Planta de procesamiento de limpieza de frijoles y legumbres

- Hogar

- Productos

- Líneas de procesamiento de limpieza de granos y semillas

- Planta de procesamiento de limpieza de frijoles y legumbres

Pureza: superior al 99,9%

Plazo de entrega: 30 días laborables

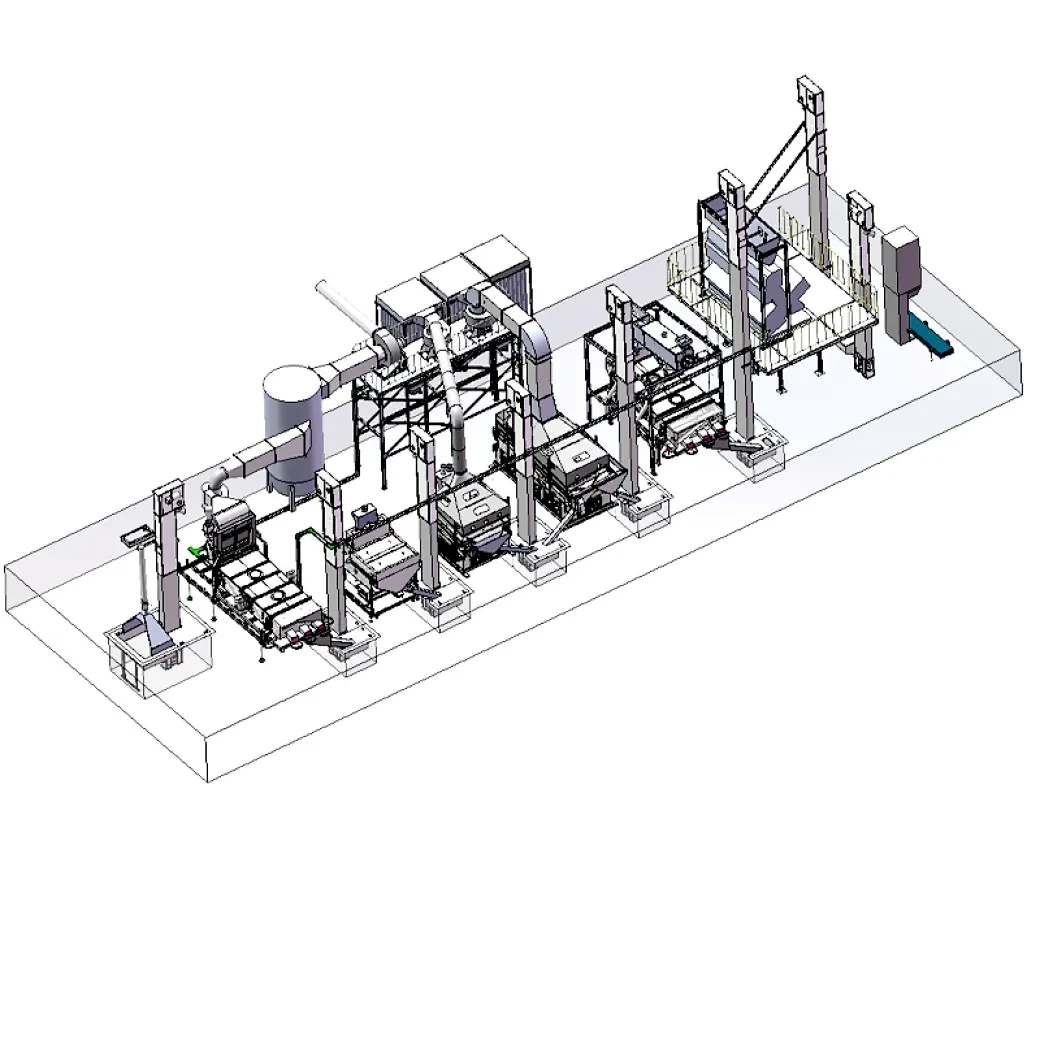

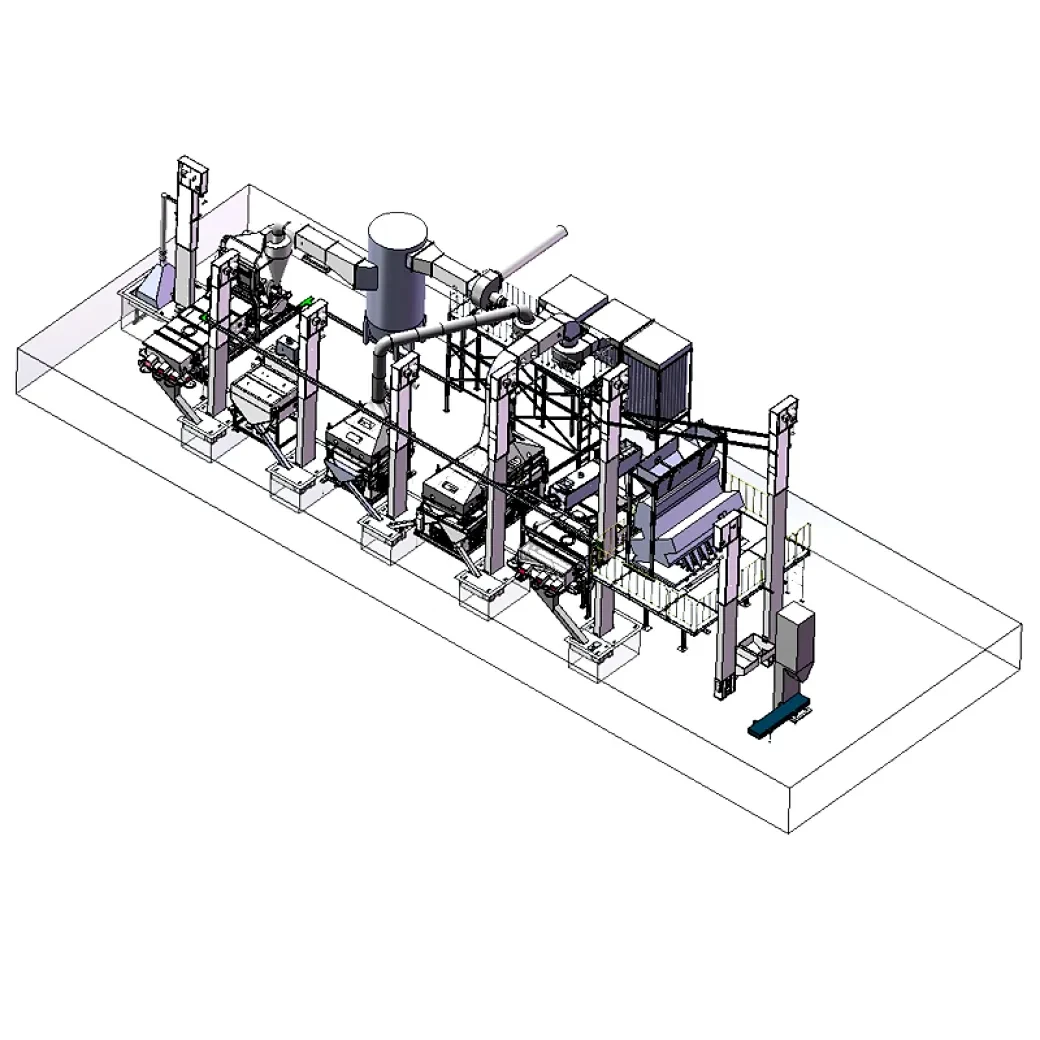

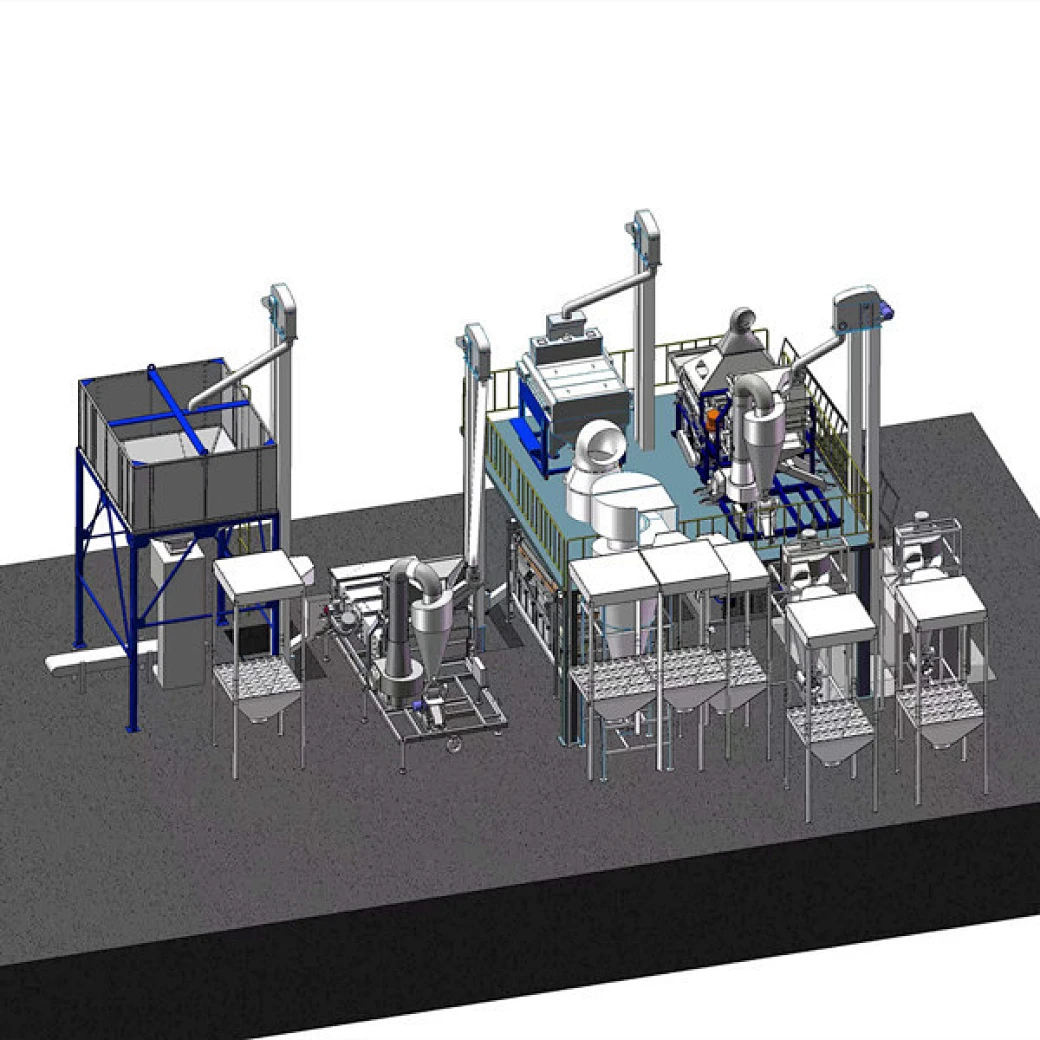

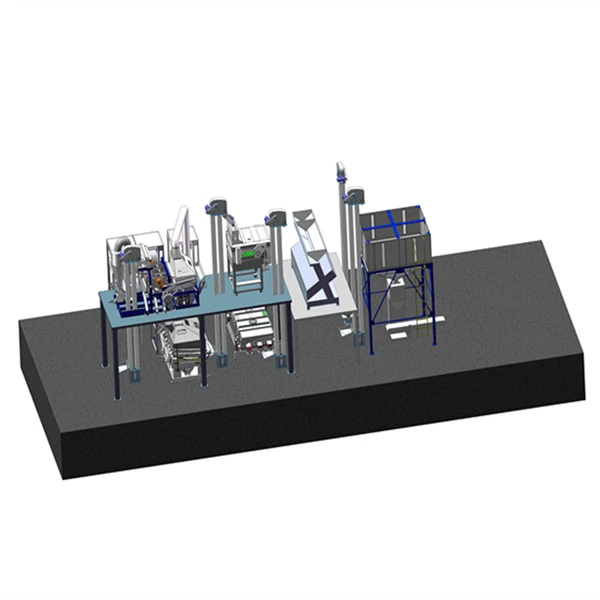

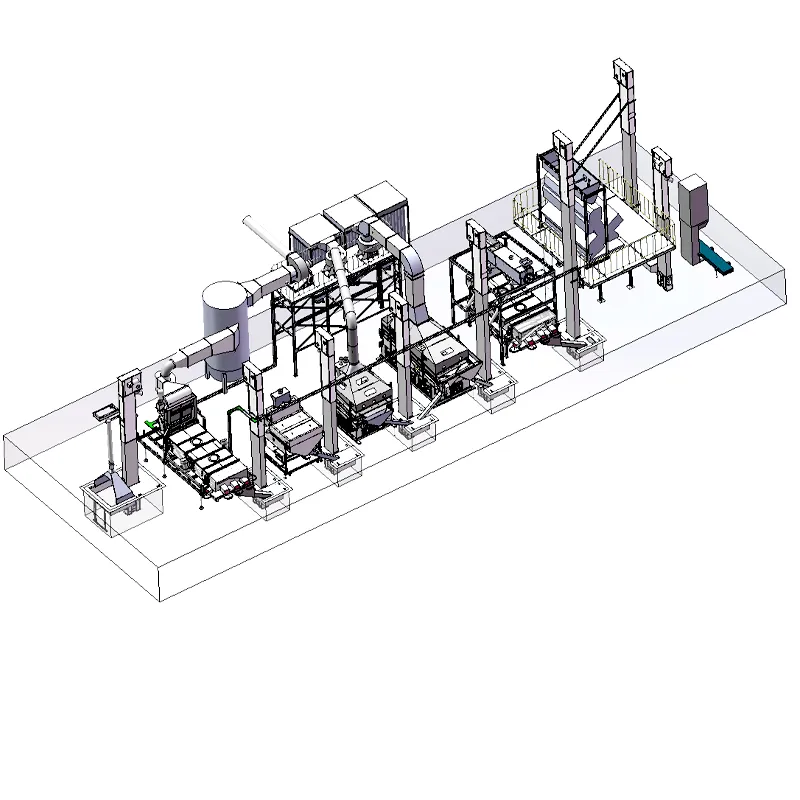

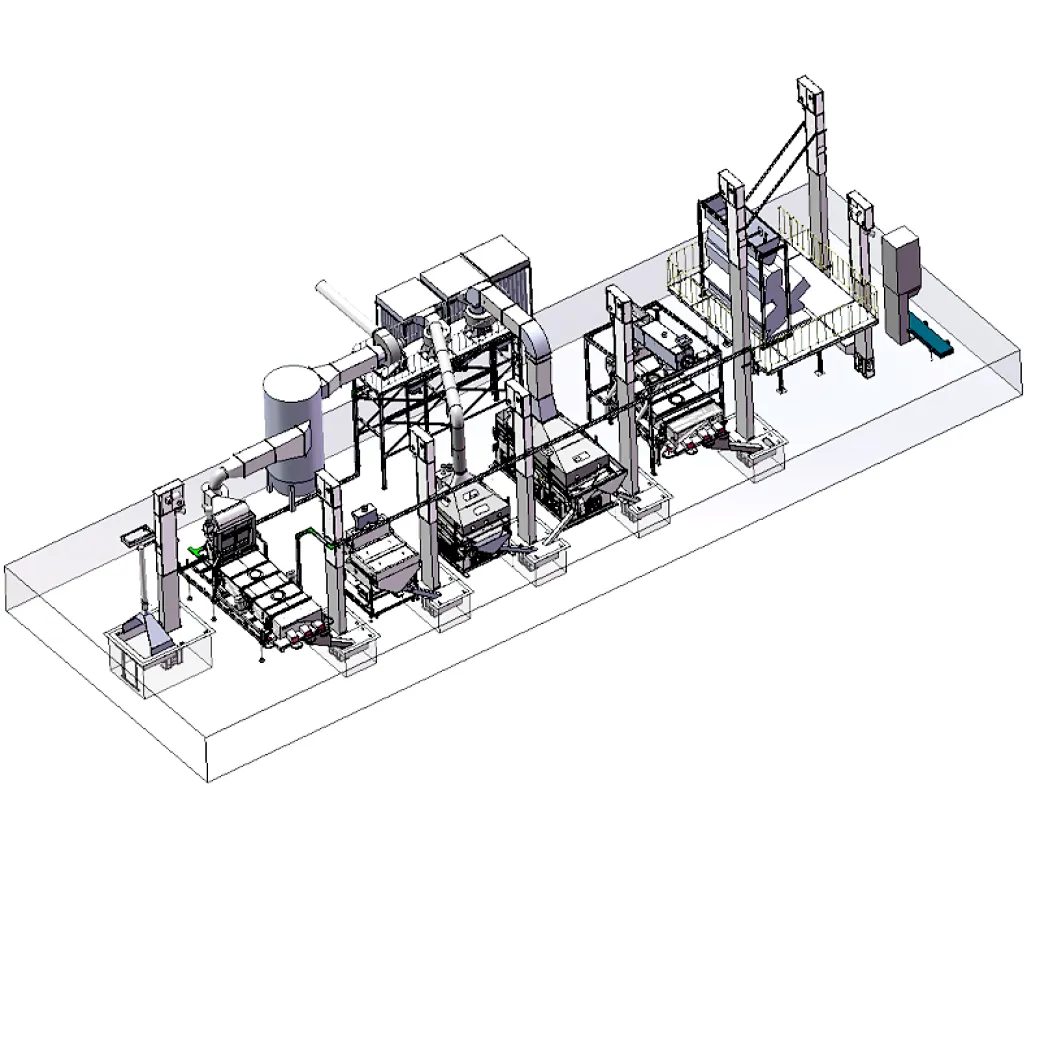

