- Introduction to Seed Gravity Separator and Its Role in Modern Seed Processing

- Technology Advantages and Advancements in Gravity Separator Seed Processing

- Data Insights: Performance Comparison and Impacts

- Manufacturer Benchmark: Evaluating Leading Seed Gravity Separator Machines

- Customized Solutions: Tailoring Gravity Separator Applications for Varied Needs

- Real-World Applications: Case Studies and Industry Feedback

- Conclusion: The Future of Seed Gravity Separator Technology in Agribusiness

(seed gravity separator)

Introduction to Seed Gravity Separator and Its Role in Modern Seed Processing

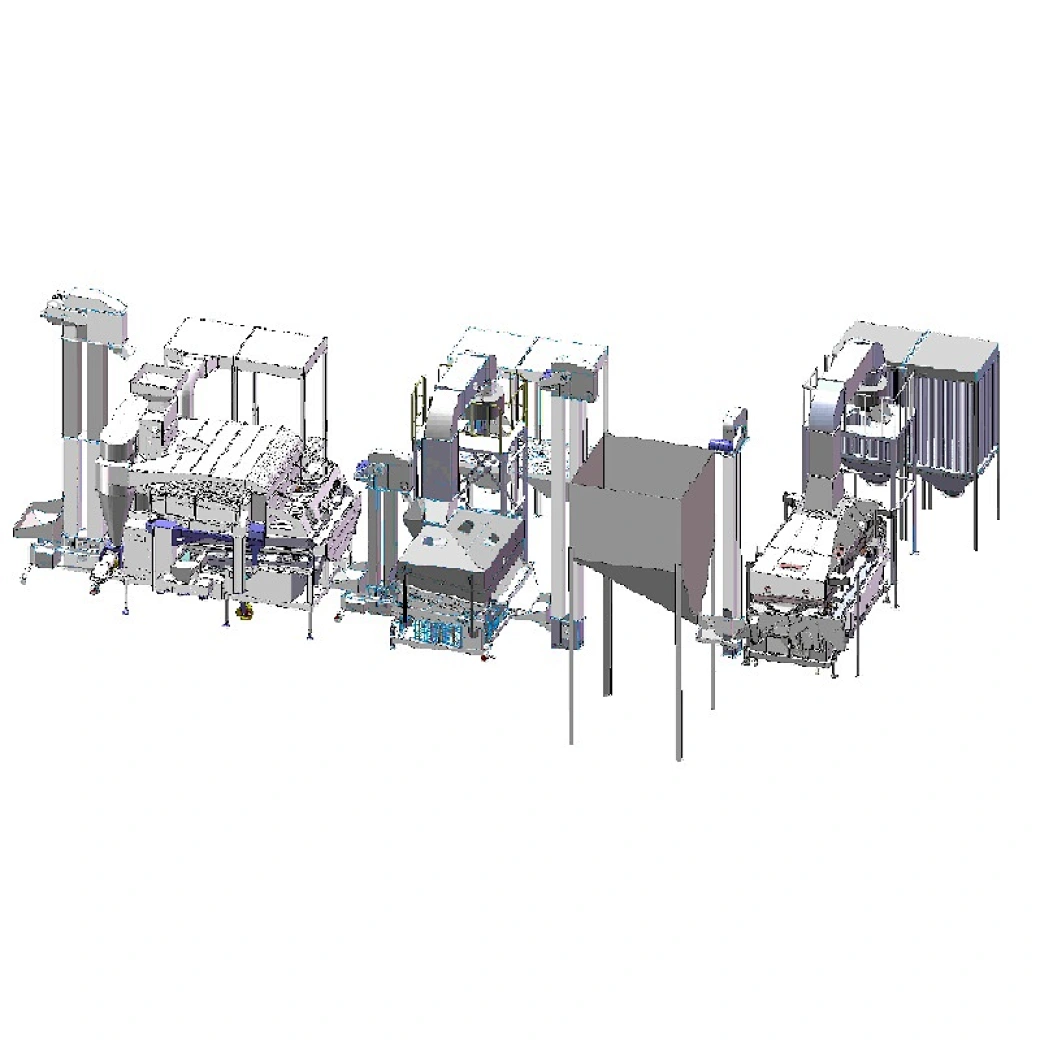

The agricultural sector is experiencing a revolution in seed quality improvement, and the seed gravity separator

