliers for a sesame peeling machine, prospective buyers should consider several critical factors beyond initial cost. Reputable manufacturers often distinguish themselves through a proven track record of innovation, adherence to international quality standards (like ISO and CE certifications), and comprehensive after-sales support. It is advisable to compare manufacturers based on their technological prowess, such as the sophistication of their dehulling mechanism (e.g., advanced blanching and vertical centrifugal separation), the durability of components, and the integration of automated controls (PLC systems). Customer feedback and the longevity of installations in various processing environments also serve as strong indicators of a manufacturer's reliability and product quality. Companies with a long service history, typically over 10-15 years, often demonstrate greater expertise and stability.

Leading providers also offer bespoke engineering services, tailoring the sesame hulling machine to specific client requirements. This might include customizing capacity to match existing production lines, integrating specialized cleaning or drying stages, or designing the system to fit unique facility layouts. For instance, some clients may require systems with enhanced water recycling capabilities for regions with water scarcity, or specific power configurations. These customized solutions ensure seamless integration into a client's existing infrastructure, maximizing operational efficiency and minimizing installation challenges. Companies that offer comprehensive project planning, installation, and operator training exemplify a commitment to partnership and long-term client success, fostering trust and ensuring optimal performance of the sesame processing equipment.

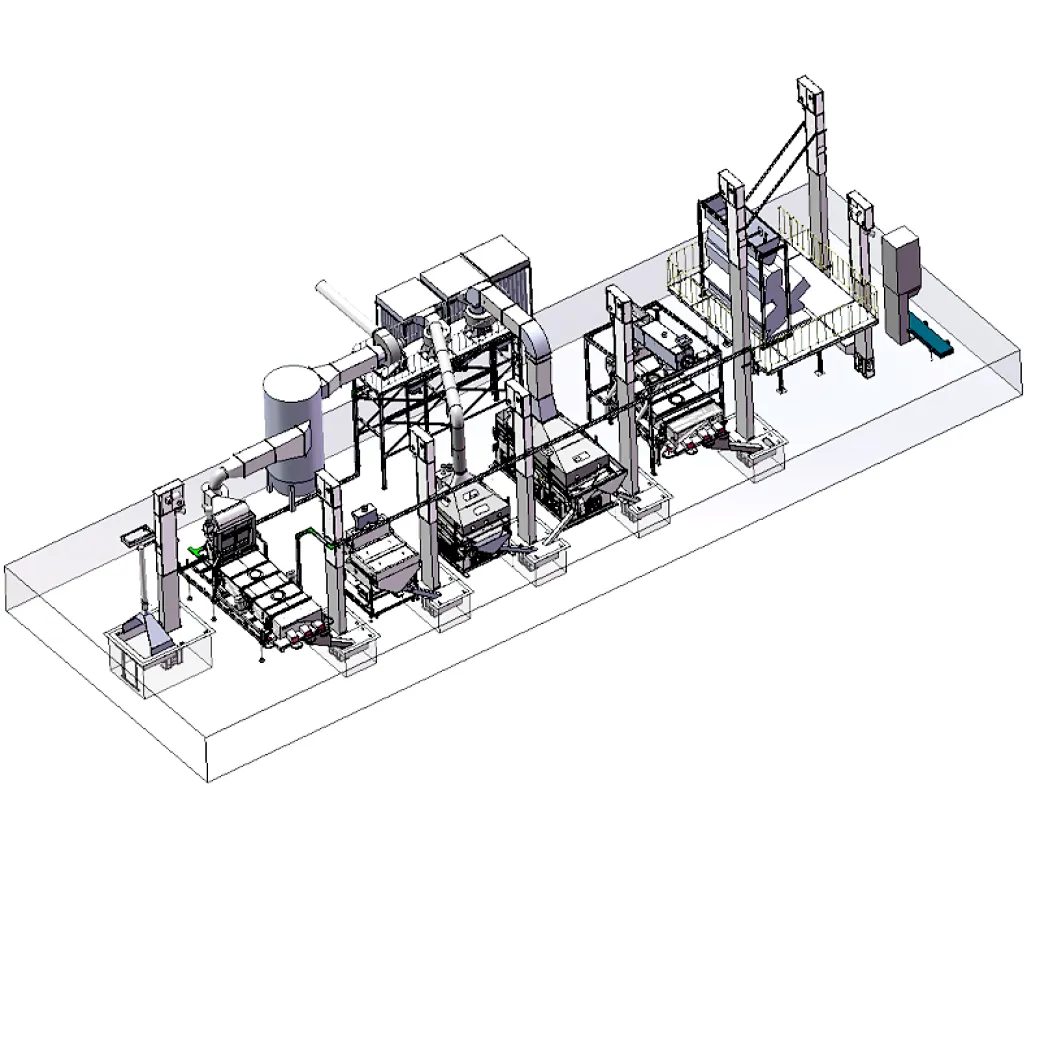

Figure 2: An industrial-scale sesame processing machine integrated into a complete production line.

Case Studies and Customer Endorsements

A prominent tahini manufacturer in the Middle East recently upgraded their facility with a new medium-scale sesame peeling machine. Prior to the upgrade, they faced challenges with inconsistent peeling rates and high water consumption. After implementing the advanced dehulling system with its integrated water recycling and precise temperature control for blanching, they reported a consistent dehulling rate of 98.5% and a 30% reduction in water usage. The improved efficiency led to a significant increase in their production capacity and a noticeable enhancement in the quality and consistency of their tahini, allowing them to expand into new export markets. This real-world application demonstrates the transformative impact of investing in state-of-the-art sesame processing technology.

