- Understanding Elevator Rice Mill: Concept and Importance

- Working Process: The Role of Rice Mill Elevator Buckets

- Technical Advancements Driving Productivity Gains

- Comparing Leading Rice Mill Elevator Manufacturers

- Cost Dynamics: Factors Influencing Elevator Rice Mill Price

- Tailored Solutions: Customization in Rice Mill Elevator Systems

- Elevator Rice Mill in Action: Case Studies and Industrial Impact

(elevator rice mill)

Understanding Elevator Rice Mill: Concept and Importance

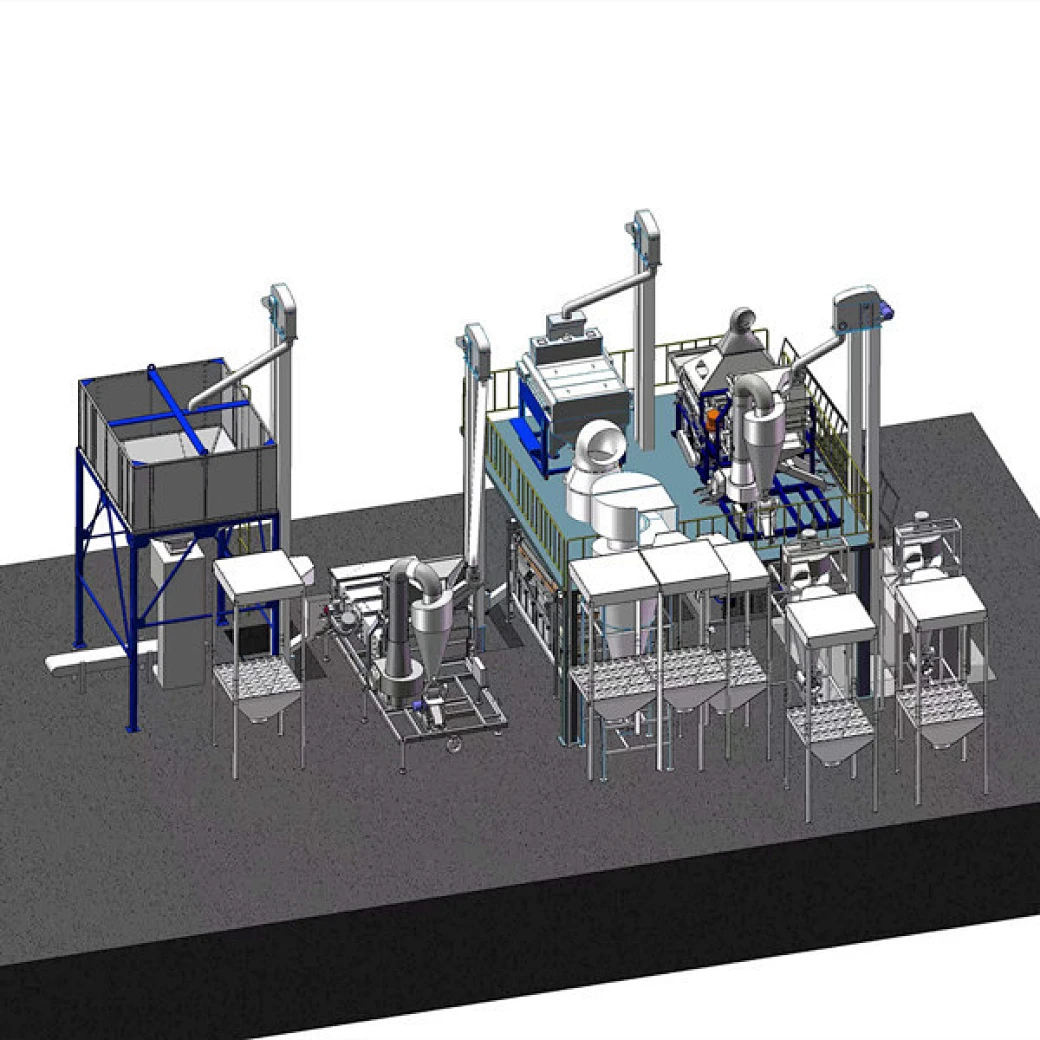

Elevator rice mill systems have become an irreplaceable component in contemporary rice processing facilities. As the world’s demand for milled rice continues to rise—UN data suggests global consumption exceeded 510 million metric tons in 2023—the need for reliable, efficient, and scalable rice milling technology is greater than ever. At the core of this trend stand elevator rice mill

