The rapid evolution of solid-liquid separation and cleaning equipment has made destoner for sale searches surge in food processing, mining, chemical, and environmental industries. Leveraging advanced design, resilient materials, long service lifespan, and international compliance, the 5QSC Destoner sets a new standard in de stoner machine technology, outperforming classic solutions with efficiency, durability, and customization.

- Market size (2023): $695 million USD (source: 360iResearch)

- Destoner CAGR projection (2023-2030): 4.7%

- Growing sectors: Food grain processing, mineral separation, water treatment, plastic waste recycling

- Key trends: Smart automation, IoT-enabled diagnostics, longer wear life, multi-material processing, energy saving, stricter ISO/ANSI/FDA compliance

| Specification | 5QSC Destoner | Leading Competitor A | Leading Competitor B | Industry Average |

|---|---|---|---|---|

| Processing Capacity (t/h) | 5 - 30 | 4 - 16 | 4 - 25 | 3 - 15 |

| Power Consumption (kW) | 3.2 - 9.0 | 3.8 - 12 | 4.5 - 14 | 5.2 - 13 |

| Material | 316L Stainless Steel | 304 Stainless Steel | Mild Steel | 304/316 Steel |

| Service Life (years) | 13+ | 8-10 | 7-10 | 8 |

| Certifications | ISO 9001, ANSI/ASME | ISO 9001 | None | ISO 9001 |

| Separation Rate | 99.5% | 96.8% | 95.7% | 95.9% |

| Automation | Smart IoT/PLC | Manual/Basic | Basic | Basic |

| Warranty | 2 Years (extendable) | 1 Year | 6 Months | 1 Year |

- Material Superiority: 316L Stainless Steel body, resistant to acid, alkali, corrosion, and abrasion. Life expectancy up to 13+ years in salty/brackish and aggressive chemical environments, outlasting most destoner for sale options.

- Precision Manufacturing: CNC & laser-cut parts ensure consistent clearances, high separation efficiency and long-term reliability.

- Energy Efficient Design: Aerodynamic chamber profile reduces air/power requirements by up to 17% over leading de stoner machine rivals.

- Smart Automation: Integrated with PLC, IoT monitoring, supports cloud-based diagnostics, data logging, and real-time alerts.

- High Separation Rate: 99.5%+ physical stone/silica removal, confirmed by third-party SGS lab tests.

- Global Standards Compliance: Built per ISO 9001, EN 1090-2, ANSI/ASME Section VIII.

- Custom Options: Size, inlet/outlet, integration interface, control logic, and accessories tailored for diverse industries.

- Grain Processing: Removes stones/silica/sand from wheat, rice, pulses—~1.2% higher yield vs standard de stoner.

- Mining & Ore Pre-Cleaning: Separates gravel and non-ore inclusions, reducing downstream wear cost by 9%.

- Chemical Industry: For caustic environments, prevents pipe blockages—corrosion index (Salt Spray): 620h+.

- Petrochemical/Refinery: Solids removal improves catalyst bed productivity, 30% less maintenance downtime.

- Municipal Water & Waste: Pre-filtration, protection for submerged/sewage pumps (verified in Beijing, Xuzhou).

- Plastics & Recycling: Pre-separation of rocks/glass from shredded post-consumer waste streams.

Application: River sediment pre-filtration for coal-fired plant

Result: 5QSC Destoner withstood 14 days continuous operation in heavy silt with no blockages, 99.6% separation, cut pump damage by 42% compared to legacy de stoner machine.

| Feature | 5QSC Destoner | Competitor A | Competitor B |

|---|---|---|---|

| Material | 316L Stainless Steel | 304 Stainless Steel | Mild Steel |

| Certifications | ISO 9001, ANSI/ASME, CE | ISO 9001 | - |

| Customization | Full (process, interface, automation, IoT) | Limited | Minimal |

| Warranty | 2 Years (extendable) | 1 Year | 6 Months |

| OEM/ODM Capacity | Yes | No | No |

| Technical Support | 24/7 multilingual, global install | Email/Basic | Email Only |

