Precision Engineering for Superior Seed Quality in Modern Agriculture

In the highly competitive and increasingly demanding agricultural sector, the foundational element for a successful and abundant yield is undeniably the quality of the seeds planted. For a diverse range of stakeholders, from vast commercial farming enterprises to specialized seed propagation centers and advanced grain processing facilities, the strategic investment in cutting-edge seed cleaning technology is not merely an operational cost but a pivotal strategic imperative for sustained growth and profitability. The profound evolution of seed processing methodologies has led to the development of highly sophisticated machinery, capable of performing meticulous foreign matter removal, precise size grading, and accurate density separation. These advanced capabilities collectively result in significantly enhanced germination rates, robust plant vigor, and ultimately, a substantial increase in overall crop productivity. Among these critical technological innovations, the wheat seed cleaning machine stands as an indispensable cornerstone, brilliantly embodying the perfect synergy of precision engineering, advanced automation, and deep agricultural science. This comprehensive document aims to meticulously explore the intricate facets of modern wheat seed cleaning, with a particular focus on the technological advancements that are defining industry leadership and providing a decisive competitive edge in today's global market. We will thoroughly examine the comprehensive manufacturing processes that rigorously guarantee machine longevity and peak performance, elaborate extensively on the detailed technical specifications that underscore their operational superiority, and illustrate their transformative impact across a myriad of diverse application scenarios within the broader agricultural and food processing landscapes. The escalating global demand for high-quality, safe, and traceable grain necessitates the widespread adoption of reliable, highly efficient, and intelligent cleaning solutions, making a detailed examination of such machinery crucial for informed decision-making by discerning B2B buyers and technical professionals.

Manufacturing Excellence and Engineering Integrity for Reliable Seed Processing

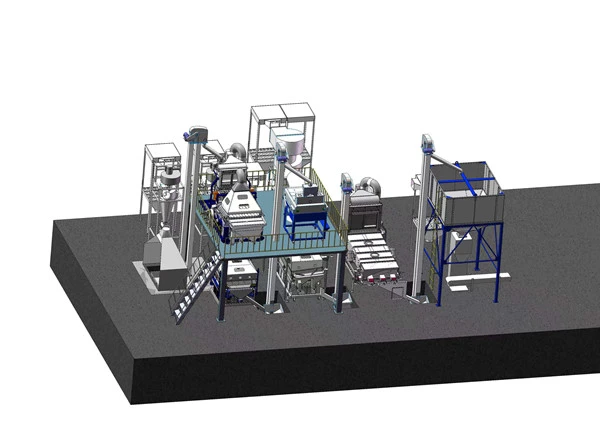

The inherent robustness and unwavering operational performance of a cutting-edge wheat seed cleaning machine are never accidental; instead, they are the direct and measurable outcomes of extraordinarily rigorous manufacturing processes coupled with an unyielding commitment to engineering integrity. Our flagship PLC Auto Cleaner With Gravity Table & Vibration Grader, for instance, is meticulously fabricated using only premium-grade materials, predominantly high-tensile structural steels for the frame and stainless steel alloys for all contact parts, such as sieves, chutes, and collection bins. These materials are specifically selected for their exceptional durability, superior corrosion resistance even when exposed to abrasive grain dust and moisture, and remarkable longevity, particularly crucial for continuous operation in demanding agricultural environments with varying humidity and temperatures. The intricate manufacturing journey commences with ultra-precision material cutting, often leveraging advanced laser or plasma cutting technologies to ensure exact component dimensions and intricate shapes with minimal material waste. This critical phase is immediately followed by sophisticated fabrication processes, including fully automated robotic welding, which guarantees robust, uncompromised structural integrity throughout the machine's framework. This prevents the formation of stress cracks and mitigates material fatigue over extended operational periods, directly contributing to a lower total cost of ownership over the machine's extensive lifespan.

Crucial mechanical components, including the highly intricate parts of the gravity table, air screen separation units, and the precision vibration grader, undergo meticulous CNC (Computer Numerical Control) machining. This highly precise manufacturing method allows for engineering tolerances measured in mere microns, ensuring perfect alignment, minimal operational friction, and optimal fluid dynamics for airflows, as well as precise vibrational frequencies critical for effective seed separation based on density and size. Beyond fabrication, the rigorous assembly phase adheres to stringent, multi-layered quality control protocols. These include comprehensive dimensional checks against engineering blueprints, exhaustive functional testing of individual modules, and full system integration tests under simulated load conditions. Every single wheat seed cleaning machine undergoes rigorous inspection against international benchmarks such as ISO 9001 for overall quality management and relevant ANSI standards for specific mechanical and electrical components, thereby ensuring unquestionable global compliance, operational safety, and unwavering reliability. The sophisticated electrical and automation systems, particularly the core PLC (Programmable Logic Controller) unit, are subjected to extensive debugging, comprehensive calibration, and full-scale operational trials to guarantee seamless, intelligent, and highly responsive automated operation. This meticulous attention to detail at every single stage, from the initial sourcing of raw materials to the final assembly, precise calibration, and pre-delivery testing, collectively ensures an impressive operational lifespan, often extending well beyond 15-20 years with routine preventative maintenance, significantly reducing downtime and maximizing long-term return on investment for agricultural businesses.

