In the competitive world of grain processing, purity is paramount. Achieving a flawless final product free from stones, glass, metal, and other heavy impurities is not just a quality standard—it's a market differentiator. This comprehensive guide delves into the core technology that makes this possible: the grain destoner machine. We will explore industry trends, technical specifications, and how leading models like the 5QSC Destoner are revolutionizing grain purification for suppliers worldwide.

The Unseen Contaminant: Why Grain Purity is a Growing Global Concern

The global demand for high-quality, safe-to-eat grains is at an all-time high. According to data from the Food and Agriculture Organization (FAO), global cereal production is projected to exceed 2.8 billion tonnes. With this massive scale comes an increased risk of contamination. Stones and other heavy foreign materials can enter the supply chain at various stages, from harvesting to transportation. The consequences are severe:

- Equipment Damage: Stones can cause catastrophic damage to downstream processing equipment like grinders, hullers, and flakers, leading to costly downtime and repairs.

- Product Recall: A single contaminated batch can lead to expensive product recalls, damaging brand reputation and consumer trust.

- Reduced Market Value: Grain lots with higher impurity levels fetch lower prices on the international market.

This has fueled a significant trend towards investing in advanced sorting technology. A modern grain destoner machine is no longer a luxury but a critical control point (CCP) in any HACCP (Hazard Analysis and Critical Control Points) plan for a serious grain processor. The market for agricultural sorting equipment is expected to grow at a CAGR of 6.5% through 2028, with destoning technology at the forefront of this expansion.

Deconstructing the Destoner: The Science of Specific Gravity Separation

At its core, a grain destoner machine operates on a simple yet elegant principle of physics: specific gravity. It separates materials based on their density differences. While grains have a certain density, contaminants like stones, soil clods, and glass fragments are significantly denser.

The process, often referred to as fluidization, works as follows:

- Input & Vibration: Grain mixed with impurities is fed onto an inclined, vibrating screen deck. The deck's powerful, dual-motor vibration stratifies the material.

- Fluidization with Air: A powerful fan system forces a uniform stream of air up through the screen mesh. This air pressure is precisely calibrated to lift the lighter grains, creating a "fluidized bed" where they float and flow downhill towards the clean grain outlet.

- Gravity's Pull: The heavier contaminants (stones) are not lifted by the air. Due to the screen's vibration and inclination, they remain in contact with the screen surface and travel "uphill" against the flow of the grain, eventually being discharged from a separate stone outlet.

This sophisticated interplay of vibration, air pressure, and gravity ensures an exceptionally high degree of separation, often achieving purity levels exceeding 99.9%. A multi grain destoner machine can be calibrated to handle a wide variety of products, from tiny sesame seeds to larger coffee beans, by adjusting these three key parameters.

Introducing the 5QSC Destoner: Setting the Benchmark for Purity and Efficiency

When searching for reliable destoner machine suppliers, discerning buyers look for a combination of performance, durability, and support. The 5QSC Destoner series, available from leading manufacturers like Beibu, exemplifies these qualities. Engineered for high-capacity, continuous operation, the 5QSC model is a testament to precision engineering in agricultural processing.

The 5QSC is not just a machine; it's an integrated purification solution. Its design focuses on maximizing separation efficiency while minimizing grain loss and energy consumption. Key features that set it apart include a fully adjustable screen deck, a precision negative pressure fan system for dust control, and dual vibratory motors for consistent, powerful stratification. This makes it an ideal multi grain destoner machine for processors handling diverse product lines.

Discover the 5QSC Destoner SeriesDeep Dive: Technical Specifications of the 5QSC Grain Destoner Machine

Understanding the technical parameters is crucial for selecting the right machine. Below is a detailed breakdown of the 5QSC series specifications. These figures demonstrate the machine's capacity to adapt to various operational scales, a key consideration for growing businesses.

| Model | Capacity (T/H) | Power (kW) | Screen Size (mm) | Air Volume (m³/h) | Weight (kg) | Dimensions (L*W*H, mm) |

|---|---|---|---|---|---|---|

| 5QSC-5 | 5.0-6.0 | 5.5 + 1.1 | 1250 x 1400 | 8000-9500 | 850 | 2000 x 1650 x 1700 |

| 5QSC-7 | 7.0-8.0 | 7.5 + 1.5 | 1250 x 1800 | 10000-12000 | 1100 | 2000 x 2050 x 1750 |

| 5QSC-10 | 10.0-12.0 | 11 + 1.5 | 1500 x 2000 | 12000-15000 | 1500 | 2200 x 2250 x 1800 |

| 5QSC-15 | 15.0-18.0 | 15 + 2.2 | 1500 x 2500 | 16000-19000 | 1950 | 2200 x 2750 x 1900 |

Note: Capacity is based on wheat with a moisture content of ≤13% and impurity rate of ≤2%. Actual performance may vary based on grain type, moisture, and impurity levels. Power is listed as (Fan Motor + Vibration Motor).

