Explore the latest in grain cleaning machines, unravelling key innovations, industry benchmarks, and high-efficiency lines. Discover how Grains Cleaning Processing Line meets the evolving demands of quality grain processing, from technical specs to real project applications.

See Product Details Grains Cleaning Processing LineIndustry Trends: The Evolution of Grain Cleaning Machines in 2024

Latest market research by Grand View Research (source) estimates the grain cleaning equipment market to surpass USD 1.8 billion by 2027, growing at a CAGR of 4.2%. Factors contributing to this surge include the adoption of advanced gravity grain cleaner technologies, and specialty equipment for seeds such as grass seed cleaning equipment.

Product Specifications: Grain Cleaning Equipment Parameters

Key Parameters for Leading Grain Cleaning Machines (2024)

| Model | Type | Capacity (t/h) | Cleaning Efficiency (%) | Power (kW) | Material | Standard Certification | Application |

|---|---|---|---|---|---|---|---|

| GCL-60 | Gravity Table Grain Cleaner | 6-8 | 99.2 | 7.5 | 304 Stainless Steel | ISO 9001:2015, CE | Corn, Wheat, Beans |

| GCL-120 | Grass Seed Cleaning Equipment | 12-15 | 98.7 | 13.5 | 316 Stainless Steel | ANSI, FDA-GMP | Grass Seeds, Barley |

| GCL-200 | Combined Cleaner | 20-25 | 97.9 | 18.5 | Carbon Steel + Coating | ISO 14001 | Rice, Oats, Millet |

| GCL-PRO | Multi-Stage Grain Cleaning Processing Line | 28-32 | 99.5 | 24.0 | Heavy-Duty Stainless Steel | CE, RoHS | All Grains & Seeds |

