- Introduction to Mini Destoner Machines and Their Industrial Relevance

- Technical Advantages and Working Principles

- Analyzing Mini Destoner Machine Price in the Marketplace

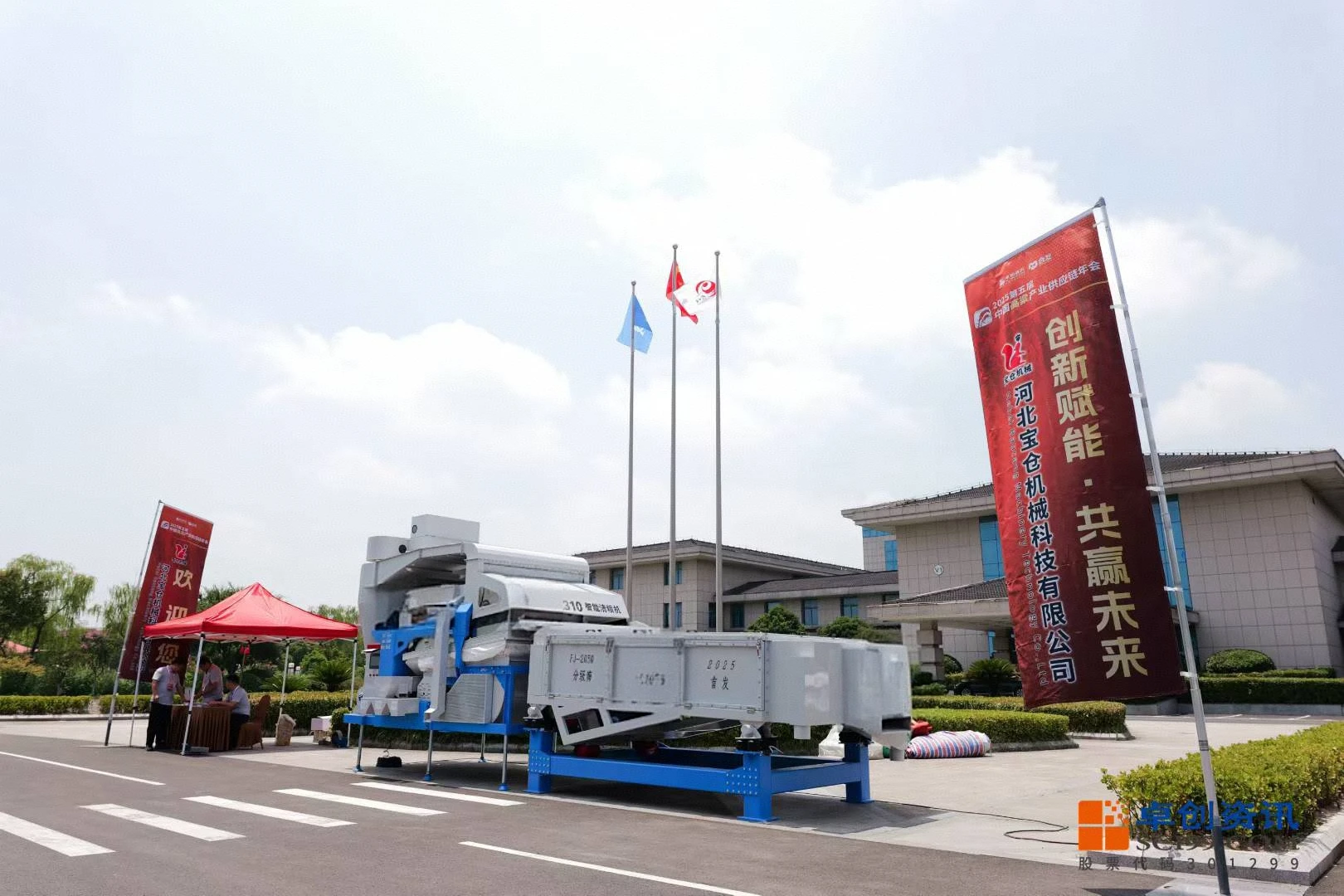

- Comparative Analysis of Leading Manufacturers

- Tailored Solutions and Customization Benefits

- Use Cases and Practical Application Scenarios

- Conclusion: Why the Mini Destoner Machine Is Essential

(mini destoner machine)