Technical Parameters and Advanced Features: The Core of PLC Auto Cleaner Performance

The PLC Auto Cleaner With Gravity Table & Vibration Grader represents the current pinnacle of modern seed cleaning technology, integrating a sophisticated and multi-layered suite of functionalities meticulously designed for achieving optimal seed purity with minimal valuable seed damage. At its operational core lies a comprehensive multi-stage cleaning process that addresses a wide spectrum of impurities. Initially, an efficient air-screen pre-cleaner system swiftly removes lighter foreign matter, such as dust, chaff, straw particles, and undeveloped or shriveled seeds, through precise aspiration and initial coarse sieving. Following this primary separation, the material then progresses to the highly accurate vibration grader, which meticulously separates seeds based on their precise size and shape using multiple layers of oscillating screens with varying mesh dimensions. This precise size grading ensures a remarkable uniformity in the seed batch, a characteristic absolutely crucial for subsequent processing stages, consistent planting, and uniform crop emergence in the field. The most distinctive and high-precision feature of this advanced wheat seed cleaning machine is undoubtedly the integrated gravity table. This unit performs an ultra-sensitive separation based on the specific gravity of individual kernels, effectively removing shriveled, diseased, insect-damaged, or otherwise compromised kernels, along with stones, clods of dirt, and other heavier impurities that may be similar in size to healthy wheat seeds but differ significantly in density. This multi-dimensional and sequential approach guarantees an unparalleled level of purity in the final seed product, directly impacting germination rates, overall crop vitality, and long-term yield potential.

The entire intricate cleaning process is intelligently orchestrated and fully automated by a state-of-the-art PLC (Programmable Logic Controller) system. This advanced control unit offers unparalleled automation capabilities and precise, real-time control over every critical operational parameter. Operators can effortlessly and accurately adjust airflow volumes, vibration frequencies of the screens and gravity table, screen angles, and material feed rates through an intuitive HMI (Human-Machine Interface) touchscreen. This adaptability allows the machine to be perfectly tuned to match the unique characteristics of different wheat seed varieties, varying moisture content, and diverse contamination levels, thereby optimizing cleaning efficiency and minimizing any potential loss of valuable healthy seed. This level of granular, automated control is absolutely vital for consistently achieving the rigorous quality standards now demanded by today's global agricultural markets and seed certification bodies. Key operational parameters of our advanced wheat seed cleaning machine underscore its superior capability in meeting high-volume demands. Typical models within this series boast impressive throughput capacities ranging from 5 to 20 tons per hour (TPH) for wheat, depending on the specific model configuration and the nature of the incoming grain, making them exceptionally suitable for diverse operational scales, from medium-sized agricultural cooperatives to vast commercial grain handling facilities. The power consumption of the system is highly optimized for energy efficiency, with integrated Variable Frequency Drives (VFDs) ensuring that all motors operate at their most energy-efficient points, thereby significantly reducing overall electricity costs. For example, a mid-range model typically consumes approximately 15-25 kW, representing a highly efficient power-to-performance ratio given its immense processing capabilities. The design prioritizes user-friendliness, incorporating intuitive HMI touchscreens for effortless operation, comprehensive data monitoring, and quick access to real-time performance analytics. Furthermore, intelligent features like automatic fault detection, remote diagnostics capabilities, and self-cleaning mechanisms significantly reduce the need for manual intervention, enhance overall operational safety, and drastically minimize downtime, ensuring continuous, reliable, and highly productive performance throughout critical peak seasons. These extensive technical advantages translate directly into higher operational efficiency, superior product quality, and enhanced profitability, unequivocally justifying the investment for discerning buyers seeking long-term value and peak performance in their seed processing and grain management operations.

