How to choose a suitable Paddy cleaning machine-Beibu Machinery gives you the perfect answer

Rice, as an important food crop in the world, is the fruit of mature rice ears. Its caryopsis is composed of husk and brown rice, which is then processed into rice for daily consumption. It likes warm and humid environment and is widely planted in Asia, America and Africa. It takes several months from sowing to harvesting. It is full of farmers' hard work and finally becomes the staple food on the table, nourishing thousands of lives.

For paddy processing companies, the key to transforming this gift from nature into high-quality products lies in the fine screening of paddy. In this important link, an efficient paddy screening equipment is particularly critical. The cleaning machine with excellent performance can efficiently remove all kinds of impurities such as light impurities, small impurities, and large impurities, ensuring the purity of paddy and laying a solid foundation for subsequent processing.

What kind of rice screening machine can be called excellent?

First of all, efficiency is the key criterion for measuring the performance of screening equipment. An excellent cleaning machine can process a large amount of rice while maintaining a high degree of screening effect, ensuring the effective removal of impurities without damaging the paddy itself.

Secondly, the stability of the equipment should not be underestimated. It can cope with complex processing environments, operate stably for a long time, reduce failure rates, and improve production continuity.

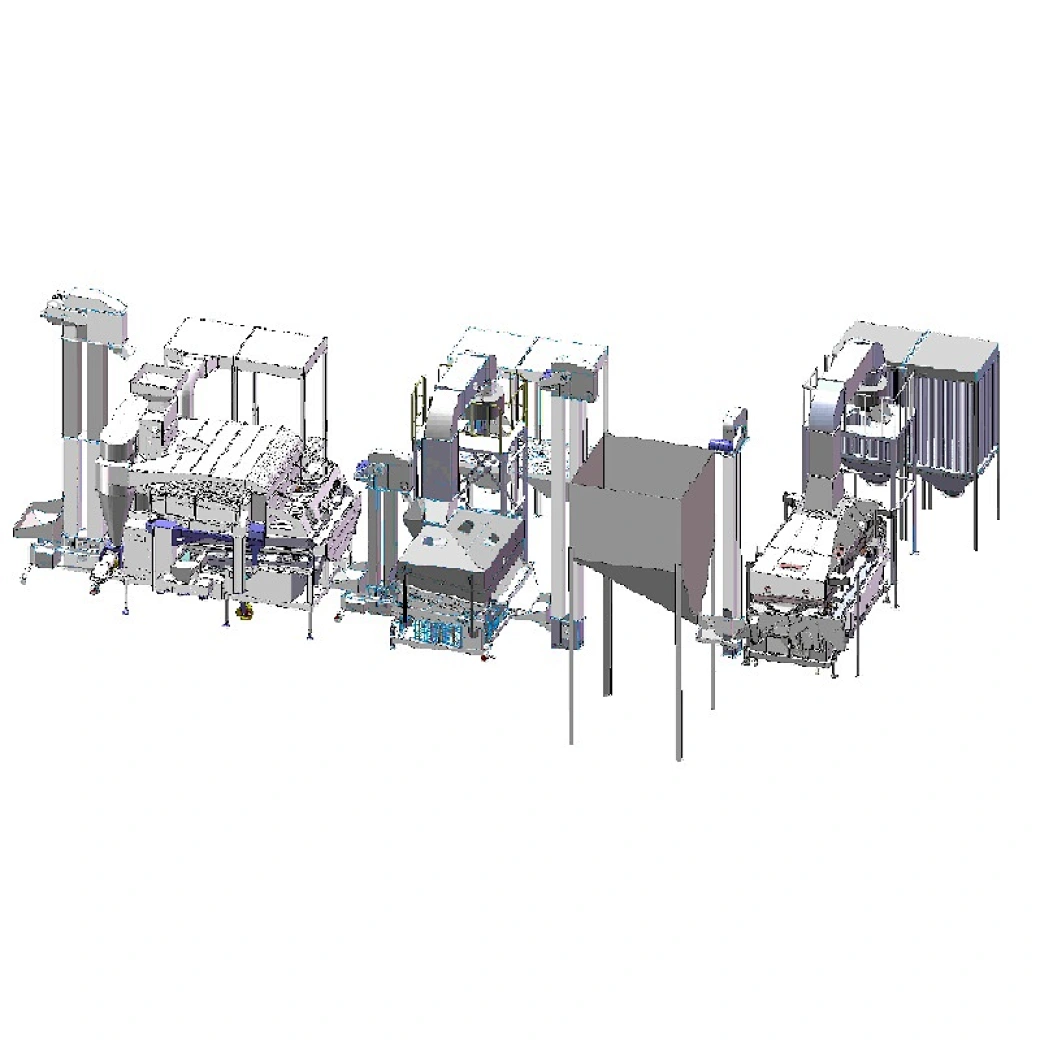

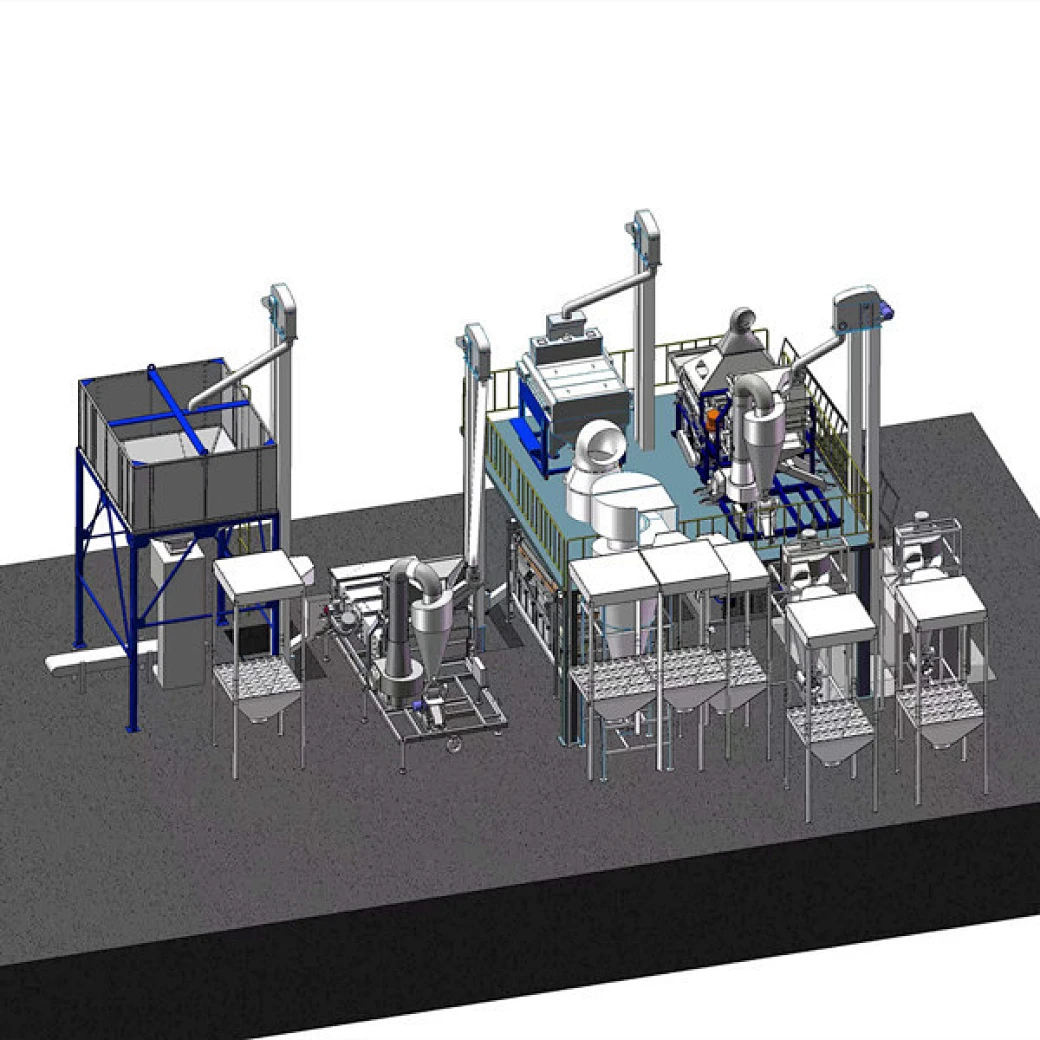