Data-Driven Performance: Visualizing the 5QSC Advantage

Data provides clarity. To understand the real-world impact of the 5QSC grain destoner machine, we've visualized its performance metrics and application scope. These charts illustrate why it's a preferred choice for modern processing facilities.

Separation Efficiency Comparison

Common Applications by Volume

From Blueprint to Powerhouse: The Manufacturing Process Explained

The reliability of a grain destoner machine is a direct result of the quality of its manufacturing process. Reputable destoner machine suppliers follow stringent protocols, combining robust materials with precision engineering. Here’s a look at the typical lifecycle of a 5QSC Destoner.

1. Material Sourcing

High-tensile Q235 carbon steel for the frame; SS304 stainless steel for all grain-contact parts to meet food-grade standards (FDA compliant).

2. Precision Fabrication

Laser cutting and CNC machining for frame components ensures perfect alignment. Screen decks are woven with high-manganese steel for wear resistance.

3. Assembly & Welding

Skilled technicians assemble the frame. Robotic welding is used for critical joints to guarantee structural integrity and a long service life.

4. Quality Control

ISO 9001:2015 certified process. Vibration motors are tested for 48 hours. Air pressure consistency is verified with anemometers.

- Manufacturing Craftsmanship: The core frame is built using robust casting techniques for the motor housing, providing superior vibration dampening. All sheet metal is processed via CNC punching and bending for tolerances within ±0.1mm.

- Detection Standards: Every machine undergoes a rigorous quality assurance protocol. This includes vibration analysis to check for imbalances, airflow uniformity tests across the entire screen deck, and a final performance test using standard grain samples. All machines are CE marked, certifying compliance with European health, safety, and environmental protection standards.

- Service Life & Advantages: With proper maintenance, a 5QSC Destoner is engineered for a service life of over 15 years. Its primary advantages in any application are its energy efficiency (optimized fan blade design reduces power draw) and its low-maintenance vibratory motors, which are sealed and require no regular lubrication.

Versatility in Action: Application Scenarios and Case Studies

The true measure of a multi grain destoner machine is its performance across diverse industries and products. The 5QSC has proven its value in numerous settings, from large-scale commercial grain elevators to specialized coffee processing plants.

Primary Application Industries:

- Grain Milling: Protecting milling equipment by removing stones from wheat, corn, and rye.

- Seed Cleaning: Ensuring high germination rates by providing pure, uncontaminated seeds.

- Bean & Pulse Processing: Critical for products like soybeans, lentils, and chickpeas where consumer safety is paramount.

- Coffee & Cacao Production: Removing foreign objects post-drying to ensure a perfect roast and final product.

- Spice & Nut Processing: Handling products like sesame seeds, peanuts, and cashews with precision.

Case Study: Ethiopian Coffee Cooperative Boosts Export Value

Challenge: A leading coffee cooperative in the Yirgacheffe region of Ethiopia was facing challenges with meeting the stringent purity standards for specialty coffee exports to Europe and North America. Small stones and dried earth clods, similar in size to coffee beans, were leading to batch rejections and reduced profitability.

Solution: The cooperative invested in a 5QSC-7 Grain Destoner Machine. By integrating the machine into their post-hulling processing line, they could precisely calibrate the air pressure and vibration frequency to target the specific density of dried coffee cherries versus the heavier contaminants.

Results:

This success story highlights how a strategic investment in the right grain destoner machine provides a direct and measurable return on investment, transforming a business's market position.

Choosing Your Partner: How to Select the Best Destoner Supplier

The machine itself is only half of the equation. Partnering with the right destoner supplier ensures you receive not only a quality product but also the expertise and support needed for long-term success. Here is a checklist for evaluating potential destoner machine suppliers:

| Evaluation Criterion | Standard Supplier | Premier Supplier (e.g., Beibu) |

|---|---|---|

| Technical Expertise | Offers a standard product catalog. | Provides in-depth consultation, process analysis, and customized solutions. Understands your specific grain type. |

| Manufacturing Transparency | Vague on material sources and standards. | Provides full transparency on materials (e.g., SS304), certifications (ISO, CE), and manufacturing processes. |

| After-Sales Support | Limited to email support, slow response. | Offers comprehensive support including installation guidance, operator training, 24/7 technical help, and a robust spare parts supply chain. |

| Customization Capability | Offers standard models only. ✖ | Can customize dimensions, power requirements, and screen types to fit existing production lines. ✔ |

| Proven Track Record | New to the market or few case studies. | Extensive history with verifiable customer testimonials and international case studies. |

A premier destoner supplier acts as a long-term partner, committed to optimizing your process and maximizing your ROI.

