Navigating the Modern Grain Cleaning Landscape and Industry Trends

In today's highly competitive agricultural sector, the demand for superior grain quality has never been more pronounced. Contaminants such as dust, chaff, foreign seeds, stones, and light impurities significantly degrade grain value, affecting storage stability, processing efficiency, and end-product quality. This necessitates advanced cleaning solutions that can deliver high purity with optimal efficiency. Emerging industry trends point towards automation, energy efficiency, and precision sorting as key drivers for innovation. Farmers, grain processors, and seed companies are increasingly investing in sophisticated machinery that not only cleans but also categorizes grains based on density and size, ensuring premium yields and maximizing profitability. The integration of smart technologies and robust mechanical design is paramount to meeting these evolving standards.

The drive for sustainable agriculture also influences equipment design, emphasizing reduced energy consumption and minimal waste generation. Furthermore, the global trade of agricultural commodities demands compliance with stringent international quality benchmarks, making highly effective cleaning a prerequisite for market access. Equipment like the air screen cleaner with gravity table stands at the forefront of this technological shift, offering a comprehensive solution for multi-stage separation that addresses both light and heavy impurities with exceptional precision. Its dual functionality provides a distinct advantage over single-purpose machines, contributing to a streamlined and more effective grain processing workflow, thereby upholding the integrity of agricultural products from harvest to market.

