- Overview: The Essential Role of a Grinder to Make Peanut Butter

- Peanut Butter Market Insights and Data-driven Impact

- Technical Advancements in Peanut Butter Grinders

- Manufacturer Comparison: Selecting the Best Peanut Grinder

- Customization Solutions: Tailoring the Grinder for Your Production Needs

- Real-world Applications: Success Cases Across Industries

- Conclusion: How Choosing the Right Grinder to Make Peanut Butter Transforms Production

(grinder to make peanut butter)

Overview: The Essential Role of a Grinder to Make Peanut Butter

In modern food processing, the grinder to make peanut butter

is a cornerstone of efficient, consistent, and scalable production. Whether for artisanal peanut butter startups or full-scale industrial facilities, choosing the right equipment ensures quality, texture, and nutritional value are maintained at every step. Peanut butter, derived from ground roasted peanuts, is not just a favorite spread but also a key ingredient in confectionery, baked goods, and health foods. Understanding the machinery behind its production is crucial for businesses seeking to compete in a rapidly expanding global market.

Peanut Butter Market Insights and Data-driven Impact

The peanut butter market is experiencing unprecedented growth, projected to reach $5.3 billion by 2028 with a CAGR of 6.8% from 2022 to 2028, according to industry reports. This surge is fueled by health-conscious consumers, demand for plant-based protein, and rising popularity in emerging economies. As production scales, so does the necessity for efficient, hygienic, and reliable peanut grinders to make peanut butter. Notably, automation in the grinding process can improve output by 25-40% while reducing energy costs. Leading manufacturers offer continuous grinding solutions capable of processing up to 1200 kilograms per hour, catering to large-volume requirements seamlessly.

Technical Advancements in Peanut Butter Grinders

Modern peanut grinder technology has evolved far beyond simple rotary blades. Today's equipment incorporates colloid mill, stone grinding, and roller technology, delivering unparalleled consistency, precise particle size reduction, and gentle processing to retain essential nutrients and flavors. Innovations in stainless steel construction ensure compliance with rigorous sanitary standards and ease of cleaning. Advanced grinders now include features such as:

- Variable speed controls for customized texture

- Cooling systems to prevent heat damage

- Automated feeding for continuous, uniform processing

- Interchangeable grinding plates for diverse product lines

- Integrated safety systems to reduce workplace incidents

Manufacturer Comparison: Selecting the Best Peanut Grinder

Evaluating different peanut butter grinder brands requires careful attention to throughput, durability, maintenance, and customization options. The following table summarizes key data from leading manufacturers:

| Manufacturer | Model | Throughput (kg/h) | Particle Size (microns) | Material | Automation | Warranty |

|---|---|---|---|---|---|---|

| ProNutri Machinery | PN-1200 | 1200 | <15 | 304 SS | Full | 3 Years |

| Golden Mill Equipment | GM-500 | 500 | 20 | 316 SS | Semi | 2 Years |

| NutTech Solutions | NT-750 | 750 | 18 | 304 SS | Full | 3 Years |

| SuperGrind Co. | SG-400 | 400 | 22 | 304 SS | Manual | 1 Year |

Clearly, the ideal peanut grinder for peanut butter selection hinges on production needs, hygiene requirements, and expected ROI. High-throughput, full-automation machines suit large factories, while smaller or semi-automatic models help small businesses control costs.

Customization Solutions: Tailoring the Grinder for Your Production Needs

No two peanut butter producers are identical, and a one-size-fits-all peanut grinder rarely maximizes efficiency. Top manufacturers offer tailored features such as:

- Adjustable grinding chambers for diverse nut types and texture profiles

- Modular add-ons—homogenizers, vacuum de-aerators, oil injectors—for specialized recipes

- Touch-panel control systems for batch records and process optimization

- Customizable input/output connections for easy integration with bottling or packaging lines

- Sanitary design options (CIP/SIP) for regulatory compliance and reduced cross-contamination

Real-world Applications: Success Cases Across Industries

The versatility of the peanut grinder to make peanut butter extends far beyond classic sandwich spreads. In recent years, several companies have demonstrated transformative results:

Case 1: Gourmet Boutique Peanut Butter

A craft producer in Europe integrated a high-capacity colloid mill, which enabled them to increase production by 32% and introduce almond and cashew spread lines with rapid changeovers.

Case 2: Industrial-Scale Manufacturer

An Asian food group adopted a fully automated peanut grinder for peanut butter with real-time quality sensors. The result was consistent particle size below 16 microns, 20% reduction in batch rejects, and implementation of cloud-based monitoring across shifts.

Case 3: Co-manufacturing Solution

A North American snack foods brand outsourced production, requiring custom feeding systems to accommodate various nut blends. Customization efforts led to 78% faster changeover times and a significant drop in allergen cross-contamination.