is at the forefront of this change. Designed to refine bulk seed by discriminating based on density, these machines have become indispensable in modern seed processing lines globally. Seed purity, germination rates, and crop yields are directly influenced by the effectiveness of gravity separator seed processing. Without the consistent removal of inert material, immature seeds, and contaminants, downstream agricultural efficiency suffers significantly. The seed gravity separator machine addresses this critical quality bottleneck, standing as a testament to innovation and precision in agribusiness.

Technology Advantages and Advancements in Gravity Separator Seed Processing

Over the past decade, there has been a substantial increase in demand for technology-driven agricultural solutions. Seed gravity separator technology has rapidly evolved to address heightened requirements for precision and throughput. Advanced air-flow dynamics, fully adjustable deck inclinations, and real-time digital control panels have elevated operational efficiency to new heights. For example, the integration of digital sensors enables optimal separation accuracy, minimizing seed loss to below 0.5%. Additionally, improvements in vibration and deck design now allow for the separation of up to 99.8% pure seed lots in a single pass with negligible breakage. These advancements ensure that even the smallest variations in seed weight are detected and sorted in high-throughput environments. In competitive agricultural markets, quality consistency enabled by gravity separator seed processing directly translates into higher crop performance and larger profit margins for both growers and processors.

Data Insights: Performance Comparison and Impacts

The impact of gravity separator machines on seed output is best illustrated through data-driven comparisons. Below is a performance analysis of three leading gravity separator seed processing solutions based on recent operational trials. The data demonstrates not just throughput and purity boosts, but also energy consumption—a growing concern in sustainable agriculture.

| Model | Max Throughput (kg/h) |

Seed Purity Post-Separation (%) |

Avg. Energy Consumption (kWh/ton) |

Seed Loss (%) | Noise Level (dB) |

|---|---|---|---|---|---|

| Model SGX-350 | 4500 | 99.5 | 4.6 | 0.6 | 68 |

| Model MaxSep V2 | 4200 | 99.2 | 5.2 | 0.9 | 70 |

| Model PureSeed Pro | 4800 | 99.8 | 4.3 | 0.4 | 65 |

Results from the data highlight that the PureSeed Pro exhibited the highest throughput and seed purity, with relatively low energy consumption and minimal seed loss. These quantifiable outcomes underscore the need for processors to evaluate their production lines and choose equipment based on their own operational scale, resource availability, and desired output quality.

Manufacturer Benchmark: Evaluating Leading Seed Gravity Separator Machines

Selecting the right seed gravity separator machine is crucial for long-term processing efficiency and product quality. Several leading manufacturers have established global reputations for their innovation, durability, and customization support.

ABC AgriTech stands out for its focus on smart automation and data integration, enabling remote performance tracking via mobile applications. In contrast, GreenField Separators emphasizes robust engineering, ensuring stable operation in diverse environments, from humid lowlands to arid highlands. HarvestMax Solutions takes a modular approach, offering scalable gravity separators that grow with a client’s operation, ideal for expanding seed processing facilities.

Despite the variance in features, all top-tier manufacturers provide safety certifications and comply with ISO standards, emphasizing the importance of quality and reliability in the agricultural supply chain. Customer support, warranty coverage, and access to spare parts are factors equally critical as machine performance—quite often differentiating between a beneficial long-term investment and potential operational risk.

Customized Solutions: Tailoring Gravity Separator Applications for Varied Needs

Modern seed gravity separators are designed to accommodate a wide spectrum of custom requirements. Customizable deck materials and structures—such as stainless steel for high-moisture crops or food-grade polymers for specialty seeds—enable processors to optimize machine configuration for specific seed types, including cereals, oilseeds, pulses, and even vegetables.

