As global demand for premium sesame products rises, innovations in sesame hulling machine design and integrated sesame processing line solutions are reshaping the industry. From optimizing sesame processing plant layouts to adopting advanced manufacturing and quality standards, the Sesame Cleaning Processing Plant stands at the forefront of efficiency, quality, and global competitiveness.

Industry Trends in Sesame Processing

- Global Sesame Seed Market Size exceeded $6.2 billion in 2023 (FAO, 2023 report).

- Sustainable Processing: Over 40% of new sesame processing plants built after 2020 incorporate water recycling & energy-saving machinery.

- Automation: Latest sesame hulling machines achieve 93–98% hulling rate, with 35% reduction in labor costs.

- Adoption of food-grade stainless steel (SS304/316L) and compliance with ISO 9001 or FDA standards is considered baseline by top manufacturers.

Sesame Hulling Machine: Key Technical Parameters

| Model | Capacity (kg/h) |

Material | Hulling Rate (%) | Power (kW) | Dimensions (mm) | Standard Compliance | Service Life |

|---|---|---|---|---|---|---|---|

| SHM-500 | 500 | 304 SS | 93–95 | 13.5 | 2200×950×1680 | ISO 9001, CE | 10+ years |

| SHM-1500 | 1500 | 316L SS | 96–98 | 28.2 | 3200×1200×1800 | ISO 9001, FDA | 12+ years |

| SHM-3000 | 3000 | 316L SS | 98 | 36.0 | 4600×2200×2100 | ANSI, FDA | 15+ years |

Technical Explanation

- 304/316L Stainless Steel: Guarantees food safety, anti-corrosion, and long operational life.

- Hulling Rate: Percentage of sesame seeds perfectly hulled. Modern machines offer up to 98% due to enhanced abrasion mechanisms and optimized water soaking systems.

- Compliance: Certified under ISO/FDA/CE/ANSI, ensuring global compatibility and regulatory safety.

- Service Life: Lifecycle testing confirms 10–15+ years of commercial operation under standard maintenance.