The flagship product of Beibu Machinery, the Z310 intelligent grain cleaning machine, is an ideal choice to meet these standards. It is like a rigorous guardian, and can accurately remove dust, straw, barren seeds, broken grains, and empty shells, without missing any subtle details that may affect the quality of Paddy.

Equipment features:

1. The equipment has high integration and PLC intelligent adjustment, which can realize one-button switching and cleaning of different materials;

2. It occupies a small area; it reduces multiple lifting and reduces processing losses;

3. It adopts an ultra-large specific gravity table (2300*2000mm) and a widened screen box structure (screen box width 2000*1500mm) to ensure large output and high cleanliness;

4. The front and rear air screens are equipped with independent cyclone dust collectors and fans, which are easy to adjust and flexible to operate, and the dust removal during the processing is environmentally friendly;

5. The unique balance structure design effectively reduces abnormal vibration of the equipment and ensures stable operation of the equipment.

Scope of application:

Used for the cleaning and processing of various crop seeds and commercial grains such as rice, various beans, sesame, peanuts, wheat, corn, rapeseed, barley, millet, etc.

Reliable screening equipment can not only improve screening efficiency and save valuable manpower and time costs, but also provide consumers with safer and healthier food choices, winning their trust and favor.

Beibu Machinery, as a high-tech enterprise with a good reputation and strong technical strength, focuses on providing professional solutions for grain processing and seed cleaning. We not only provide first-class screening equipment, but also provide one-stop services from equipment selection, installation and commissioning to later maintenance, ensuring that your paddy processing process is more professional and efficient.