Tras la limpieza de toda la planta, la pureza de los granos y legumbres alcanza el 99,99 %. La línea de procesamiento elimina impurezas como polvo, impurezas ligeras, hojas, cáscaras, impurezas grandes y pequeñas, piedras, arena, semillas en mal estado, etc. El proceso tecnológico es de última generación en China.

The cleaning line for beans and pulses is a relatively common line. Such machines are required in various countries and regions. The following is a set of beans and pulses production line that is more than the standard.

Capacidad: 5t/h - 10t/h (la capacidad se puede personalizar)

La pureza: superior al 99,9%

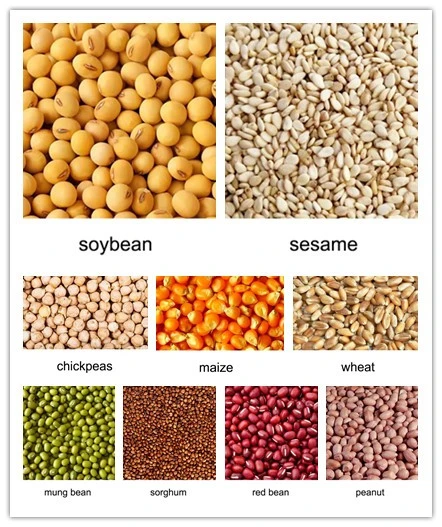

Puede limpiar frijoles mungo, frijoles de soja, frijoles, legumbres y granos de café.