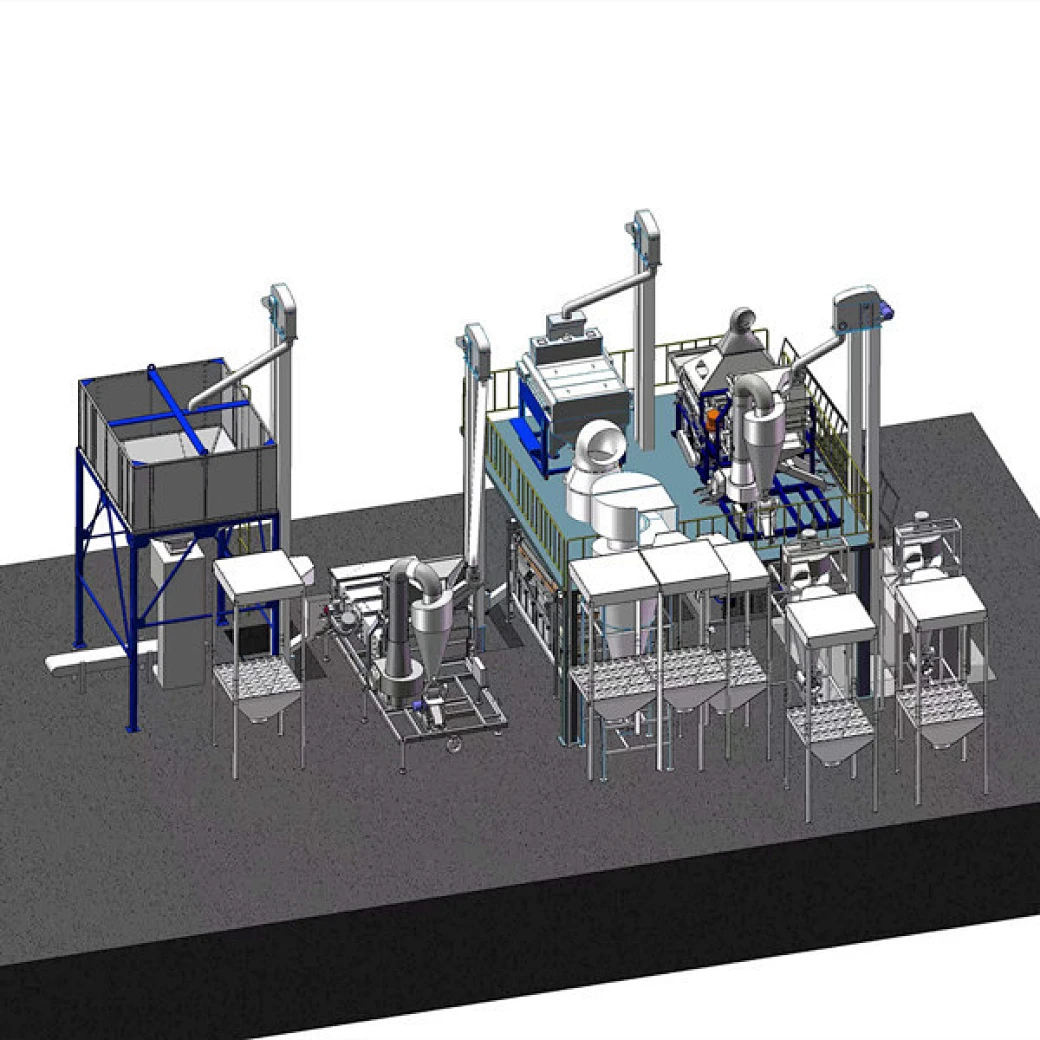

Introducing the 5XFZ-25SC Air Screen Cleaner with Gravity Table: Technical Specifications

The 5XFZ-25SC Air Screen Cleaner with Gravity Table is engineered to deliver unparalleled cleaning performance for a wide array of grain types. This machine seamlessly integrates air aspiration, multi-layer sieving, and gravity separation technologies to ensure a high-purity output. It is particularly adept at handling commodities like wheat, corn, rice, beans, and various seeds, effectively removing light impurities via aspiration, large and small impurities through screening, and separating materials of similar size but differing specific gravities on the gravity table. The robust design and advanced control systems provide operators with precise adjustments, optimizing cleaning efficiency and minimizing grain loss.

Designed for continuous operation in demanding environments, the 5XFZ-25SC incorporates features that ensure longevity and ease of maintenance, contributing to a lower total cost of ownership. Its modular construction allows for straightforward integration into existing processing lines, making it a versatile asset for grain processing facilities of varying scales. The efficiency gains realized through its precise separation capabilities directly translate into higher marketable yields and reduced post-processing requirements, making the 5XFZ-25SC a cornerstone technology for modern grain handling operations that demand superior quality.

Key Technical Parameters: 5XFZ-25SC Air Screen Cleaner with Gravity Table

| Parameter | Specification (Approximate) | Unit/Detail |

|---|---|---|

| Model | 5XFZ-25SC | |

| Capacity (Wheat) | 5-8 | Tons/hour (for primary cleaning) |

| Capacity (Seed Cleaning) | 1-3 | Tons/hour (for fine cleaning) |

| Overall Dimensions (L x W x H) | 3500 x 2000 x 3200 | mm |

| Total Power | 7.5 - 9.0 | kW |

| Weight | ~1800 | kg |

| Screen Layers | 3-5 | Adjustable, depending on application |

| Cleaning Purity | Up to 99% | For target commodity |

| Gravity Table Inclination | Adjustable | For density separation |

Comprehensive Process Flow of the Air Screen Cleaner with Gravity Table

The cleaning process for the 5XFZ-25SC air screen cleaner with gravity table is meticulously designed to ensure maximum purity and efficiency, integrating several stages of separation. Initially, raw grain enters the feeding hopper and is uniformly distributed into the air aspiration system. Here, a controlled airflow removes lighter impurities such as dust, chaff, and undeveloped grains. This preliminary air separation significantly reduces the load on subsequent cleaning stages, enhancing overall machine performance and extending the lifespan of the screening components. The aspiration system's fan speed and damper settings are precisely adjustable to accommodate varying grain types and impurity levels, ensuring optimal removal without unnecessary loss of good grain.

Following aspiration, the grain proceeds to the multi-deck vibrating screen system. These screens are custom-perforated to separate grains by size, effectively removing oversized foreign materials (like straw, large stones) on the top screens and undersized impurities (like sand, small broken grains) through the bottom screens. The oscillation frequency and amplitude of the screens are finely tuned to promote efficient stratification and separation. The sieving system incorporates a self-cleaning mechanism, often involving rubber balls or brushes, to prevent screen clogging and maintain consistent throughput. This mechanical separation is crucial for preparing the grain for the final, more precise density sorting.

