- Locust Beans Processing: Industry Overview & Market Trends

- Technical Parameters: Comparing locust beans processing machine & Beans Cleaning Machine

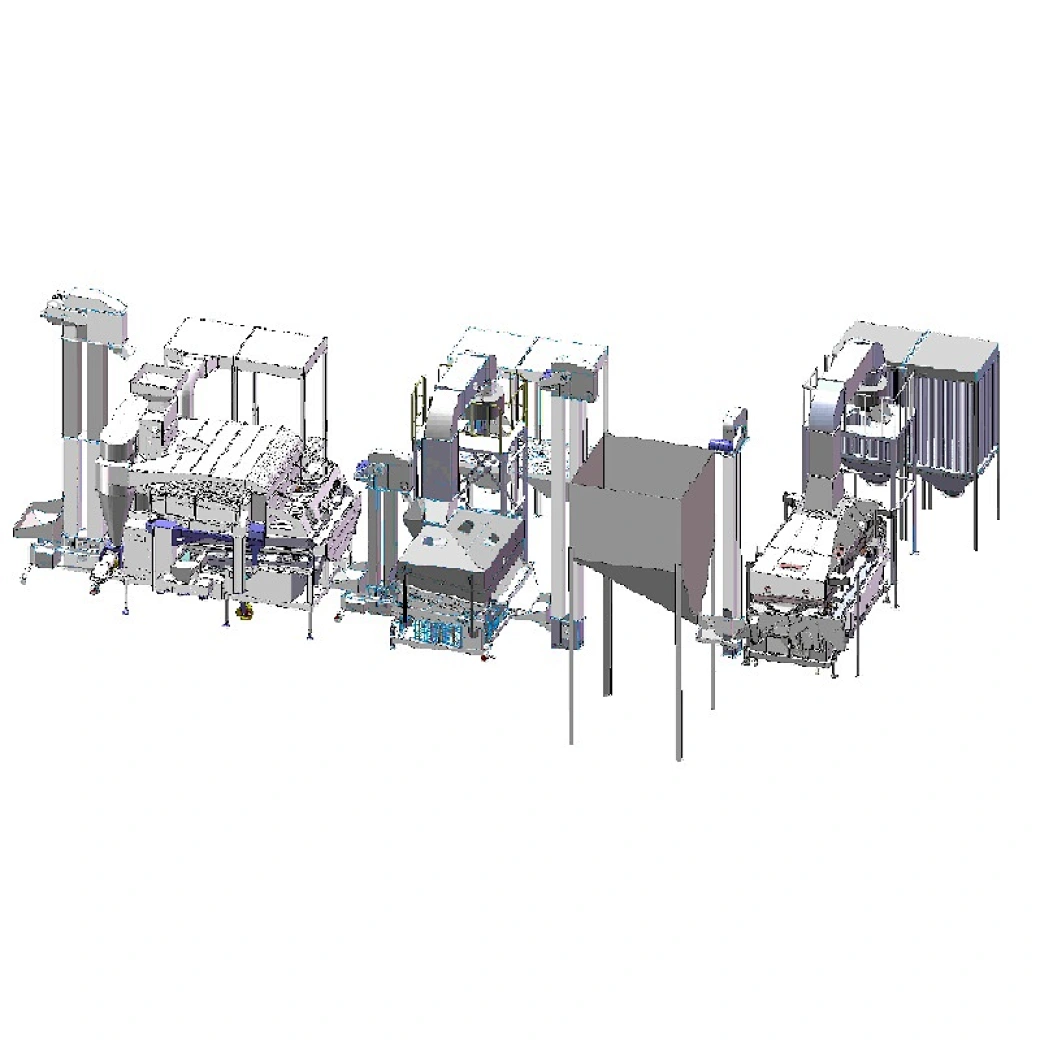

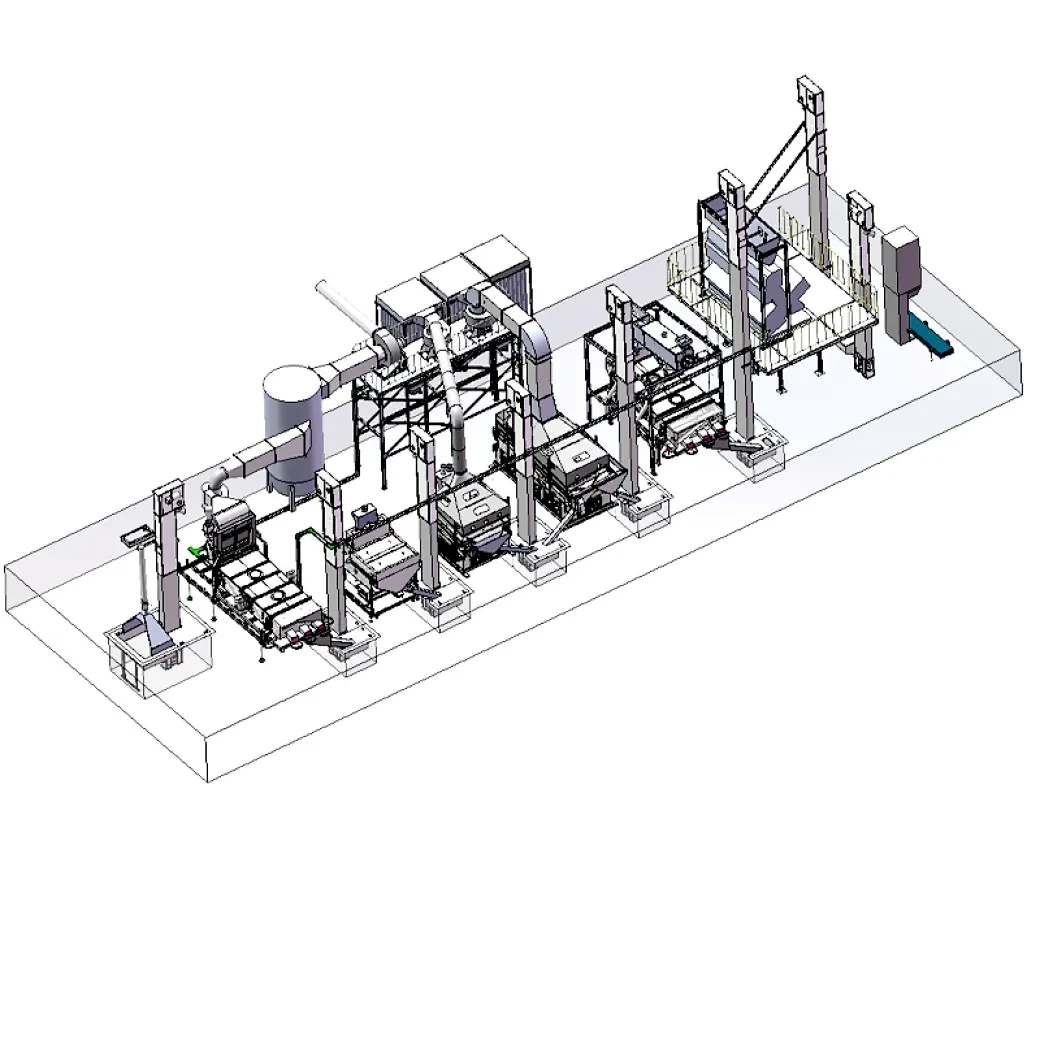

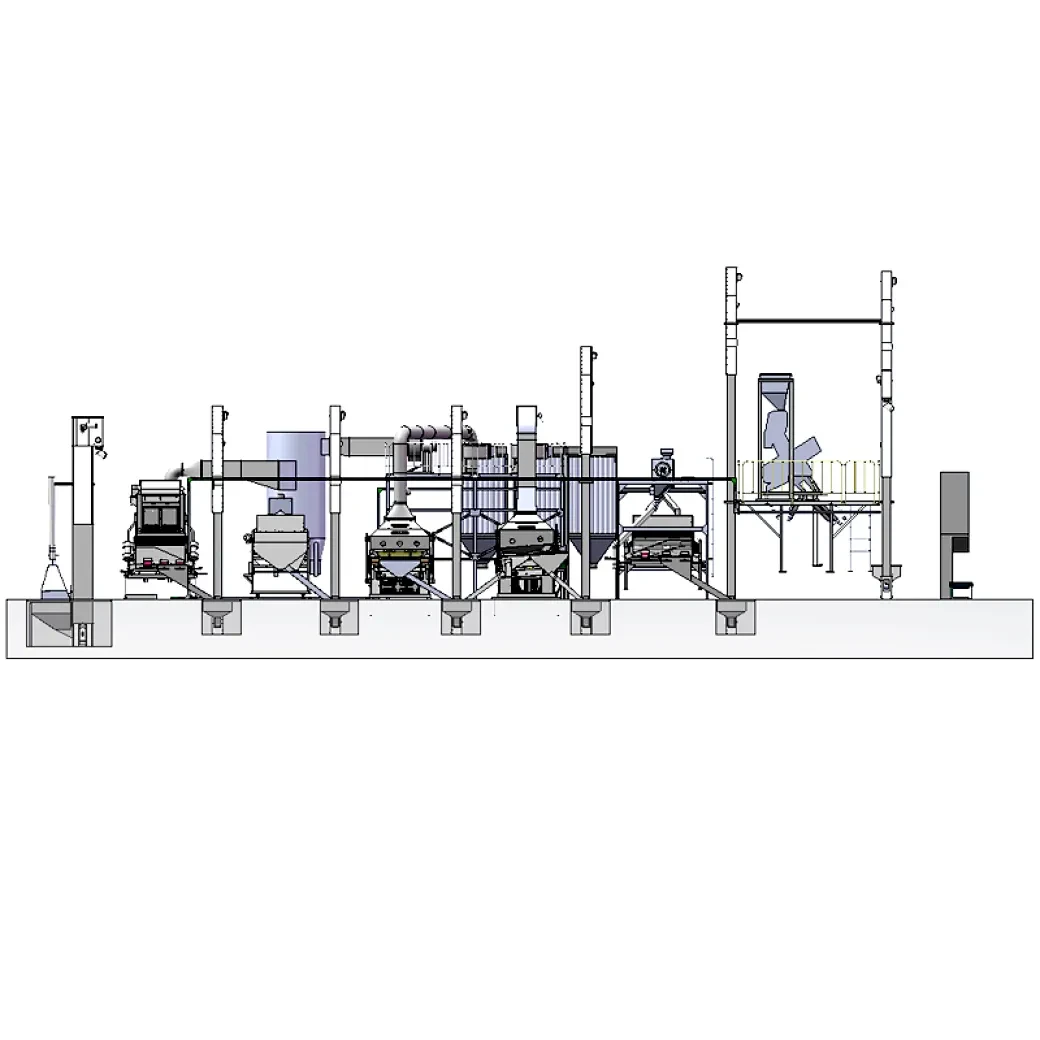

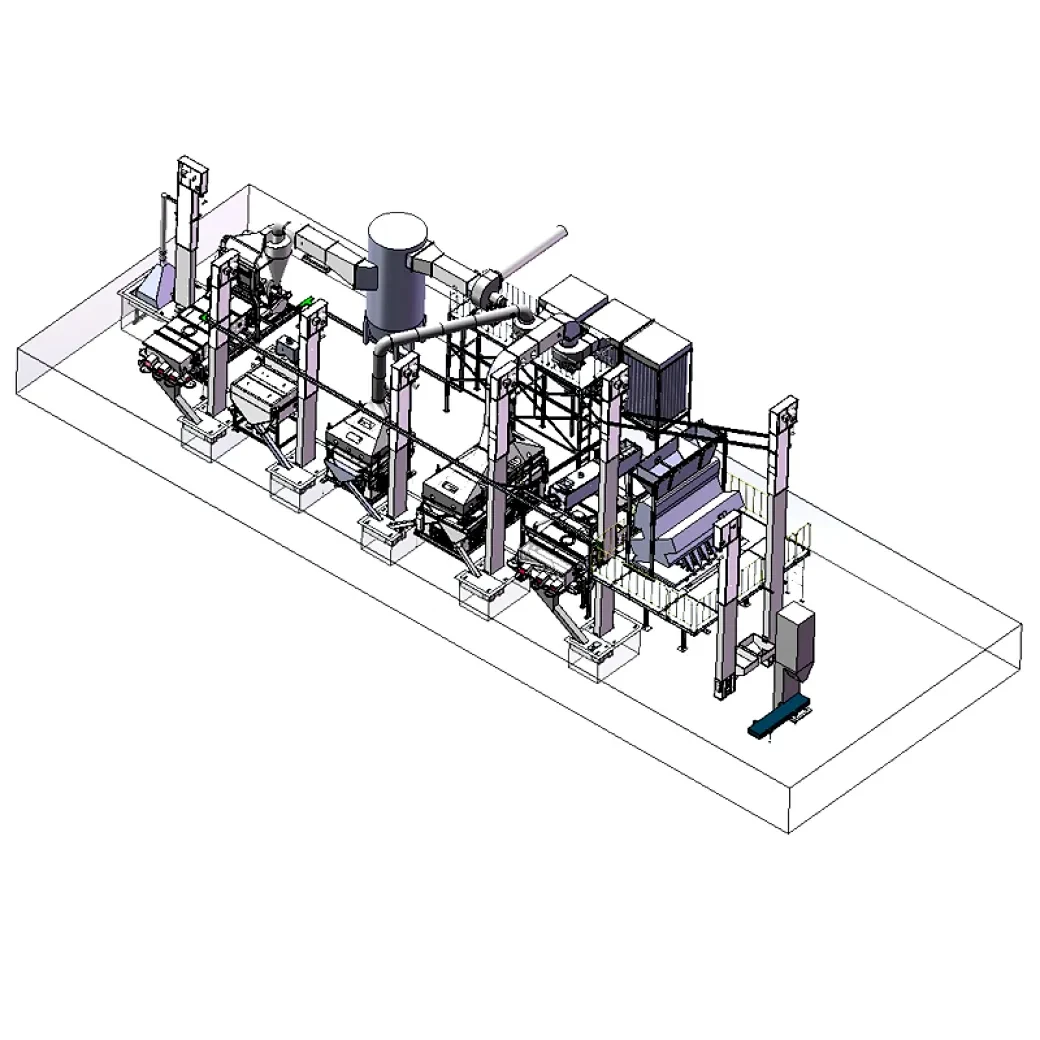

- Complete Locust Beans Processing Flow: Step-by-Step with Visual Guide

- Material, Craftsmanship & Standards: What Sets Top Machines Apart?

- Application Scenarios & Industry Case Studies