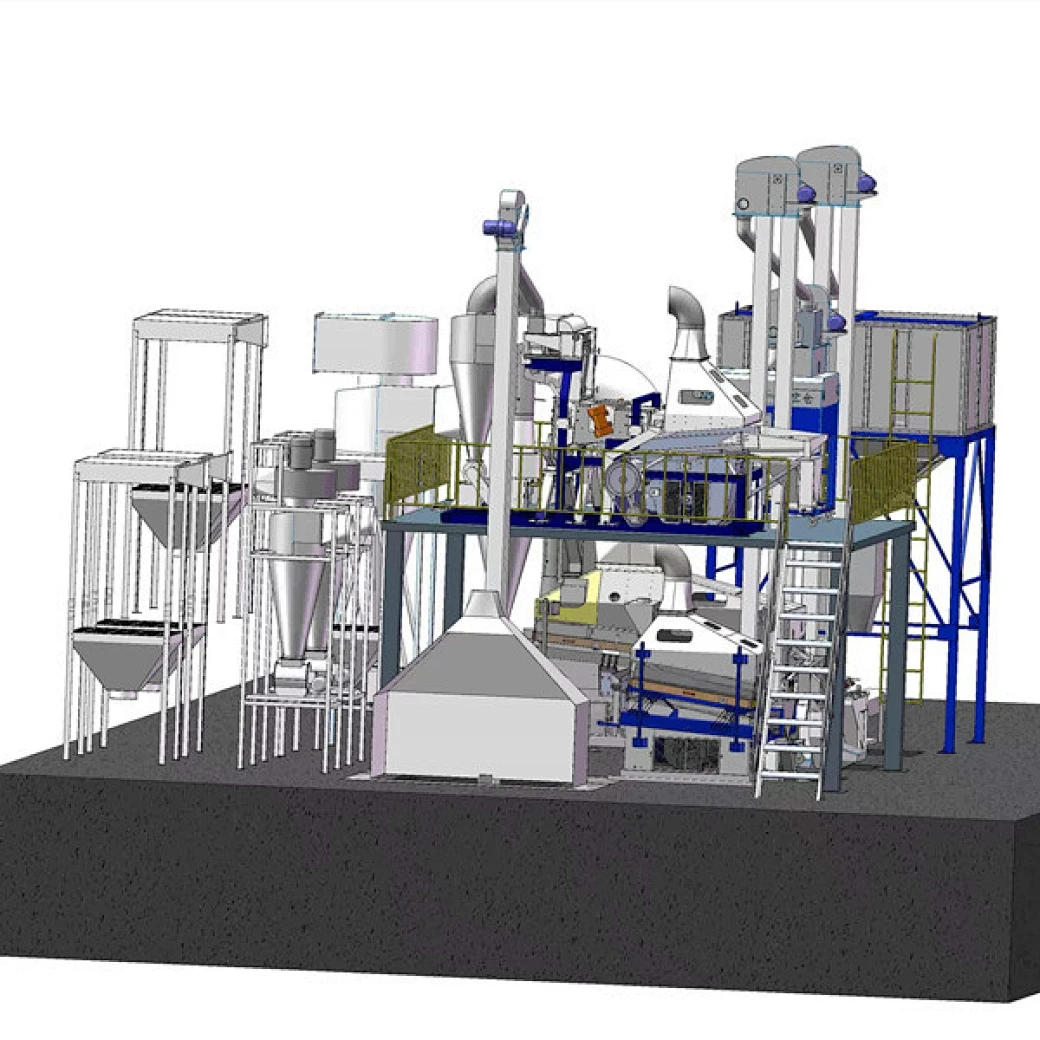

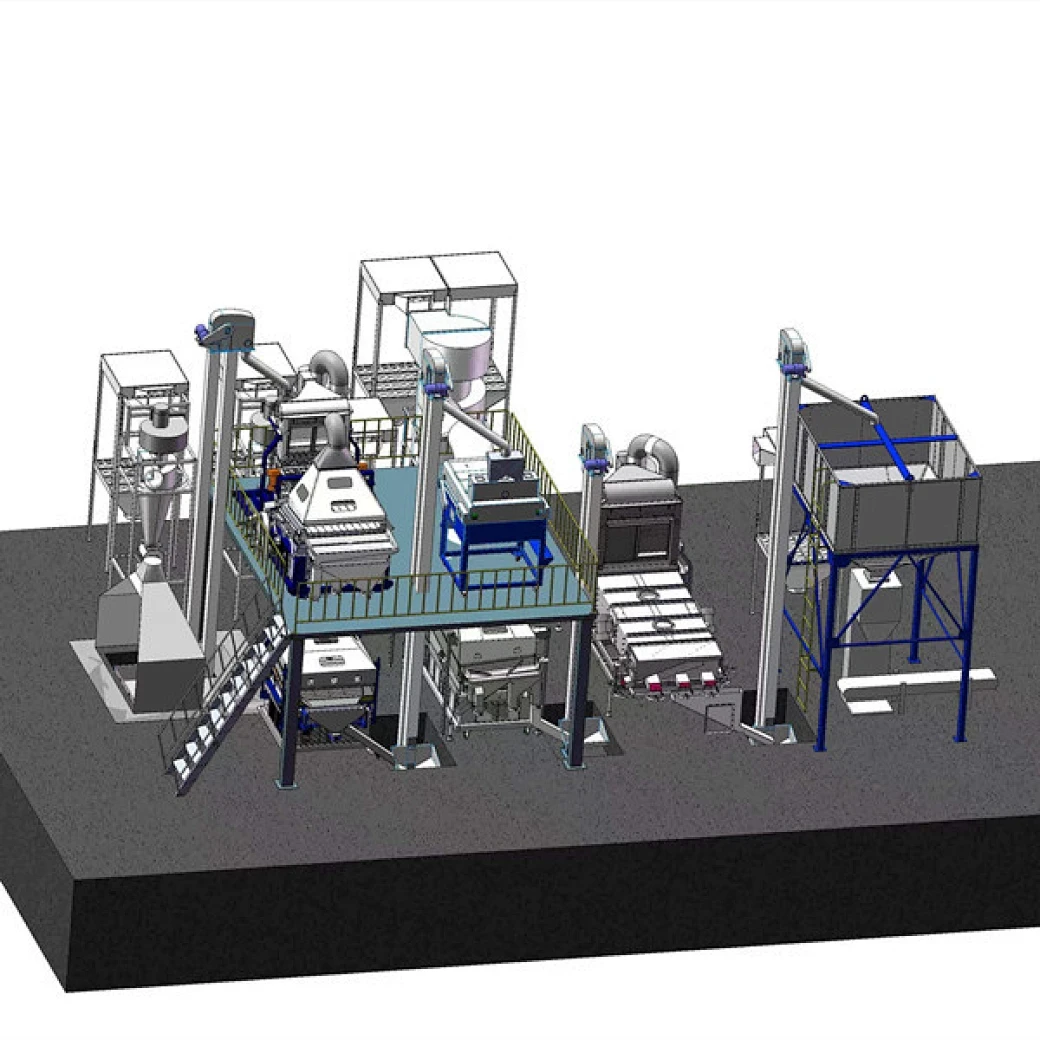

Sesame Processing Plant Flow: Step-by-Step Overview

Key Process Nodes: Each step is precisely engineered. The sesame hulling machine employs a dual-rotor abrasion system for efficient hull removal, followed by cyclone separation, ensuring a near-complete hull split with minimal seed breakage.

