Sesame, a nutrient-rich oilseed, has been a staple in human diets for millennia, revered for its distinct flavor, nutritional value, and versatility. From being a key ingredient in tahini and halva to enhancing baked goods and providing a healthy source of oil, sesame's global demand continues to surge. However, unlocking the full potential of this tiny seed often hinges on an efficient and hygienic processing stage, particularly the removal of its hull. This is where advanced machinery like the sesame hulling machine becomes indispensable, serving as the cornerstone of any modern sesame processing line.

The Growing Global Demand for Sesame and Processing Innovations

The global sesame market is experiencing robust growth, driven by increasing consumer awareness of its health benefits, rising demand for plant-based proteins, and expanding applications in the food, cosmetic, and pharmaceutical industries. According to recent market analyses, the global sesame seeds market size was valued at approximately USD 6.5 billion in 2023 and is projected to reach over USD 10 billion by 2030, growing at a compound annual growth rate (CAGR) of around 6-7%. This upward trajectory puts immense pressure on the supply chain to deliver high-quality, processed sesame efficiently and at scale.

Automation and technological advancements are critical in meeting this demand. Traditional hulling methods are labor-intensive, less hygienic, and often result in lower yields. Modern sesame hulling machine technology, integrated into a comprehensive sesame processing plant, addresses these challenges by offering automated, high-capacity solutions that ensure superior product quality, enhanced food safety, and operational cost savings. The industry is trending towards fully automated, integrated systems that minimize human intervention, reduce contamination risks, and maximize output.

