How the Destoner working for Grain and Seeds to remove Stones?-Hebei Beibu Machinery Technology Co.,LTD

Working principle of grain and bean de-stoner

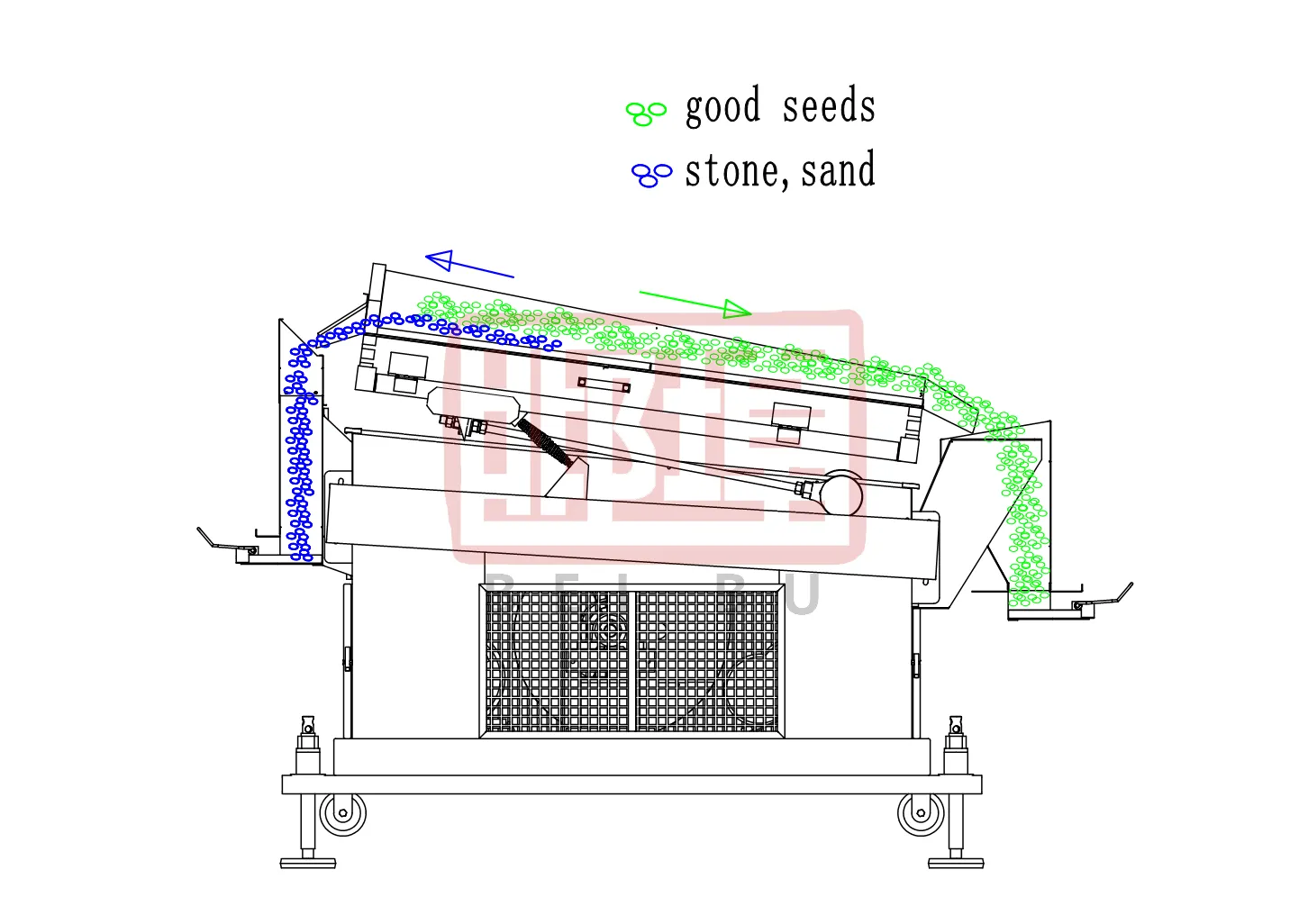

Grain and bean de-stoner is a special equipment that utilizes the differences in density and suspension speed between materials and impurities, and effectively removes stones, mud and other heavy impurities in grains (such as wheat, rice, corn) and beans (such as soybeans and mung beans) through the combination of vibration screening and airflow. Its core working principle can be divided into the following parts:

1. Material feeding and preliminary screening

The grain or beans to be cleaned enter the vibrating screen plate (stone removal screen surface) of the de-stoner evenly through the feeding device. The screen plate is usually arranged at an angle and has fish scale holes or raised structures of a specific shape to promote the flow and stratification of materials.

2. Vibration and stratification

The screen plate reciprocates under the action of the vibration mechanism driven by the motor, causing the material to continuously jump on the screen surface and move to the higher end. Since the density of heavy impurities such as stones and metals is much greater than that of grain particles, during the vibration process, the heavy impurities gradually settle to the bottom of the screen plate, while the lighter grain floats on the upper layer, forming automatic stratification.

3. Airflow suspension and separation

The built-in fan of the equipment generates a stable upward airflow, which passes through the holes of the sieve plate, making the grain particles "semi-suspended", further promoting the separation of light and heavy materials. The lighter grain flows to the lower end of the sieve plate under the action of the airflow, while the high-density impurities such as stones continue to move upward along the sieve plate due to their large inertia and are not easily driven by the airflow.

4. Impurity discharge and clean grain collection

Heavy impurities (stones, metals, etc.) are finally discharged from the high end of the sieve plate, and the cleaned grain flows out from the low end to complete the stone removal process. Some equipment is also equipped with secondary air separation or adjustment devices to optimize the separation effect and ensure the stone removal efficiency.

5. Key adjustment parameters

Vibration frequency and amplitude: affect the movement speed of the material on the sieve plate and the stratification effect.

Airflow speed: needs to be adjusted according to the type of grain to ensure that the grain is moderately suspended and not blown away.

Sieve plate inclination: determines the material flow speed and impurity discharge direction.

The equipment has a simple structure and high efficiency. It is widely used in grain processing, seed processing and bean selection industries. It can significantly improve the quality of finished products and reduce the wear of subsequent processing equipment.

Please contact us by whatapp:+86 15075173862 for more information.