s, engineered to streamline the vertical transportation of rice grains throughout multistage milling processes. This mechanism not only minimizes manual handling, which can account for up to 15% in loss and contamination, but also ensures a consistent throughput, aligning rice quality with market and export standards.

The elevator rice mill system is integral to maximizing yield. By reducing transit damage and optimizing flow rates (with bucket elevator capacities ranging from 100 to over 1200 tons per day), these systems provide a marked advantage for rice millers aiming for operational excellence. Their design focuses on minimizing broken grains and preserving the desired quality attributes—factors that directly impact profit margins and customer satisfaction across global markets.

Working Process: The Role of Rice Mill Elevator Buckets

The core operational principle of a rice mill elevator centers on the effective utilization of elevator buckets. Made from high-grade materials such as reinforced polyamide, stainless steel, or wear-resistant polymers, these buckets play a pivotal role in the vertical transport of rice at various stages—cleaning, hulling, polishing, and grading.

Typically, the working process entails buckets attached to a belt or chain, scooping rice kernels from the bin and raising them vertically. As buckets reach the designated height, centrifugal force enables precise discharge into processing units. This method substantially reduces spillage and mechanical breakage, with modern bucket designs boasting fill factors above 90% efficiency and drop heights adjusted to minimize impact. The advanced synchronization between motor speed, belt tension, and feed rate allows operators to fine-tune capacity, meeting both high-output industrial and specialized boutique milling requirements.

Technical Advancements Driving Productivity Gains

Technical innovations have transformed traditional elevator rice mill systems into high-efficiency, low-maintenance assets. Recent data shows that the integration of programmable logic controllers (PLCs) and sensor-based real-time monitoring can increase system uptime by up to 18%, while automated lubrication systems reduce maintenance labor by 22%. In addition, anti-static bucket materials prevent grain adhesion and blockages, ensuring smoother operations during high-humidity cycles—an essential feature in monsoon-affected regions.

The adoption of variable frequency drives (VFDs) optimizes elevator speed according to grain type and volume, balancing energy consumption against peak productivity. For instance, studies reveal mills employing VFD-controlled elevators have achieved energy savings of 12-16% compared to fixed-speed counterparts. Furthermore, modular construction facilitates rapid part replacement, minimizing downtime and supporting the scalability required for operators seeking to diversify product offerings or accommodate seasonal volumes.

Comparing Leading Rice Mill Elevator Manufacturers

Selecting a manufacturer significantly influences an elevator rice mill system’s reliability, after-sales support, and overall lifecycle cost. Below is a comparative summary of prominent rice mill elevator manufacturers, highlighting key technical specifications and differentiators:

| Manufacturer | Max Capacity (TPD) | Material Options | Certifications | Warranty (Years) | Global Service Network |

|---|---|---|---|---|---|

| Satake Corporation | 1300 | Stainless Steel, Polyamide | ISO, CE | 3 | Asia, Americas, Europe |

| Buhler Group | 1200 | Food-Grade Polymer, Steel | ISO, ATEX | 2 | Worldwide |

| Milltec Machinery | 900 | Mild Steel, Polymer | ISO | 2 | Asia, Africa |

| Fowler Westrup | 1000 | Stainless Steel, Polymer | ISO, CE | 3 | Asia, Africa |

As the table illustrates, global brands offer diverse capacity options, material flexibility, and certification standards. The choice of rice mill elevator manufacturer should therefore be guided by local service presence, raw material compatibility, and system integration capabilities.