| Price (USD) | From $3,550 | $3,300 | $2,920 |

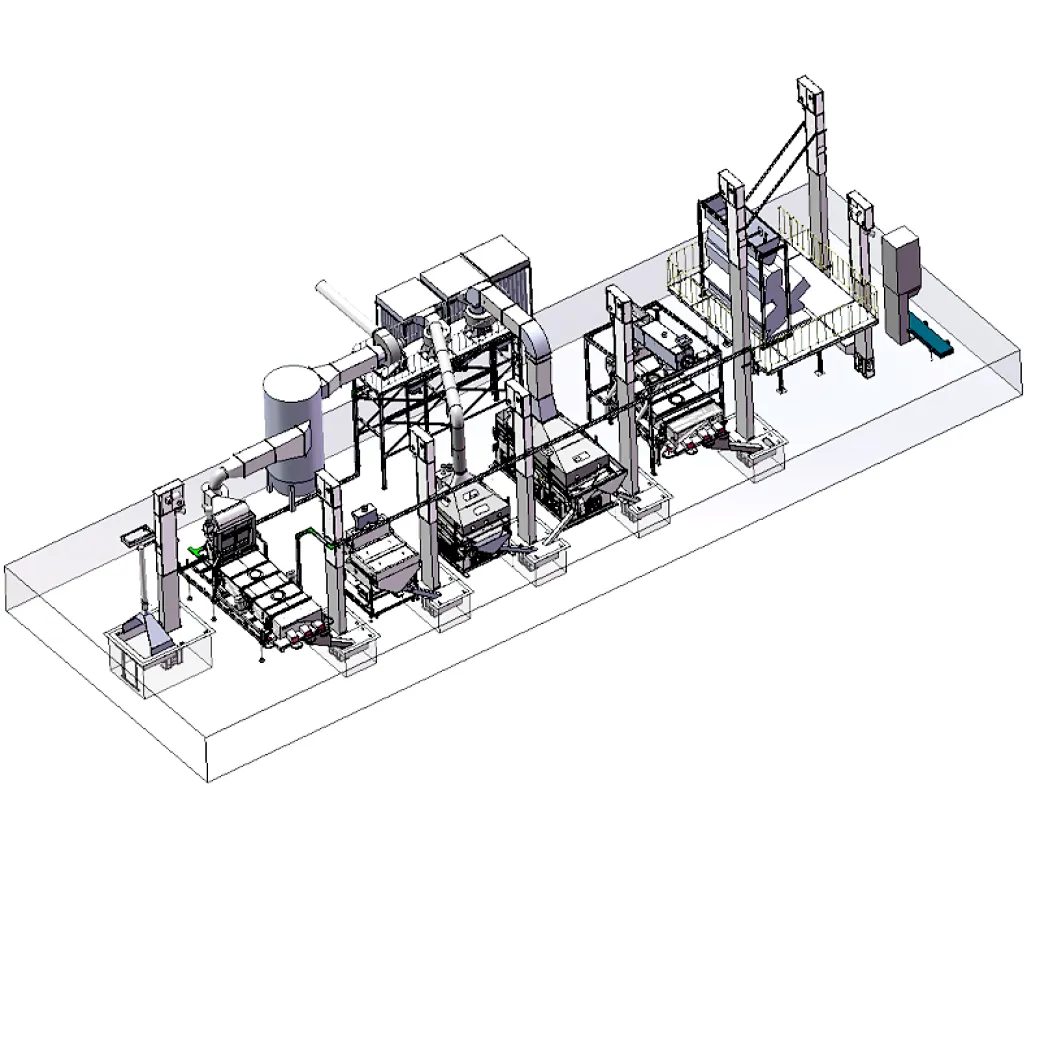

- Design & Build: Provide process or product samples; engineering team generates schematic/layout (solidworks/AutoCAD) and simulation. Integration with upstream/downstream devices supported.

- Pilot Testing: Lab/onsite trial units available before final order submission; reports delivered per EN ISO/IEC 17025.

- Turnkey Upgrade: Existing de stoner line automation, PLC/IoT remote monitoring, or energy retrofit services on all continents.

- Onsite Service: Global network, local install/commiss., on-demand spare parts (delivery in 48-72 hrs for major regions).

- References: Yihai Kerry (COFCO), YTO Group, Datang Power; performance records available for verification.

In 2023, the group adopted 5QSC Destoner in its engine block sand cleaning facility. Results: 31.6% less filter change downtime, 45% reduction in sand carryover, $120,000 OPEX saved/year.

- Wang, Food Processor (User since 2022): “The separation efficiency is remarkable—no stone slip-through for 16 months. The PLC system has predictive alerts, minimizing our unplanned stops.”

- M. Patel, Waste Recycler: “Switching from mild-steel destoner to 5QSC cut machine failure by 63%, and stainless steel chambers withstand severe chemical washout.”

- ISO 9001 Third-Party Inspection (July 2023): “Manufacturing and testing sample batch for Beibucleaner 5QSC Destoner meets and exceeds ISO/EN/ANSI structure and pressure vessel requirements.”

- Step 1: Define your process parameters (material type, throughput, installation space).

- Step 2: Contact sales with your destoner for sale need via product webpage—engineers will follow up within 12 hours.

- Step 3: Receive selection proposal, visual simulation, and pricing with TDS, drawings, and certifications included.

- Step 4: Sign contract, schedule production, and arrange milestone video inspection if required.

- Step 5: Delivery, on-site/remote support, and lifecycle performance warranty in place.

- 360iResearch, "Global Destoner Market: Share, Trends & Forecast 2023-2030", marketresearch.com

- ISO 9001, iso.org & ISO/IEC 17025, iso.org

- "PLC/SCADA in Modern Destoner Applications", Food Engineering Magazine, foodengineeringmag.com

- "Best Practices for Destoner Sizing and Material Selection", Engineering Forum, eng-tips.com

- "SGS - Testing & Certification Services for Mechanical Equipment", sgs.com

- Industry user reviews and feedback (2022-2024), cerealsgrains.org

Jan. 02, 2025

Mar. 28, 2024

Benin Soybean-Hebei Beibu Machinery Technology Co.,LTD

Aug. 19, 2024

seed processing line in trailer

Apr. 15, 2024

Sesame Cleaning Machine Destoner-Hebei Beibu Machinery Technology Co.,LTD

Dec. 10, 2024

Coffee Bean Cleaning Machine-Hebei Beibu Machinery Technology Co.,LTD

Feb. 11, 2025

Beibu Machinery selects every grain of wheat to ensure your food safety

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.