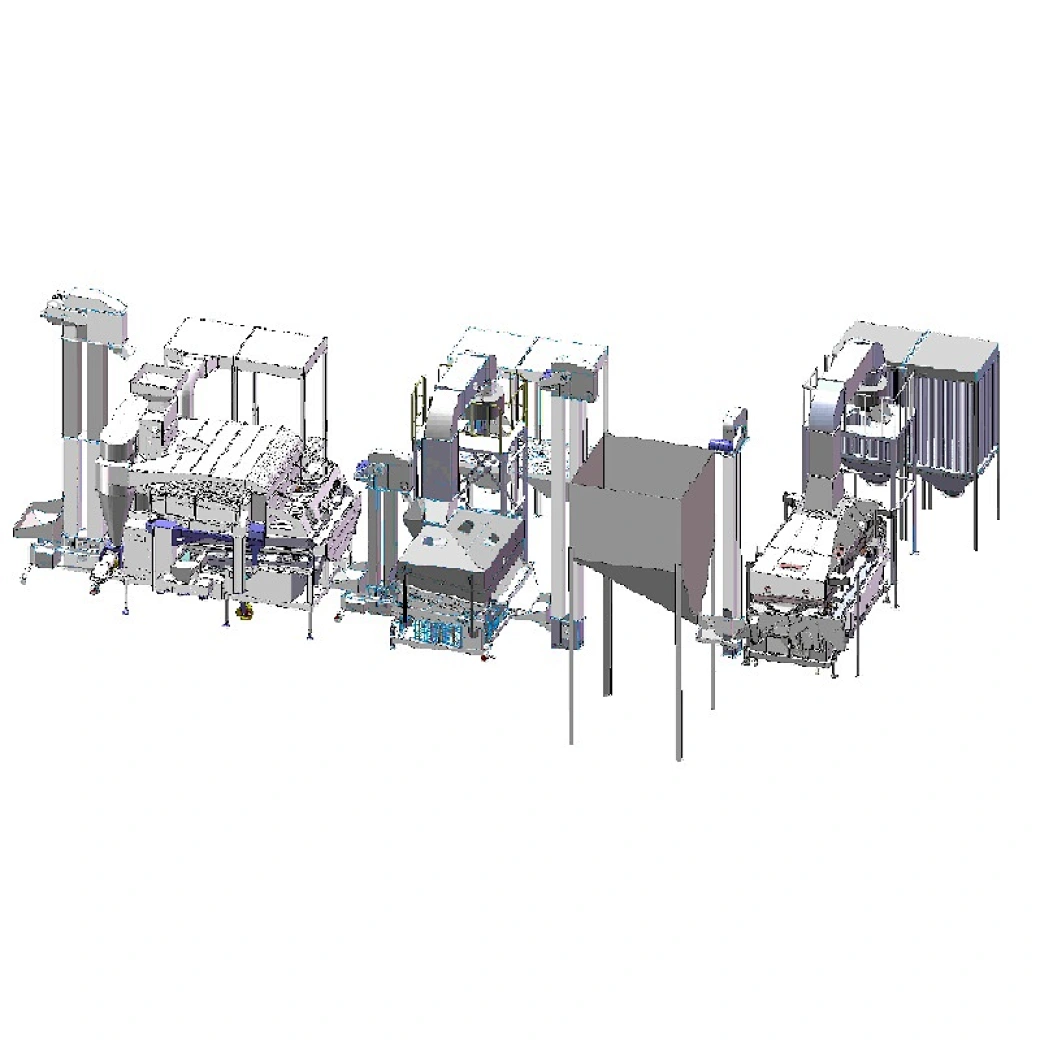

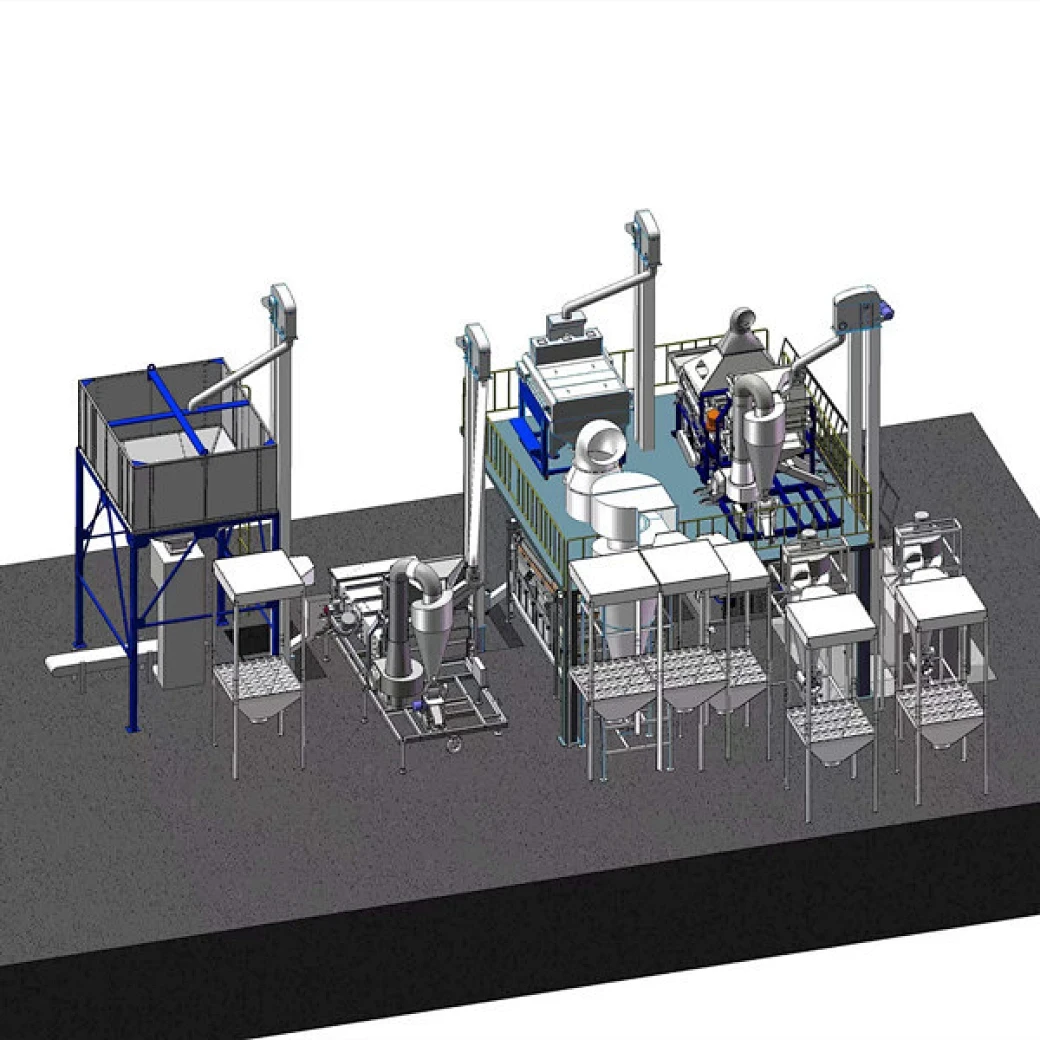

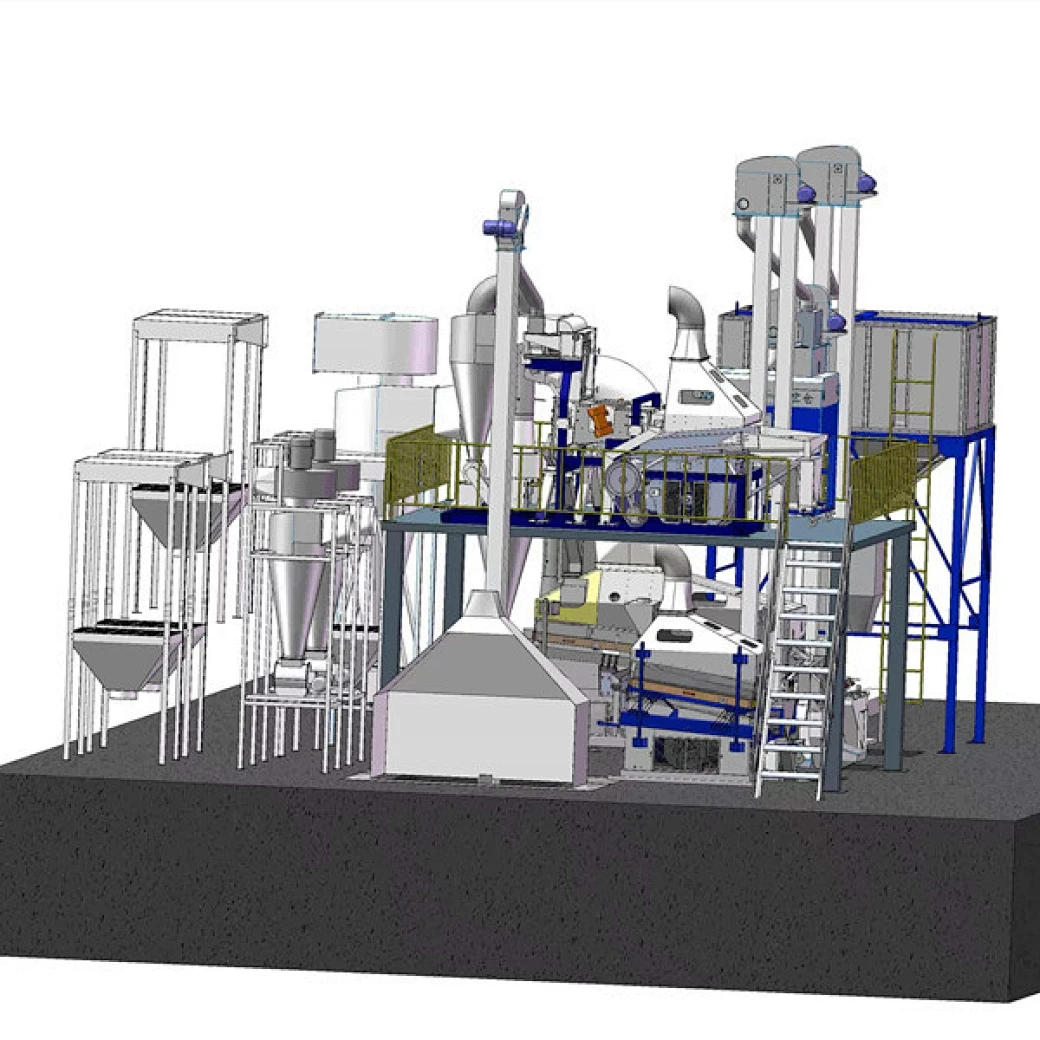

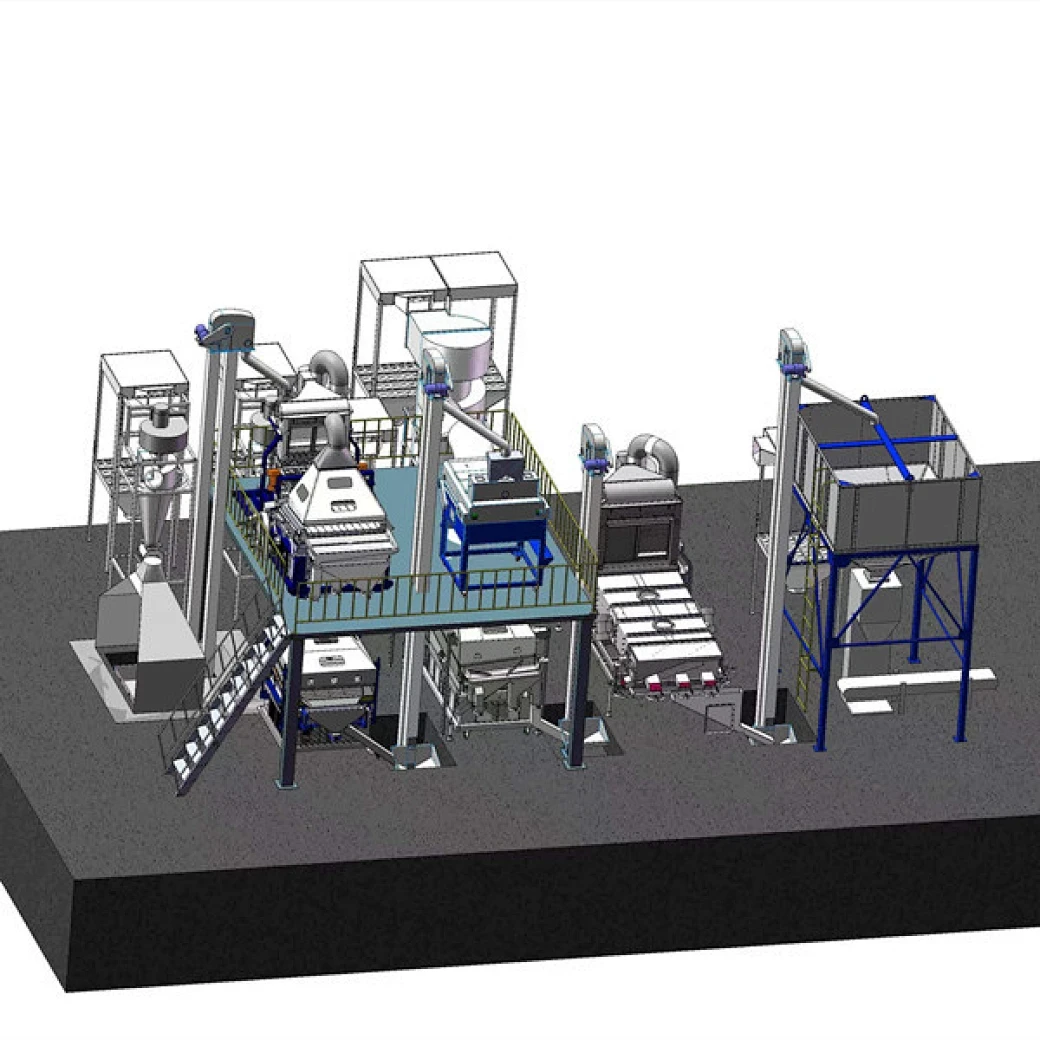

Our product, the Sesame Cleaning Processing Plant, available at https://www.beibucleaner.com/sesame-cleaning-processing-plant.html, embodies these advancements, providing a holistic solution from raw seed cleaning to efficient hulling and drying.

Understanding the Core Technology: The Sesame Hulling Machine

The sesame hulling machine is the heart of any sesame processing line focused on producing hulled sesame seeds. Its primary function is to meticulously separate the outer hull (bran) from the inner kernel, a process crucial for improving the seed's appearance, digestibility, taste, and overall quality. The hull, while fibrous, can be bitter and negatively impact the flavor profile and color of the final product. Efficient hulling ensures a whiter, purer, and more palatable sesame seed, suitable for a wide range of applications.

Detailed Process Flow of a Sesame Hulling Machine

