The Imperative Role of Advanced Grain Cleaning in Modern Agriculture

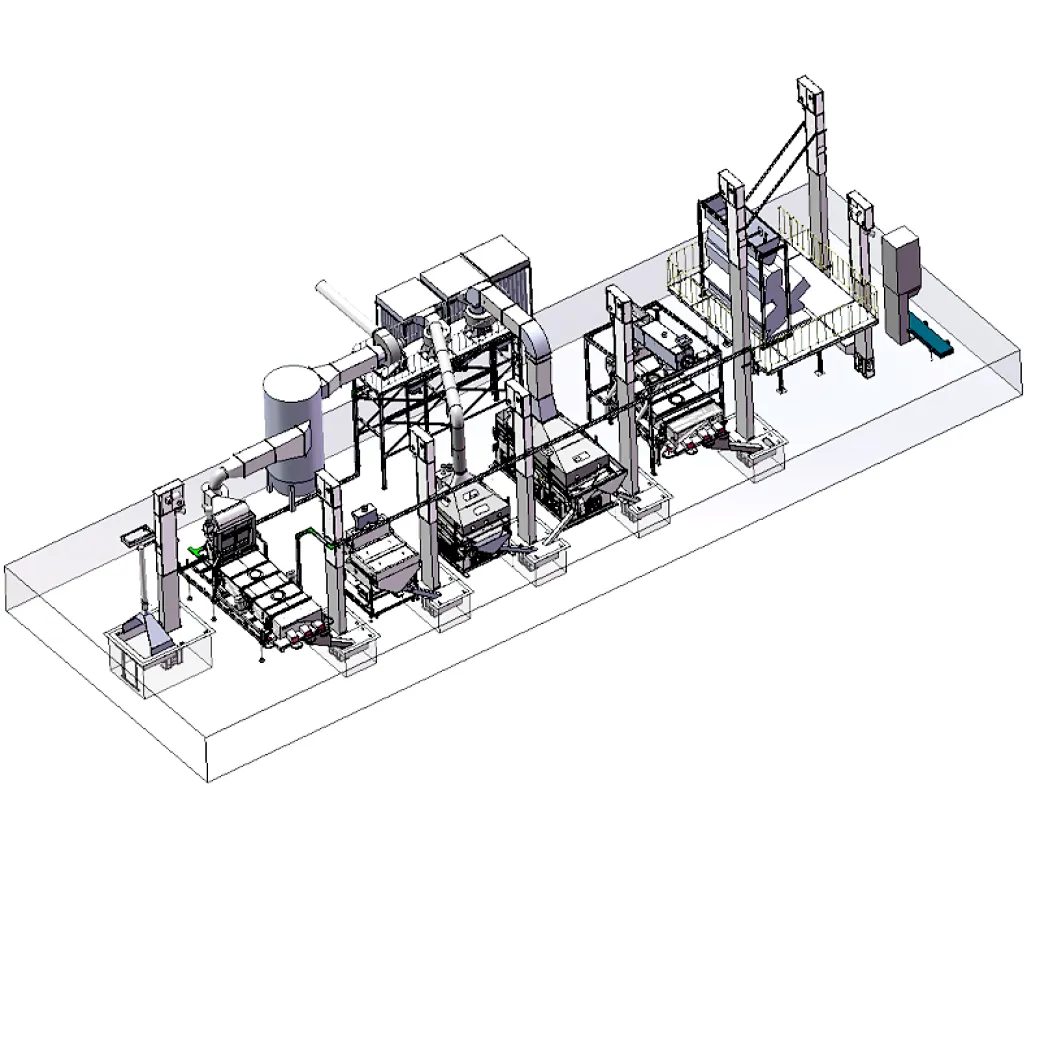

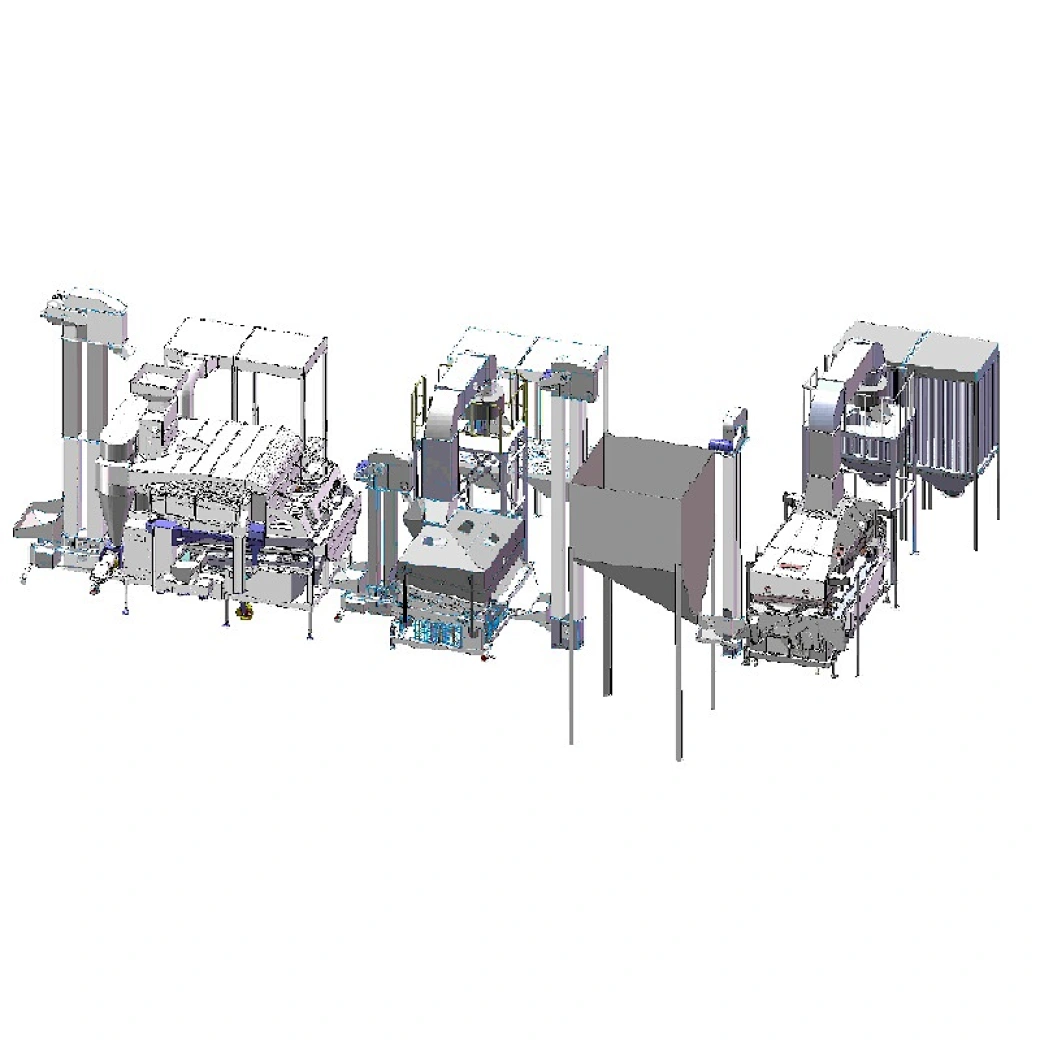

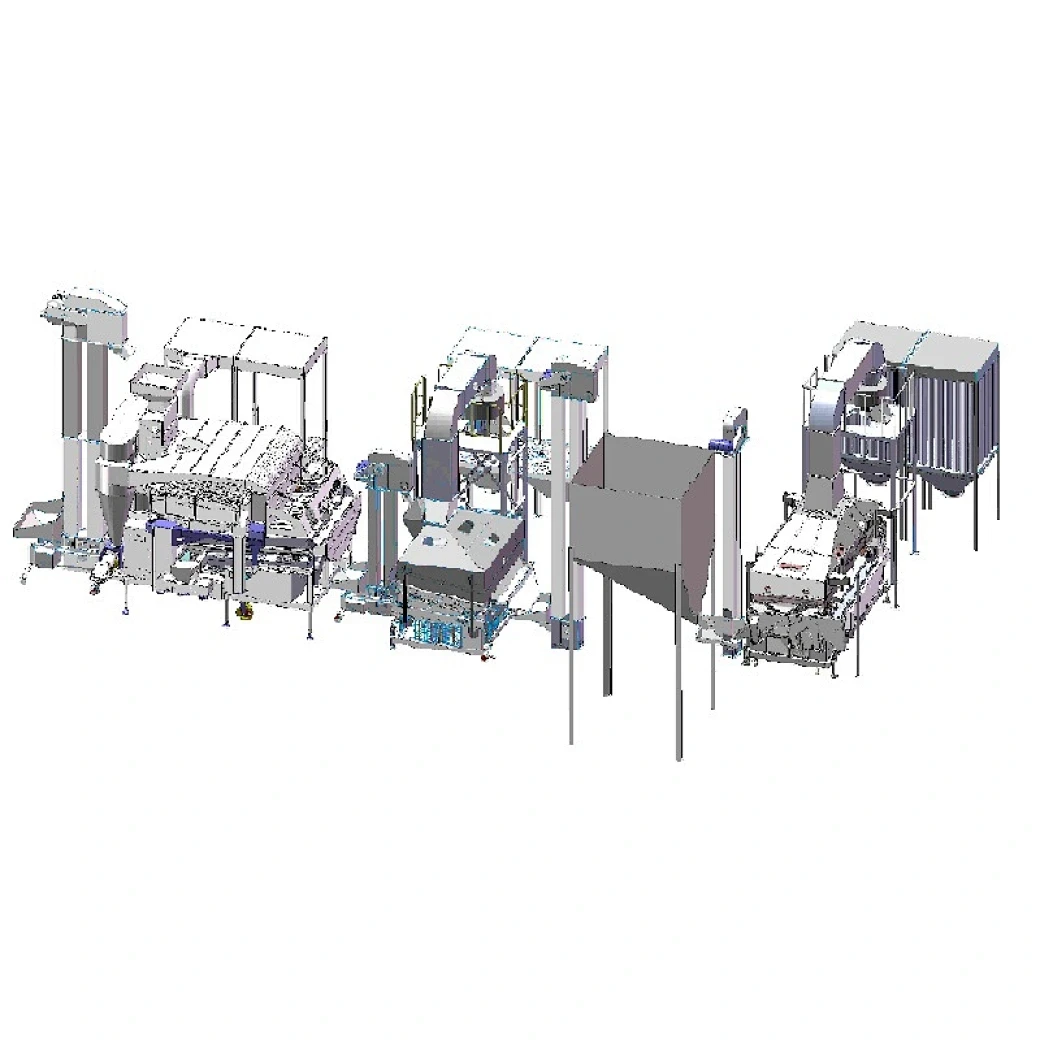

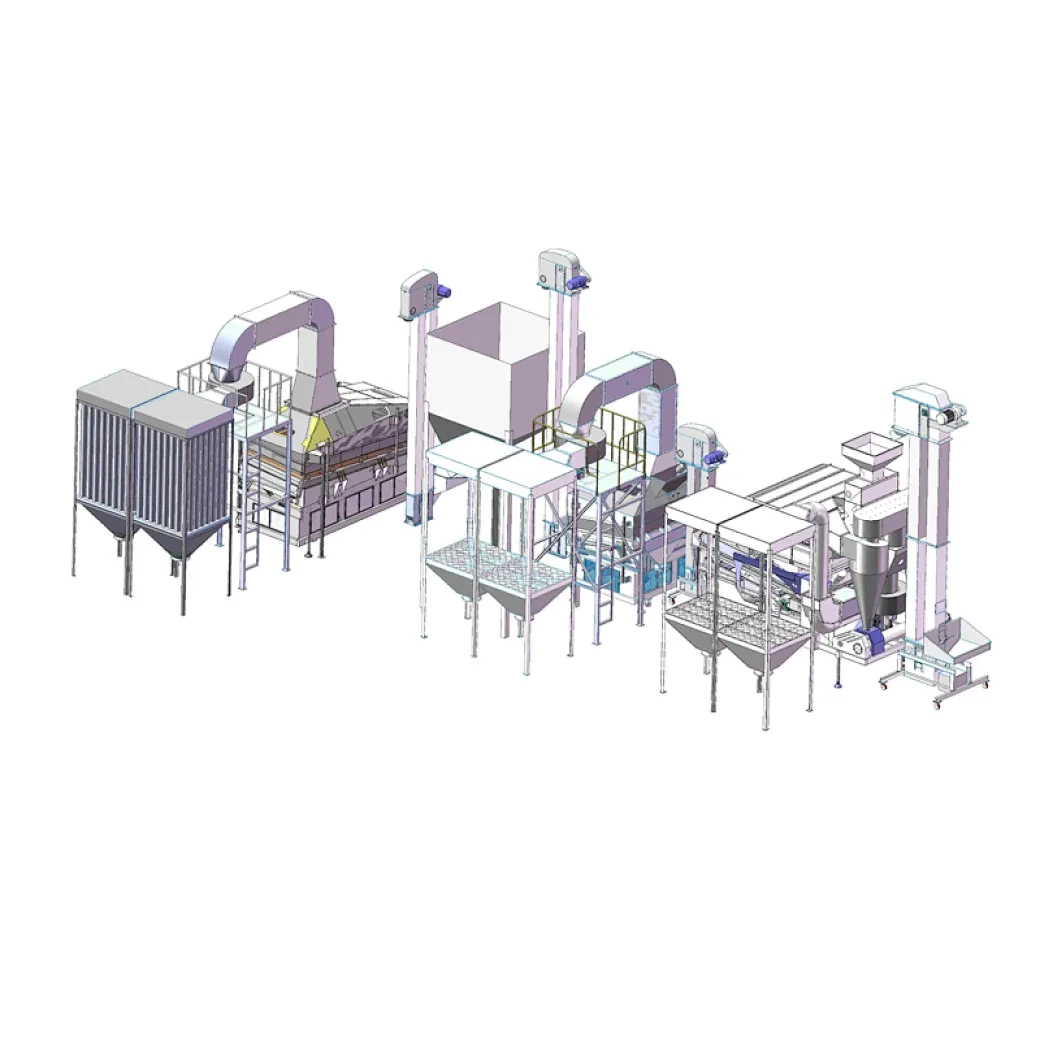

In today's global agricultural landscape, ensuring the purity and quality of grains is paramount for food security, processing efficiency, and market competitiveness. At the core of this assurance are advanced grain cleaning machines. These sophisticated systems are engineered to meticulously remove impurities such as dust, chaff, broken