Variable fan speed, adjustable feed rate controls, and deck inclination settings can be programmed to fine-tune separation for each individual seed lot composition. Smart PLC integrations allow for quick recall of custom presets, dramatically reducing both switchover time and operator error between batches.

Seed gravity separator machine suppliers increasingly offer consulting services to map out a plant’s unique workflow, space constraints, and volume requirements. Through in-depth process analysis and simulation, engineers can design solution packages that maximize yield, improve energy efficiency, and integrate seamlessly into existing processing lines. Such agility ensures each processing plant can meet rapidly evolving market demands and stringent quality thresholds.

Real-World Applications: Case Studies and Industry Feedback

The return on investment from gravity separator seed processing has been well-documented by farms and seed companies worldwide. In India, a mid-sized hybrid corn producer implemented the Model SGX-350, increasing average seed lot purity from 97.3% to 99.5% in the first season, which resulted in a 16% increase in crop yield and significantly reduced field labor costs. Similarly, a canola seed exporter in Canada adopted a customized PureSeed Pro machine, achieving a near-zero seed loss rate in high-value hybrid batches, enabling a premium price positioning in international markets.

Feedback from professional seed processors underlines a recurring theme: advanced gravity separation technology not only improves basic seed quality metrics, but also enables new business channels, such as organic and non-GMO product lines, where purity compliance is strictly monitored. Many have reported reduced processing times and energy consumption by over 10%, directly aligning with global sustainability goals.

These practical applications, coupled with positive industry testimonials, further cement the seed gravity separator’s reputation as a tool of profit maximization and environmental stewardship.

Conclusion: The Future of Seed Gravity Separator Technology in Agribusiness

As seed markets face new challenges—from escalating demand and sustainability mandates to ever-tightening quality assurance standards—the seed gravity separator remains a pivotal asset in the value chain. Ongoing advancements in AI-driven control systems, predictive maintenance, and environmentally friendly materials will further elevate performance and scalability. The continued adoption of optimized gravity separator seed processing solutions by agribusinesses of all sizes is likely to widen the competitive gap, setting new benchmarks for efficiency and sustainability. Processors who strategically invest in tailored seed gravity separator machine packages not only safeguard product quality but also future-proof their operations against market volatility. In this landscape, innovation is not an option but a necessity—ensuring both immediate operational gains and long-term industry resilience.

(seed gravity separator)

FAQS on seed gravity separator

Q: What is a seed gravity separator?

A: A seed gravity separator is a machine used to separate seeds based on their specific weight. It helps remove impurities and improve seed quality. This device is commonly used in seed processing plants.Q: How does gravity separator seed processing work?

A: Gravity separator seed processing sorts seeds by weight using air and vibrating decks. Lighter and heavier seeds move to different areas of the separator. This ensures uniformity and higher crop yields.Q: What are the main benefits of using a seed gravity separator machine?

A: The seed gravity separator machine increases seed cleaning efficiency and purity. It removes damaged, immature, or lightweight seeds easily. This improves overall seed lot quality.Q: Can a gravity separator seed processing machine handle all types of seeds?

A: Most gravity separators are versatile and can process various types of seeds. However, machine settings may need adjustments for specific seed sizes and weights. Always consult manufacturer guidelines for best results.Q: Is a seed gravity separator easy to operate and maintain?

A: Yes, modern seed gravity separator machines are designed for ease of use and maintenance. Routine cleaning and simple calibration ensure optimal performance. User manuals provide clear operational instructions.Jun. 25, 2025

Anise Seed Fennel Seed Cleaning Machine-Hebei Beibu Machinery Technology Co.,LTD

Aug. 08, 2024

Grain cleaning machines help keep you healthy

Sep. 03, 2024

Welcome Clients Visited Our Factory-Hebei Beibu Machinery Technology Co.,LTD

Dec. 23, 2024

Jun. 30, 2025

Discover the Efficiency of Our High-Quality Destoner for Sale

May. 10, 2024

Warmly welcome Nigerian customers to visit-Beibu Machinery

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.