Cost Dynamics: Factors Influencing Elevator Rice Mill Price

Elevator rice mill price varies widely, reflecting technological features, build quality, and after-sales support. Entry-level systems for small capacities (100-200 TPD) can start around $9,000, while top-tier industrial setups exceeding 1,000 TPD may command investments upwards of $60,000. Several key factors contribute to this price range:

- Material Selection: Premium-grade stainless steel and anti-corrosive finishes increase system lifespan but drive up initial costs, whereas basic polymer options offer affordability at the expense of durability.

- Automation Level: Inclusion of PLCs, remote diagnostics, and self-cleaning features can add 10-20% to capital cost but deliver lower long-term operational expenses.

- Energy Efficiency: High-efficiency motors and VFDs are often priced higher but result in annual utility cost reductions of $2,000–$5,000 depending on plant size.

- Service and Spare Parts Access: Manufacturers with robust after-sales networks help mitigate lifetime maintenance costs, safeguarding system uptime and ROI.

When budgeting for rice mill elevator investment, stakeholders must balance short-term outlays against productivity, reliability, and compliance needs in increasingly regulated markets.

Tailored Solutions: Customization in Rice Mill Elevator Systems

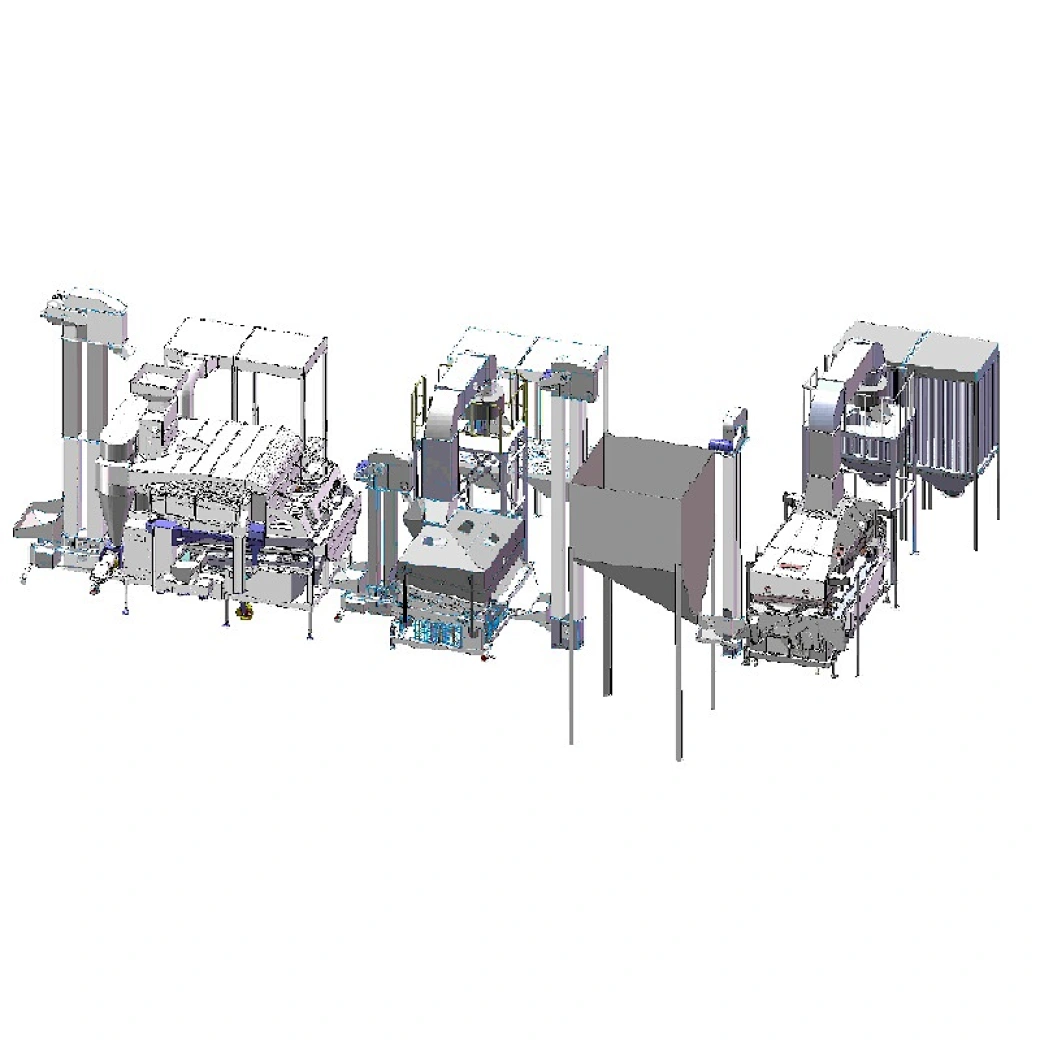

The growing diversity of rice varieties—hybrid, organic, specialty fragrant, or sticky—necessitates customization of elevator rice mill configurations. Custom solutions provide enhanced compatibility with unique grain properties, delivering measurable advantages in yield and quality retention.

Customizable aspects include:

- Bucket Design and Spacing: Adjusted for grain size and throughput requirements.

- Material Selection: For processing high-moisture grains or abrasive rice types.

- Discharge Point Modification: Precision drop heights to align with downstream machinery and prevent breakage.

- Integration with IoT Sensors: Real-time monitoring for temperature, vibration, and grain flow patterns.

Elevator Rice Mill in Action: Case Studies and Industrial Impact

Real-world deployments underscore the transformative effects of modern elevator rice mills on productivity, product quality, and economic sustainability. For instance, a large milling operation in Thailand recently upgraded to an all-stainless-steel elevator system with auto-calibrating VFDs, resulting in a 14% output increase and a 9% improvement in head rice yield—critical for export-grade product acceptance.