The operation of a modern sesame hulling machine integrated within a sesame processing plant involves several critical stages, each designed to optimize the hulling process and ensure maximum yield with minimal breakage. While variations exist (wet hulling vs. dry hulling), the wet hulling method is predominant due to its higher efficiency and better end-product quality, especially for white sesame seeds. Here's a typical flow:

- Raw Seed Cleaning (Pre-cleaning): Before hulling, raw sesame seeds are subjected to an initial cleaning phase to remove impurities. This often involves a multi-stage process:

- Vibrating Screen/Sifter: To separate larger foreign materials (straw, sticks, stones) and finer particles (sand, dust).

- Destoner: Utilizes specific gravity differences to separate heavier stones from lighter sesame seeds, often using an air-blown system.

- Magnetic Separator: Removes any metallic impurities that might be present.

Expert Insight: Proper pre-cleaning is paramount. Contaminants can damage the hulling machine, reduce hulling efficiency, and compromise food safety. Adherence to ISO 22000 principles for food safety management begins right from this stage.

- Soaking/Blanching: Cleaned sesame seeds are soaked in hot water, typically around 50-60°C, for a specific duration (e.g., 20-30 minutes). This step is crucial for softening the hull, making it easier to detach from the kernel. Some advanced systems might use a blanching process where seeds are briefly exposed to steam or hot water at higher temperatures to further loosen the hull and deactivate enzymes, preserving color.

Technical Note: The water quality used for soaking must meet potable water standards, often requiring a robust water treatment system within the sesame processing plant.

- Hulling (Mechanical Abrasion): The softened seeds are then fed into the sesame hulling machine. This machine typically employs a centrifugal force or mechanical agitation combined with abrasion. As the seeds tumble and rub against each other and the machine's inner walls (often lined with abrasive material), the softened hulls are gently rubbed off. The design minimizes kernel breakage while maximizing hull removal.

Expert Insight: The design of the hulling chamber and the speed of agitation are critical parameters to achieve a high hulling rate (e.g., 98-99%) with a low breakage rate (e.g., <5%). Precision engineering and CNC machining of critical parts ensure consistent performance.