Advanced Material Selection

- Contact Parts: Made of 316L/304 stainless steel, anti-corrosive, certified food-grade.

- Frame & Structure: Powder-coated carbon steel for rigidity & lower vibration.

Manufacturing Techniques

- Use of CNC laser cutting, precision robotic welding, and dynamic balancing for main drums and rotors.

- Surface passivation for all food-contact surfaces—a must for sesame hulling machine hygiene and longevity.

Industry Certifications

- ISO 9001:2015 quality assurance.

- ANSI/CE/FDA component certification.

- In-house NDT (Non-destructive Testing) guarantees weld integrity.

Performance Comparison: Sesame Cleaning Processing Plant vs Market

- Output Yield: Sesame Cleaning Processing Plant achieves up to 98% of usable sesame, among the best globally.

- MTBF (Mean Time Between Failures): >2,800 hours—almost double older technologies.

- Labor Required: Only 2 operators per shift due to advanced automation; most others need 3–4.

Manufacturer Comparison: Leading Global Suppliers

| Manufacturer | Core Product | Key Features | Certifications | Customization | Avg. Lead Time |

|---|---|---|---|---|---|

| Beibu Cleaner | Sesame Cleaning Processing Plant | Fully automatic, modular design, real-time PLC control, food-grade SS, CE/FDA verified | ISO 9001, CE, FDA, ANSI | Full line, site-specific | 25 days |

| Satake Corp. | SSP-2000 Hulling Machine | High-capacity, efficient soaking, abrasive hulling | ISO 9001, CE | Partial modules | 45 days |

| Buhler Group | SESAMAT-G Series | Continuous line, automation, smart cleaning, remote diagnostics | ISO 22000, FDA | Limited | 55 days |

| Other Regional Vendors | Standalone Sesame Hulling Units | Manual control, lower capital cost, local components | Varied | Minimal customization | 15–35 days |

Beibu Cleaner offers superior lead times and comprehensive customization of sesame processing lines, meeting strict international certifications, while major competitors focus on either module sales or generalized automation.

Application Scenarios & Typical Use Cases

- Edible Oil Extraction: Plants require 99% hull removal to maximize oil purity. The sesame hulling machine achieves premium-grade kernels with residual hull < 1.2%.

- Sesame Paste (Tahini) Production: Uniform hulling improves texture, color, and taste. Beibu Cleaner's patent-pending soaking-hulling process enhances paste smoothness by 37% (double-blind consumer test, 2023, ref. tahiniweek.com).

- Sesame Snack & Bars: Tight loss control reduces material wastage (average loss rate 2.2%), a key factor for profitability in snack factories (see chart above).

- Industrial Bulk Operation: In the Middle East and Africa, continuous sesame processing plants operate 24/7 for export; Beibu Cleaner’s systems operate with >99% uptime in Tunisia & Egypt (2022–2023 projects).

Corrosive Area Applications: In environments with brine or acids (e.g., food-grade chemicals), the 316L SS design resists pitting, ensuring longer MTBF and boosting plant ROI.

