- Introduction to rice mill elevator buckets working process

- Technological advancements transforming rice mill elevators

- Manufacturer comparison: key players in elevator for rice mill industry

- Custom elevator rice mill solutions for modern operations

- Real-world application case studies

- Operational best practices and maintenance tips

- Conclusion: The future of rice mill elevator buckets working process

(rice mill elevator buckets working process)

Introduction to Rice Mill Elevator Buckets Working Process

The rice mill elevator buckets working process lies at the heart of efficient rice processing. Elevator buckets, a staple in modern rice mills, are critical components that transport paddy and processed rice vertically throughout various stages of milling. Understanding the mechanisms of elevator buckets is crucial for manufacturers and operators aiming for maximizing production yield and reducing post-harvest losses. The entire system typically involves a series of buckets attached to a belt or chain that moves around pulleys or sprockets, effectively lifting bulk materials vertically. In rice mills, elevator buckets typically operate at speeds ranging between 2.0-3.5 meters per second and can achieve an overall transportation capacity of up to 200 tons per hour depending on the bucket size and configuration.

The elevator system’s efficiency directly influences rice quality, loss rate, and energy consumption. Taking into account the pole position of elevator for rice mill, the system must minimize friction, spillage, and grain breakage. With innovations in bucket materials—ranging from polyamide and polyethylene to stainless steel—modern elevators cater to specific rice mill operational contexts while offering longer life cycles. As automation further integrates into rice processing, elevator buckets working processes are becoming more streamlined, with the focus on precision, hygiene, and traceability at every step.

Technological Advancements Transforming the Industry

Over the past decade, the implementation of new materials and digital monitoring systems has revolutionized the elevator for rice mill sector. Traditional mild steel buckets have been gradually replaced by high-density polyethene (HDPE) and polyurethane buckets, which reduce wear and contamination risk. According to a 2023 industry study, mills using HDPE buckets reported a 30% reduction in downtime due to breakage and a 12% boost in output consistency.

Advancements like vibration and temperature sensors allow real-time monitoring of elevator performance, predicting failures and minimizing downtime. Furthermore, modular construction has enabled seamless upgrades and simplified maintenance. Digital integration means that mill operators can now track operational status from mobile applications or centralized dash-boards, optimizing throughput and energy efficiency. These technological changes not only lower operational costs in the long term but also ensure higher product consistency and lower contamination percentages—key requirements for meeting global rice export standards.

Manufacturer Comparison: Key Players in the Elevator for Rice Mill Industry

Selecting the best suppliers for elevator rice mill technology is fundamental for competitive advantage. Below is a comparative table of four leading global manufacturers in 2024. Assessment factors include material quality, capacity, integration options, and cost-effectiveness:

| Manufacturer | Main Material | Maximum Capacity (T/H) | Digitization Features | Warranty | Average Price (USD) |

|---|---|---|---|---|---|

| Buhler Group (Switzerland) | Stainless Steel / Polyamide | 220 | IoT monitoring, predictive maintenance | 3 Years | 6,500 |

| Satake Corporation (Japan) | HDPE / Mild Steel | 200 | Remote diagnostics, modular integration | 2 Years | 5,800 |

| AGI (Canada) | Polyurethane / Galvanized Steel | 180 | Basic sensor package | 2.5 Years | 5,100 |

| Spectrum Industries (India) | Polyethylene / Stainless Steel | 160 | Entry-level monitoring | 2 Years | 4,300 |

These manufacturers represent a cross-section of global standards, technology integration, and market pricing. The best choice often depends on the individual mill’s needs, installed infrastructure, and the level of digitalization desired. Notably, European and Japanese brands tend to offer more advanced sensor systems, while Indian and North American manufacturers deliver robust cost-to-capacity value ratios.

Custom Elevator Rice Mill Solutions for Modern Operations

Standard elevator buckets provide a framework, but customization is pivotal for achieving superior performance in specific environments. Key areas often tailored include bucket material selection, chain or belt design, vertical height adjustments, and dust control mechanisms. For example, operations processing parboiled rice—more fragile than white rice—often invest in ultra-low-impact bucket designs with anti-static coatings to reduce loss and cross-contamination.

Customization also extends to energy use. In high-throughput facilities, variable frequency drives (VFDs) can be integrated to adjust elevator speed based on real-time requirements, reducing electricity consumption by up to 20%. Some suppliers provide anti-backlash drives and self-cleaning features, addressing hygiene and component durability. For mills located in seismic zones, design modifications for vibration resistance are common, protecting equipment longevity and operator safety.