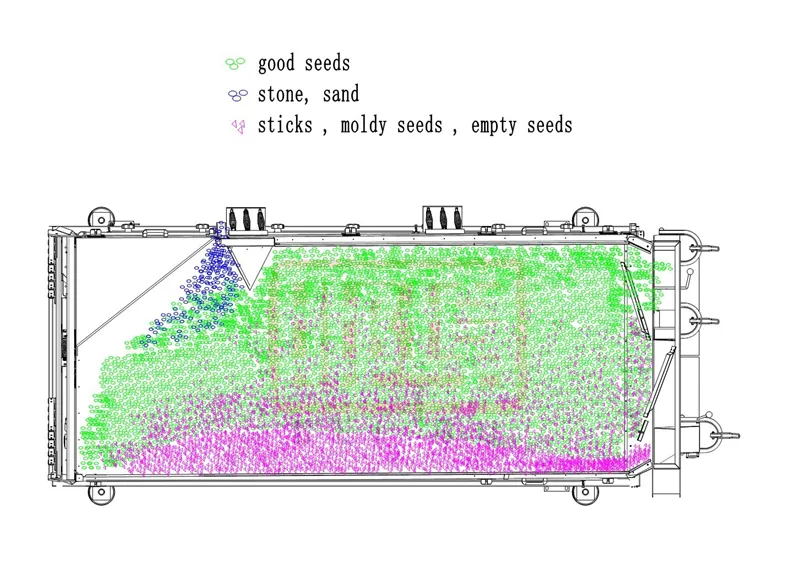

- Hull-Kernel Separation (Specific Gravity Separation): This is arguably the most ingenious part of the wet hulling process. The mixture of hulled kernels, water, and loosened hulls is directed to a separation unit, typically a specific gravity separator or a centrifugal separator.

- Specific Gravity Separator: Utilizes the density difference between the heavier hulled kernels and the lighter hulls suspended in water. As the mixture flows, the heavier kernels sink and are collected, while the lighter hulls float and are skimmed off or overflowed with the water.

- Centrifugal Separation: Some advanced systems may use centrifugal force to separate the lighter hulls from the heavier kernels.

Application Highlight: This stage showcases the machine's ability to ensure a pure end-product. Effective separation minimizes the need for manual sorting and guarantees a high-quality hulled sesame output.

- Washing/Rinsing: The separated hulled kernels undergo further rinsing with fresh water to remove any residual hull fragments or slime, ensuring a clean and bright product.

- De-watering: After washing, the hulled sesame seeds contain significant moisture. A de-watering machine, such as a centrifugal dehydrator, is used to remove excess surface water, bringing the moisture content down to around 8-12%. This prepares the seeds for efficient drying.

Energy Efficiency: Modern de-watering systems are designed to be highly energy-efficient, often recovering water for reuse in earlier stages of the sesame processing line.

- Drying: The de-watered seeds are then transferred to a dryer (e.g., fluid bed dryer, hot air dryer). Drying is essential to reduce the moisture content to a safe level (typically 3-5%) for long-term storage, preventing mold growth and preserving quality.

This systematic process ensures that the sesame hulling machine delivers consistently high-quality hulled sesame seeds, meeting stringent food safety standards and market demands.

Key Components, Materials, and Manufacturing Excellence

The reliability and performance of a sesame hulling machine are directly tied to the quality of its components, the materials used, and the precision of its manufacturing processes. For our Sesame Cleaning Processing Plant, we prioritize:

- Material Selection: All components that come into contact with sesame seeds or water are meticulously crafted from food-grade stainless steel, primarily SUS304 or SUS316L. These materials are chosen for their exceptional corrosion resistance, durability, and inertness, ensuring no contamination of the food product. Non-contact parts are typically made from robust carbon steel, often powder-coated for corrosion protection and aesthetics.

- Manufacturing Processes: Our machines undergo a rigorous manufacturing process:

- Precision CNC Machining: Critical components, especially those involved in hulling and separation, are precision-machined using Computer Numerical Control (CNC) technology. This ensures tight tolerances, perfect fitment, and optimal operational efficiency.

- Laser Cutting: For intricate shapes and paneling, laser cutting provides high accuracy and clean edges, reducing material waste and ensuring precise assembly.

- Automated Welding: Food-grade welding techniques (e.g., TIG welding) are employed to create smooth, crevice-free surfaces that prevent bacterial accumulation and facilitate easy cleaning. All welds are inspected to meet industry standards.

- Surface Treatment: Polishing and passivation are applied to stainless steel surfaces to enhance corrosion resistance and maintain hygiene.

- Detection and Quality Control: Every machine and component undergoes stringent quality checks. We adhere to international standards such as ISO 9001 for quality management systems and strive for compliance with industry-specific certifications like FDA for food contact materials. Each unit is tested for functionality, performance parameters (hulling rate, breakage rate), and safety before dispatch. Our internal testing protocols mirror critical industry benchmarks, ensuring peak performance under varied conditions.

- Usage Lifetime: Designed for continuous industrial operation, our sesame hulling machine and associated equipment have an estimated service life of 15-20 years with proper maintenance, showcasing their robust construction and material quality. This longevity translates into a lower total cost of ownership for our clients.

- Applicable Industries: While primarily designed for food processing, the principles of hygienic and efficient separation make our technology relevant for various sectors requiring similar processing, including nut processing, seed oil extraction, and some specialized chemical processing where precise separation is critical. However, our primary focus remains the food industry, particularly in applications for snack foods, confectionery, bakery, and sesame oil production.

