The Advanced Engineering Behind Your Sesame Processing Success

The global demand for sesame and its derivatives, from tahini to sesame oil, continues its upward trajectory, driven by increasing consumer awareness of its nutritional benefits and versatility across various culinary and industrial applications. This surge necessitates robust, efficient, and impeccably hygienic processing solutions, with the sesame hulling machine standing as the undeniable linchpin of any high-capacity sesame processing line. Our state-of-the-art Sesame Cleaning Processing Plant integrates cutting-edge technology to transform raw sesame seeds into perfectly hulled products, ready for further applications in the food industry, including baking, confectionery, and oil pressing. The meticulous design and manufacturing of each component, particularly the sophisticated hulling mechanism, underscore our unwavering commitment to precision engineering and stringent food safety standards. We understand implicitly that in the highly regulated and quality-driven food processing industry, every detail matters—from the initial selection of raw materials to the exhaustive post-manufacturing quality control, ensuring that our machinery not only meets but consistently exceeds industry benchmarks for efficiency, operational longevity, and pristine hygiene. This comprehensive approach is designed to deliver sustainable, high-yield solutions that empower businesses to meet escalating market demands while maintaining the absolute highest product quality and purity, solidifying their position in a competitive global landscape.

At the very core of our sesame hulling machine lies a meticulously engineered manufacturing process, one that begins with the scrupulous selection of premium-grade materials to guarantee maximum durability and sanitation. For all components that come into direct contact with sesame seeds, we predominantly utilize certified food-grade stainless steel, specifically SUS304 and SUS316L, which are globally renowned for their exceptional corrosion resistance, superior hygienic properties, and inherent durability. These properties are absolutely crucial for maintaining impeccable product purity and extending the equipment's lifespan in the demanding, moisture-rich food processing environments. The fabrication process itself employs advanced, highly automated techniques such as precision laser cutting for intricate parts, ensuring exact dimensions and minimizing material waste, thereby optimizing resource utilization. This is systematically followed by automated welding processes, which are critically applied to guarantee robust joints and perfectly seamless surfaces, a vital step in preventing bacterial accumulation and facilitating effortless cleaning, which is paramount for food safety compliance. Critical mechanical components, including precision shafts and high-performance bearings, undergo meticulous CNC machining to achieve exceptionally tight tolerances, ensuring smooth, vibration-minimized operation and an extended service life under continuous heavy loads. Advanced surface treatments, such as electropolishing or passivation, are expertly applied to further enhance the material's inherent corrosion resistance and to provide a superior, ultra-smooth, and easy-to-clean finish. Throughout this entire manufacturing cycle, stringent, multi-stage quality control measures are rigorously implemented. This includes comprehensive material certifications to verify precise chemical composition, non-destructive testing (NDT) like ultrasonic or radiographic inspection for absolute weld integrity, and highly accurate dimensional inspections using sophisticated coordinate measuring machines (CMMs) to ensure all components meet precise engineering specifications and international standards. Our unwavering adherence to global standards such as ISO 9001 for quality management systems and CE marking for European market conformity emphatically underscores our steadfast commitment to delivering globally recognized, supremely reliable equipment. This meticulous and uncompromising approach ensures that each sesame hulling machine leaving our advanced manufacturing facility is exceptionally robust, highly energy-efficient, and supremely capable of delivering consistent, high-quality output for well over 15-20 years with proper maintenance, significantly outperforming conventional alternatives and providing an enduring return on investment for our discerning clients.

