The Hand Sewing Machine has become a critical tool in the manufacturing of polypropylene (PP) bags, offering a blend of durability, efficiency, and adaptability. Designed for industrial and commercial use, this machine is tailored to meet the demands of diverse applications, particularly in regions like Africa, where it plays a pivotal role in grain bag production. This article delves into the technical specifications, functional advantages, and real-world applications of the Hand Sewing Machine, while also exploring the expertise of its manufacturer, Hebei Beibu Machinery Technology Co., Ltd..

Product Overview

The Hand Sewing Machine is a specialized device engineered for the precise and efficient sewing of polypropylene (PP) bags. Its design incorporates a range of configurations, including single-thread, double-thread, cable-powered, and battery-operated models, ensuring adaptability to different operational needs. The machine is particularly renowned for its use in the African market, where it is widely employed for sewing grain bags, a critical component in agricultural supply chains.

One of the standout features of this machine is its robust construction, which ensures longevity and reliability in high-volume production environments. The Hand Sewing Machine is equipped with advanced motor technology, enabling it to operate at a maximum speed of 22,000 RPM, as noted in its technical specifications. This capability makes it a preferred choice for manufacturers seeking to optimize productivity while maintaining high-quality output.

Technical Specifications

The Hand Sewing Machine is built to meet rigorous industrial standards, as evidenced by its detailed technical specifications. Below is a comprehensive table outlining the key parameters of the machine:

| Specification | Details |

|---|---|

| Needle Type | GK9 |

| Thread Specification | 21 2*3 Nylon Threads |

| Stitch Length | 7-11mm |

| Max. Sewing Thickness | 0.2-6mm |

| Max. Sewing Speed | 2700/m |

| Motor Power | 210W (Maximum Speed: 22,000 RPM) |

| Dimensions | 29.3cm x 21cm x 28.5cm |

| Weight | 3KG |

The machine’s specifications highlight its versatility and efficiency. The GK9 needle type ensures precision in stitching, while the 21 2*3 nylon threads provide durability and resistance to wear. The adjustable stitch length (7-11mm) allows for customization based on the specific requirements of the PP bags being produced. Additionally, the machine’s ability to handle materials with a thickness of 0.2-6mm makes it suitable for a wide range of applications, from lightweight to heavy-duty bag manufacturing.

Key Features and Advantages

The Hand Sewing Machine offers several advantages that make it a preferred choice for manufacturers. One of its primary benefits is its portability, especially in the battery-operated model, which allows for flexible use in remote areas without access to a power supply. This feature is particularly beneficial in regions like Africa, where the machine is commonly used for grain bag production.

Another notable feature is the machine’s high-speed operation, which enhances productivity. With a maximum speed of 2700 stitches per minute, the Hand Sewing Machine can significantly reduce production time, making it an ideal solution for businesses aiming to meet high demand. The 210W motor ensures consistent performance, while the 22,000 RPM capability allows for rapid and efficient stitching.

The machine’s compact design (29.3cm x 21cm x 28.5cm) and lightweight (3KG) further contribute to its portability and ease of use. These attributes make it suitable for both small-scale operations and large manufacturing facilities. Additionally, the machine’s durability is reinforced by its robust construction, which minimizes the need for frequent maintenance and repairs.

Applications and Industry Use Cases

The Hand Sewing Machine is primarily used for sewing polypropylene (PP) bags, but its versatility extends to other applications. The machine’s adaptability is evident in the various configurations available, including single-thread, double-thread, cable-powered, and battery-operated models. These options cater to different production environments and requirements.

One of the most significant applications of the Hand Sewing Machine is in the African market, where it is widely used for sewing grain bags. The machine’s ability to handle thick materials (up to 6mm) and its portability make it an essential tool for agricultural producers. According to NIST (National Institute of Standards and Technology), the integration of reliable and efficient machinery is crucial for enhancing agricultural productivity and ensuring food security in developing regions.

In addition to grain bag production, the Hand Sewing Machine is employed in the manufacturing of various PP products, including packaging materials, industrial bags, and other custom applications. Its ability to accommodate different thread specifications and stitch lengths ensures that it can meet the diverse needs of manufacturers.

Company Background: Hebei Beibu Machinery Technology Co., Ltd.

The Hebei Beibu Machinery Technology Co., Ltd. is a leading manufacturer of industrial sewing machines, with a strong focus on innovation and quality. Based in Hebei, China, the company has established itself as a reliable supplier of machinery for the PP bag manufacturing industry. Their commitment to research and development has enabled them to produce machines that meet global standards while addressing the specific needs of their clients.

According to NIST, the role of manufacturers in driving technological advancements cannot be overstated. Hebei Beibu Machinery Technology Co., Ltd. exemplifies this by continuously improving its product offerings to align with evolving industry demands. The company’s dedication to quality is reflected in the Hand Sewing Machine, which is designed to deliver exceptional performance and reliability.