Typical Performance Parameters of a Sesame Hulling Machine

Understanding the specifications is crucial for potential buyers to assess suitability for their production needs. Below is a table illustrating typical parameters for our sesame hulling machine models:

| Parameter | Unit | Typical Range/Value | Description |

|---|---|---|---|

| Model (Example) | - | BH-1000 | Indicative model for mid-scale production |

| Capacity | kg/hour (input) | 500 - 2000 | Raw sesame input processing rate |

| Hulling Rate | % | ≥ 98% | Percentage of seeds successfully hulled |

| Whole Kernel Rate | % | ≥ 95% | Percentage of hulled seeds that remain unbroken |

| Total Power | kW | 7.5 - 22 | Combined power of all motors in the hulling unit |

| Water Consumption | L/hour | Approx. 200 - 500 | Water needed for soaking, separation, and rinsing. (Recycling systems reduce net consumption) |

| Dimensions (L×W×H) | meters | Varies by model | Overall footprint of the hulling unit |

| Contact Material | - | Food Grade SUS304/SUS316L | Ensures hygiene and corrosion resistance |

| Operating Noise Level | dB(A) | < 75 | Designed for relatively quiet operation |

Technological Advantages of Our Sesame Cleaning Processing Plant

Our comprehensive Sesame Cleaning Processing Plant, featuring the advanced sesame hulling machine, offers a suite of technological advantages that set it apart in the market and provide significant benefits to our clients:

- High Efficiency and Yield: Precision engineering ensures an industry-leading hulling rate (typically 98%+) while maintaining an exceptionally high whole kernel rate (≥95%). This directly translates to higher output and profitability for our clients.

- Superior Product Quality: The multi-stage cleaning, soaking, hulling, and separation processes consistently produce bright white, clean, and intact hulled sesame seeds, meeting stringent international quality standards for appearance and purity.

- Enhanced Food Safety and Hygiene: Constructed entirely from food-grade SUS304/316L stainless steel for all contact parts, the plant adheres to strict sanitary design principles. Smooth, crevice-free surfaces prevent bacterial accumulation and facilitate easy cleaning and maintenance. Compliance with HACCP and ISO 22000 standards is inherent in our design philosophy.

- Automation and Reduced Labor Costs: Featuring advanced PLC control systems and intuitive human-machine interfaces, the entire sesame processing line is highly automated, minimizing the need for manual intervention. This significantly reduces labor costs, improves operational consistency, and lessens the potential for human error.

- Energy and Water Efficiency: Our designs incorporate energy-saving motors, optimized process flows, and innovative water recycling systems (e.g., using separated water from the de-watering stage for initial washing), leading to lower utility consumption and reduced environmental impact. For instance, our systems can achieve up to a 30% reduction in water consumption compared to older models due to advanced recycling mechanisms.

- Durability and Low Maintenance: Built with robust materials and subjected to rigorous quality control, our machinery is designed for continuous, heavy-duty operation. This ensures extended lifespan and minimal downtime, reducing maintenance costs and enhancing operational reliability.

- Versatility: The system can be configured to process various types of sesame seeds (white, black, brown) with minor adjustments, offering flexibility for different product demands.

Application Scenarios and Industry Impact

The hulled sesame seed is a versatile ingredient, and our sesame hulling machine and comprehensive sesame processing plant serve a wide array of industries:

- Food Processing Plants: For the production of hulled sesame seeds used in baked goods (breads, bagels), confectionery (halva, sesame snaps), savory snacks, and breakfast cereals.

- Sesame Oil Mills: Hulled sesame seeds produce a lighter, milder, and often more preferred sesame oil, especially for culinary uses where strong flavor from the hull is undesirable.

- Tahini and Hummus Manufacturers: The primary ingredient for these popular Middle Eastern and Mediterranean staples is high-quality hulled sesame paste, requiring efficient hulling for a smooth, non-bitter product.

- Confectionery and Dessert Industries: Hulled sesame is used as a topping or ingredient in various sweet treats, providing texture and nutritional value.

- Nutritional Supplement Manufacturers: As a rich source of calcium, magnesium, and healthy fats, hulled sesame is increasingly incorporated into health bars, protein mixes, and other dietary supplements.

In each of these scenarios, the reliable performance of our sesame hulling machine directly contributes to increased production efficiency, enhanced product quality, and ultimately, greater market competitiveness for our clients. For instance, a client in the Middle East reported a 15% improvement in their tahini's sensory profile after implementing our hulling solution, leading to a significant boost in their market share.

Choosing the Right Partner: Manufacturer Comparison and Customization

When investing in a sesame processing plant, selecting the right manufacturer is as crucial as the technology itself. While direct comparisons of specific brands are beyond the scope here, evaluating potential partners based on key criteria is essential:

- Experience and Specialization: Look for manufacturers with a proven track record (e.g., over 20 years in the industry) and specialized expertise in sesame processing. Deep understanding of sesame varieties, hulling challenges, and food safety standards is invaluable.