Operational Excellence and Key Technical Specifications

The operational advantages inherent in our advanced sesame hulling machine are multifaceted, primarily centering on maximizing decortication efficiency while simultaneously minimizing broken kernel rates—both of which are absolutely critical metrics for achieving optimal profitability within the sesame processing industry. Our innovative design meticulously incorporates cutting-edge abrasive hulling technology, which is engineered to gently yet highly effectively separate the hull from the kernel, consistently achieving an impressive hulling rate of over 98% with an industry-leading broken kernel rate typically maintained below 2%. This exceptional performance is directly attributed to the precise calibration of optimized rotor speeds, the utilization of precisely engineered abrasive surfaces, and an integrated, intelligent water softening and circulation system that accurately prepares the sesame seeds for optimal hulling. This pre-treatment system functions by meticulously adjusting the seeds' moisture content and effectively reducing water hardness, thereby preventing mineral buildup within the machine's critical components and ensuring consistent performance. Furthermore, the inherent energy efficiency of our machines represents a significant competitive advantage; our systems feature optimized motor ratings and intelligent power management systems meticulously designed to substantially reduce operational costs over the machine's extensive lifespan. For instance, a typical commercial-scale sesame hulling machine designed for high throughput consumes approximately 0.25 kWh per kilogram of hulled sesame, a figure demonstrably lower than prevalent industry averages, translating into considerable long-term savings. Beyond mere efficiency, the machine's design places paramount importance on ease of cleaning and maintenance, integrating intuitive features such as quick-release components and full CIP (Clean-in-Place) compatibility. These capabilities allow for entirely automated cleaning cycles, which drastically minimize downtime, optimize labor allocation, and ensure the highest possible standards of hygiene are consistently met. The modular construction underpinning our entire Sesame Cleaning Processing Plant further facilitates easy expansion or seamless integration into existing production lines, offering unparalleled operational flexibility to adapt rapidly to evolving market demands and production needs. These collective features contribute significantly to a lower total cost of ownership (TCO) and a superior return on investment (ROI) for our esteemed clients, solidifying our reputation as a trusted leader in the industrial food processing equipment sector.

Our unwavering commitment to transparency and technical excellence is comprehensively reflected in the detailed specifications we provide for all our sesame hulling machine models. Gaining a thorough understanding of these precise technical parameters is absolutely crucial for B2B decision-makers to make an informed choice and select the most appropriate equipment for their specific production scale, operational requirements, and long-term business objectives. The following meticulously compiled table provides a concise yet comprehensive overview of typical performance metrics and key technical specifications you can unequivocally expect from our leading models, each expertly designed for various capacities within a fully integrated and high-performance sesame processing line. These presented figures are not merely theoretical; they are meticulously derived from rigorous, controlled internal testing procedures conducted at our state-of-the-art facilities and are further empirically verified through extensive real-world client operational data collected over prolonged periods. This dual validation approach unequivocally illustrates the consistent, reliable, and superior performance our machinery consistently delivers under diverse operating conditions. From critical parameters such as processing capacity, accurately measured in tons per hour (T/H), to optimized power consumption figures and precise overall dimensions, each parameter has been painstakingly optimized through extensive research and development to ensure maximum throughput with minimal resource utilization and environmental impact. Furthermore, the exceptionally robust construction, primarily employing premium SUS304/316L stainless steel, guarantees not only exceptional durability and resilience but also strict adherence to the most rigorous global food safety regulations, including those implicitly aligned with international standards such as FDA guidelines for food contact materials. This ensures absolute product purity, preventing any form of cross-contamination or compromise to the final hulled sesame product's integrity. These highly specialized machines are precision-engineered for continuous, heavy-duty operation, operating reliably around the clock if required, standing as a true testament to their superior build quality, the innovative engineering principles employed, and the extensive research and development investment that underpins their creation, guaranteeing a formidable asset for any sesame processing enterprise.