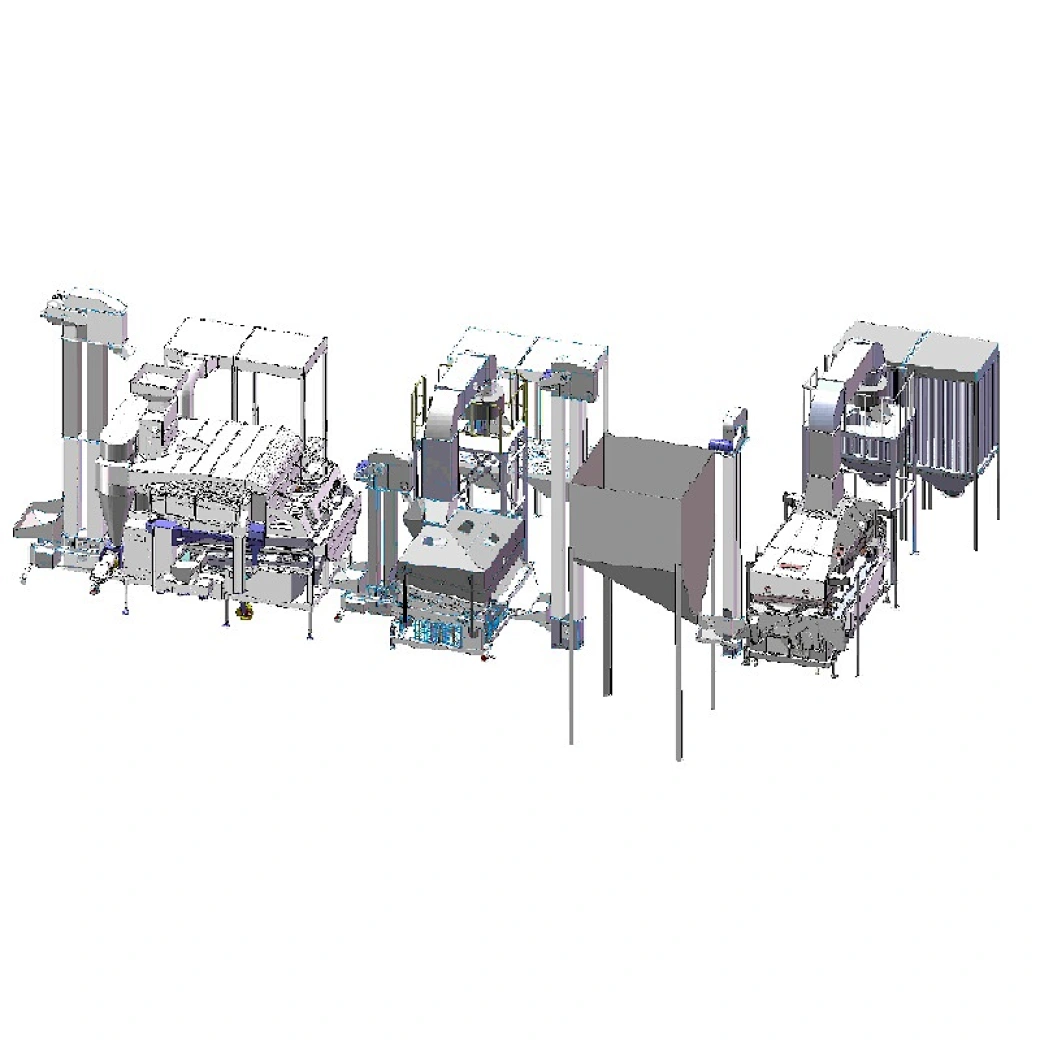

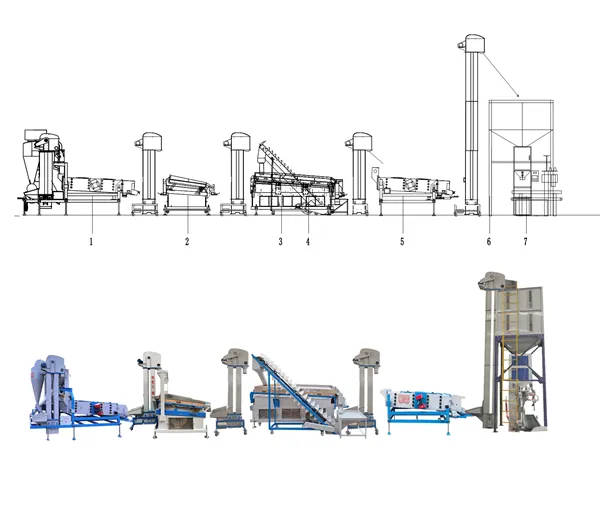

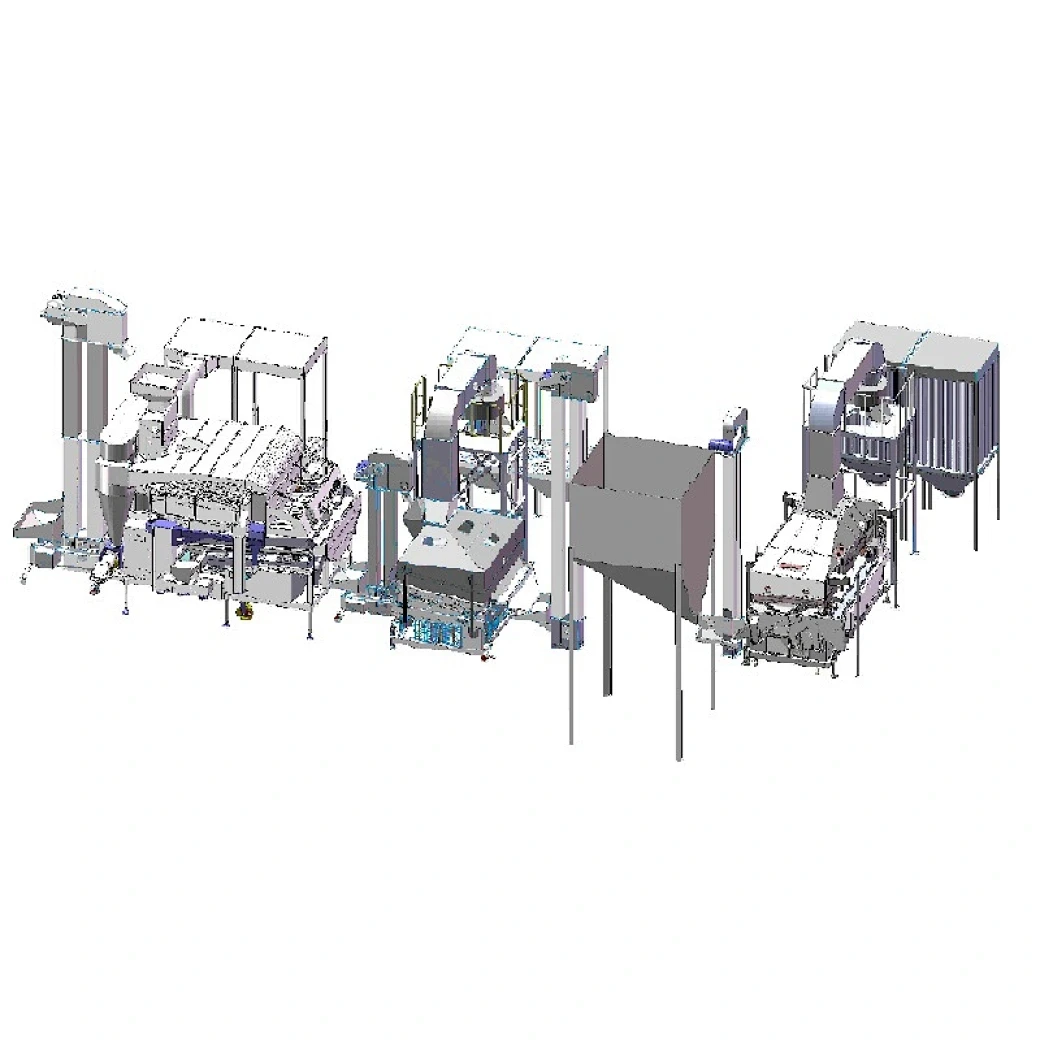

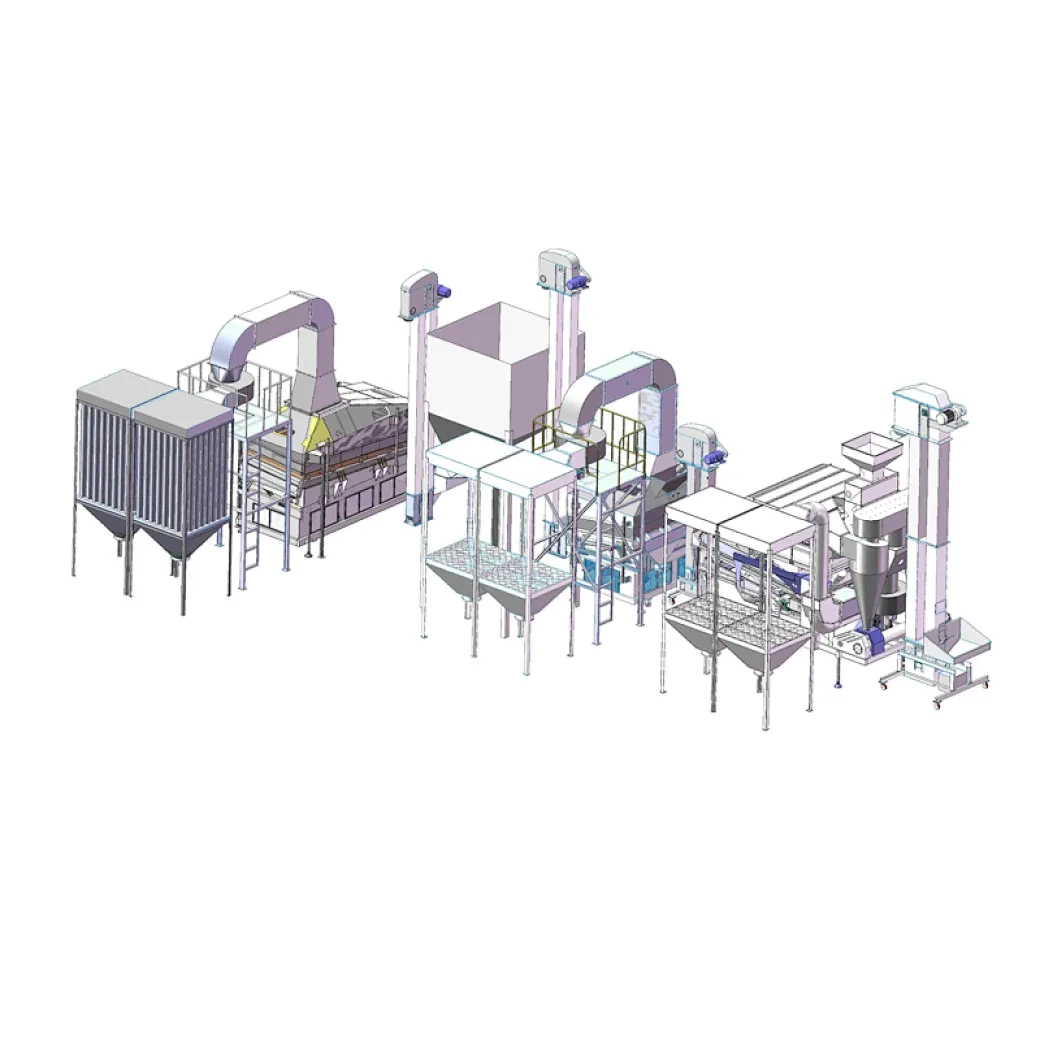

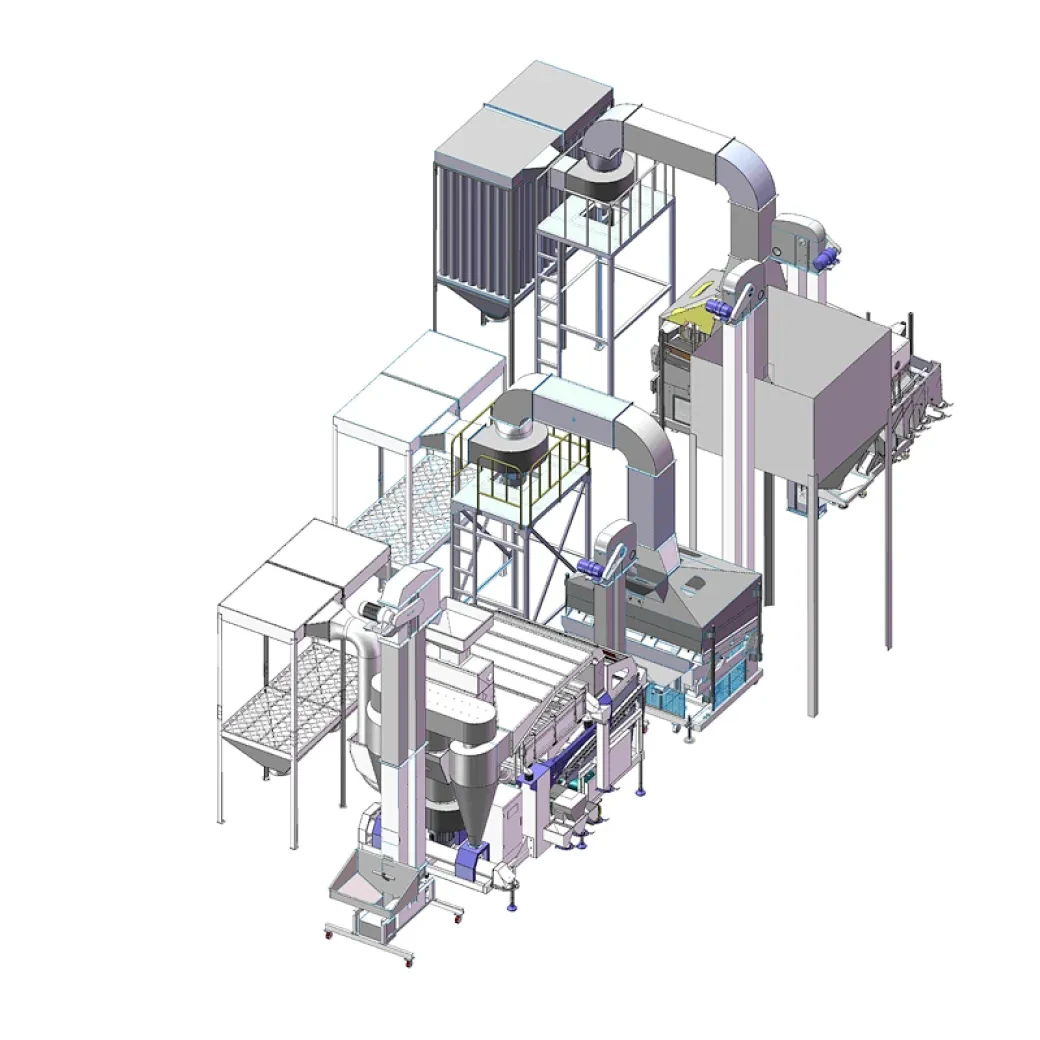

Manufacturing & Process Flow Explained

The Grains Cleaning Processing Line integrates automated, modular stations to maximize throughput and cleaning efficiency. Below is an illustrated workflow:

Receiving hopper, conveyor system

Material: Carbon steel (powder coated)

Removes large impurities

Rotary drum/Sieve, galvanized steel

Density-based separation

316 SS deck, low-vibration mounts

Removes stones, heavy particles

Air-blown jet, ISO-calibrated

Extracts ferrous metals

High-coercivity neodymium magnets

Final sieve, aspiration, grading

CNC-cut stainless mesh

Conveyors & silos, resin-coated steel