- Comparative Analysis: Leading Manufacturers & Custom Solutions

- Product Data Visualization: Tables & Charts

- Why Choose Beans and Pulses Cleaning Processing Plant?

- FAQ: Professional Insights on Locust Beans & Beans Cleaning Technology

- After-Sales Service, Lead Time & Quality Assurance

- References & Authoritative Citations

1. Locust Beans Processing: Industry Overview & Market Trends

The global demand for locust beans processing machine and bean cleaning solutions has surged in response to rising needs for high-efficiency food processing and export-quality legume products. According to a Grand View Research report, the legume processing sector is projected to grow at a CAGR of 7.2% from 2023 to 2029, with Africa and Southeast Asia being the largest user regions for locust bean cleaning technologies.

These machines are central to the production of:

- Edible locust bean products (e.g. “iru”, “dawadawa” in West Africa functional foods)

- Pulse-based protein ingredients for global food systems

- Feed, pharmaceutical, and cosmetic raw materials from processed locust beans and pulses

2. Technical Parameters: Comparing Locust Beans Processing Machine & Beans Cleaning Machine

Efficient bean cleaning is contingent on advanced process stages, optimal material selection, and robust system integration. Below is a parameter table comparing typical locust beans processing machines versus multifunctional beans and pulses cleaning plants.