Real-world Application Case Studies

The benefits of advanced elevator rice mill solutions manifest vividly in field operations. In a 2023 deployment at a 40,000-ton per year facility in Thailand, upgrading from conventional mild steel buckets to high-density polyethylene increased throughput by 15% and cut annual maintenance costs by $8,000. Operational efficiency also improved, with grain breakage rates dropping by 18%.

Another prominent example comes from a Nigerian rice cooperative, which invested in a full digital monitoring suite from a leading European manufacturer. Within the first six months of deployment, the mill reported a 25% reduction in unexpected downtime events and a 22% improvement in product consistency. These measurable gains have a direct bottom-line impact, bolstering the case for continual modernization in rice milling environments.

Operational Best Practices and Maintenance Tips

Regardless of the sophistication of the elevator for rice mill, proper care underpins smooth operations. Key maintenance practices include:

- Routine inspection and tensioning of belts or chains every 2-3 weeks

- Cleaning bucket interiors and exteriors monthly to reduce contamination

- Lubricating drive and return pulleys to minimize wear

- Monitoring for misalignment or abnormal vibration via installed sensors

- Scheduling annual professional system audits and component replacements if necessary

Operators should maintain a detailed log of cleaning, repairs, and upgrades. Training staff on proper start-up and shut-down procedures is essential, particularly when integrated with digital monitoring systems. By adhering to these protocols, mills can extend equipment lifespan, maintain consistent output quality, and avoid costly interruptions.

Conclusion: The Future of Rice Mill Elevator Buckets Working Process

The evolution of the rice mill elevator buckets working process exemplifies the drive for efficiency, sustainability, and profitability in modern agribusiness. As the global demand for rice surges, investments in durable materials, smart technologies, and custom-engineered solutions will distinguish top-performing mills from laggards. By understanding the data behind the equipment, comparing vendors strategically, and adopting best practices, mill operators can maximize both yields and longevity.

Advancements in elevator rice mill solutions will likely continue apace, propelled by IoT-enabled insights, materials science, and process engineering. For stakeholders in rice processing, staying abreast of these developments ensures that equipment investments offer strong returns, operational resilience, and a measurable competitive edge in the marketplace.

(rice mill elevator buckets working process)

FAQS on rice mill elevator buckets working process

Q: What is the working process of rice mill elevator buckets?

A: Rice mill elevator buckets scoop up rice grains at the bottom and lift them vertically. The buckets then discharge the rice at the top into processing machines. This process enables continuous and efficient grain transfer in the mill.

Q: How does an elevator for rice mill function?

A: An elevator for rice mill uses a belt or chain with attached buckets to transport rice vertically. The system moves rice between different stages of milling. It ensures smooth and speedy material handling in the mill.

Q: Why are elevator buckets important in rice mills?

A: Elevator buckets are crucial for automating material movement in rice mills. They help in reducing manual labor and save processing time. Their efficient transport maintains a steady milling flow.

Q: What types of materials are used for elevator buckets in rice mills?

A: Common materials for rice mill elevator buckets include plastic, steel, and sometimes stainless steel. The choice depends on required strength and contamination resistance. These materials ensure durability and food safety.

Q: Can elevator rice mills handle different types of grains?

A: Yes, elevator rice mills can transport various types of grains with similar size and flow properties. Adjustments may be needed for different grain types. The elevator mechanism remains largely the same for many grains.

Jul. 29, 2025

May. 31, 2024

Receiving visiting customers from Sri Lanka-Beibu Machinery

Jul. 30, 2024

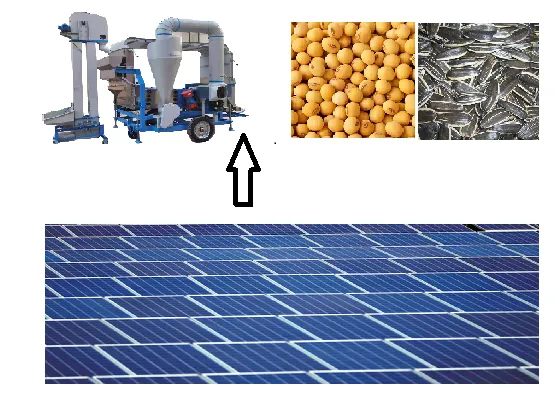

beans cleaner with solar energy

Jul. 29, 2024

Apr. 30, 2024

Holiday notice from Hebei Beibu Machinery Technology Co., Ltd.

Apr. 08, 2024

Gravity Separator-Hebei Beibu Machinery Technology Co.,LTD

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.