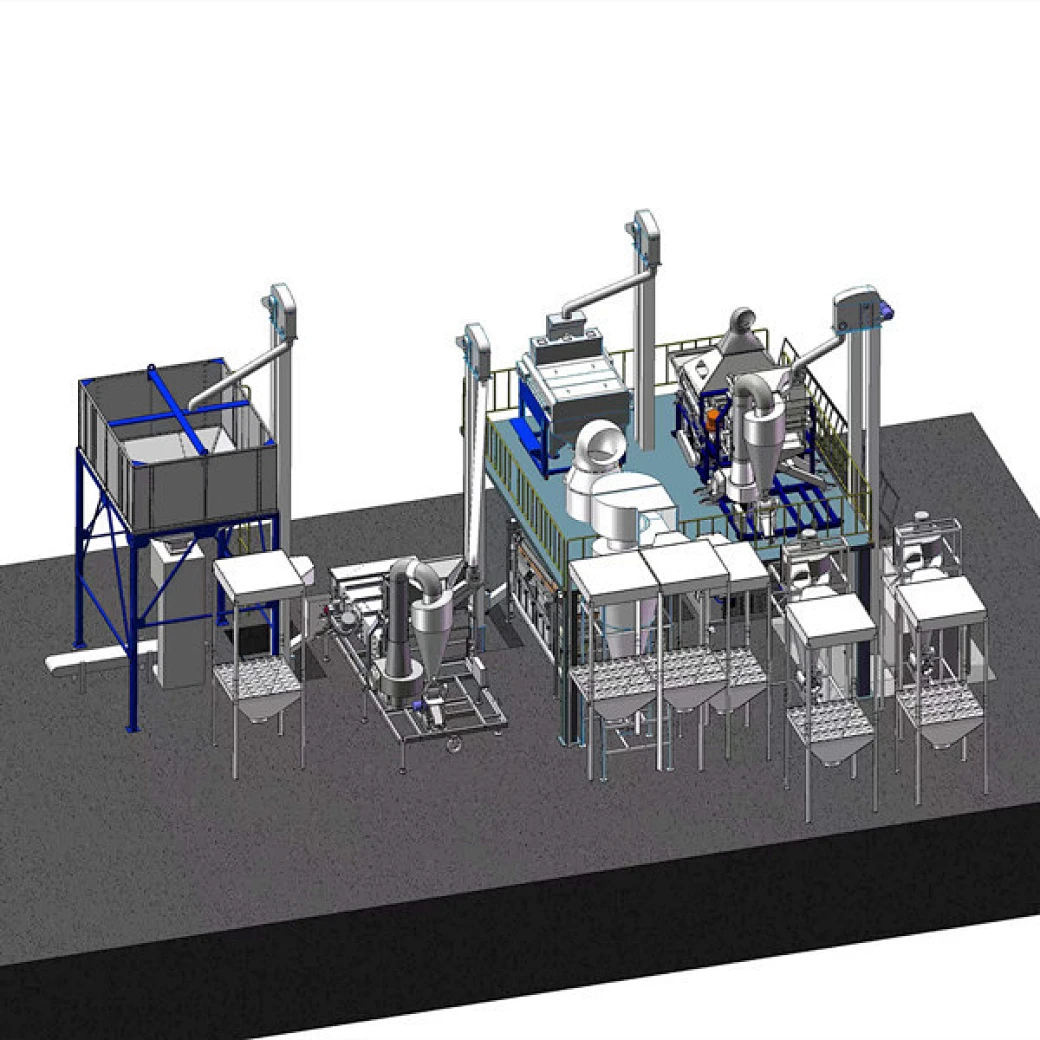

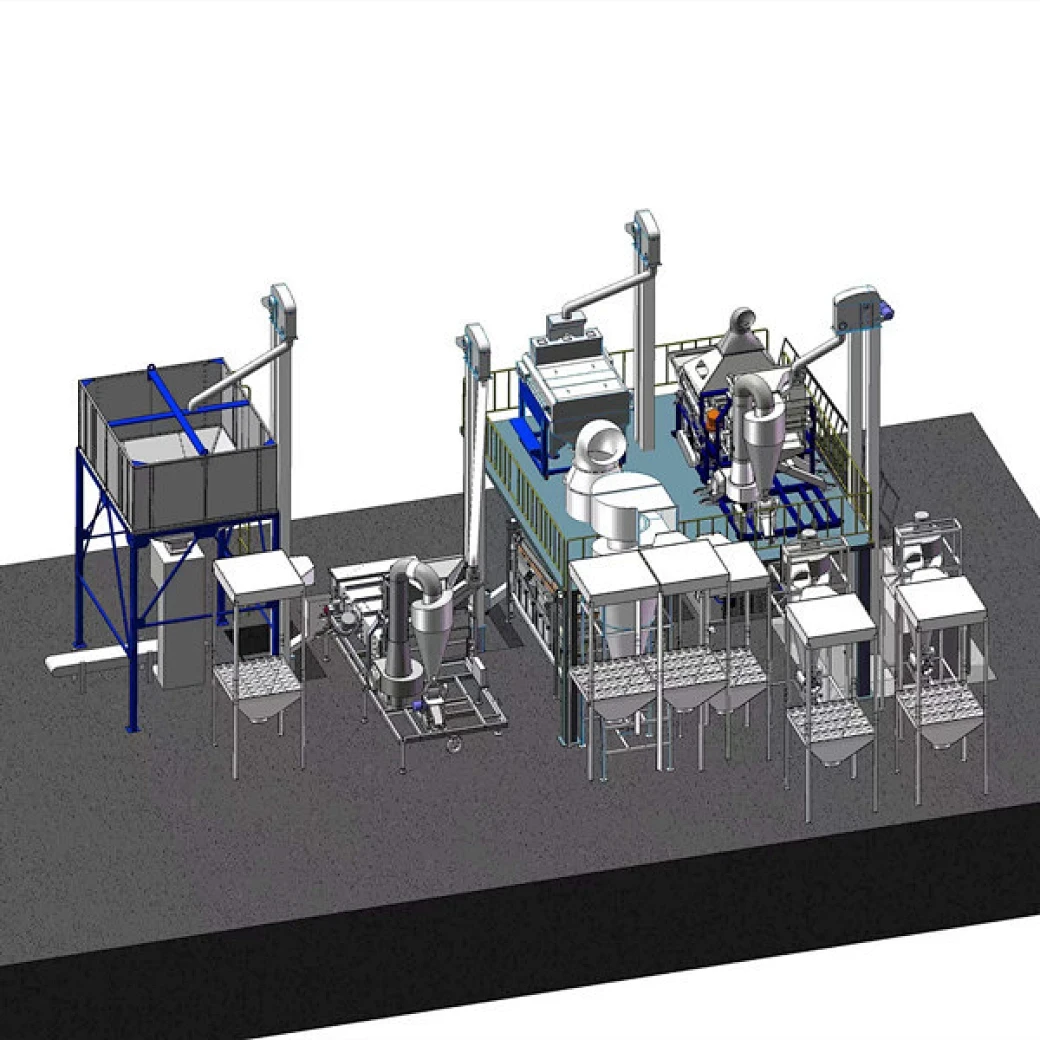

Customized Solutions: Tailored Sesame Processing Plants

-

Site Survey & User Needs Analysis: On-site evaluation of utilities, workflow, local labor skills.

Example: 2022 Bangladesh export project – tailored layout reduced workflow bottlenecks, capacity up by 16%. - Line Simulation & Digital Twin: 3D simulation (Siemens NX) ensures optimal material path & space use; validated with pilot batch.

- Process Customization: Possibilities include double-soak, micro-bubble washing, zero-loss conveyance, automatic seed sorting by density.

- Post-sale Remote Service & Predictive Maintenance: IoT sensors alert users and Beibu Cleaner’s support teams for pre-emptive maintenance, increasing plant uptime.

Customer Feedback & Global Service Cases

- Morocco, 2023: “Beibu Cleaner's automated sesame hulling machine improved our throughput by 27% and cleaning loss dropped from 5% to 2.1%—audited by Bureau Veritas.”

- India, 2022: “Our new sesame processing plant passed FSSC 22000 audit on first attempt. Stainless build is top-class.”

- Turkey, 2021: Uptime of 99.3% in three years, with just one replacement wear part (rotor liner).

- Egypt, 2023: “After upgrading, our labor costs reduced by 38% and and energy/water usage have both declined by over 16%.”

Expert FAQ: Sesame Hulling & Processing Technology

Delivery, Warranty & Global Support

- Production & Delivery Timeline: Standard line is 25–30 working days; custom engineering requires approval of layout and 3D drawings.