- Technology and Innovation: Assess the manufacturer's commitment to R&D. Do they incorporate the latest automation, energy-saving, and hygiene technologies? Are their sesame hulling machine designs patented or recognized for innovation?

- Quality and Certifications: Verify adherence to international quality management systems (ISO 9001) and food safety standards (ISO 22000, HACCP, FDA-compliant materials). Request references or factory audits.

- Customization Capabilities: A reputable manufacturer should offer flexible solutions. Not all sesame processing plant needs are identical. Look for a partner who can provide tailored designs based on your specific capacity requirements, space limitations, budget, and desired end-product specifications. This might include varying hulling capacities (e.g., from 500 kg/hour to 5 tons/hour), integration with existing lines, or specific drying technologies.

- After-Sales Support and Service: This is critical. Evaluate their support infrastructure, including installation assistance, operator training, spare parts availability, warranty provisions, and responsive technical support (e.g., 24/7 hotline, remote diagnostics).

- Client Testimonials and Case Studies: Real-world applications and client feedback offer the most compelling evidence of a manufacturer's reliability and the effectiveness of their sesame hulling machine.

Tailored Solutions for Diverse Needs

We understand that every client's needs are unique. Our approach to providing a sesame processing plant is highly collaborative and solution-oriented. We offer:

- Capacity Scaling: From small-to-medium scale operations requiring a basic sesame hulling machine to large-scale industrial sesame processing lines, we design systems that match your throughput requirements precisely.

- Modular Design: Our plants are often built with modular components, allowing for future expansion or integration with existing equipment, providing flexibility as your business grows.

- Layout Optimization: We work with clients to design efficient plant layouts, considering available space, workflow, and safety regulations.

- Specific Processing Needs: Whether you require ultra-white sesame for confectionery, or specific drying profiles for enhanced flavor, we can customize the process parameters and equipment to meet these niche requirements.

- Turnkey Solutions: From initial consultation and design to manufacturing, installation, commissioning, and training, we offer comprehensive turnkey solutions, ensuring a seamless project execution.

Case Studies and Client Successes

Over two decades, we've partnered with numerous businesses across the globe, helping them achieve their sesame processing goals. While specific client names remain confidential, the impact of our sesame hulling machine and sesame processing plant solutions is evident:

- Major Food Ingredient Supplier, Europe: A leading supplier of food ingredients sought to upgrade their aging sesame hulling system to meet stricter hygiene standards and increase capacity. We implemented a fully automated Sesame Cleaning Processing Plant, incorporating our high-efficiency sesame hulling machine and advanced water recycling. Result: A 25% increase in daily output, a 10% reduction in water consumption, and successful certification under new EU food safety regulations. Their product quality now consistently exceeds market expectations, solidifying their position as a premium supplier.

- Emerging Sesame Oil Producer, Africa: A startup aiming to produce high-quality cold-pressed sesame oil needed a compact yet efficient sesame processing line. We designed a custom, energy-efficient solution focusing on gentle hulling to preserve the oil's delicate flavor. Result: They achieved a premium oil product with a significantly higher yield than projected, enabling them to quickly gain market traction and expand their product line.

- Regional Confectionery Manufacturer, Asia: Facing rising labor costs and inconsistent product quality from manual hulling, this manufacturer invested in our automated sesame hulling machine and cleaning unit. Result: A dramatic reduction in labor by 70%, consistent quality of hulled sesame, and a 5% improvement in final product shelf life due to superior cleaning and drying. This allowed them to scale production and reduce operational expenditure.

These examples underscore our commitment to delivering tangible value and becoming a trusted partner in the global sesame industry.

Trustworthiness and Customer Support

At the core of our operations is a commitment to building lasting trust with our clients. This is reflected in our transparent processes, robust support systems, and unwavering dedication to product quality.

- Quality Assurance & Certification: All our equipment, including the sesame hulling machine, is manufactured under strict quality control protocols, adhering to ISO 9001 standards. We ensure that all food-contact materials comply with international food safety regulations like FDA and relevant national standards. Regular internal audits and third-party inspections validate our commitment to excellence.

- Warranty & After-Sales Service: We provide a comprehensive warranty for all major components of our Sesame Cleaning Processing Plant, typically ranging from 1 to 2 years, covering manufacturing defects and ensuring peace of mind. Beyond the warranty period, we offer long-term technical support, spare parts supply, and maintenance services.

- Delivery & Installation: We provide clear delivery timelines (typically 8-12 weeks for standard configurations, longer for highly customized plants) and detailed installation instructions. Our experienced engineers are available for on-site installation supervision and commissioning, ensuring smooth startup of your sesame processing line.

- Operator Training: Comprehensive training programs are provided for your operational staff, covering machine operation, routine maintenance, troubleshooting, and safety procedures. This empowers your team to run the sesame hulling machine efficiently and safely.