La línea de procesamiento incluye las máquinas que se muestran a continuación.

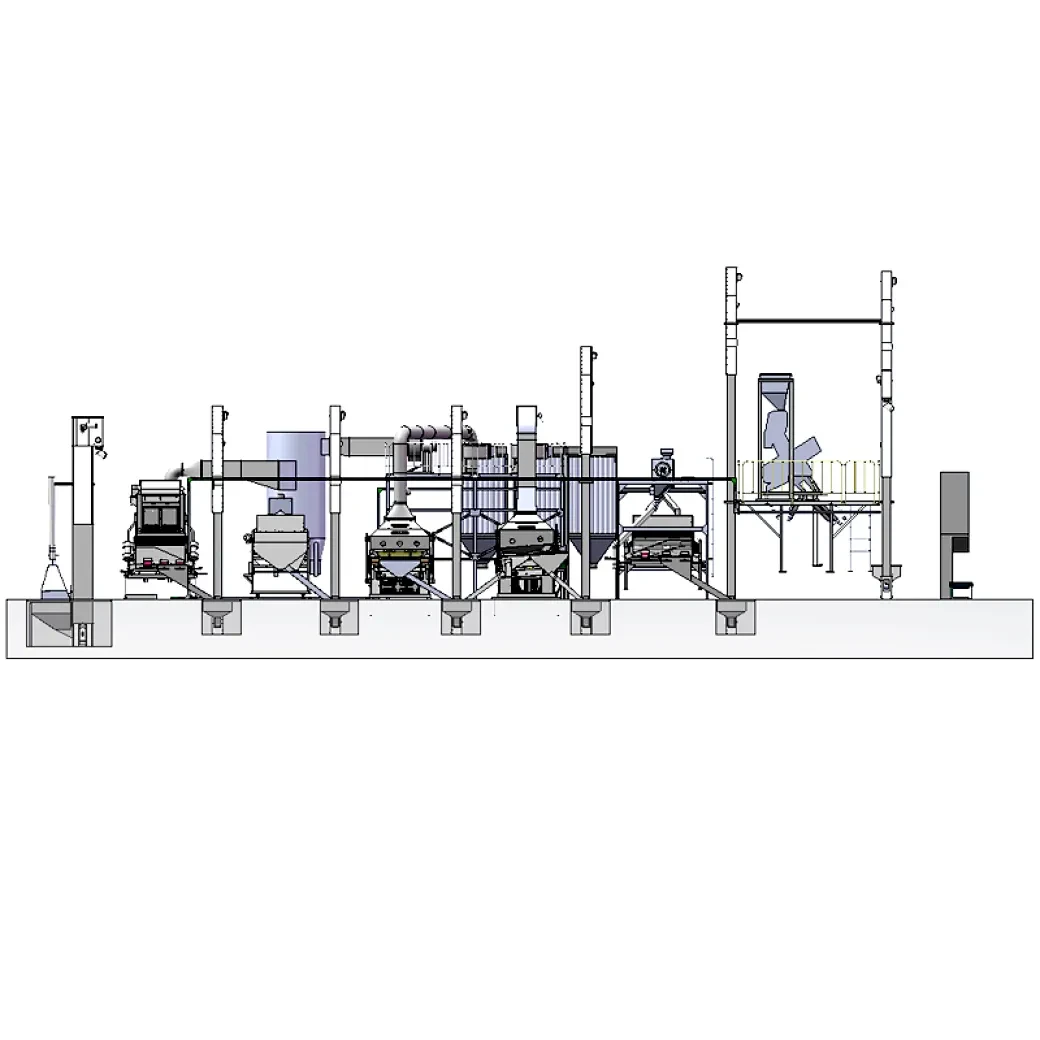

5XFS-10C air screen cleaner ,5CX-5 Magnetic Separator, 5QSC-10 De-stoner, 5XZ-8 gravity separator,5XPG-5 Polishing machine (especially for green mung beans); DTY-10M elevator loading the beans and pulses to the processing machine, Color sorter machine remove the different color beans and Automatic Packing Machine in the final section pack bags for loading containers, Dust collector system for keep warehouse clean.

Including:5XFS-10C Air Screen Cleaner with Gravity Table for removing the dust,light impurities,bigger and smaller impurities than beans;

Separador magnético 5CX-5 para eliminar tierra dura y terrones;

5QSC-10 Despedregadora para eliminar piedras;

Separador de gravedad 5XZ-8 que elimina los palitos pequeños y los granos podridos y mohosos;

Clasificadora vibratoria 5XFJ-10C para clasificar los granos;

Clasificador de colores para eliminar el

Maquina envasadora para envasar sésamo en sacos de 50kg.