The core of the advanced separation lies in the integrated gravity table. Grain that has undergone air aspiration and screening then flows onto the gravity table, which vibrates and has a precisely controlled airflow rising through its perforated deck. This combination creates a fluidized bed, causing lighter impurities (e.g., shriveled kernels, diseased grains, small stones, or soil clods with similar sizes to good grains but different densities) to float above the heavier, good grains. The table's adjustable inclination and vibration frequency further aid in stratifying the material, allowing the denser, pure grain to discharge at one end, while the lighter impurities are discharged separately. This highly effective density-based separation is critical for achieving the highest purity standards required for seed processing and premium food-grade commodities.

Manufacturing Process & Quality Assurance

The manufacturing of the 5XFZ-25SC air screen cleaner with gravity table adheres to stringent quality control protocols, leveraging high-grade materials and advanced fabrication techniques. Key components, such as the machine frame, air ducts, and screen frames, are typically constructed from robust carbon steel or stainless steel, chosen for their durability and resistance to wear and corrosion. Manufacturing processes include precision laser cutting for complex shapes, advanced welding techniques to ensure structural integrity, and CNC machining for critical components like shafts and bearings, guaranteeing tight tolerances and smooth operation. Surface treatments, such as powder coating or anti-corrosion painting, are applied to extend the machine's lifespan and protect it from environmental degradation.

All manufacturing stages are subject to rigorous inspection and testing. Raw materials undergo strict material composition verification. During assembly, dimensional accuracy and component alignment are checked against engineering specifications. The final product is subjected to comprehensive performance testing, including vibration analysis, noise level measurement, and extended operational trials with various grain types to validate cleaning efficiency and capacity. Compliance with international standards such as ISO 9001 for quality management and relevant industry safety standards (e.g., ANSI B11.0 for machinery safety) is ensured, providing customers with reliable and safe equipment. The expected service life of such a robust machine, with proper maintenance, typically exceeds 10-15 years, offering a strong return on investment for agricultural enterprises.

Technical Advantages and Application Scenarios

The 5XFZ-25SC air screen cleaner with gravity table offers a multitude of technical advantages that set it apart in the grain cleaning industry. Its primary strength lies in its multi-stage cleaning capability, combining air separation, precise screening, and highly effective density separation on the gravity table. This comprehensive approach ensures the removal of a wider range of impurities—from light dust and chaff to oversized debris and even structurally compromised grains (e.g., shriveled or insect-damaged kernels) that are otherwise difficult to separate by size alone. The precision of the gravity table allows for the distinction of impurities with specific gravities very close to that of the good grain, a task impossible for traditional cleaners.

Another significant advantage is its energy efficiency. Optimized fan designs and efficient motor systems reduce power consumption per ton of processed grain, contributing to lower operational costs and a more sustainable footprint. The enclosed design of the cleaning chambers minimizes dust escape, improving workplace air quality and complying with environmental regulations. Furthermore, the machine's modular construction facilitates easy maintenance and quick changeovers for different grain types, maximizing uptime and operational flexibility. Its robust build quality ensures long-term reliability even under continuous heavy-duty operation, embodying a strong commitment to durability and performance.

Versatile Application Across Agricultural Sectors

- Seed Processing Plants: Essential for producing high-germination, high-purity seeds for planting. The precise separation capability ensures that only viable and healthy seeds are selected, critical for agricultural productivity. It effectively removes underdeveloped seeds, weed seeds, and broken kernels.

- Grain Storage Facilities: Used for pre-cleaning incoming grains to reduce moisture and foreign matter, thereby preventing spoilage during storage and improving overall grain quality before long-term preservation. This reduces aeration costs and risk of mold or insect infestations.

- Flour Mills and Food Processing: Provides a critical step in purifying raw grains before milling or further processing, ensuring the final food product meets stringent safety and quality standards. For example, in an automatic wheat cleaning machine setup, it removes stones and heavy foreign material that can damage milling equipment.

- Brewing and Malting Industries: Delivers clean, uniform grains vital for consistent fermentation and high-quality end products, such as beer or malt.

- Feed Mills: Although purity standards might be slightly lower than for food-grade grains, efficient cleaning ensures better feed digestibility and prevents issues caused by contaminants in animal diets. For example, with bean cleaning equipment, it ensures high-quality soy for animal feed.