Typical Technical Specifications: PLC Auto Cleaner With Gravity Table & Vibration Grader

| Parameter | Value/Range | Benefit to User |

|---|---|---|

| Model Name | PLC Auto Cleaner With Gravity Table & Vibration Grader | High-precision, automated multi-stage cleaning for diverse impurities. |

| Capacity (Wheat, Primary Cleaning) | 5 - 20 TPH (Tons Per Hour) | Scalable solutions for various farm/plant sizes, ensuring high throughput. |

| Achievable Purity Rate | ≥99.5% | Ensures superior seed quality, leading to significantly higher germination and stronger crops. |

| Foreign Matter Removal Efficiency | >98% (Light Impurities), >95% (Stones/Heavy Impurities) | Comprehensive and effective removal of diverse contaminants, including challenging ones. |

| Broken Kernel Rate | <0.5% | Minimizes loss of valuable, healthy seed, preserving integrity and yield. |

| Total Installed Power | 15 - 25 kW (Varies by capacity model) | Energy-efficient operation contributes to lower overall running costs and environmental impact. |

| Control System | Advanced PLC with intuitive HMI Touchscreen & SCADA compatibility | Automated, user-friendly, precise parameter control, remote monitoring, and data logging for optimization. |

| Construction Material | High-Tensile Steel Frame, Food-Grade Stainless Steel for Contact Parts | Ensures exceptional durability, superior corrosion resistance, and extended operational life. |

Transformative Application Scenarios & Broad Industry Impact

The strategic deployment of a high-performance wheat seed cleaning machine, such as the sophisticated PLC Auto Cleaner, transcends mere operational necessity to become a pivotal and transformative factor in optimizing agricultural productivity and enhancing overall profitability across numerous sectors within the grain value chain. In the context of large-scale commercial farming operations, integrating such advanced machinery ensures that every hectare of land is planted with the purest, most viable seeds available. This meticulous attention to seed quality directly translates to measurably higher germination rates, leading to more uniform crop stands, reduced competition from weeds or volunteer plants, and ultimately, significantly increased yields per acre. The machine's unparalleled ability to precisely remove damaged, diseased, or undesirable weed seeds plays a crucial preventative role, inhibiting the spread of crop pathogens and unwanted species, thereby substantially reducing the future need for costly post-emergence weed control treatments and fungicide applications, offering both economic and environmental benefits. For specialized seed processing companies, the wheat seed cleaning machine acts as the central pillar of their stringent quality assurance programs. It empowers them to consistently produce premium-grade, certified seeds that command higher market prices due to their proven genetic purity, high germination vigor, and freedom from contaminants. Such companies extensively leverage the machine's exceptional efficiency and high throughput capacity to process vast volumes of seeds swiftly and effectively, enabling them to meet peak seasonal demands and ensuring a consistent, reliable supply of high-quality planting material to their diverse clientele, both domestically and internationally.

Beyond conventional farming practices, the profound impact of such advanced cleaning technology extends significantly into specialized agricultural applications, including sophisticated agricultural research institutions and large-scale grain storage and handling facilities. Research centers extensively utilize these highly precise machines for preparing homogenous and meticulously cleaned seed samples essential for conducting accurate experimental trials. This ensures that the integrity of research outcomes is never compromised by variations in initial seed quality or the presence of contaminants, allowing for truly scientific and reproducible results. For commercial grain storage operations, employing a powerful wheat cleaning machine plant system prior to long-term storage is an absolutely crucial step for preventing costly spoilage, mitigating severe insect infestations, and inhibiting undesirable fungal or mold growth within silos and warehouses. By meticulously removing foreign matter, excess moisture-prone impurities, and damaged kernels, the cleaning process drastically reduces the risk of spoilage that could otherwise compromise the entire batch of stored grain, leading to significant financial losses. Furthermore, the inherent capacity for customization inherent in the PLC Auto Cleaner's modular design allows for its seamless integration into existing processing lines or the development of bespoke, turn-key solutions tailored precisely for specific grain types (e.g., durum wheat vs. common wheat), highly specific throughput requirements, or adherence to stringent regional and national quality standards. This unparalleled operational flexibility ensures that whether the client requires a continuous, high-volume industrial operation or a more specialized, smaller-batch cleaning task for premium seed lots, there is a configurable solution that can meet the demand with optimal efficiency, exceptional precision, and unmatched reliability. This ultimately drives tangible improvements in overall output quality, enhances operational resilience, and delivers substantial economic returns for our valued clients, fostering long-term success in their agricultural endeavors.