Another notable case involved a large-scale confectionery company in Southeast Asia that needed to process thousands of kilograms of sesame seeds daily for their popular snack bars. Their existing equipment was struggling with high breakage rates, impacting product aesthetics and increasing waste. Upon installation of a high-capacity sesame hulling machine featuring optimized friction-based peeling and gentle separation, their breakage rate dropped to below 1.5%. The client lauded the machine's robust construction, minimal maintenance requirements, and the responsive customer support provided during installation and commissioning. These success stories underscore the tangible benefits of choosing a reliable partner for critical food processing equipment, ensuring operational excellence and sustained business growth.

Trustworthiness and Support: FAQ, Delivery, and Warranty

Frequently Asked Questions (FAQ)

Q: What types of sesame seeds can this machine process?

A: Our sesame peeling machine is designed to effectively process various types of sesame seeds, including white, black, and brown sesame, optimizing the peeling process for each variety to achieve high dehulling rates and minimal breakage.

Q: How does the machine ensure food safety and hygiene?

A: All food-contact parts are constructed from high-grade SUS304 or SUS316L stainless steel, complying with FDA food contact material regulations. The design prioritizes easy cleaning and sanitization, minimizing cross-contamination risks and ensuring compliance with stringent food safety standards.

Q: What are the typical maintenance requirements?

A: Routine maintenance primarily involves regular cleaning, lubrication of moving parts, and periodic inspection of wear components such as peeling blades or brushes. Detailed maintenance schedules and guidelines are provided in the operational manual, ensuring maximum uptime and extended machine life.

Delivery and Warranty Information

Our commitment to customer satisfaction extends through the entire procurement process, from initial consultation to after-sales support. Standard delivery times for most sesame processing machine models typically range from 30 to 60 business days, depending on customization requirements and current production schedules. We provide comprehensive logistic support, including secure packaging and worldwide shipping, ensuring your equipment arrives safely and on time. Each machine comes with a standard 12-month warranty covering manufacturing defects and component failures under normal operating conditions. Extended warranty options and comprehensive service contracts are also available for enhanced peace of mind. Our dedicated customer support team is available 24/7 to assist with installation, training, troubleshooting, and spare parts procurement, ensuring your operation runs smoothly and efficiently.

References

- Food and Agriculture Organization of the United Nations (FAO). Agricultural production statistics and reports.

- International Organization for Standardization (ISO). ISO 9001 Quality Management Systems - Requirements.

- Food and Drug Administration (FDA). Code of Federal Regulations, Title 21 - Food and Drugs.

- European Committee for Standardization (CEN). CE Marking Directives and Harmonized Standards.

- Journal of Food Engineering. Various articles on oilseed processing and dehulling technologies.