| Parameter | Model A (Entry-Level) | Model B (Mid-Range) | Model C (High-Capacity) |

|---|---|---|---|

| Processing Capacity (T/H) | 0.5 - 1.0 | 1.5 - 2.5 | 3.0 - 5.0 |

| Total Power (kW) | 18 - 25 | 35 - 50 | 60 - 85 |

| Hulling Rate (%) | >98 | >98.5 | >99 |

| Broken Rate (%) | <2.0 | <1.5 | <1.0 |

| Material Contact Parts | SUS304 | SUS304/SUS316L | SUS316L |

| Dimensions (L×W×H, m) | 3.5×1.8×2.5 | 4.2×2.0×3.0 | 5.0×2.5×3.5 |

| Weight (kg) | 1800 - 2500 | 3000 - 4500 | 5500 - 8000 |

Tailored Solutions and Unwavering Support

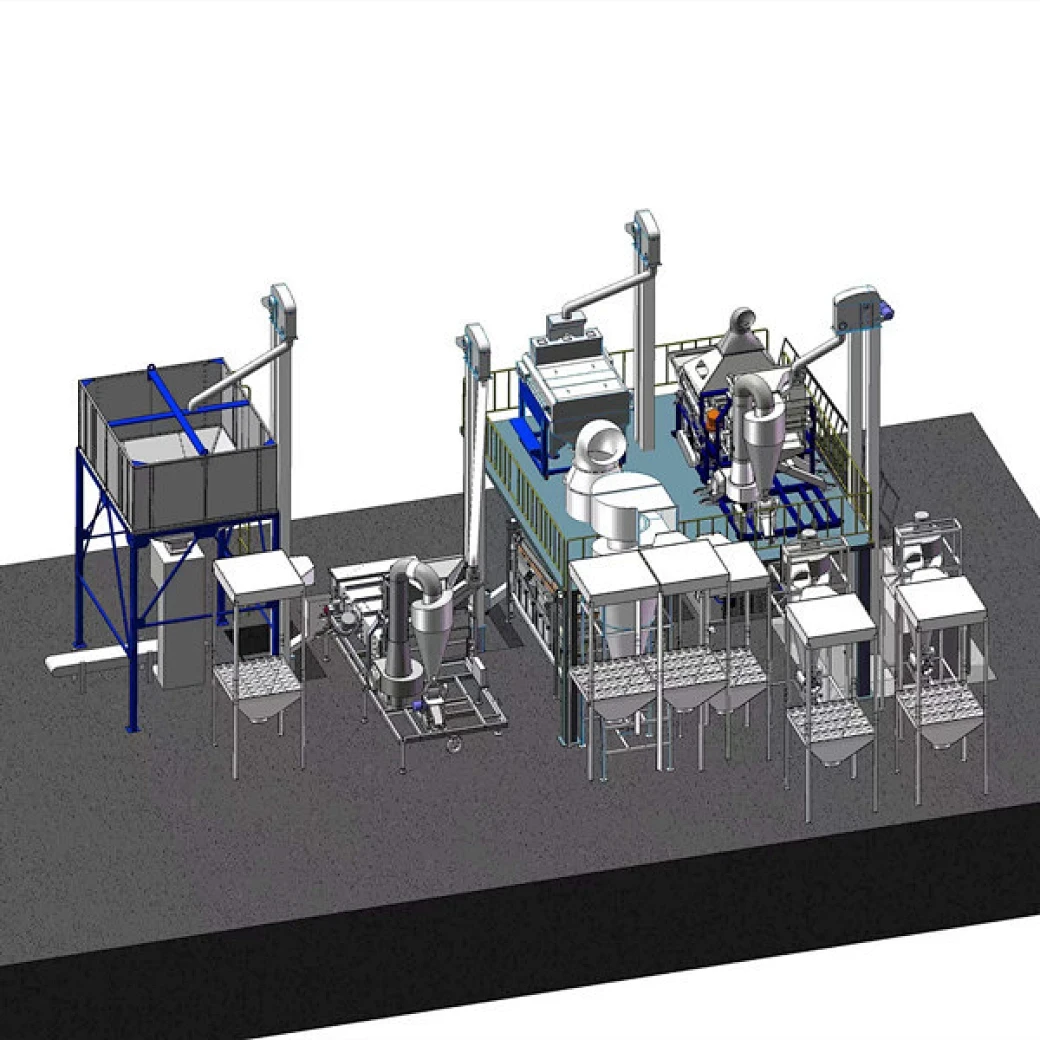

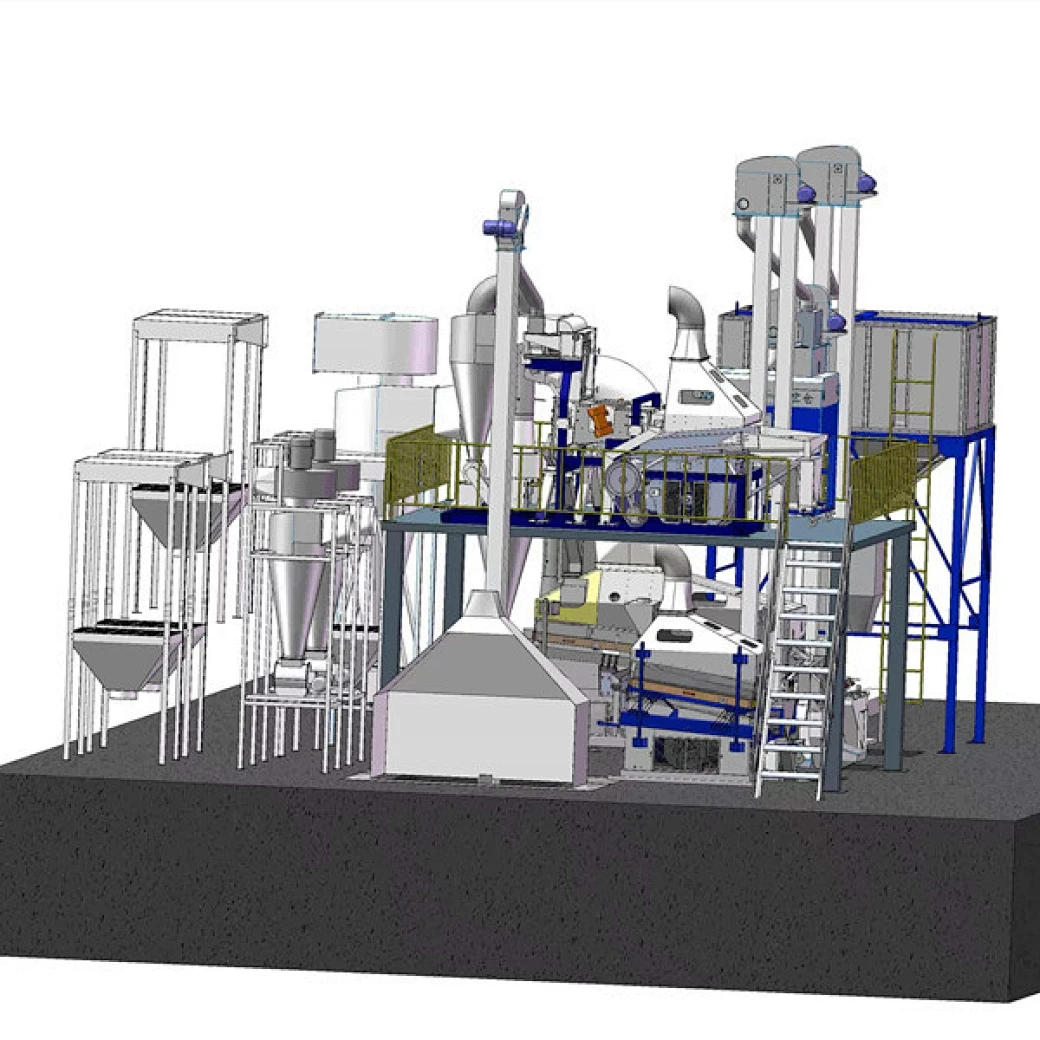

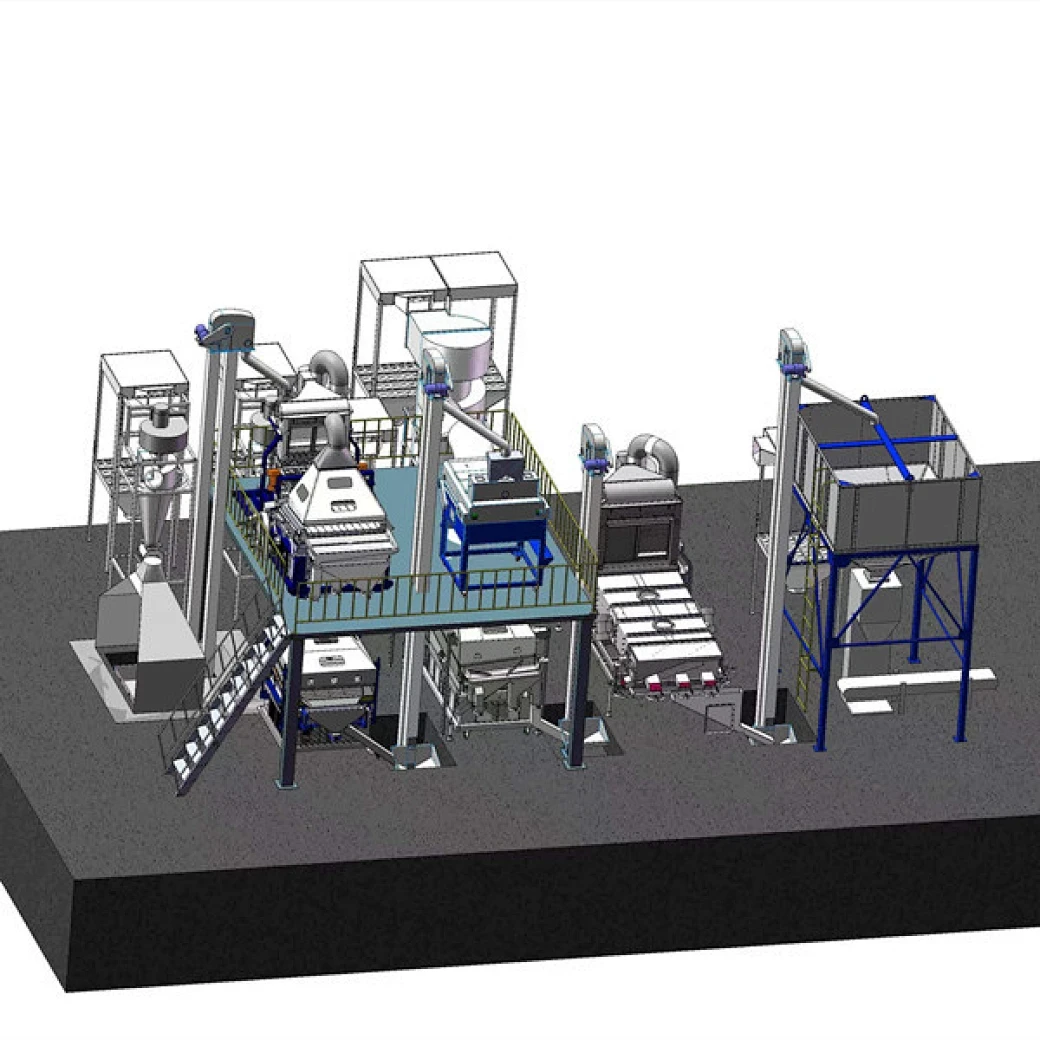

Recognizing unequivocally that each client's operational landscape, strategic production goals, and specific market demands are inherently unique, we excel in providing highly customized, turnkey solutions for our comprehensive sesame processing plant and individual sesame hulling machine units. Our expert engineering team engages in profound collaboration with clients from the very outset, spanning initial feasibility studies and optimal plant layout design to seamless equipment integration and final commissioning. This bespoke, client-centric approach meticulously ensures that whether you require a compact, highly efficient system specifically designed for emerging markets or a high-capacity, fully automated sesame processing line tailored for large-scale industrial operations, the proposed solution is perfectly aligned with your specific throughput demands, available space constraints, and allocated budget. We diligently provide detailed CAD layouts, photorealistic 3D renderings, and