- Introduction: Understanding the Importance of a Destoner for Rice

- Why Stone Removal is Crucial in the Rice Milling Process

- Technical Innovations in Rice Destoner Machines

- Comparative Analysis: Leading Rice Destoner Brands & Manufacturers

- Pricing Breakdown: What Influences Rice Destoner Price and Machine Selection?

- Tailored Destoner Solutions for Different Rice Milling Needs

- Case Studies: Real-World Impact of Investing in a Modern Destoner for Rice

(destoner for rice)

Introduction: The Evolving Role of a Destoner for Rice Production

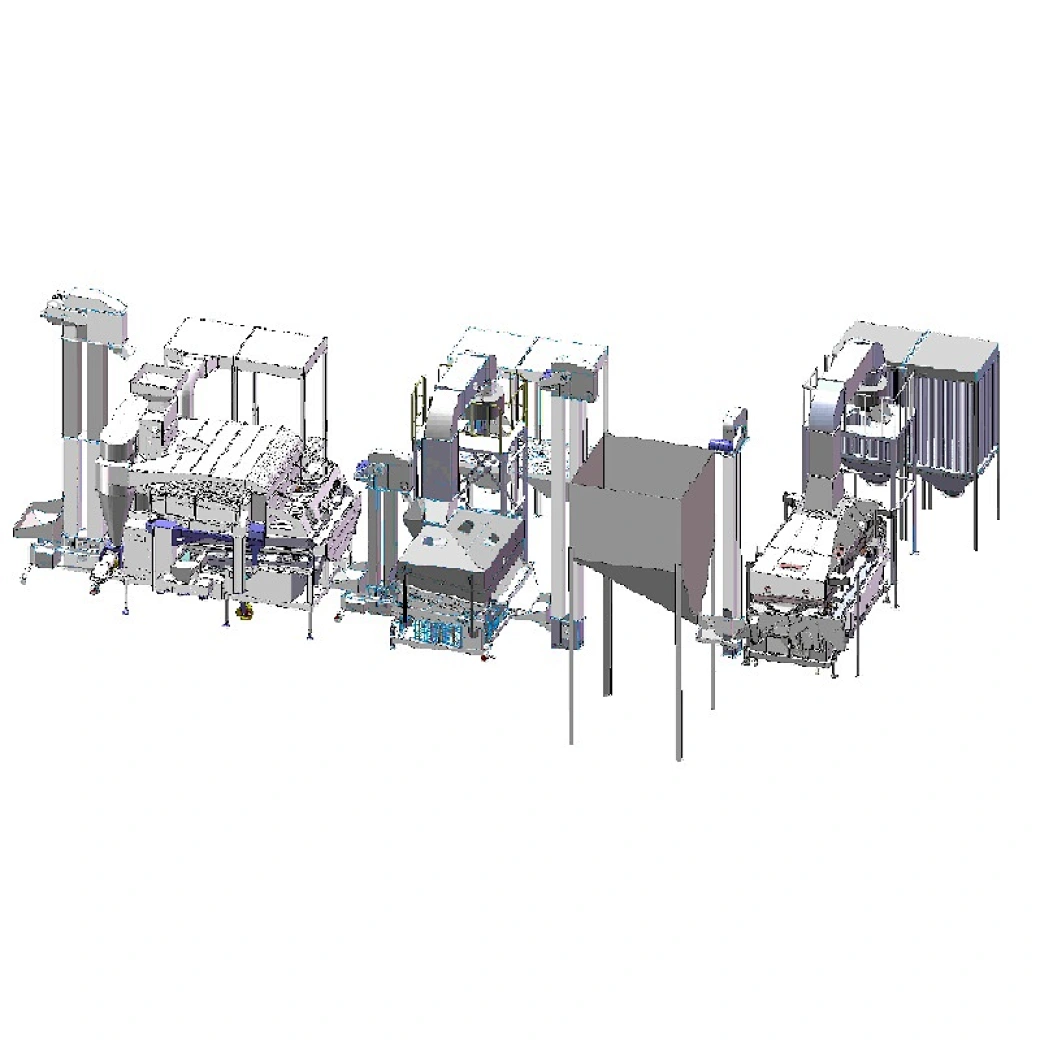

Modern rice processing demands the highest levels of purity and efficiency. At the core of this process is the destoner for rice

, a vital machine designed to remove stones and heavy impurities from raw paddy and milled rice. Its significance in the global rice industry is underscored by rising standards for food safety, consumer expectations, and strict export regulations. According to a recent report by the International Rice Research Institute, post-harvest loss due to stone contamination can reach up to 2–5% of total rice yield annually, contributing directly to financial setbacks for millers and exporters. The growing demand for reliable, automated rice cleaning has made destoners an essential investment for both small-scale and industrial rice mills worldwide.

Why Stone Removal is Crucial in the Rice Milling Process

Removing inorganic materials like stones, mud balls, and metal fragments is not just about improving rice appearance—it's a matter of food safety and operational efficiency. Foreign objects in rice can severely damage downstream milling machines and have led to frequent shutdowns and increased maintenance costs. Furthermore, contaminated rice can result in recalls and trade rejections, with estimates showing that markets like the EU and US have zero-tolerance policies for physical impurities. A comprehensive study of rice contaminants revealed that rice lots with more than 0.01% stone content are automatically disqualified in several importing countries. Integrating a rice destoner, therefore, is crucial for compliance, brand reputation, and operational productivity.