- Materials: All contact parts are made of 304/316 stainless steel—highly resistant to corrosion, food-grade compliant, and durable for intensive operation (expected lifespan: 12-18 years under average use).

- Manufacturing: Core components are CNC machined for ±0.1 mm tolerance. Key junctions undergo pressure testing (EN 1092-1) and magnetic inspections for safety integrity.

- Coatings & Protection: Non-contact frames feature double-layer powder coating (ASTM B117 certified) for anti-rust and anti-alkali resistance.

- Industry Certification: Each line is delivered with full test reports, process flow documentation, compliance with ISO 9001, CE, RoHS, and, for food use, FDA food-grade standard.

Technology Advantages of Modern Grain Cleaning Machines

- Ultra-High Precision Gravity Grain Cleaner: Advanced airflow and gravity-driven tables ensure cleaning accuracy >99.2%, reducing contaminant levels to under 0.05%—critical for export-grade cereals and seeds.

- Energy Efficiency: Use of low-drag motors, inverter-controlled fans, and precision sieves reduce energy consumption by up to 18% versus legacy designs (3rd-party test: TÜV Rheinland, 2023).

- Wear-Resistant Construction: All internal chutes, screens, and impellers are made using abrasion-resistant stainless. Real-life service cycles reach >30,000 hours before scheduled maintenance.

- Smart Sensors & Automation: Built-in dust, pressure, and vibration sensors allow for remote monitoring, predictive maintenance and remote alarm functions.

- Low Residue/Changeover Time: Innovative quick-release mechanisms cut cleaning changeover for different grain types to as little as 40 minutes.

- Dust-Free Environment: All grain cleaning machines integrate EN/ISO standard aspirators and cyclone dust collectors, ensuring operator safety and regulatory compliance (OSHA, EU-ATEX).

Data Visualization: Performance & Efficiency Analysis

Leading Manufacturers: Grain Cleaning Machines

| Provider | Main Products | Annual Installations | Certifications | Customization | Support |

|---|---|---|---|---|---|

| BEIBU Cleaner | Gravity grain cleaner, grass seed cleaning equipment, full processing line | 550+ | ISO, CE, FDA | Full line tailor-made design | 24/7 expert team, global install |

| Satake | Destoners, rotary pre-cleaners | 440+ | ISO, ANSI | Standard models | Regional agents |

| Bühler Group | Sifters, combiners, air classifiers | 470+ | CE, ATEX | Partial line customization | 24h helpdesk |

| Westrup | Fine seed graders, gravity tables | 320+ | CE, ISO 45001 | Component-based | Email/phone, training |

Tailored Solutions: Custom Grain Cleaning Machines & Processing Line

Each grain type poses unique cleaning challenges—foreign seed contamination, density variance, seed coat fragility, and dust emission all require bespoke engineering.