Understanding the Modern Sesame Peeling Machine: An Industry Overview

The global demand for sesame products, ranging from tahini and sesame oil to bakery ingredients, continues its upward trajectory, propelling innovation in the processing industry. At the heart of this advancement lies the sesame peeling machine, a pivotal piece of equipment designed to efficiently remove the hull from sesame seeds. This process, known as dehulling, is crucial for improving the taste, nutritional value, and digestibility of sesame, while also extending its shelf life by reducing bitterness. Modern peeling machines are engineered for high throughput, minimal breakage, and superior hygiene, meeting the stringent quality standards of today’s food industry. They represent a significant leap from traditional methods, offering unparalleled precision and operational efficiency for manufacturers worldwide.

Industry trends indicate a strong shift towards automation and integration, with manufacturers increasingly seeking solutions that offer lower energy consumption and reduced water usage, alongside robust performance. The market for sesame processing equipment is driven by rising consumer awareness regarding healthy eating and the versatility of sesame seeds in various culinary applications. Companies specializing in this machinery are focusing on modular designs, allowing for easier scalability and customization to specific production needs. Furthermore, there's a growing emphasis on smart technologies, integrating sensors and PLC controls to optimize the peeling process, monitor parameters in real-time, and ensure consistent product quality, thus establishing new benchmarks for the entire sesame processing machine sector.

The Advanced Manufacturing Process of a Sesame Peeling Machine

The construction of a high-performance sesame peeling machine involves meticulous engineering and adherence to stringent quality controls to ensure durability, efficiency, and food safety. The primary material choice is food-grade stainless steel (e.g., SUS304 or SUS316L) for all parts that come into contact with the sesame seeds. This material is chosen for its excellent corrosion resistance, ease of cleaning, and inertness, preventing any contamination of the food product. Manufacturing processes include precision CNC machining for critical components like rollers and impellers, ensuring tight tolerances for optimal dehulling performance and minimal seed breakage. Laser cutting and automated welding techniques are employed for fabricating the machine's frame and tanks, guaranteeing structural integrity and leak-proof operation.

Each stage of manufacturing is subject to rigorous inspection and testing protocols. Components undergo material verification tests, dimensional checks, and surface roughness measurements to comply with industry standards such as ISO 9001 for quality management and ANSI standards for specific mechanical parts. Before assembly, all electrical components are tested for compliance with CE or UL standards, ensuring operational safety. The final assembled sesame seed peeling equipment undergoes comprehensive functional testing, including trial runs with actual sesame seeds to verify peeling rate, breakage rate, water consumption, and energy efficiency. This exhaustive process ensures a service life typically exceeding 15 years, even under continuous industrial operation, providing a reliable solution for various food processing industries, including edible oil production, confectionery, and bakery. The design also emphasizes energy efficiency, contributing to lower operational costs for end-users.

Figure 1: Automated sesame peeling machine designed for high efficiency and hygienic operation.

Technical Parameters and Performance Benchmarks

Selecting the appropriate sesame seed peeling machine requires a thorough understanding of its technical specifications and performance capabilities. Key parameters include processing capacity, power consumption, dimensions, and critical performance indicators such as the dehulling rate and the breakage rate. Modern machines typically boast a dehulling rate exceeding 98% and a breakage rate below 2%, reflecting advanced design and precision manufacturing. Water consumption, an important consideration for operational costs and environmental impact, has also been significantly optimized in recent models, with efficient water recycling systems often integrated. These technical parameters directly translate into operational efficiency, cost-effectiveness, and the quality of the final peeled sesame product.

Below is a comparative table detailing common technical specifications for various sesame hulling equipment models, showcasing the range of capacities and the associated resource requirements. These figures are derived from extensive testing and real-world application data, providing a reliable reference for potential buyers. Such data is vital for project planning, enabling businesses to size their equipment accurately based on production volume targets and available utilities. Understanding these benchmarks allows for informed decision-making, ensuring that the chosen sesame hulling machine aligns perfectly with operational demands and long-term business goals, contributing to overall profitability and product quality.