Investment Considerations: Analyzing Price and Long-Term Return on Investment

When agricultural businesses consider the strategic acquisition of advanced machinery, particularly a sophisticated wheat seed cleaning machine, the discussion invariably and logically turns to the "price of wheat cleaning machine" and, more critically, the projected long-term return on investment (ROI). While the initial capital outlay for a state-of-the-art PLC Auto Cleaner With Gravity Table & Vibration Grader might appear to be a more substantial investment compared to simpler, less automated, or outdated alternatives, this investment is demonstrably and rapidly justified by the profound operational efficiencies and superior qualitative enhancements it consistently delivers. The unparalleled precision and comprehensive automation offered by our advanced PLC control system drastically reduce the reliance on manual labor, leading to very substantial and quantifiable savings in ongoing operational costs over the machine's lifespan. Furthermore, the superior cleaning efficiency inherent in our multi-stage separation process ensures minimal loss of valuable, healthy good seeds during the cleaning operation, translating directly into a higher marketable yield from every batch processed. The machine's consistent ability to deliver cleaned seeds with purity levels routinely exceeding 99.5% ensures that growers achieve optimal germination rates and cultivate healthier, more vigorous crops, which in turn leads to premium market prices for their high-quality produce and a significant improvement in overall farm or processing plant profitability.

For agricultural businesses with diverse operational scales and specific budget considerations, the question of a "small wheat cleaning machine price" versus the cost of larger, more industrial-grade models is also a pertinent inquiry. While our core focus and expertise lie in providing high-capacity, fully automated seed cleaning solutions for commercial operations, we are acutely aware of and responsive to the varying needs across the agricultural market. Our flexible manufacturing capabilities and the modular design of our cleaning lines allow for extensive customization to precisely suit specific throughput requirements. This ensures that clients can procure a system that perfectly matches their unique operational scale and budget without making an unnecessary over-investment in excess capacity or features they don't require. The extended operational lifespan of our machines, robustly backed by superior construction materials and strict adherence to international quality standards such as ISO, significantly minimizes long-term maintenance expenditures and reduces unplanned downtime, thereby substantially contributing to a lower total cost of ownership over several decades. Additionally, our readily accessible and comprehensive after-sales support, including guaranteed spare parts availability and expert technical assistance, further safeguards the client's investment, ensuring continuous operation. By optimizing seed quality to an exceptional degree, dramatically reducing operational inefficiencies, and consistently contributing to higher, more reliable crop yields, the PLC Auto Cleaner represents a truly strategic asset that continually pays dividends through enhanced productivity, superior product quality, and a decisive competitive advantage in the marketplace, solidifying its position as a wise and highly profitable long-term investment for any serious agricultural enterprise aiming for sustainable growth and premium output.

Trustworthiness: Comprehensive Service, Robust Warranty, and Proactive Client Support

Building and, more importantly, sustaining profound trust with B2B clients in the specialized agricultural machinery sector extends far beyond simply delivering a high-quality wheat seed cleaning machine; it fundamentally encompasses a comprehensive, unwavering commitment to unparalleled service, robust warranty provisions, and proactive, responsive customer support throughout the entire lifecycle of the product. Our steadfast commitment to achieving absolute client satisfaction commences even before a purchase is finalized, with expert consultation services meticulously aimed at thoroughly understanding each client's specific operational needs, unique challenges, and ambitious growth objectives. This highly collaborative and consultative approach ensures that the client makes an informed investment in the precise machine configuration that perfectly addresses their unique operational requirements and desired throughput capacities, thereby avoiding misallocation of capital. Upon the successful acquisition of our machinery, we provide meticulously detailed technical documentation, intuitively designed comprehensive operational manuals, and dedicated, hands-on training programs for the client's operational personnel. This ensures they are fully proficient and confident in safely operating, effectively maintaining, and efficiently troubleshooting the PLC Auto Cleaner, thereby empowering our clients to maximize the machine's inherent efficiency and extend its already impressive operational longevity while simultaneously minimizing potential operational disruptions during critical periods. Our dedicated after-sales support team comprises highly skilled engineers and technicians who are readily available for immediate technical assistance, remote diagnostics, and, when absolutely necessary, rapid on-site support, ensuring prompt and effective resolution of any issues that may arise during the machine's extensive operational life, thereby guaranteeing continuous productivity.