| Parameter | Locust Beans Processing Machine | Beans and Pulses Cleaning Processing Plant (View Product) |

|---|---|---|

| Capacity | 800–2,500 kg/h | 2,000–10,000 kg/h (Customizable) |

| Cleaning Stages | 3–5 (Pre-cleaning, washing, decorticating) | Up to 9 (Pre-cleaning, De-stoning, Gravity, Air Separation, Polishing, Color Sorting,...) |

| Material | SUS304, Mild Steel available | 100% SUS304 or 316 Stainless Steel, food-grade coatings |

| Automation Level | Semi-automatic | Fully automatic w/ PLC, remote IoT control |

| Sieving Fineness | ≥98% | ≥99.2% |

| CERTIFICATION | ISO 9001, CE Option | ISO 9001, CE, FDA food-contact, ANSI |

| Power Consumption | 10–23 kW/h | 18–60 kW/h (high throughput, energy-efficient motors) |

| Noise Level | <68 dB(A) | <63 dB(A) (Vibration-damping structure) |

| Typical Warranty | 12 months | 24–36 months (+Lifetime tech support) |

3. Complete Locust Beans Processing Flow: Step-by-Step with Visual Guide

Raw beans loaded, bulk impurities (stones, stalks) removed

Heavier particles separated via vibration/gravity

Water jet clean, detachable hulls & stuck dirt

Precise classification, ensures homogeneity

Surface dust removal, light chaff blown off

Optical detection rejects discolored beans; ready for packing

- Dirty water recycling with 3-stage micro-filtration (ISO 14001 environmental compliance)

- Modular sieve mesh exchange for multi-bean processing adaptability

- Stainless assemblies machined via high-precision CNC for resistance to abrasion and corrosion

- Integrated inline quality inspection and error alert systems (conforms to FDA Food Safety Modernization Act)

4. Material, Craftsmanship & Standards: What Sets Top Machines Apart?

Locust beans processing machine and industrial beans cleaning machine performance highly depend on:

- Material Selection: SUS 304/316L stainless steel (rustproof, acid resistance), FDA food-contact proven; mild steel options for non-food use

- Craftsmanship: Core structural parts are manufactured using multi-axis CNC milling; seamless welding achieves watertight, hygienic joints and enhanced rigidity.

- Surface Finish: Ra ≤0.6μm for food-contact surfaces prevents residue buildup, easy CIP (clean-in-place) maintenance.

- Detection Standards: Full machine pass-through under ISO 9001:2015, ANSI/NSF/3-A for food equipment safety; electricals tested to CE/UL standards.

- Design Life: > 20,000 machine hours (documented according customer running logs, supported by independent industry audits).

- Anti-corrosion Protocols: All wet areas electropolished; seals & gaskets of food-grade silicone or Viton™, resist detergents and steam.

- ISO 9001:2015 QMS for production

- FDA CFR 21, ISO 22000, ANSI/3A/CE/CCC (customized for international projects)

5. Application Scenarios & Industry Case Studies

Application Sectors:

- Food manufacturing (fermented locust bean condiments, canned beans, protein ingredients)

- Pharmaceuticals (extraction of locust bean gum polysaccharides)

- Pet food, animal feed pre-processing

- Specialty chemicals (gum bases, thickeners)

- Municipal water pre-treatment (using bean husk fiber byproducts)

Industry Testimonial:

- Nigeria, 2023: A medium-scale condiments manufacturer processed over 9,000 tons/year of locust beans using fully configurable cleaning and de-hulling modules, reducing water consumption by 22%.

- Vietnam, 2022: Integration of color sorter and destoner led to a premium edible bean yield boost by 18%. ROI realized within 11 months.

- Spain, 2021: A pharmaceutical-grade gum manufacturer adopted food-grade, electropolished process lines, complying with ISO 22000 and FDA requirements, enabling supply to EU and US ingredient buyers.