Technical Innovations in Rice Destoner Machines

The technological landscape of rice mill destoner machines has evolved significantly over the last decade. Modern models leverage advanced separation techniques—utilizing vibration, pneumatic suction, and stratification by density to maximize removal efficiency. Newer electronic sensors provide unparalleled accuracy, allowing destoners to identify and segregate even smaller impurities. For example, the latest generation of double-layer vibration destoners achieves a remarkable impurity removal efficiency of up to 99.7%. Other advancements include real-time dust control systems, automatic feed adjustment, and energy-saving motors. This integration of smart controls reduces operator intervention and ensures consistent output quality, setting new industry standards in food processing machinery.

Comparative Analysis: Leading Rice Destoner Brands & Manufacturers

Selecting a rice mill destoner involves more than just choosing a piece of equipment; it necessitates consideration of reliability, lifespan, after-sales service, and integration with existing milling lines. The table below illustrates the technical specifications and unique selling points of leading rice destoner manufacturers.

| Manufacturer/Model | Capacity (T/H) | Stone Removal Efficiency (%) | Energy Consumption (kW) | Automatic Controls | Warranty (Years) |

|---|---|---|---|---|---|

| Satake FDS200M | 5.0 | 99.7 | 1.6 | Yes | 2 |

| Buhler DRGA | 6.5 | 98.9 | 2.1 | Yes | 3 |

| Milltec DSR15 | 4.2 | 99.2 | 1.4 | Optional | 1 |

| Yongxiang QSX100 | 3.0 | 98.2 | 1.2 | No | 2 |

Differences among brands extend to localized service support, ease of integration, and customization options. Global brands often offer integrated solutions with digital monitoring, while regional manufacturers may deliver more cost-effective and maintainable units.

Pricing Breakdown: What Influences Rice Destoner Price and Machine Selection?

The rice destoner price can range from under $3,500 for basic, manually operated units to over $25,000 for automated, high-throughput industrial models. Key factors affecting pricing include throughput capacity, degree of automation, build materials (stainless steel vs. carbon steel), energy efficiency, after-sales warranty, and compatibility with digital monitoring systems. As per recent market data from Global Rice Tech Expo, approximately 40% of buyers opt for mid-range machines ($7,000–$12,000) that balance quality, efficiency, and operational cost. It's also observed that the choice often depends on the size of mill operation, available budget, and specific rice varieties handled—since sticky or aromatic varieties may require special handling or machine settings.

Tailored Destoner Solutions for Different Rice Milling Needs

Not all rice mills face the same operational challenges. Small community mills may prioritize affordability and simplicity, while commercial-scale processors seek automation, throughput, and integration with digital control networks. Customizing a rice destoner machine solution starts with an assessment of daily milling volumes, rice grain characteristics, and existing line configurations. Advanced suppliers now offer modular designs, allowing mills to upgrade capacity or integrate extra impurity detection modules as they expand. For example, modular dust extraction kits can be retrofitted into units less than five years old, significantly improving working conditions and compliance with local pollution standards. Additionally, some suppliers have introduced remote diagnostics and online technical support, minimizing downtime and maximizing the return on investment for millers worldwide.

Case Studies: The Business Impact of Modern Destoner for Rice Integration

Real-world applications of destoner innovation reveal the technology's profound impact across diverse rice processing environments. A major Southeast Asian rice exporter implemented a full-automation upgrade, incorporating a new destoner for rice supported by IoT analytics; within six months, they reported a 3.8% increase in milling yield and a 28% reduction in machinery downtime due to fewer contaminant-induced damages. For a medium-scale West African processor, switching to an energy-efficient destoner led to annual power savings of $2,400 and streamlined export approval for new markets, thanks to sub-0.01% impurity rates. Other documented case studies show that community rice mills adopting semi-automatic destoners reduced manual labor requirements by up to 50% and doubled their output capacity within the first operational year. These results underscore the significance of the right destoner solution in enhancing profitability, food safety, and global competitiveness.

(destoner for rice)

FAQS on destoner for rice

Q: What is a destoner for rice and how does it work?

A: A destoner for rice is a machine used to separate stones and heavy impurities from rice grains using differences in density. It ensures the rice is clean and safe for consumption. The process enhances rice quality before further processing or packaging.Q: How much does a rice destoner machine cost?

A: The rice destoner machine price can range from $500 to $5,000 depending on capacity, brand, and features. Prices may vary by supplier and region. It's best to compare specifications and reviews before purchasing.Q: Why is a rice mill destoner important in rice production?

A: A rice mill destoner removes stones and foreign materials, protecting downstream equipment from damage. It also improves the quality and safety of the final rice product. This is essential for efficient and reliable rice milling operations.Q: How do I choose the right rice destoner for my needs?

A: Consider factors like capacity, required throughput, power usage, and destoning efficiency. Check the rice destoner price and warranty options from different suppliers. Matching machine specifications to your operation ensures optimal results.Q: Are there maintenance requirements for rice destoner machines?

A: Yes, regular cleaning and periodic part checks are necessary to maintain performance. Following the manufacturer’s maintenance schedule reduces downtime and extends the lifespan of the destoner. Always use genuine spare parts for the best results.Mar. 25, 2024

Multi Types Grain Cleaning Machine-Hebei Beibu Machinery Technology Co.,LTD

Jun. 30, 2025

Unlocking Grain Purity: The Essential Destoner Machine

Feb. 05, 2025

The new year for grains cleaning machine has begun

Jun. 30, 2025

Explore the Benefits of Magnetic Separator Technology

Dec. 16, 2024

Grain Cleaning Machine Loading-Hebei Beibu Machinery Technology Co.,LTD

Oct. 21, 2024

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.