Introduction: The Importance of Mini Destoner Machine in Modern Processing

In the evolving landscape of agricultural and food processing, the mini destoner machine

has emerged as an indispensable tool for businesses seeking efficiency and quality assurance. This compact equipment specializes in the removal of stones and heavy impurities from a variety of grains, with particular relevance to rice, coffee, cereals, and pulses. Demand for mini rice destoner machines has grown steadily, reflecting the heightened focus on end-product purity and the increasing regulatory standards in food safety globally.

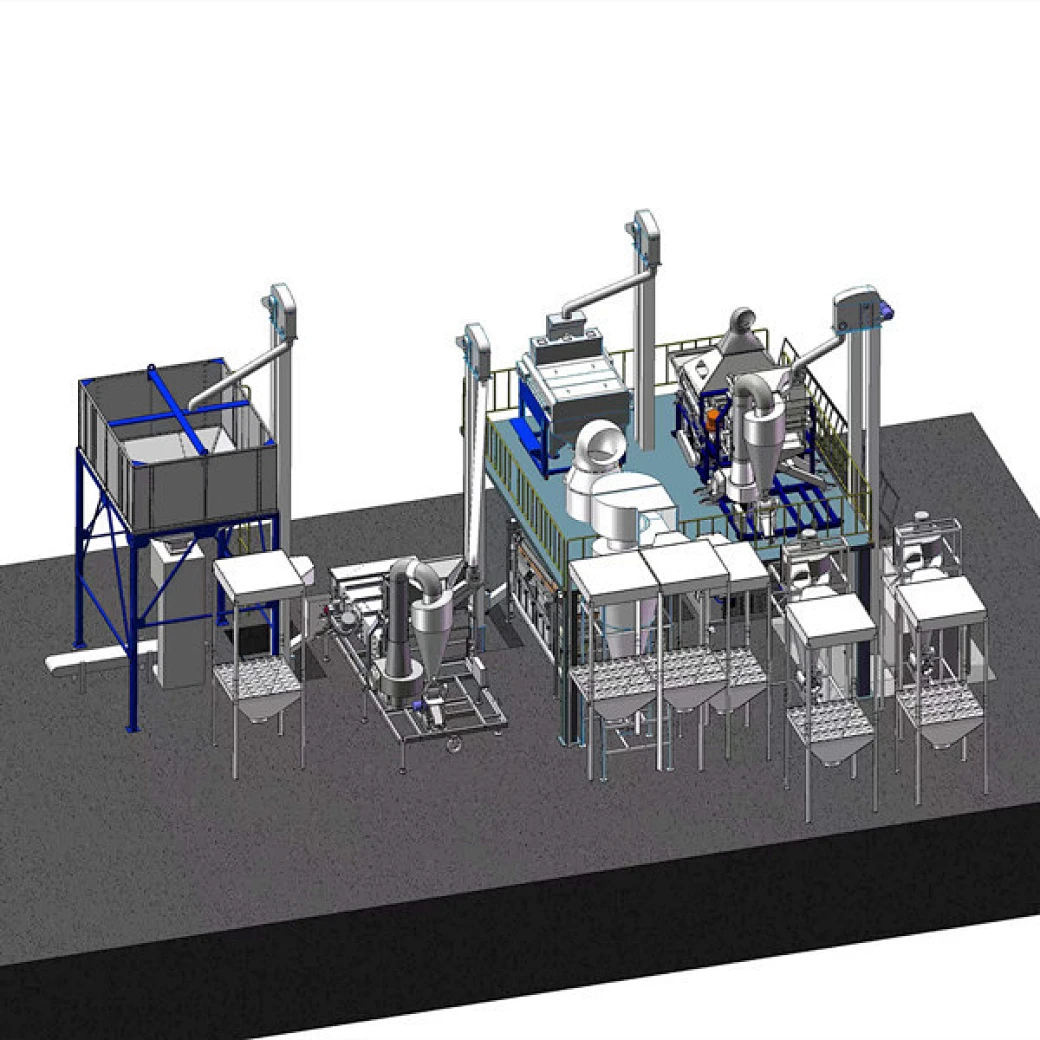

From small-scale processing units to medium-sized commercial operations, the mini destoner machine offers an optimal solution for those who require reliable destoning capabilities without the spatial or budgetary constraints of traditional larger machinery. The flexibility, combined with advanced separation technologies, ensures that both functionality and cost-effectiveness are delivered in a single compact system.

Technical Advantages and Working Principles

The mini destoner machine utilizes a combination of airflow, vibration, and sieving action to effectively separate stones and dense contaminants from food grains. Its innovative design features adjustable inclination angles and precise control systems, which enable users to fine-tune performance for different grain types and impurity loads.

A major strength lies in its efficiency. Modern mini destoner machines typically achieve destoning purities of over 99.5%, significantly reducing product recalls or reprocessing costs. Advanced sensors and control panels further enhance operational reliability and minimize manual intervention, contributing to user-friendly operation and reduced labor dependency.

- Purity Rate: Up to 99.8%

- Capacity: 300 – 1,200 kg/h (Depending on Model and Product)

- Power Consumption: Typically 0.75 – 1.5 kW

- Footprint: Less than 1.5 m²

- Noise Emission: Below 70 dB

By leveraging high-quality stainless steel and modular construction, these machines are not only durable and easy to maintain but also compliant with global food safety standards. The compact design makes them ideal for integration into existing processing lines.

Evaluating Mini Destoner Machine Price and Market Factors