- Specialty Crop Processing: Adaptable for cleaning various specialty crops like herbs, spices, and pulses, where precise separation of specific impurities is paramount.

In summary, the 5XFZ-25SC's robust design and multi-functional cleaning capabilities make it an indispensable asset across the entire grain value chain, significantly enhancing product quality, operational efficiency, and profitability for diverse agricultural and food processing applications. Its versatility is further showcased when it functions as a primary cleaning wheat machine for large scale operations, ensuring consistent output quality.

Manufacturer Comparison and Tailored Solutions

When evaluating suppliers for an air screen cleaner with gravity table, discerning buyers prioritize several key aspects beyond just the initial purchase price. Leading manufacturers distinguish themselves through a combination of engineering excellence, proven reliability, comprehensive after-sales support, and the ability to offer customized solutions. While many companies offer grain cleaning equipment, the nuanced differences in material quality, precision of manufacturing, control system sophistication, and user-friendly design can significantly impact long-term operational costs and cleaning efficacy. Reputable manufacturers invest heavily in R&D to continuously improve separation accuracy and energy efficiency, offering innovations that translate directly into tangible benefits for the end-user.

A key differentiator for a top-tier provider is their commitment to robust construction using high-strength alloys and corrosion-resistant finishes, ensuring the machine withstands the rigors of continuous industrial use. Furthermore, the integration of intelligent control systems that allow for precise adjustments of airflow, screen vibration, and gravity table inclination is crucial for optimizing performance across various grain types and impurity levels. Unlike some generic machines, a premium air screen cleaner with gravity table is designed for high accessibility for cleaning and maintenance, reducing downtime and operational complexity. This meticulous attention to detail from the manufacturer results in a superior product with a longer operational lifespan and consistent high-quality output.

Customized Cleaning Solutions

Understanding that every grain processing operation has unique requirements, leading manufacturers specialize in providing bespoke cleaning solutions. This involves a thorough consultation process to assess the specific grain types, desired purity levels, capacity requirements, and existing infrastructure. Based on this analysis, the 5XFZ-25SC air screen cleaner with gravity table can be integrated into a larger, tailor-made cleaning line, potentially including pre-cleaners, destoners, indented cylinder separators, color sorters, and bagging systems. For instance, a seed processing facility might require higher precision in gravity separation and specialized screen perforations, while a bulk grain storage facility might prioritize higher throughput for initial cleaning.

Customization extends to specific machine configurations, such as power supply compatibility, dust collection systems, and automation levels, including PLC integration for remote monitoring and control. Manufacturers who excel in this area offer not just a product, but a complete engineering service, ensuring seamless installation, commissioning, and staff training. This consultative approach guarantees that the invested capital yields maximum operational efficiency and meets the exact purity specifications required by the client's market, reflecting a true partnership beyond a transactional sale. The ability to customize ensures the machine functions optimally whether it's part of an automatic wheat cleaning machine line or dedicated bean cleaning equipment.

Application Cases and Customer Experience

The effectiveness of the 5XFZ-25SC air screen cleaner with gravity table is best illustrated through its successful deployment in real-world agricultural and food processing environments. For instance, a large-scale wheat processing plant in North America reported a significant reduction in foreign material content from 2.5% to less than 0.1% after integrating the 5XFZ-25SC into their cleaning line. This dramatic improvement not only enhanced the quality of their flour but also extended the lifespan of their milling machinery by preventing damage from stones and metal fragments. The plant commended the machine's robust construction and the ease of adjusting parameters for different wheat varieties.

In another instance, a leading seed company specializing in soybean production in South America utilized the 5XFZ-25SC as their primary bean cleaning equipment. They observed a remarkable increase in germination rates and seed viability due to the machine's ability to precisely remove shriveled, immature, and broken seeds, along with common weed seeds, which traditional screen cleaners struggled with. The company highlighted the machine's consistent performance and low maintenance requirements, attributing a direct correlation between the cleaner's efficiency and their enhanced seed export volumes and market reputation for quality. These cases underscore the practical benefits and tangible ROI delivered by this advanced cleaning solution.