These cases highlight the importance of the right peanut grinder to make peanut butter, adapting to markets, safety protocols, and growth needs.

Conclusion: How Choosing the Right Grinder to Make Peanut Butter Transforms Production

Selecting an optimal grinder to make peanut butter is crucial for scaling up, ensuring product quality, and meeting modern consumer demand. As the industry grows, producers must invest in robust, efficient, and customizable equipment that accommodates both volume and niche focuses. By leveraging technological innovation, conducting thorough manufacturer comparisons, pursuing tailored solutions, and learning from real-world applications, food businesses will be well-positioned for profitability and sustainability in the thriving peanut butter market. The future belongs to those who innovate—one grind at a time.

(grinder to make peanut butter)

FAQS on grinder to make peanut butter

Q: What type of grinder should I use to make peanut butter at home?

A: You should use a peanut grinder specifically designed to make peanut butter. These grinders have strong motors and durable blades for processing nuts. Electric models are often preferred for ease and consistency.Q: Can I use a regular food processor as a grinder to make peanut butter?

A: Yes, a powerful food processor can serve as a grinder to make peanut butter. However, dedicated peanut butter grinders usually yield a smoother texture. Always ensure the appliance can handle hard nuts.Q: What features should a peanut grinder to make peanut butter have?

A: A good peanut grinder for peanut butter should have adjustable settings, a powerful motor, and sturdy stainless steel blades. It should also be easy to clean. Safety features are an added bonus.Q: Is it cheaper to make peanut butter at home using a peanut grinder?

A: Making peanut butter at home with a grinder can be more cost-effective. You control the ingredients and portion size. Plus, homemade peanut butter is often healthier.Q: How do I clean a grinder after making peanut butter?

A: Disassemble the grinder and wash all removable parts with warm, soapy water. Use a brush to remove any stuck peanut residue. Thorough drying prevents rust and keeps your peanut grinder in good shape.Jan. 22, 2025

