How to choose a professional coffee bean cleaning production line-Beibu Machinery

With the coming of Christmas, most coffee bean producing areas in Asia, Africa and America have entered the busiest picking season of the year, and this busy farming event will last until March of the following year.

During this period, coffee farmers must not only ensure that ripe coffee fruits are picked in time, but also quickly send them to the processing plant for professional treatment to prevent the coffee fruits from deteriorating and affecting the quality of coffee beans. The entire processing process is both complex and delicate, and each step is crucial and determines the quality of the final coffee.

Beibu Machinery, as a grain seed machine manufacturer with more than ten years of experience, has always insisted on providing professional solutions for customers, adhering to the core value of "customer interests first", and is committed to providing professional screening machinery and professional technical solutions. With professional technical strength, we will help your career development.

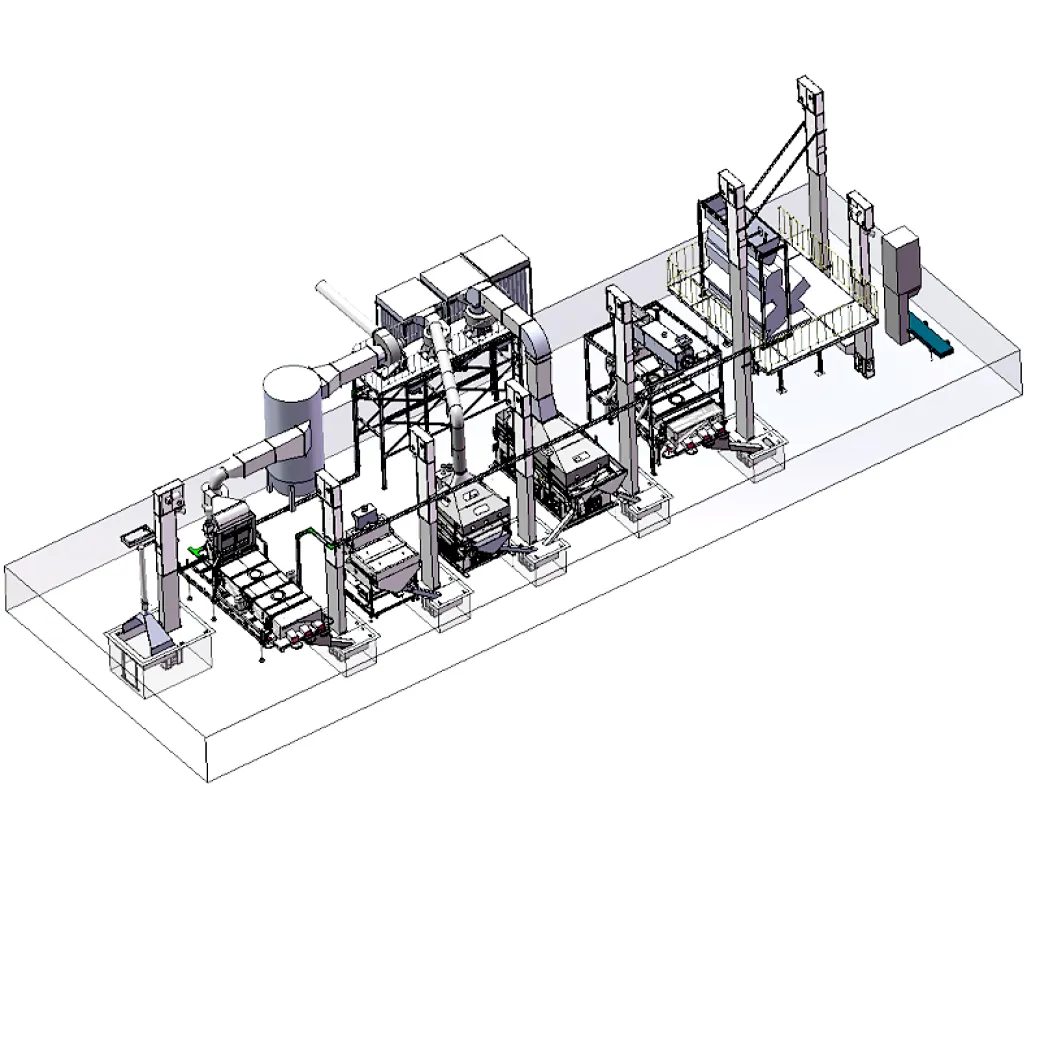

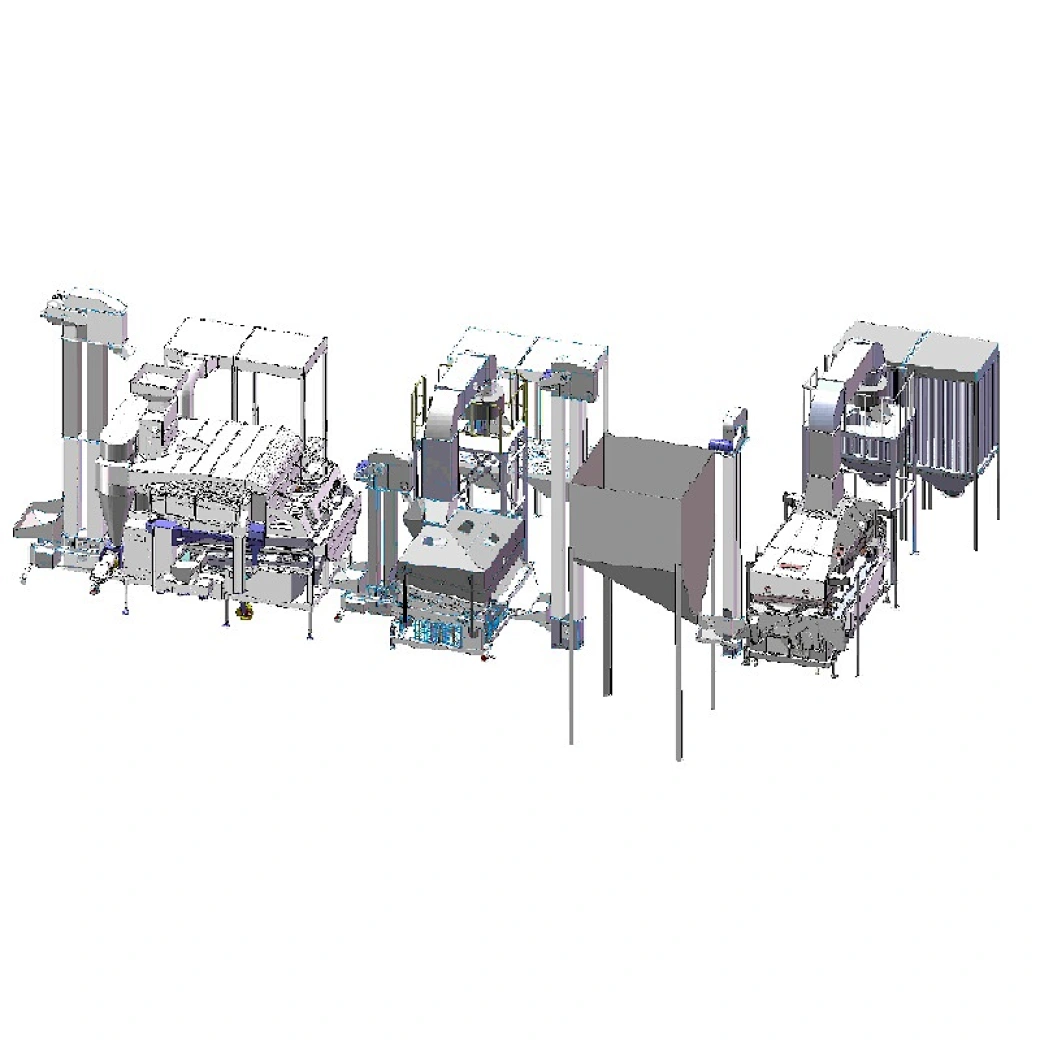

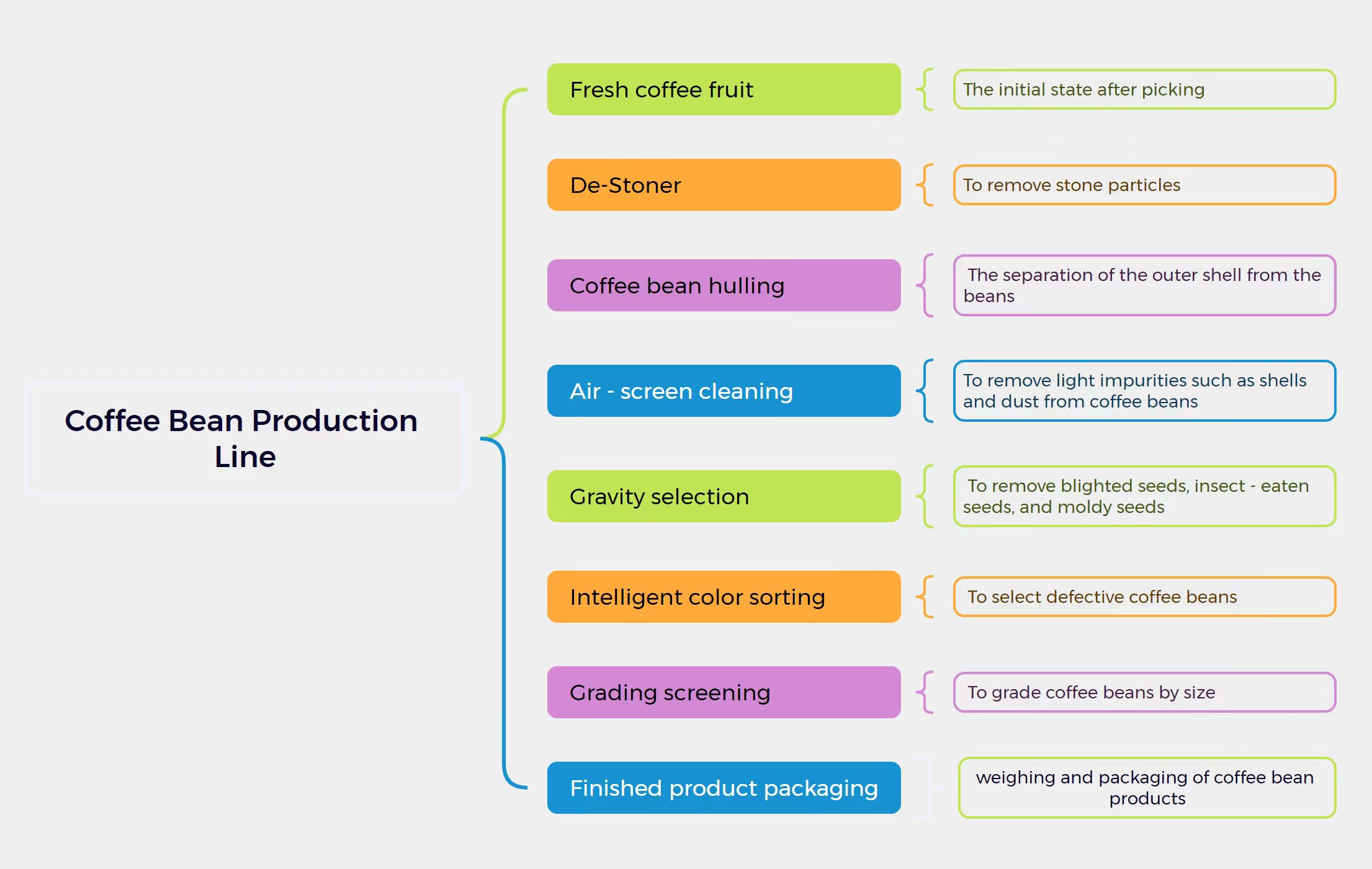

Coffee bean production line cleaning process

Step1-Destoner

The de-stoner is responsible for removing stone particles mixed in the coffee beans. This step ensures the purity of the coffee beans and lays a solid foundation for subsequent processing.