advanced simulations to precisely visualize the proposed plant design, allowing for iterative refinement and optimization long before manufacturing even begins, thereby minimizing costly changes later. Our expertise extends far beyond merely supplying cutting-edge machinery; we offer comprehensive project management, meticulously overseeing every stage to ensure seamless execution from the initial order placement through to the final operational handover. This all-encompassing service includes critical assistance with utility requirements, efficient ventilation strategies, and robust waste management protocols, providing a holistic, end-to-end solution that proactively addresses all facets of establishing and running a successful, profitable sesame processing facility. Furthermore, our robust, globally distributed after-sales support infrastructure stands as a fundamental cornerstone of our unwavering commitment to ensuring sustained client success, guaranteeing long-term operational stability, peak efficiency, and maximum uptime for all our installed systems.

Our profound dedication to achieving unparalleled client satisfaction is further profoundly exemplified by our comprehensive suite of support services, meticulously designed to ensure continuous operational excellence. We proudly offer an industry-leading warranty of 24 months for major components and 12 months for wear parts, a commitment that significantly exceeds the industry average and powerfully demonstrates our absolute confidence in the inherent durability, unwavering reliability, and superior craftsmanship of our sesame hulling machine. Our standard delivery cycle ranges efficiently from 8 to 12 weeks, precisely depending on the specific complexity and the level of customization required for each individual order, with transparent and proactive communication meticulously maintained throughout the entire production and intricate logistics phases. Post-installation, our highly certified and experienced technicians provide thorough, hands-on on-site training for your operational staff, comprehensively covering everything from optimal daily operation and diligent routine maintenance procedures to advanced troubleshooting techniques, ensuring your team is fully equipped and confidently capable of maximizing the machine's full potential. We also provide swift and effective remote diagnostic support, coupled with a readily available and strategically stocked inventory of genuine spare parts, meticulously designed to minimize any potential downtime and ensure continuous production. Customer feedback consistently highlights the remarkable reliability and consistent performance of our equipment, alongside the exceptional responsiveness and profound expertise of our dedicated support team. For instance, a recent valued client in the Middle East reported a remarkable 25% increase in throughput capacity and an impressive 15% reduction in overall energy consumption after seamlessly upgrading to our high-capacity sesame hulling machine, a success story amplified by the exceptional post-sale service that ensured a profoundly smooth and successful transition. These compelling testimonials emphatically underscore our proven track record and the tangible, measurable benefits our cutting-edge solutions consistently bring to businesses operating within increasingly competitive global markets, thereby powerfully reinforcing our established authority and unwavering trustworthiness as a leading, innovative manufacturer in the food processing machinery sector.

Frequently Asked Questions (FAQ)

Q1: What makes your sesame hulling machine superior in terms of broken kernel rate?

Our sesame hulling machine consistently achieves exceptionally low broken kernel rates, typically maintained below 1.5% for our high-capacity models. This superior performance is a direct result of a finely tuned combination of meticulously calibrated abrasive surfaces, precisely optimized rotational speeds, and an advanced pre-hulling soaking system. This innovative pre-treatment mechanism accurately controls the moisture content of the sesame seeds, which gently softens the hull without compromising the integrity of the delicate kernel. This ensures a gentle yet remarkably effective decortication process. Furthermore, the machine's intelligent design minimizes mechanical stress points and provides highly adjustable parameters, allowing operators to fine-tune the hulling process with unparalleled precision for different sesame varieties and varying moisture levels, offering exceptional flexibility and stringent quality control. This level of precision engineering is a direct outcome of extensive research and development, coupled with continuous refinement based on real-world performance data analysis, enabling us to consistently deliver optimal performance in diverse operational settings globally.

Q2: How do you ensure the hygiene and food safety of your sesame processing equipment?