kernels, foreign seeds, and other unwanted materials, directly impacting the final product's value and safety. This comprehensive overview delves into the intricate world of grain cleaning technology, exploring its industrial applications, technological advancements, and the critical parameters that define leading-edge solutions like the Grains Cleaning Processing Line. We will specifically address the nuances of systems designed for specialized tasks, including those incorporating a gravity grain cleaner, and dedicated grass seed cleaning equipment, alongside advanced gravity table grain cleaner units, providing a holistic perspective for B2B decision-makers.

Industry Trends Shaping Grain Processing Efficiency

The agricultural sector is witnessing a transformative shift driven by demands for higher purity, reduced waste, and sustainable practices. Key industry trends influencing the development and deployment of grain cleaning machines include enhanced automation, the integration of Artificial Intelligence and IoT for predictive maintenance, and an increased focus on energy efficiency. Manufacturers are increasingly adopting modular designs, allowing for scalable solutions that can be easily integrated into existing processing lines or expanded to meet growing capacity needs. Furthermore, there's a significant push towards developing multi-functional units capable of handling a diverse range of grain types, from cereals and legumes to specialty seeds, requiring adaptable cleaning mechanisms and precise separation technologies. This evolution ensures that modern grain processing facilities can achieve optimal operational performance while meeting stringent quality standards.