When considering acquiring a mini destoner machine, price is a central factor for many businesses, especially those operating on tight margins or limited space. The mini destoner machine price varies depending on multiple parameters, such as capacity, materials used, brand reputation, and the extent of technical features offered.

As of mid-2024, the price range for new mini rice destoner machines typically falls between $900 and $3,000. Lower-end models suit small businesses or farms, offering basic destoning functionality. In contrast, high-end units, optimized for industrial usage, integrate automation, digital displays, and precision airflow settings. Data from recent procurement platforms reveal that around 40% of buyers prioritize energy efficiency, even if the initial price is 10–20% higher.

It is also crucial to account for after-sales support, warranty offerings, and spare parts availability, as these elements heavily impact the machine’s overall lifecycle cost. A competitive mini destoner machine price does not always guarantee long-term value without the backing of a responsive and established supplier.

Manufacturer Comparison: Data-Driven Evaluation of Leading Brands

To aid in strategic decision-making, the following table compares top manufacturers of mini destoner machines based on critical metrics, including capacity, core features, pricing, and support offerings.

| Manufacturer | Model | Capacity (kg/h) | Purity (%) | Power (kW) | Mini Destoner Machine Price (USD) | Warranty | Support Network |

|---|---|---|---|---|---|---|---|

| GrainTech Pro | GTP-430 | 300–800 | 99.5 | 0.8 | 1,150 | 18 months | Global (60+ countries) |

| AgroClean | AC Mini-600 | 450–1,000 | 99.8 | 1.1 | 1,790 | 24 months | Regional (Asia, Africa) |

| RicePurity Solutions | RP-M Compact | 400–900 | 99.6 | 1.0 | 1,580 | 12 months | Global (40+ countries) |

| EasyProcess | EP-DST500 | 350–700 | 99.1 | 1.2 | 1,280 | 18 months | National (US only) |

While all options offer robust performance, AgroClean’s AC Mini-600 stands out in terms of warranty period and accuracy, particularly for processors seeking extended support and slightly higher capacity. GrainTech Pro’s global presence ensures quicker access to after-sales services, while RicePurity Solutions balances capacity and competitiveness in pricing. The decision ultimately hinges on specific operational needs and long-term service expectations.