Food safety and uncompromising hygiene are paramount principles that guide every aspect of the design and manufacturing of our entire sesame processing line, including each individual sesame hulling machine. All components that come into direct contact with sesame seeds are exclusively constructed from certified food-grade stainless steel (predominantly SUS304 or SUS316L), which inherently prevents corrosion and effectively inhibits bacterial growth. The machines are meticulously designed with smooth, seamless surfaces and minimal crevices, significantly facilitating thorough and efficient cleaning procedures. Many of our advanced models seamlessly incorporate fully integrated Clean-in-Place (CIP) systems, which enable automated washing and sanitization without requiring any disassembly, thereby minimizing labor and ensuring consistent sanitation. Furthermore, our manufacturing processes strictly adhere to rigorous international hygiene standards, and our products implicitly meet the comprehensive requirements for safe food handling, aligning with principles upheld by leading regulatory bodies such as the FDA concerning material safety, design for sanitation, and overall quality assurance protocols in food processing equipment. We also provide detailed cleaning protocols and comprehensive operational guidelines to actively assist clients in maintaining peak hygienic conditions and ensuring regulatory compliance at all times.

Q3: Can your sesame hulling machine be integrated into an existing processing line?

Absolutely. Our sesame hulling machine models are meticulously designed with inherent modularity and exceptional flexibility, making them highly adaptable and remarkably simple to integrate into existing sesame processing plant setups. Our dedicated engineering team conducts thorough on-site assessments and comprehensive consultations to gain a deep understanding of your current infrastructure, existing production flow, and precise integration requirements. Based on this detailed analysis, we then provide highly tailored integration solutions, which may include custom-designed conveyors, specialized hoppers, seamless control system compatibility, and optimized utility connections. Our primary goal is to ensure a truly seamless transition and the achievement of optimal performance within your existing operational framework, thereby minimizing any potential disruption to current production and maximizing efficiency gains. We possess extensive, proven experience in successfully upgrading and modernizing a wide range of existing facilities, ensuring that our new, advanced equipment perfectly complements your current assets and significantly enhances overall line productivity and profitability.

Q4: What kind of after-sales support and maintenance do you offer?

We pride ourselves on providing truly comprehensive and proactive after-sales support, meticulously designed to ensure the long-term optimal performance and enduring reliability of your sesame hulling machine. This robust support framework includes an industry-leading warranty (extending up to 24 months for critical components), readily available genuine spare parts from our globally distributed inventory, and access to a highly responsive and deeply knowledgeable technical support team. We offer expert on-site installation and meticulous commissioning services, which are accompanied by detailed operational and hands-on maintenance training for your dedicated personnel. For efficient troubleshooting, we provide advanced remote diagnostics capabilities and immediate telephone support. Our commitment to your success extends to offering comprehensive preventive maintenance programs and scheduled periodic inspections, all meticulously designed to prolong the machine's lifespan, ensure consistent output quality, and maintain peak operational efficiency. This proactive and client-focused approach to customer service demonstrably minimizes potential downtime and maximizes the return on your significant investment in our advanced sesame processing line equipment, solidifying our partnership for your long-term success.

References and Authority

- International Organization for Standardization (ISO). ISO 9001 Quality Management Systems.

- Food and Agriculture Organization of the United Nations (FAO). "Sesame: post-harvest operations." FAO Agricultural Services Bulletin, No. 153.

- European Committee for Standardization (CEN). Machinery Directive 2006/42/EC.

- U.S. Food & Drug Administration (FDA). Food-Contact Materials Guidelines.

Jul. 15, 2024

Bag Hand Sewing Machine-Hebei Beibu Machinery Technology Co.,LTD

Nov. 28, 2024

Apr. 11, 2024

clean sameme with higest purity

Mar. 19, 2025

Best Time for Booking Grain Cleaning Machine-Hebei Beibu Machinery Technology Co.,LTD

Jul. 09, 2025

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.