Trust and Assurance: Our Commitment to Quality

We understand that purchasing industrial machinery is a significant investment. That's why we build trust through transparency, guarantees, and unwavering customer support.

- Delivery & Logistics: We offer a streamlined global shipping process, with typical delivery cycles of 30-45 days from order confirmation to port. All machines are securely crated to prevent damage during transit.

- Warranty & Quality Promise: Every 5QSC Grain Destoner Machine comes with a comprehensive 24-month warranty covering all non-wear parts. We guarantee a separation efficiency of over 99.5% for targeted contaminants under specified operating conditions.

- Customer Support: Our support extends beyond the sale. We provide detailed installation manuals, video tutorials, and remote diagnostics support. Our engineers are available to help you fine-tune the machine for new products or changing conditions.

Frequently Asked Questions (FAQ)

The screen deck is typically made from high-manganese steel or woven stainless steel mesh. This is critical because the deck is subject to constant abrasion from the grain and stones. High-manganese steel offers exceptional wear resistance, ensuring a long service life and consistent performance without tearing. For food-grade applications or processing corrosive materials, SS304 or SS316 stainless steel is used to prevent contamination and corrosion.

The negative pressure system, created by the fan, is crucial for two reasons. First, it ensures a controlled and uniform upward airflow through the screen, which is essential for creating a stable fluidized bed. Second, and equally important, it acts as a dust control system. Any dust generated during the process is pulled into the fan system and can be exhausted to a cyclone or bag filter, keeping the operating environment clean and reducing product loss.

Yes, absolutely. The 5QSC series is designed as a multi grain destoner machine. For oily seeds, we may recommend specific screen types with a special coating to prevent oil residue buildup, which could clog the screen apertures. The vibration amplitude and frequency can also be finely tuned to ensure that oily seeds flow freely without sticking, maintaining high separation efficiency.

While both operate on the principle of specific gravity, their primary function differs. A grain destoner machine is designed specifically to remove heavy impurities (like stones) from lighter material (grain). A gravity separator is more versatile and can separate materials with much smaller differences in density. It can be used to grade seeds by weight, removing shriveled, damaged, or insect-bored seeds from the healthy ones. A destoner is a prerequisite for a gravity separator in a full processing line.

The 5QSC is designed for low maintenance. The primary tasks are: 1) Regular inspection and cleaning of the screen deck to ensure no apertures are blocked. 2) Checking the tension of the fan belt (if applicable). 3) Periodically inspecting the rubber vibration absorbers for wear and tear. The vibratory motors are sealed for life and require no lubrication. We recommend a full inspection every 500 hours of operation.

Installation is straightforward. The machine needs to be placed on a solid, level concrete floor and connected to the appropriate power supply. We provide a detailed manual and video guide. Calibration involves adjusting three main parameters: 1) Air volume (via a damper on the fan), 2) Screen deck inclination angle, and 3) Vibration frequency (via the control panel). The process involves feeding a small sample and observing the separation, making small adjustments until clean grain flows to one outlet and stones to the other, with minimal grain loss in the stone outlet.

Look for suppliers with internationally recognized certifications. ISO 9001:2015 demonstrates a commitment to a quality management system in design and manufacturing. The CE Mark is essential for equipment sold in the European Economic Area, indicating it meets high safety, health, and environmental protection requirements. For food-related applications, confirmation that contact parts are made of FDA-compliant materials like SS304 stainless steel provides an extra layer of assurance.

Further Reading & Industry Insights

To deepen your understanding of grain processing technology and standards, we recommend exploring these authoritative sources:

A discussion on the "Importance of Destoning in Modern Milling" can often be found in industry forums like the Grain & Feed Milling Technology Forum. Insights from professionals highlight real-world challenges and solutions. (e.g., World-Grain.com for industry news)

For academic research on the principles of separation, scholarly articles provide in-depth analysis. A relevant study is: "Design and Development of a Destoner for Cleaning Food Grains" published in the International Journal of Current Microbiology and Applied Sciences. (e.g., Search for related articles on ScienceDirect)