6. Comparative Analysis: Leading Manufacturers & Custom Solutions

Comparing leading companies in the field of pulse processing and bean cleaning solutions reveals major differentiators:

| Brand / Manufacturer | Core Strength | Certifications | Customizable? | Warranty | Support Scope |

|---|---|---|---|---|---|

| Beibu Cleaner (China) | Multi-stage cleaning, seamless automation, IoT-enabled, ISO/FDA, 20+ yrs experience | ISO9001, CE, FDA Food | Yes, full line modularity | 2–3 yrs | Global, 24/7, Multi-language |

| Bühler Group (Switzerland) | Optical sorting, energy-saving, robust design | ISO9001, CE, FDA | Limited | 1 yr | Global, Regional |

| SATAKE (Japan) | Rice/bean hybrid plants, advanced grading | ISO, CE | Partial | 1–2 yrs | Asia/EMEA |

| Local OEMs | Cost competitive, short delivery, basic automation | ISO9001, local safety | Rudimentary | 6–12 mo | On-site only |

Custom Solution Highlight: The Beans and Pulses Cleaning Processing Plant stands out with:

- Modular processing line (adaptable to local bean variety)

- PLC/IoT automation & big data analytics for traceability

- On-site and remote technical support

- Options for GMP, FDA, and Halal/HACCP compliance

7. Product Data Visualization: Tables & Charts

- ■ Beibu Beans Plant

- ■ Generic Processing Machine

- ■ Power (kWh / 1T Output)

- ■ Premium Output

- ■ Off-grade

| Model | Capacity (kg/h) | Power (kW) | Stages | Dimension (mm) | Material |

|---|---|---|---|---|---|

| BPL-2000 | 2000 | 18 | 5 | 4200×2600×3150 | SUS304 |

| BPL-5000 | 5000 | 31 | 7 | 6100×3200×3250 | SUS304 |

| BPL-10000 | 10000 | 52 | 9 | 8700×4100×3760 | SUS316 |

8. Why Choose Beans and Pulses Cleaning Processing Plant?

- Highest Hygiene: Food-grade stainless, antibiofilm surface, all module washdown compatible

- Absolute Cleanliness: ≥99.2% bean cleaning accuracy (field proven, see published test)

- Energy Efficient: Uses up to 35% less energy than legacy models

- Digital Monitoring: IoT for remote diagnostics, real-time OEE (Overall Equipment Efficiency)

- Fast ROI: Typical payback <12 months for medium-scale lines

- Comprehensive Support: Site survey, design-integration, operator training, and prompt spares service

9. FAQ: Professional Insights on Locust Beans & Beans Cleaning Technology

10. After-Sales Service, Lead Time & Quality Assurance

Delivery Time: 30–45 business days for most models; expedited delivery possible for standard configurations.

Warranty: 2–3 years (machine), with lifetime technical support by remote or on-site intervention.

Customer Support: Installation guidance, operator training (on-site/online), application process optimization, 24/7 hotline, and rapid spare parts response.

Certifications Supplied: Full CE (Europe), FDA (US), export documentation, DQ/IQ/OQ/PQ validation for pharmaceutical lines.

OEM/ODM: Available—engineering support for process customization and regional standards compliance.

11. References & Authoritative Citations

- Grand View Research. “Beans Market Size, Share & Trends Report 2023-2030.” https://www.grandviewresearch.com/industry-analysis/beans-market

- Food Engineering Magazine. “Processing Equipment Upgrades 2023.” https://www.foodengineeringmag.com/articles/99123-processing-equipment-upgrades-2023

- ISO 22000:2018. “Food Safety Management Systems – Requirements.” https://www.iso.org/standard/64771.html

- “Assessment of Cleaning Efficiency of Dual Bean Processing Line,” ResearchGate, 2023. https://www.researchgate.net/publication/369451003

- FDA CFR 21 Food Compliance: https://www.fda.gov

Dec. 10, 2024

Coffee Bean Cleaning Machine-Hebei Beibu Machinery Technology Co.,LTD

Jun. 19, 2024

78 sets sesame cleaning machines shipped-Beibu Machinery

Jan. 10, 2025

Assisting the development of grains

Jun. 28, 2024

Multi Functions Soybean Cleaning Machine-Hebei Beibu Machinery Technology Co.,LTD

May. 31, 2024

Receiving visiting customers from Sri Lanka-Beibu Machinery

May. 13, 2024

Peanut shelling machine, peanut cleaning machine packing and shipping-Beibu Machinery

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.