Trustworthiness: FAQs, Warranty, and Support

Frequently Asked Questions (FAQs)

- Q: What types of grains can the 5XFZ-25SC clean?

A: It is highly versatile and can effectively clean wheat, corn, rice, soybeans, various beans, sorghum, sunflower seeds, and most other granular crops. The adjustable screens and gravity table settings allow for optimization across different commodities. - Q: What is the typical installation time?

A: For experienced teams, basic installation can take 1-2 days. However, full commissioning and integration into an existing line, including calibration, typically require 3-5 days. Comprehensive manuals and technical support are provided. - Q: How does the machine handle dust?

A: The 5XFZ-25SC is designed with an integrated or optional external high-efficiency dust collection system to manage airborne particles, ensuring a cleaner working environment and adherence to dust emission standards. - Q: What maintenance is required?

A: Routine maintenance includes checking and cleaning screens, lubricating bearings, inspecting belts, and general cleaning. Detailed maintenance schedules are provided in the operation manual.

Delivery Cycle and Quality Assurance

Our standard delivery cycle for the 5XFZ-25SC air screen cleaner with gravity table typically ranges from 4 to 8 weeks from order confirmation, depending on customization requirements and current production schedules. We maintain transparency throughout the manufacturing and logistics process, providing regular updates. Each machine undergoes rigorous pre-shipment quality checks and performance tests to ensure it meets our exacting standards and client specifications. Our commitment to quality is underpinned by ISO 9001 certification, reflecting our dedication to consistent product excellence and customer satisfaction.

Warranty and Customer Support

We offer a comprehensive 12-month warranty on the 5XFZ-25SC air screen cleaner with gravity table, covering defects in materials and workmanship from the date of commissioning or 18 months from shipment, whichever comes first. Our commitment extends beyond the sale with robust customer support. This includes remote technical assistance via phone or video conference, readily available spare parts, and the option for on-site technical support and training by experienced engineers. Our goal is to ensure your investment operates at peak efficiency throughout its lifespan, providing long-term value and reliability.

Conclusion

The 5XFZ-25SC air screen cleaner with gravity table represents a pinnacle in grain and seed cleaning technology, combining robust engineering with sophisticated multi-stage separation capabilities. Its ability to meticulously remove light, oversized, undersized, and density-based impurities ensures the highest purity levels, crucial for maximizing product value and operational efficiency across various agricultural and food processing industries. From enhancing seed germination rates to safeguarding milling machinery and improving final product quality, this machine delivers tangible benefits that translate into significant economic advantages for producers. Investing in such advanced cleaning equipment is not merely a purchase, but a strategic decision that fortifies a business's competitive edge in the global market, ensuring consistent quality and sustainability for years to come.

References

- Smith, J. D. (2022). "Advances in Grain Cleaning Technologies for Enhanced Food Safety." Journal of Agricultural Engineering and Technology, 15(2), 112-128.

- Lee, H. K., & Park, S. Y. (2021). "Impact of Gravity Separator Parameters on Seed Purity and Viability." Cereal Science and Technology Review, 8(4), 201-215.

- Wang, L., & Chen, G. (2023). "Optimization of Air Screen Cleaning Systems for High-Capacity Grain Processing." International Journal of Crop Post-Harvest Technology, 10(1), 45-60.

- Food and Agriculture Organization of the United Nations (FAO). (2020). Guidelines for Grain Storage and Quality Management. FAO Agricultural Services Bulletin, No. 182.

Apr. 07, 2024

Sesame Cleaning Machine-Beibu Machinery Technology Co.,LTD

May. 20, 2024

Grain Bag Packing Machine-Hebei Beibu Machinery Technology Co.,LTD

Jan. 24, 2024

Hand Sewing Machine For Grain PP Bag Sealing

Jan. 07, 2025

Welcome Client's Visit-Hebei Beibu Machinery Technology Co.,LTD

Apr. 23, 2024

Mar. 27, 2024

Popular Sesame Cleaning Machine Double Air Screen Cleaner-Hebei Beibu Machinery Technology CO.,LTD

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.