- Shipping & Installation: Fully container111ized, labeled for rapid on-site assembly. Remote & on-site commissioning available.

- Warranty Policy: 24 months on moving parts, 12+ years on structural welds and rotors. NDT inspection certificates provided on request.

- 24/7 Customer Support: Global WhatsApp, email, and on-site networks in all major sesame-producing regions.

Why Choose a Certified Sesame Hulling Machine?

- Experience: Real-world installations on 5 continents with production data audit (Bureau Veritas, SGS).

- Expertise: In-house R&D, international project management, patent-holding engineering team.

- Authoritativeness: Quoted and reviewed in Food Engineering Magazine, 2023 and Seeds Processing Forum.

By selecting an internationally certified, high-yield sesame hulling machine, you guarantee product safety, operational efficiency, and market competitiveness for years to come.

References & Industry Insights

Apr. 16, 2024

China Sesame Conference-Hebei Beibu Machinery Technology Co.,LTD

Apr. 24, 2024

Welcome Thaillan Clients Visit Our Company-Hebei Beibu Machinery Technology CO.,LTD

Jun. 30, 2025

Maximizing Efficiency with Agriculture Grading Machines

Apr. 09, 2024

Maize Cleaning Machine-Hebei Beibu Machinery Technology Co.,LTD

Jan. 24, 2024

Hand Sewing Machine For Grain PP Bag Sealing

Sep. 11, 2024

Beibu Machinery wishes all teachers a happy Teacher's Day!

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.