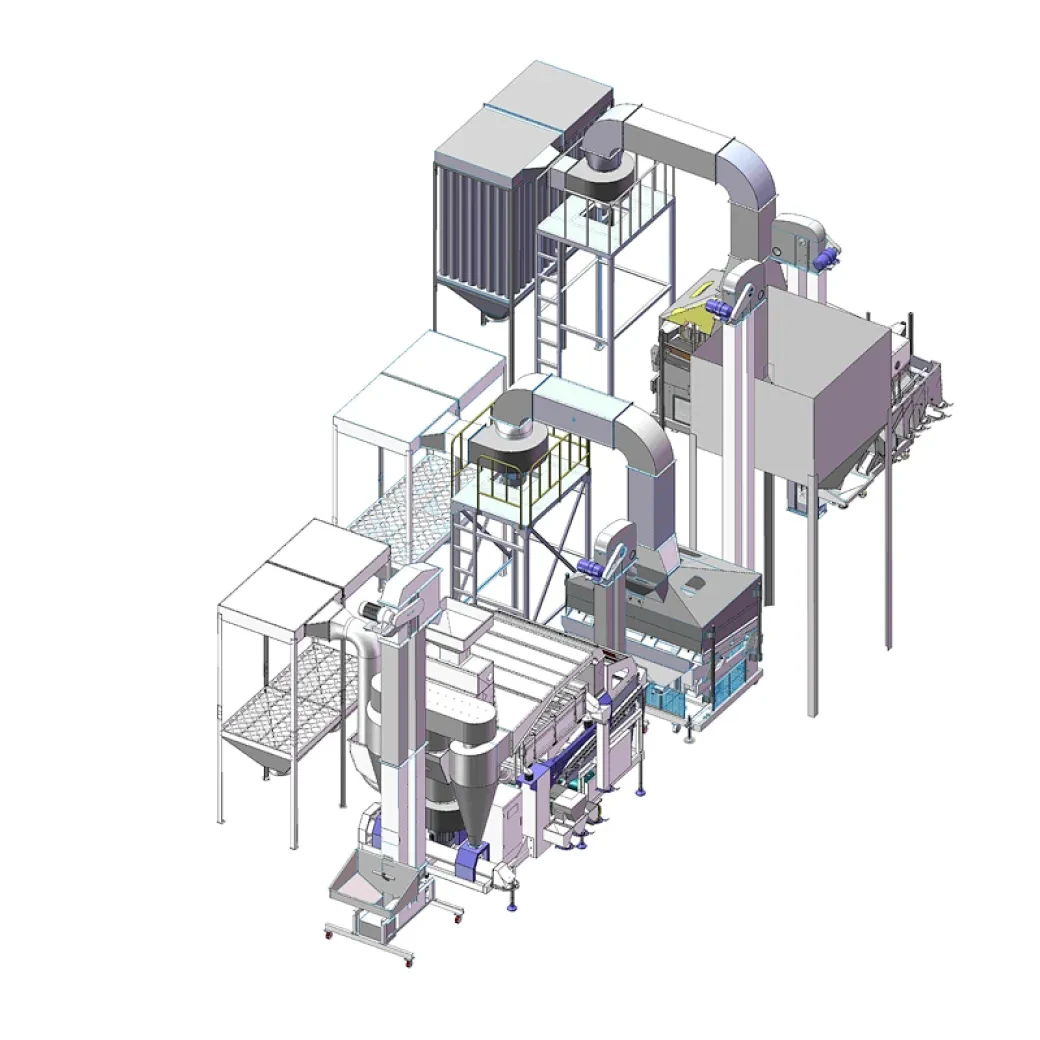

Anatomy and Precision Manufacturing of Advanced Grain Cleaners

The sophisticated performance of modern grain cleaning machines stems directly from their meticulous manufacturing process and the selection of premium materials. Components are typically crafted from high-grade stainless steel (e.g., SUS304 for food contact surfaces) to ensure hygiene, corrosion resistance, and longevity, while structural frames utilize robust carbon steel, often with specialized coatings for enhanced durability. Manufacturing processes include precision CNC machining for critical parts like sieves and air ducts, ensuring exact tolerances for optimal separation efficiency. Advanced laser cutting and robotic welding techniques contribute to structural integrity and consistent quality. Each unit undergoes rigorous inspection standards, adhering to international benchmarks such as ISO 9001 for quality management and relevant ANSI standards for mechanical components. This commitment to quality engineering results in machines with an expected operational lifespan of 15-20 years, under proper maintenance. These machines find essential application across diverse sectors including food processing plants, seed multiplication centers, animal feed mills, and breweries, where they are vital for preparing raw materials to specific purity levels, ultimately contributing to energy savings by reducing reprocessing needs and offering superior corrosion resistance for continuous, reliable operation.