Step 2-Coffee Beans Shelling

The shelling machine mechanically separates the outer shell of the coffee beans from the beans. This process strives to minimize damage to the internal structure of the coffee beans to protect their natural aroma and taste, which is essential to maintaining the quality of the coffee beans and retaining their unique flavor.

Coffee beans before and after shelling

Step 3-Wind screening and grading

Wind screening uses wind power to accurately remove the shells, dust and other light impurities from the coffee beans. This process is based on the power of controlling the airflow to blow away the light impurities in the coffee beans, and then remove the petals and broken particles in the coffee beans through the grading screen, thereby further improving the purity of the coffee beans.

Step 4- Gravity Selection

The working principle of the gravity selection machine is to use the difference in specific gravity between coffee beans and other impurities for screening. In this process, gravity separates impurities with lighter specific gravity such as empty seeds, insect-infested grains, and moldy grains from healthy coffee beans, thereby improving the overall quality of coffee beans.

Step 5- Intelligent Color Sorting

The color sorter uses color recognition to sort out coffee beans with surface defects and imperfections. When coffee beans pass through the channel of the color sorter, the internal camera will judge each coffee bean according to the preset program. Coffee beans that do not meet the requirements will be quickly blown out by gas, ensuring the high quality of the coffee beans.

Step 6-Grading and screening

Grading and screening accurately classifies coffee beans by size through mechanical shaking. In this process, coffee beans of appropriate size will pass through the screen smoothly, while those beans that are too large or too small will be guided to specific channels on both sides of the equipment for separation, ensuring the uniformity and consistency of the final coffee beans.

Step 7- Finished product packaging

Weighing and packaging is the last important step in the coffee bean production process! The packaging scale can provide efficient and accurate weighing and packaging services. For some customers with requirements, the packaging bags can also choose whether to vacuum! The packaging machine can improve production efficiency and reduce the operating costs of the enterprise.

Packaged coffee beans

If you want to build a professional coffee bean production line? Beibu Machinery provides you with professional technical solutions. We not only provide high-quality screening and processing equipment, but also provide a full range of technical support and services to ensure that your production line produces high-quality coffee beans.

Contact number: WhatsApp+8615564532062!

Jul. 25, 2025

Grain cleaning machine in Dubai

Recently, we have just completed a set of grain and sesame cleaning machines installed in Dubai.

Thi

Jan. 20, 2025

Sesame Cleaning Machine Delivery-Hebei Beibu Machinery Technology Co.,LTD

Want to know details of Sesame Cleaning Machine? Leading supplier-Beibu Machinery will share knowledge of sesame cleaning machine.Click the link to get more information.

Jun. 13, 2024

Soybean Cleaning Machine Destoner-Hebei Beibu Machinery Technology Co.,LTD

Want to know details of Soybean Cleaning Machine Destoner?Beibu Machinery will share knowledge of Soybean Cleaning Machine,soybean seed cleaning machine for you.Click the link to get more information.

Dec. 16, 2024

Grain Cleaning Machine Loading-Hebei Beibu Machinery Technology Co.,LTD

WeHebei Beibu Machinery Technology Co.,LTD which is the supplier for the grain and seeds cleani

Jun. 25, 2025

Anise Seed Fennel Seed Cleaning Machine-Hebei Beibu Machinery Technology Co.,LTD

Anise Seed Fennel Seed Cleaning Machine-Hebei Beibu Machinery Technology Co.,LTD

We,Hebei Beibu Mac

Dec. 26, 2024

Merry Christmas!-Hebei Beibu Machinery Technology Co.,LTD

We,Hebei Beibu Machinery Technology Co.,LTD which is the supplier for the grain and seeds cleanin

Beibu Machinery

Not choosing expensive equipment, but the most suitable grain cleaning solution

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

Leave Your Message