The Grains Cleaning Processing Line can be configured according to:

- Input grain type, bulk density and impurity percentage

- Output requirement (purity grade, capacity)

- Integrated gravity table vs. multi-stage air separation

- Modular installation: on-site retrofit or green-field plant

- Material upgrades for high-corrosion or moist environments (316L SS, PTFE coatings)

- Automation & PLC integration with user-friendly HMI

- Compliant with destination-country standards (e.g., ANSI, GOST, Bureau Veritas)

Application Cases: Real-World Success and Results

Case Study: Kazakh Grain Export Terminal (2023)

- Challenge: Consistent cleaning of mixed wheat/barley at 26 t/h, seed impurity for EU market.

- Solution: Full grain cleaning machines line with gravity table, magnetic separator, and programmable pre-cleaning.

- Results: Yield loss reduced by 1.7%, energy costs down 13%, 15% faster output. Customer received ISO 22000 food safety certification.

Feedback: Indonesian Rice Cooperative

"Switching to the Grains Cleaning Processing Line allowed us to upgrade 18-year-old systems—annual output rose by 24%, machine changeovers are below 1 hour, and our export clients in Japan confirmed zero cross-contamination claims post-install."

- Food processing (wheat, rice, corn, beans)

- Seed multiplication and packaging

- Breweries/Maltsters (barley, rye)

- Agro-exporters

- Feed manufacturing

- Ethanol & starch plants (corn)

FAQ & Professional Terminology

-

Q1: What is the main material used in grain cleaning machines for food-grade applications?

A: 304/316 stainless steel is standard, meeting FDA and EU food-contact requirements, offering corrosion resistance and long-term durability. -

Q2: Which standards must a gravity grain cleaner comply with?

A: Common standards include ISO 9001 for quality, CE marking for safety, and if for export to the US, FDA GMP for food safety assurance. -

Q3: How does the gravity separation process work?

A: It uses vibratory tables and calibrated airflow to stratify kernels by density, efficiently segregating stones, lighter chaff, and foreign weed seeds. -

Q4: What is the difference between a gravity table and rotary drum pre-cleaner?

A: Gravity tables target density differences; rotary pre-cleaners remove coarse foreign matter. Integration achieves higher final purity. -

Q5: What installation standards are applied?

A: Equipment is supplied per EN 1090 and ISO 14122 (safety, access platforms). Electrical panels follow UL or IEC standard as required. -

Q6: Can I get product qualification/certification support for exports?

A: Yes, full documentation (ISO/CE/FDA/RoHS) and testing reports included for plant start-up and customs clearance. -

Q7: Is there a standard warranty and after-sales service period?

A: All grain cleaning machines carry a 2-year warranty, with lifetime technical support and global parts logistics.

Delivery Time, Warranty & Customer Support

- Standard models: 21-35 days from payment confirmation

- Custom lines: 50-70 days, depending on configuration and compliance needs

Warranty:

- 24 months on all mechanical & electrical components; extended warranty options up to 5 years available

Support:

- 24/7 technical hotline and online diagnostics

- On-site installation, commissioning and operator training (in over 30+ countries)

- Full machine operation and maintenance manuals in English, Russian, Spanish, Arabic etc.

Conclusion & References

Sep. 14, 2024

Mid-Automn Festival And harvest

Feb. 20, 2025

Beans in Mexico-Hebei Beibu Machinery Technology Co.,LTD

Jan. 24, 2024

Magnetic Separator for removing hard soil and clods

Apr. 23, 2024

Beibu Machinery participated in the 2024 China Feed Industry Exhibition

Jun. 03, 2024

Coffee Bean Cleaning Processing Line in Guinea-Hebei Beibu Machinery Technology Co.,LTD

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.