Key Technical Parameters and Performance Benchmarks

When evaluating grain cleaning machines, understanding their technical specifications is crucial for matching equipment to operational demands. Performance metrics provide clear benchmarks for efficiency and effectiveness. The capacity, typically measured in tons per hour (t/h), indicates the volume of grain the machine can process. Cleaning efficiency, often expressed as a percentage, quantifies the proportion of impurities removed from the raw input. Purity, another critical percentage, reflects the percentage of pure grain in the output. Power consumption (kW) and overall dimensions are vital for operational costs and facility integration. Noise levels are increasingly important for workplace safety and compliance. Below is a representative table illustrating common technical parameters for high-performance grain cleaning lines, highlighting the typical ranges one might expect from industry-leading solutions designed for various capacities and grain types, including specialized gravity grain cleaner units.

| Parameter | Typical Range/Value | Significance |

|---|---|---|

| Capacity (t/h) | 5 – 200+ | Throughput volume, impacts scalability of operations. |

| Cleaning Efficiency (%) | 98.5% – 99.9% | Percentage of impurities removed, crucial for product quality. |

| Final Grain Purity (%) | 99.5% – 99.9% | Purity of output grain, vital for market standards. |

| Power Consumption (kW) | 5 – 75 | Operational energy cost, indicative of energy efficiency. |

| Dimensions (L x W x H) | Varies by model | Footprint and integration requirements within a facility. |

| Noise Level (dB) | < 80 | Impact on working environment, compliance with regulations. |

Diverse Application Scenarios and Strategic Advantages

The versatility of modern grain cleaning machines extends their utility across an impressive array of agricultural and industrial applications. From large-scale grain elevators handling wheat, corn, and soybeans to specialized facilities processing rice, barley, and even exotic seeds, these machines are indispensable. Specialized units, such as dedicated grass seed cleaning equipment, ensure precise separation for high-value propagation materials, maximizing yield and quality. The integration of a gravity table grain cleaner is particularly effective for separating grains by density, removing stones, glass, and other heavy impurities that might otherwise escape traditional sieve or air classification systems. The strategic advantages are manifold: improved grain quality translates directly into higher market value and reduced rejections; efficient impurity removal minimizes wear and tear on downstream processing machinery; and enhanced storage stability prevents spoilage and pest infestations, safeguarding investments. These benefits underscore the critical role advanced grain cleaning plays in the entire agricultural value chain.

Manufacturer Comparison and Tailored Customization Solutions

Choosing the right manufacturer for grain cleaning machines involves a comprehensive evaluation of their R&D capabilities, manufacturing quality, after-sales support, and most importantly, their capacity for customization. Leading manufacturers distinguish themselves by offering not just off-the-shelf solutions but also highly tailored systems designed to meet unique operational challenges. This might include integrating specific cleaning stages (e.g., pre-cleaning, fine cleaning, gravity separation, destoning), adapting capacity to precise throughput requirements, or ensuring compatibility with existing facility layouts and automation systems. For instance, a producer focusing on organic grains might require specific material handling features to prevent cross-contamination, while a large-scale silo operator might need seamless integration with complex conveying systems. Our commitment to client-specific solutions ensures that whether you need specialized grass seed cleaning equipment or a high-capacity system for commodity grains, the Grains Cleaning Processing Line can be precisely configured to deliver optimal performance and maximize your return on investment.