Tailored Solutions and Customization Options

As the diversity in processing requirements grows, many manufacturers offer customizable options on mini destoner machines. This allows businesses to align the machine’s configuration with their unique grain types, process volumes, and integration needs.

Common customization features include adjustable feed hoppers, multiple sieve sets for varying grain sizes, and the integration of dust extraction units to comply with workspace hygiene regulations. For industrial clients, manufacturers may even develop automated controls that synchronize with existing PLC systems, providing real-time monitoring and remote troubleshooting.

Case studies have demonstrated a typical 30% increase in production throughput after incorporating custom settings based on grain characteristics. For example, in pulse processing plants, modular extensions for multiple grain types shortened changeover times by nearly 70% compared to fixed-standard models, highlighting the tangible benefits of a bespoke solution.

Practical Applications: Real-World Impact and Case Studies

Across diverse geographies, mini destoner machines are solving real processing issues, from smallholder farmers to commercial mills. In South India, a rice cooperative documented a 99.7% reduction in stone contamination after installing a mini rice destoner machine, leading to a 15% increase in their export orders due to improved grain quality certifications.

In sub-Saharan Africa, the introduction of portable mini destoner machines enabled maize millers with limited infrastructure to achieve standardization, improving their pricing leverage in local markets. Another case in Latin America saw a coffee processor extend machine runtime by over 1,400 hours annually through the adoption of automated cleaning cycles, reducing downtime costs by 12% year-on-year.

These cases emphasize the machine’s adaptability, minimal maintenance demands, and direct impact on operational profitability, especially for small to mid-sized enterprises often constrained by financial outlays and space.

Conclusion: Mini Destoner Machine as a Game Changer for Modern Processing

The mini destoner machine, with its high precision, adaptability, and compact design, has fundamentally transformed how grain processors approach quality assurance and operational efficiency. Whether the priority is securing a favorable mini destoner machine price or achieving the highest purity rates, today's models deliver tangible value across multiple dimensions.

Data-driven comparisons confirm that leading manufacturers not only offer reliable performance but also cater to nuanced processing needs via customization and support networks. The compelling use cases, substantiated by field data, underscore the mini rice destoner machine’s pivotal role in boosting product value and market competitiveness.

Businesses that prioritize modernization, food safety, and cost-effectiveness will find that integrating a mini destoner machine into their operations is not only an investment in equipment but a foundation for future-ready, scalable processing.

(mini destoner machine)

FAQS on mini destoner machine

Q: What is a mini destoner machine?

A: A mini destoner machine is a compact device designed to remove stones and impurities from grains, such as rice or pulses. It is ideal for small-scale processors or home use. This machine enhances food quality and processing efficiency.

Q: How much does a mini destoner machine price typically cost?

A: The mini destoner machine price usually ranges from $100 to $500, depending on features and capacity. Prices may vary by brand and seller. Always compare specifications before purchasing.

Q: What types of grains can a mini rice destoner machine process?

A: A mini rice destoner machine is mainly used for cleaning rice, but it can also process other small grains like millet and lentils. It efficiently removes stones and debris. Check the product specs for supported grain types.

Q: Is the mini destoner machine easy to operate and maintain?

A: Yes, mini destoner machines are designed for easy use and maintenance. Most models offer simple controls and easily accessible parts for cleaning. Regular maintenance ensures longer machine life and better performance.

Q: Where can I buy a reliable mini destoner machine?

A: You can purchase mini destoner machines from agricultural equipment stores, online marketplaces, or directly from manufacturers. Always choose reputable sellers and check customer reviews. Compare warranties and after-sales support for added assurance.

Jul. 21, 2025

Aug. 12, 2024

Soybean Cleaning and Grading Machine-Hebei Beibu Machinery Technology Co.,LTD

May. 07, 2024

Soybean Oil Expeller-Hebei Beibu Machinery Technology Co.,LTD

Jul. 03, 2024

Apr. 18, 2024

how seed coating machine work ?

Jan. 03, 2025

How to choose a rapeseed cleaning machine - Beibu Machinery solves your difficulties

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.