- Customer Support: Our dedicated customer support team is available via multiple channels (phone, email, online portal) for technical assistance, spare parts inquiries, and general queries. We pride ourselves on rapid response times to minimize any potential downtime.

- Transparent Pricing: We believe in clear, itemized pricing, ensuring you understand the value you receive for your investment in our sesame processing plant.

Frequently Asked Questions (FAQ)

Here are some common questions we receive regarding our sesame hulling machine and related equipment:

Q1: What is the ideal moisture content for raw sesame seeds before processing in the sesame hulling machine?

A1: For optimal cleaning and hulling efficiency, raw sesame seeds should ideally have a moisture content between 5-8%. Seeds that are too dry may lead to higher breakage during hulling, while overly moist seeds can hinder separation and increase the risk of mold during storage.

Q2: What is the primary difference between wet hulling and dry hulling processes?

A2: Wet hulling, which our sesame hulling machine primarily utilizes, involves soaking sesame seeds in water to soften the hull before mechanical abrasion. This method typically results in a higher hulling rate, lower kernel breakage, and a brighter, whiter final product. Dry hulling, in contrast, processes seeds without pre-soaking, often leading to lower efficiency and more broken kernels.

Q3: What materials are used for the parts of the sesame hulling machine that come into contact with the sesame seeds?

A3: All components that are in direct contact with sesame seeds, water, or the final product are made from high-grade food-grade stainless steel, typically SUS304 or SUS316L. This ensures maximum hygiene, prevents corrosion, and complies with international food safety standards (e.g., FDA requirements).

Q4: How often does the sesame processing line require maintenance?

A4: Routine daily checks (e.g., cleaning, visual inspection) are recommended. More comprehensive maintenance, including lubrication, inspection of wear parts, and calibration, should be performed weekly or monthly, depending on the operational intensity. We provide a detailed maintenance schedule in our operation manual to ensure optimal performance and longevity of your sesame hulling machine.

Q5: What is the typical lifespan of a sesame hulling machine from your company?

A5: With proper operation and adherence to the recommended maintenance schedule, our sesame hulling machine and other components of the sesame processing plant are designed for a robust service life of 15 to 20 years. This longevity is attributed to the high-quality materials and precision manufacturing processes employed.

Q6: How does your system ensure food safety and hygiene throughout the sesame processing line?

A6: Our system employs multiple layers of food safety assurance. This includes exclusive use of food-grade stainless steel (SUS304/316L) for contact surfaces, sanitary design principles that minimize crevices and facilitate easy cleaning (CIP-compatible where applicable), robust impurity removal stages (destoner, magnetic separator), and adherence to ISO 22000 and HACCP guidelines in both design and operation. Regular internal and external audits ensure compliance.

Q7: Can the sesame hulling machine process different varieties of sesame seeds?

A7: Yes, our sesame hulling machine is versatile and can effectively process various types of sesame seeds, including white, black, and brown varieties. Minor adjustments to soaking time, water temperature, or machine settings might be required to optimize the hulling process for specific seed characteristics, which our technical team can advise on during commissioning.

Conclusion and Industry Outlook

The sesame hulling machine stands as a pivotal piece of equipment in the rapidly expanding global sesame market. As consumer demand for healthy, plant-based ingredients continues to soar, the need for efficient, hygienic, and high-quality sesame processing solutions becomes ever more critical. Our Sesame Cleaning Processing Plant, with its advanced sesame hulling machine at its core, represents the pinnacle of modern sesame processing technology, offering unparalleled efficiency, product quality, and operational reliability.

By focusing on robust engineering, adherence to international food safety standards, and providing comprehensive customer support, we empower our clients to not only meet but exceed market expectations. The future of sesame processing is bright, driven by automation, sustainability, and a continuous pursuit of excellence in yield and purity. Investing in a state-of-the-art sesame processing line is not just an equipment purchase; it's an investment in a resilient, profitable, and future-proof food production business.

Further Reading and References:

- Food and Agriculture Organization of the United Nations (FAO) - FAOSTAT Production Data for Sesame

- Journal of Food Science and Technology - Recent advancements in sesame processing technologies (Example link, subject to change based on actual research)

- International Food Policy Research Institute (IFPRI) - Trends and prospects in the oilseed sector (Example link, subject to change based on actual research)

- ISO (International Organization for Standardization) - Official website for ISO standards

Aug. 15, 2024

How Gravity Separator Working for Soybean Cleaning-Hebei Beibu Machinery Technology Co.,LTD

Feb. 05, 2025

The new year for grains cleaning machine has begun

Mar. 26, 2024

Hot Selling for Sesame Cleaning Machine-Hebei Beibu Machinery Technology CO.,LTD

Jan. 24, 2024

Aug. 16, 2024

wheat cleaning machine for seed

Jun. 17, 2024

three types grain packing machines

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.