Conclusion

The Hand Sewing Machine represents a significant advancement in the field of industrial sewing technology. Its robust design, high-speed operation, and adaptability make it an indispensable tool for manufacturers, particularly in the production of PP bags. The machine’s versatility, as demonstrated by its various configurations, ensures that it can cater to a wide range of applications, from agricultural use in Africa to industrial packaging solutions worldwide.

As highlighted by NIST, the integration of reliable and efficient machinery is essential for driving economic growth and innovation. Hebei Beibu Machinery Technology Co., Ltd. continues to play a vital role in this process by delivering high-quality products that meet the evolving needs of the market. For businesses seeking to enhance their production capabilities, the Hand Sewing Machine offers a compelling solution that combines performance, durability, and adaptability.

Video Demonstration

Watch the Hand Sewing Machine in action:

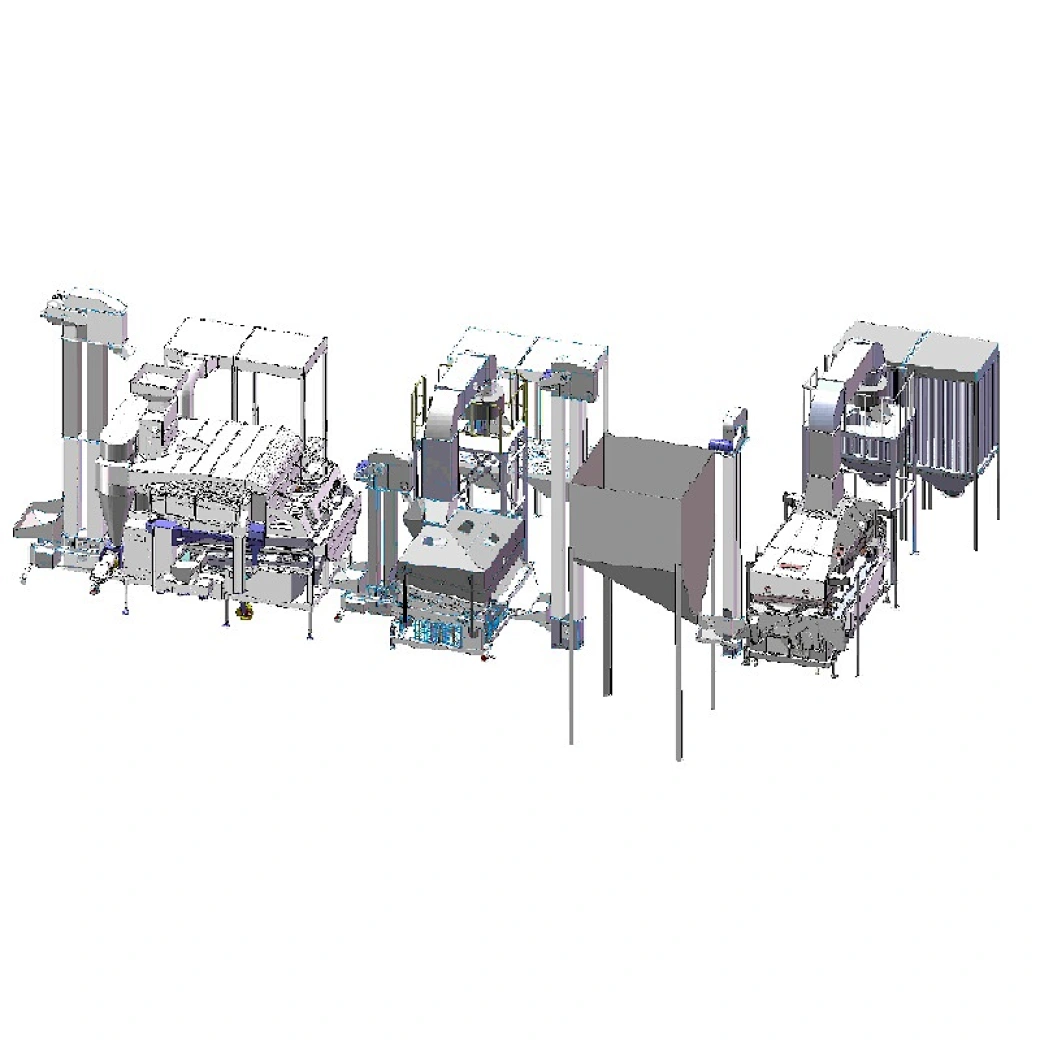

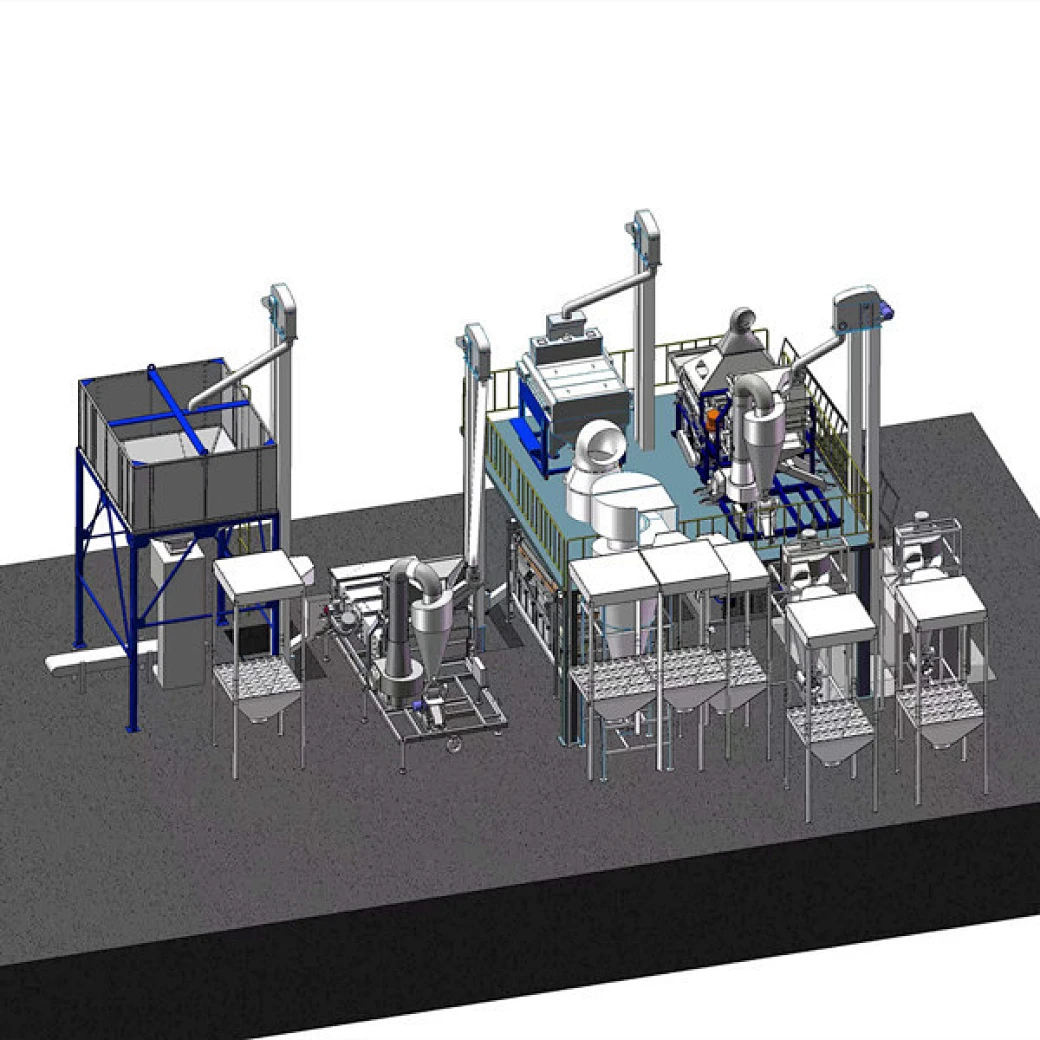

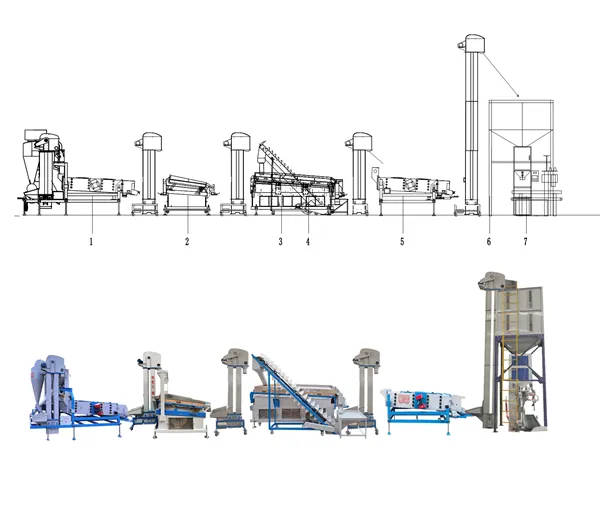

Product Images

Explore the Hand Sewing Machine in detail:

References

National Institute of Standards and Technology (NIST) – "Driving Innovation Through Measurement Science and Standards."

Jun. 03, 2024

Coffee Bean Cleaning Processing Line in Guinea-Hebei Beibu Machinery Technology Co.,LTD

Aug. 11, 2024

BEIBU machinery-2024 China Changji Seed Exhibition and Trade Fair ended perfectly!

Feb. 20, 2025

Beans in Mexico-Hebei Beibu Machinery Technology Co.,LTD

Mar. 26, 2024

Hot Selling for Sesame Cleaning Machine-Hebei Beibu Machinery Technology CO.,LTD

Nov. 08, 2024

Grain cleaning machines to Central Asia

May. 21, 2024

Grain Cleaning Machine in Big Capacity-Hebei Beibu Machinery Technology Co.,LTD

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.