Dec. 10, 2024

Coffee Bean Cleaning Machine-Hebei Beibu Machinery Technology Co.,LTD

Dec. 05, 2024

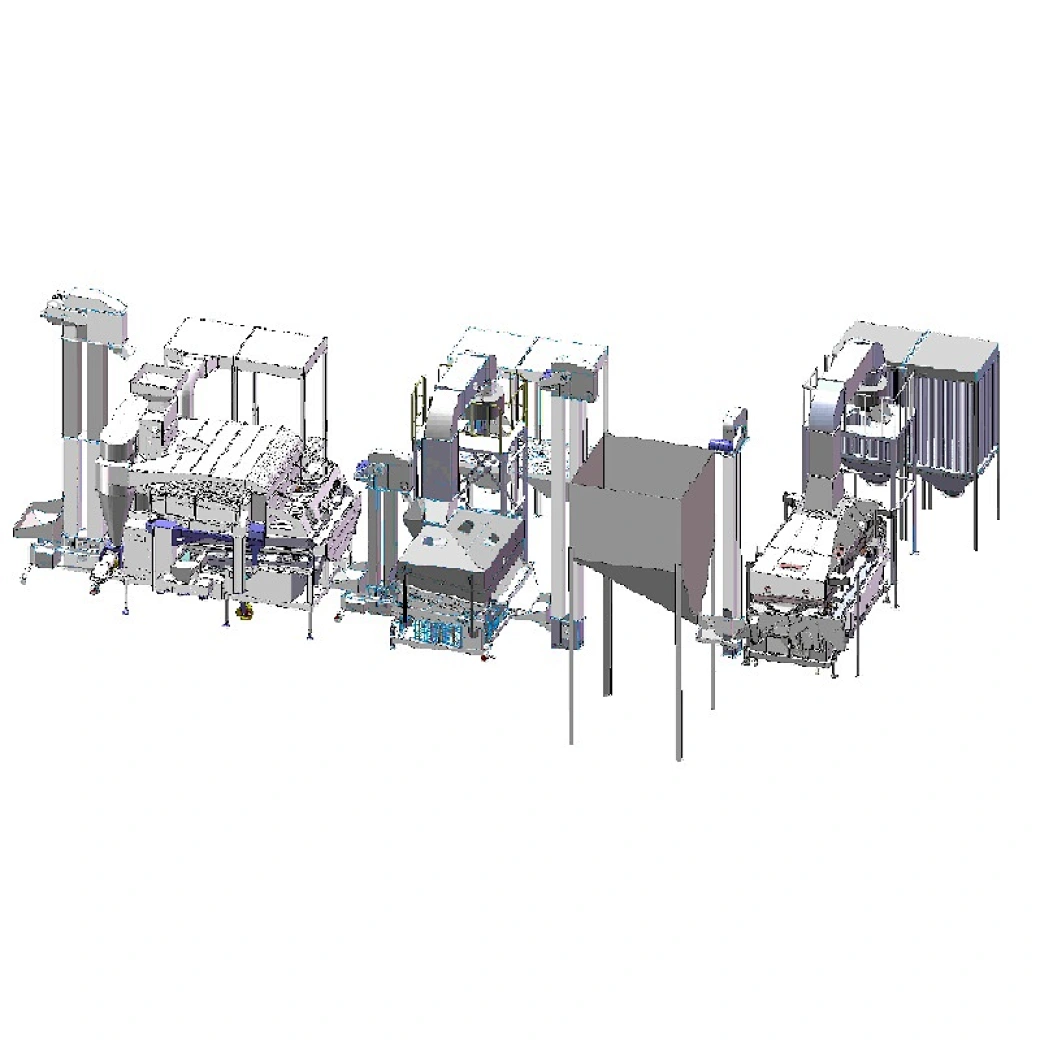

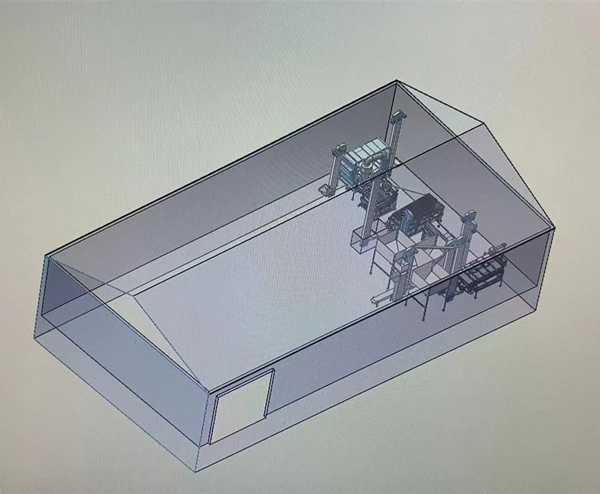

Beibu Machinery-Multiple production lines shipped together

Mar. 28, 2024

Benin Soybean-Hebei Beibu Machinery Technology Co.,LTD

May. 20, 2024

Cassia Seeds Cleaning Machine-Hebei Beibu Machinery Technology Co.,LTD

Jul. 19, 2024

The latest sesame cleaning machine experiment

Apr. 08, 2024

Gravity Separator-Hebei Beibu Machinery Technology Co.,LTD

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.