Another notable example is a West African rice cooperative that implemented sensor-driven elevator buckets matched exactly to local paddy characteristics. Post-installation reviews reveal maintenance incidents halved, and batch-to-batch consistency improved by 23%. These outcomes emphasize not only technical advantages but also the elevated market positioning afforded by cutting-edge rice mill elevator systems.

In conclusion, the evolution and sophisticated deployment of elevator rice mill technology are integral to meeting the dual challenge of scaling global food supply and maintaining stringent quality requirements. Mills that invest in advanced, well-supported elevator systems will continue to lead in efficiency, adaptability, and customer assurance.

(elevator rice mill)

FAQS on elevator rice mill

Q: What is an elevator rice mill and how does it work?

A: An elevator rice mill uses vertical elevators to convey paddy and rice between different processing machines. This system increases efficiency and saves labor. The working process ensures smooth, continuous rice milling.Q: How do rice mill elevator buckets function in the milling process?

A: Rice mill elevator buckets transport grain vertically by scooping and releasing it at different stages. They ensure minimal grain breakage and fast movement. This process is crucial for maintaining milling quality.Q: How can I choose a reliable rice mill elevator manufacturer?

A: Look for established manufacturers with good reviews, service support, and certified products. Ask about customization options for your specific needs. Reliable manufacturers provide after-sales service and spare parts.Q: What factors affect the price of a rice mill elevator?

A: Price depends on capacity, material, automation level, and brand. Additional features or customizations increase the cost. Compare quotes from different suppliers for the best deal.Q: What is the typical working process of a rice mill elevator system?

A: The elevator collects raw paddy or rice, lifts it, and delivers it to the milling or sorting machines. This cycle repeats until all processing is complete. The system ensures efficient, continuous milling operations.Mar. 20, 2024

Hand Sewing Machine for PP Bags-Hebei Beibu Machinery Technology Co.,LTD

Jan. 06, 2025

How to choose a suitable Paddy cleaning machine-Beibu Machinery gives you the perfect answer

May. 09, 2024

Gravity separator working on beans very well

Jan. 16, 2025

What to do if grain seeds contain high stone content? - Beibu Machinery solves your problems

Mar. 26, 2024

Beans Cleaning Machine Magnetic Separator-Hebei Beibu Machinery Technology CO.,LTD

Dec. 11, 2024

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.