Furthermore, the profound trust that clients place in our state-of-the-art products is robustly underpinned by a comprehensive and transparent warranty policy. This policy typically covers all major components and any potential manufacturing defects for a substantial period, often extending from 12 to 24 months from the date of commissioning or successful delivery, whichever occurs first. This extensive warranty period serves as a tangible reflection of our unwavering confidence in the superior quality of our manufacturing processes, the exceptional durability of our machinery, and the rigorous quality control standards we uphold for every wheat seed cleaning machine that leaves our facility. We also meticulously maintain a readily available and extensive inventory of genuine OEM (Original Equipment Manufacturer) spare parts, ensuring immediate availability and quick dispatch globally. This minimizes potential downtime for our clients, which is of paramount importance during critical agricultural seasons such as harvest and planting. Our typical delivery cycle for standard machine configurations ranges from 45 to 75 business days, depending on specific customization requirements and current production schedules, with clear, proactive communication provided at every single stage of the order fulfillment process to ensure transparency. Our long-standing, successful relationships with numerous leading agricultural enterprises worldwide, coupled with a proven track record of successful installations and satisfied customer testimonials globally, serve as powerful testaments to our unwavering reliability and our deep dedication to fostering enduring, mutually beneficial partnerships. This holistic and client-centric approach to customer care ensures that our clients not only acquire a leading-edge seed cleaning solution but also gain a reliable, long-term strategic partner fully committed to their sustained operational success, enhanced productivity, and continued growth in the dynamic agricultural industry.

Frequently Asked Questions (FAQ)

Q1: What specific types of impurities can the PLC Auto Cleaner effectively remove from wheat seeds?

A1: Our PLC Auto Cleaner is engineered for the comprehensive removal of an extensive array of impurities from wheat seeds. This includes light foreign matter such as dust, chaff, straw particles, and undeveloped or shriveled seeds, which are efficiently separated through aspiration and initial air-screen cleaning. It also effectively removes oversized and undersized impurities, broken kernels, and other foreign grains through precise vibration grading and multi-layered sieving. Critically, it excels at removing heavy foreign materials like stones, clods of dirt, diseased kernels, and severely shriveled seeds via advanced gravity table separation, which leverages minute differences in specific gravity. This sophisticated multi-stage approach ensures an exceptional level of purity in the final seed batch.

Q2: How does the integrated PLC control system significantly enhance the performance and operational efficiency of the wheat seed cleaning machine?

A2: The seamlessly integrated PLC (Programmable Logic Controller) system provides unparalleled advanced automation and real-time, precise control over all critical operational parameters of the machine. This includes intelligent and automated adjustment of airflow volumes, vibration frequencies for both the screens and the gravity table, precise screen angles, and accurate material feed rates. The PLC allows for perfectly optimized settings tailored specifically to different wheat seed varieties, varying moisture content, and diverse levels of contamination, ensuring maximum cleaning efficiency and minimal valuable seed loss. The intuitive HMI (Human-Machine Interface) touchscreen simplifies operation, allows for real-time performance monitoring, and facilitates rapid fault diagnosis, thereby significantly reducing reliance on manual adjustments and dramatically enhancing overall productivity and output consistency.

Q3: What is the expected operational lifespan and typical maintenance requirement for this advanced wheat seed cleaning machine?

A3: Constructed from robust, high-grade materials such as high-tensile structural steel for the frame and food-grade stainless steel for all contact parts, and meticulously manufactured using precision techniques like CNC machining, the PLC Auto Cleaner is engineered for exceptional durability and long-term reliability. With diligent routine preventative maintenance, which encompasses regular cleaning, precise lubrication of all moving components, and timely replacement of standard wear parts (such as sieves), the machine can reliably operate for 15-20 years or even significantly longer. Our comprehensive support includes detailed maintenance guidelines and readily available genuine spare parts to ensure maximum uptime and extend the operational longevity of your critical agricultural investment.

Authoritative References

- Food and Agriculture Organization of the United Nations (FAO). "Post-harvest operations and technologies for cereals and pulses." Agricultural Services Bulletin 137.

- American Society of Agricultural and Biological Engineers (ASABE). "Standards for Design and Performance of Agricultural Seed Processing and Cleaning Machinery."

- International Organization for Standardization (ISO). "ISO 9001:2015 Quality management systems — Requirements for manufacturing excellence."

- Journal of Agricultural Engineering Research. "Advancements in Seed Separation Technologies for Enhanced Crop Yields."

Jun. 10, 2024

Happy Dragon Boat Festival! -Beibu machinery

Jan. 24, 2024

Mar. 15, 2024

Soybean Destoner and Gravity Separator in Clients-Hebei Beibu Machinery Technology Co.,LTD

May. 07, 2024

Sesame and Soybean Cleaning Processing Line-Hebei Beibu Machinery Technology Co.,LTD

Sep. 10, 2024

Beibu Machinery-Sesame cleaning machine shipped to Africa

Apr. 22, 2024

Receiving visiting customers from Sudan

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.