Near to China New Year-Hebei Beibu Machinery Technology Co.,LTD

May. 27, 2024

Dec. 17, 2024

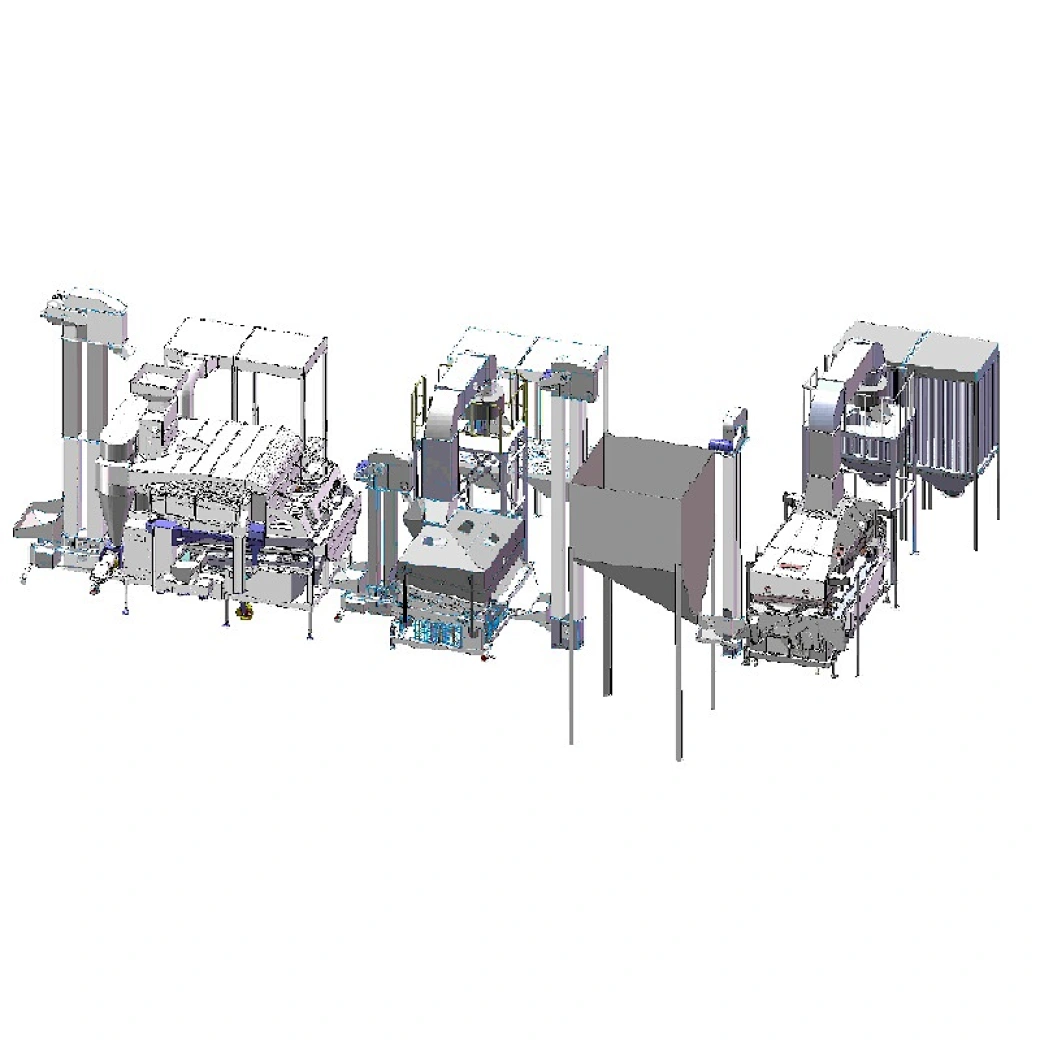

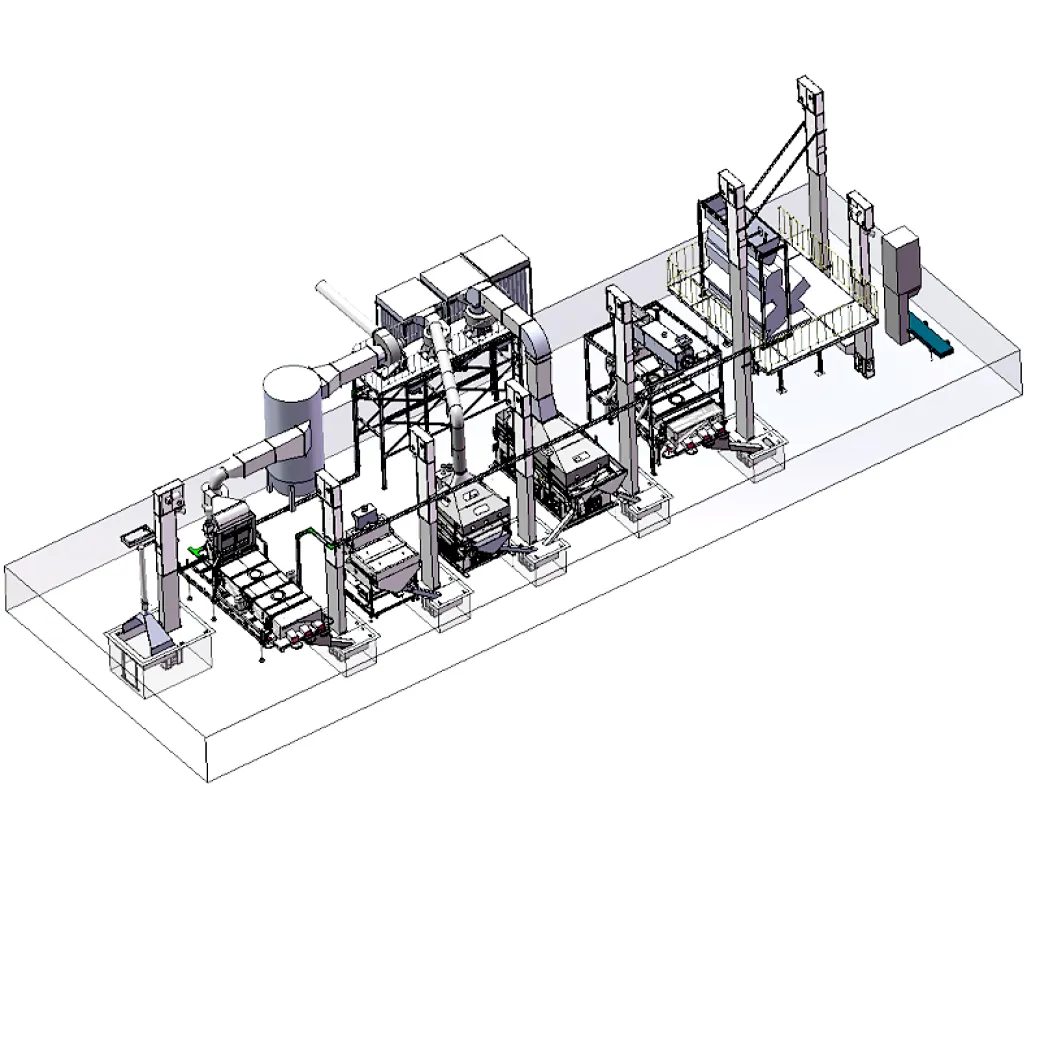

Beibu Machinery-Grain seed production line continues to deliver

Apr. 09, 2024

Popular Grain Cleaning and Grading Machine-Hebei Beibu Machinery Technology Co.,LTD

Dec. 20, 2024

Hibiscus flower processing machine

Jan. 20, 2025

Sesame Cleaning Machine Delivery-Hebei Beibu Machinery Technology Co.,LTD

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.