Real-World Application Cases and Proven Client Success

The tangible benefits of investing in high-quality grain cleaning machines are best illustrated through real-world application cases. For example, a large grain elevator in North America implemented our Grains Cleaning Processing Line, which included a high-capacity gravity table grain cleaner module. This resulted in a consistent grain purity increase from 98% to over 99.5%, significantly reducing dockage fees and enhancing their market position. Another case involved a seed company needing specialized grass seed cleaning equipment to process various forage seeds; our tailored solution achieved an impurity removal rate exceeding 99.8%, leading to higher germination rates and premium seed sales. These successes underscore our expertise and experience in delivering solutions that not only meet but exceed client expectations in terms of efficiency, product quality, and operational reliability. Our long-standing service history and partnerships with key players in the agricultural sector are testaments to our authority in the field.

Ensuring Trust: Quality Assurance, Support, and Guarantees

Building lasting partnerships in the B2B sector hinges on absolute trust, transparency, and unwavering support. Our commitment to trustworthiness is embedded in every aspect of our operations, from initial consultation to after-sales service. All our grain cleaning machines, including specialized gravity grain cleaner units, come with comprehensive warranties, typically ranging from 12 to 24 months, covering manufacturing defects and ensuring peace of mind. Our streamlined delivery process is designed for efficiency, with clear communication on lead times and logistics from order confirmation to on-site commissioning. We provide extensive customer support, including technical assistance, spare parts availability, and regular maintenance guides, ensuring optimal machine performance throughout its lifecycle. Furthermore, our products adhere to stringent international certifications, such as ISO 9001 and CE standards, reflecting our dedication to global quality benchmarks and product safety.

Frequently Asked Questions (FAQs)

-

Q: What types of impurities can your grain cleaning machines remove?

A: Our machines are designed to remove a wide range of impurities including light impurities (dust, chaff, empty husks) via aspiration systems, large impurities (straw, stones, cobs) via sieves, fine impurities (sand, broken kernels) via precise sieving, and density-based impurities (stones, metal, glass) using gravity separation technology. -

Q: Can your Grains Cleaning Processing Line be integrated into existing facilities?

A: Yes, our modular designs and flexible configurations allow for seamless integration into most existing grain processing lines. We offer engineering support to ensure compatibility and optimize layout for maximum efficiency. -

Q: What is the typical delivery and installation timeframe?

A: Delivery times vary based on machine complexity and customization, typically ranging from 8 to 16 weeks. Installation timelines are highly dependent on the project scope but are efficiently managed by our experienced technical teams.

Conclusion: Elevating Grain Quality with Precision Technology

The demand for high-quality, pure grains continues to escalate globally, making the investment in advanced grain cleaning machines not just an option, but a necessity for any serious player in the agricultural and food processing industries. Our Grains Cleaning Processing Line represents the pinnacle of engineering excellence, combining robust construction with cutting-edge separation technologies. By understanding the intricate manufacturing processes, technical parameters, and diverse application scenarios of these machines, B2B decision-makers can make informed choices that yield significant returns. We remain committed to innovation, quality assurance, and unparalleled customer support, ensuring that our solutions continue to set the benchmark for purity, efficiency, and reliability in grain processing worldwide. Partner with us to elevate your grain quality and operational performance to new heights.

References

- FAO. (2020). The State of Food and Agriculture 2020. Overcoming water challenges in agriculture. Rome.

- Pomeranz, Y. (1987). Modern Cereal Science and Technology. VCH Publishers.

- Association of Official Seed Analysts. (AOSA). (2019). Rules for Testing Seeds.

- ISO 9001:2015. (2015). Quality management systems – Requirements. International Organization for Standardization.

Mar. 29, 2024

Soybean and Maize Cleaning Machine Loading-Hebei Beibu Machinery Technology Co.,LTD

Apr. 15, 2024

Hand Sewing Machine Delivery to Togo-Hebei Beibu Machinery Technology Co.,LTD

Apr. 10, 2024

Grain Delivery Elevator-Hebei Beibu Machinery Technology CO.,LTD

Apr. 08, 2024

New Installed Sesame Cleaning Machine-Hebei Beibu Machinery Technology Co.,LTD

Apr. 11, 2024

clean sameme with higest purity

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.