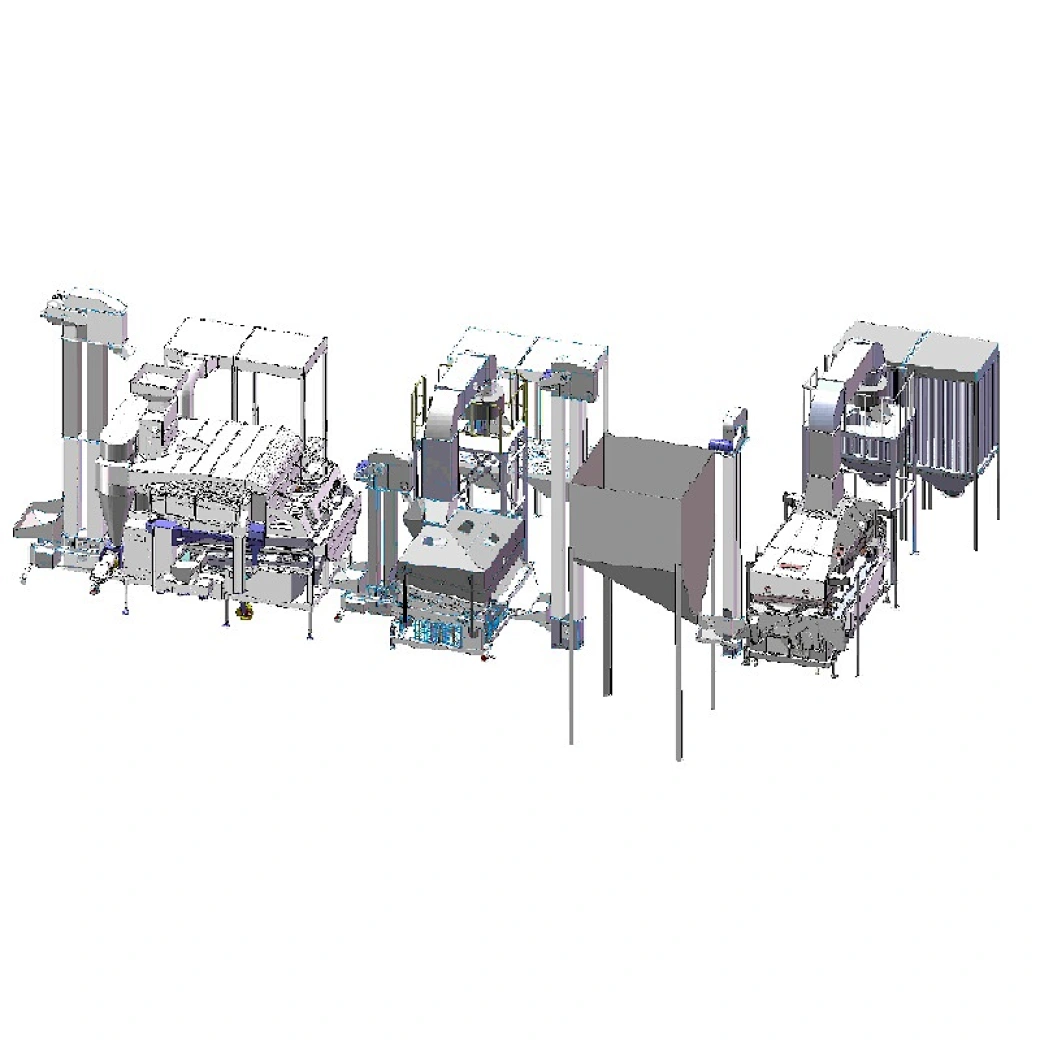

Through these machines, customers can get very clean beans. If it is not enough, some customers will ask for more specific gravity machines and polishing machines. At this time, it is basically the same as the beans sold in supermarkets.

In fact, our machine can not only clean various beans, grains, seeds, etc. It can also clean a lot of herbs, such as cumin, anise, fennel, thyme leaves, hibiscus flower, etc. It can effectively remove impurities and retain the parts that customers want to keep.

If customers have special requirements, they can put them forward to us. In this way, we can make special designs according to customer requirements.

Adhere to quality and pursue excellence. We at BEIBU Machinery Company will uphold the principle of customer first and provide customers with the best quality machines.

-

¿Para qué se utiliza una planta procesadora de limpieza de frijoles y legumbres?

Esta planta está diseñada para limpiar, clasificar y procesar diversos frijoles y legumbres como garbanzos, lentejas, frijoles mungo, frijoles rojos y frijoles gandul, para mejorar la pureza y la calidad antes del envasado o procesamiento posterior. -

¿Qué tecnologías de limpieza están incluidas en la planta?

La planta generalmente incluye limpiadores de aire, separadores por gravedad, despedregadores, separadores magnéticos, clasificadores por vibración y clasificadores por color, que proporcionan una eliminación integral de polvo, piedras, contaminantes metálicos, semillas rotas y granos defectuosos. -