Choosing Beibu Machinery means that you have chosen a reliable and professional partner. Our Z310 intelligent cleaning machine is not only a piece of equipment, but also a powerful helper on your road to wealth and income!

May. 14, 2024

Sesame and Soybean Gravity Separator arrived in Togo-Hebei Beibu Machinery Technology Co.,LTD

Want to know details of Sesame and Soybean Gravity Separator arrived in Togo?Beibu Machinery will share knowledge of Destoner ,Gravity Separator for you. Click the link to get more information.

Oct. 30, 2024

China New Policy for Africa Groundnut-Hebei Beibu Machinery Technology Co.,LTD

Want to know details of China New Policy for Africa Groundnut? Beibu Machinery will share knowledge of groundnut cleaning machine and new policy for you. Click the link to get more information.

Nov. 28, 2024

Want to know details of SEED CLEANING MACHINE READY Beibu Machinery will share knowledge of destoner , seed cleaning machinery , air screen cleaner for you.

Sep. 01, 2024

Beibu Machinery participated in the 2024 China International Sesame Conference

Under the influence of factors such as intensified geopolitical conflicts

Apr. 18, 2024

how seed coating machine work ?

Want to know details of how seed coating machine work ? ? Beibu Machinery will share knowledge of seed coating machine in seed processing plant for you. Click the link to get more information.

Jul. 19, 2024

The latest sesame cleaning machine experiment

Want to know details of The latest sesame cleaning machine experiment ? Beibu Machinery will share knowledge of mobile grain cleaner , seed gravity separator , sesame seed cleaning machine price for you.

Beibu Machinery

Not choosing expensive equipment, but the most suitable grain cleaning solution

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

Leave Your Message