| Parameter | Small Scale Model | Medium Scale Model | Large Scale Model |

|---|---|---|---|

| Capacity (kg/h) | 100-200 | 300-800 | 1000-2500+ |

| Total Power (kW) | 5-8 | 12-25 | 30-60+ |

| Dehulling Rate (%) | >97 | >98 | >98.5 |

| Breakage Rate (%) | <2.5 | <2.0 | <1.5 |

| Water Consumption (L/h) | 150-300 | 500-1200 | 1500-3000+ |

| Dimensions (L×W×H, mm) | ~2000×1000×2500 | ~3500×1500×3000 | ~5000×2000×3500 |

Application Scenarios and Strategic Advantages

The versatility of the sesame peeling machine makes it indispensable across a spectrum of food processing sectors. Its primary application is in the production of tahini and sesame paste, where a clean, hull-free seed is paramount for achieving the desired creamy texture and mild flavor. Furthermore, it's widely used in the edible oil industry for producing high-quality sesame oil, as peeled seeds yield a purer oil with less bitterness and longer shelf life. Bakeries, confectioneries, and snack food manufacturers also rely on these machines to prepare sesame seeds for toppings, ingredients in various baked goods, and healthy snack mixes, ensuring consumer appeal and food safety. The ability to process both white and black sesame seeds with high efficiency further broadens its utility in diverse culinary traditions.

The strategic advantages of investing in a high-quality sesame processing system extend beyond mere operational efficiency. Key benefits include significant improvements in product quality due to the precise removal of hulls, which eliminates bitter flavors and enhances visual appeal. This leads to higher market value for finished products and greater consumer satisfaction. Energy efficiency and optimized water usage reduce operational costs, contributing to a more sustainable production model. Moreover, the robust construction, often featuring food-grade stainless steel and sanitary design, ensures easy cleaning and maintenance, reducing downtime and adhering to strict food safety regulations like FDA compliance for food contact materials. This technological edge provides a competitive advantage in a demanding global market.

Manufacturer Comparison and Custom Solutions

When evaluating suppliers for a sesame peeling machine, prospective buyers should consider several critical factors beyond initial cost. Reputable manufacturers often distinguish themselves through a proven track record of innovation, adherence to international quality standards (like ISO and CE certifications), and comprehensive after-sales support. It is advisable to compare manufacturers based on their technological prowess, such as the sophistication of their dehulling mechanism (e.g., advanced blanching and vertical centrifugal separation), the durability of components, and the integration of automated controls (PLC systems). Customer feedback and the longevity of installations in various processing environments also serve as strong indicators of a manufacturer's reliability and product quality. Companies with a long service history, typically over 10-15 years, often demonstrate greater expertise and stability.

Leading providers also offer bespoke engineering services, tailoring the sesame hulling machine to specific client requirements. This might include customizing capacity to match existing production lines, integrating specialized cleaning or drying stages, or designing the system to fit unique facility layouts. For instance, some clients may require systems with enhanced water recycling capabilities for regions with water scarcity, or specific power configurations. These customized solutions ensure seamless integration into a client's existing infrastructure, maximizing operational efficiency and minimizing installation challenges. Companies that offer comprehensive project planning, installation, and operator training exemplify a commitment to partnership and long-term client success, fostering trust and ensuring optimal performance.

Figure 2: An industrial-scale sesame processing line, featuring key dehulling equipment.

Case Studies and Customer Endorsements

A prominent tahini manufacturer in the Middle East recently upgraded their facility with a new medium-scale sesame peeling machine. Prior to the upgrade, they faced challenges with inconsistent peeling rates and high water consumption. After implementing the advanced dehulling system with its integrated water recycling and precise temperature control for blanching, they reported a consistent dehulling rate of 98.5% and a 30% reduction in water usage. The improved efficiency led to a significant increase in their production capacity and a noticeable enhancement in the quality and consistency of their tahini, allowing them to expand into new export markets. This real-world application demonstrates the transformative impact of investing in state-of-the-art sesame processing technology.

Another notable case involved a large-scale confectionery company in Southeast Asia that needed to process thousands of kilograms of sesame seeds daily for their popular snack bars. Their existing equipment was struggling with high breakage rates, impacting product aesthetics and increasing waste. Upon installation of a high-capacity sesame hulling unit featuring optimized friction-based peeling and gentle separation, their breakage rate dropped to below 1.5%. The client lauded the machine's robust construction, minimal maintenance requirements, and the responsive customer support provided during installation and commissioning. These success stories underscore the tangible benefits of choosing a reliable partner for critical food processing equipment, ensuring operational excellence and sustained business growth.