¿Cuál es la capacidad de procesamiento típica de la planta?

Dependiendo de la configuración y la escala, la planta puede procesar de 1 a 20 toneladas por hora, adecuada para operaciones comerciales pequeñas y grandes. -

¿Puede la planta manejar diferentes tipos y tamaños de frijoles y legumbres?

Sí. La planta es ajustable y personalizable, con pantallas intercambiables, flujo de aire ajustable y configuraciones flexibles para adaptarse a una amplia variedad de granos y legumbres con diferentes tamaños y densidades. -

¿Es fácil operar y mantener la planta?

Sí. La planta está diseñada con sistemas de control intuitivos y componentes modulares para facilitar el mantenimiento. Los operadores reciben capacitación para gestionar eficazmente los parámetros de limpieza y solucionar problemas comunes.

7 de noviembre de 2024

Línea de procesamiento de limpieza de sésamo y frijoles - Hebei Beibu Machinery Technology Co.,LTD

24 de enero de 2024

Separador magnético para eliminar tierra dura y terrones

19 de septiembre de 2024

Día de carga de la máquina de limpieza de sésamo - Hebei Beibu Machinery Technology Co.,LTD

9 de mayo de 2024

Llegó la aspiradora Z310 de gran capacidad

Aug. 06, 2025

Discover the Advantages of Color Sorters in Modern Industry

16 de octubre de 2024

Carga de la máquina de limpieza de sésamo - Hebei Beibu Machinery Technology Co.,LTD

Maquinaria Beibu

Si está interesado en nuestros productos, puede optar por dejar su información aquí y nos pondremos en contacto con usted en breve.