Trustworthiness and Support: FAQ, Delivery, and Warranty

Frequently Asked Questions (FAQ)

Q: What types of sesame seeds can this machine process?

A: Our sesame peeling machine is designed to effectively process various types of sesame seeds, including white, black, and brown sesame, optimizing the peeling process for each variety to achieve high dehulling rates and minimal breakage.

Q: How does the machine ensure food safety and hygiene?

A: All food-contact parts are constructed from high-grade SUS304 or SUS316L stainless steel, complying with FDA food contact material regulations. The design prioritizes easy cleaning and sanitization, minimizing cross-contamination risks and ensuring compliance with stringent food safety standards.

Q: What are the typical maintenance requirements?

A: Routine maintenance primarily involves regular cleaning, lubrication of moving parts, and periodic inspection of wear components such as peeling blades or brushes. Detailed maintenance schedules and guidelines are provided in the operational manual, ensuring maximum uptime and extended machine life.

Delivery and Warranty Information

Our commitment to customer satisfaction extends through the entire procurement process, from initial consultation to after-sales support. Standard delivery times for most sesame processing solutions typically range from 30 to 60 business days, depending on customization requirements and current production schedules. We provide comprehensive logistic support, including secure packaging and worldwide shipping, ensuring your equipment arrives safely and on time. Each machine comes with a standard 12-month warranty covering manufacturing defects and component failures under normal operating conditions. Extended warranty options and comprehensive service contracts are also available for enhanced peace of mind. Our dedicated customer support team is available 24/7 to assist with installation, training, troubleshooting, and spare parts procurement, ensuring your operation runs smoothly and efficiently.

References

- Food and Agriculture Organization of the United Nations (FAO). Agricultural production statistics and reports.

- International Organization for Standardization (ISO). ISO 9001 Quality Management Systems - Requirements.

- Food and Drug Administration (FDA). Code of Federal Regulations, Title 21 - Food and Drugs.

- European Committee for Standardization (CEN). CE Marking Directives and Harmonized Standards.

- Journal of Food Engineering. Various articles on oilseed processing and dehulling technologies.

Feb. 07, 2025

Beibu machinery Seed cleaning machine helps you with spring farming!

May. 04, 2024

sesame cleaning season is coming

Mar. 20, 2024

Sesame and Soybean Beans Cleaning Machine Installed-Hebei Beibu Machinery Technology Co.,LTD

Jan. 20, 2025

Sesame Cleaning Machine Delivery-Hebei Beibu Machinery Technology Co.,LTD

Jun. 30, 2025

Unlocking Grain Purity: The Essential Destoner Machine

Apr. 16, 2024

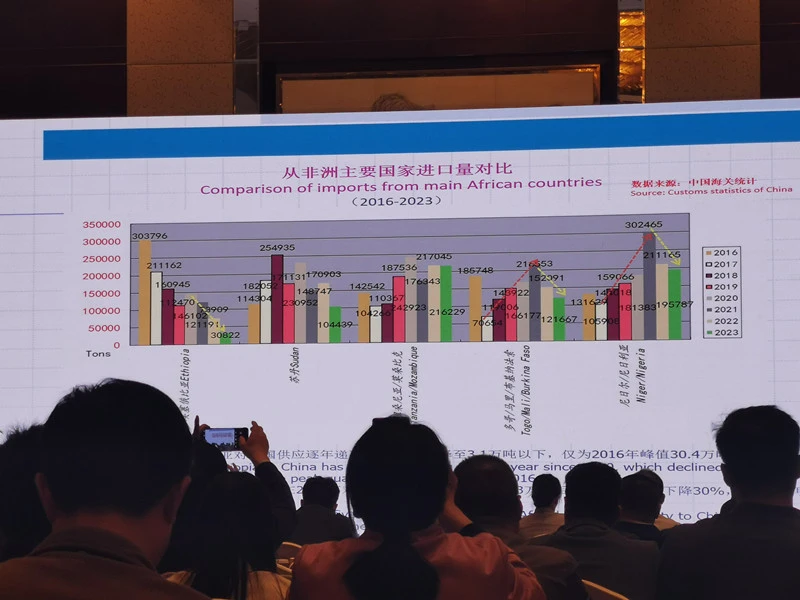

China Sesame Import Data-Hebei Beibu Machinery Technology Co.LTD

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.