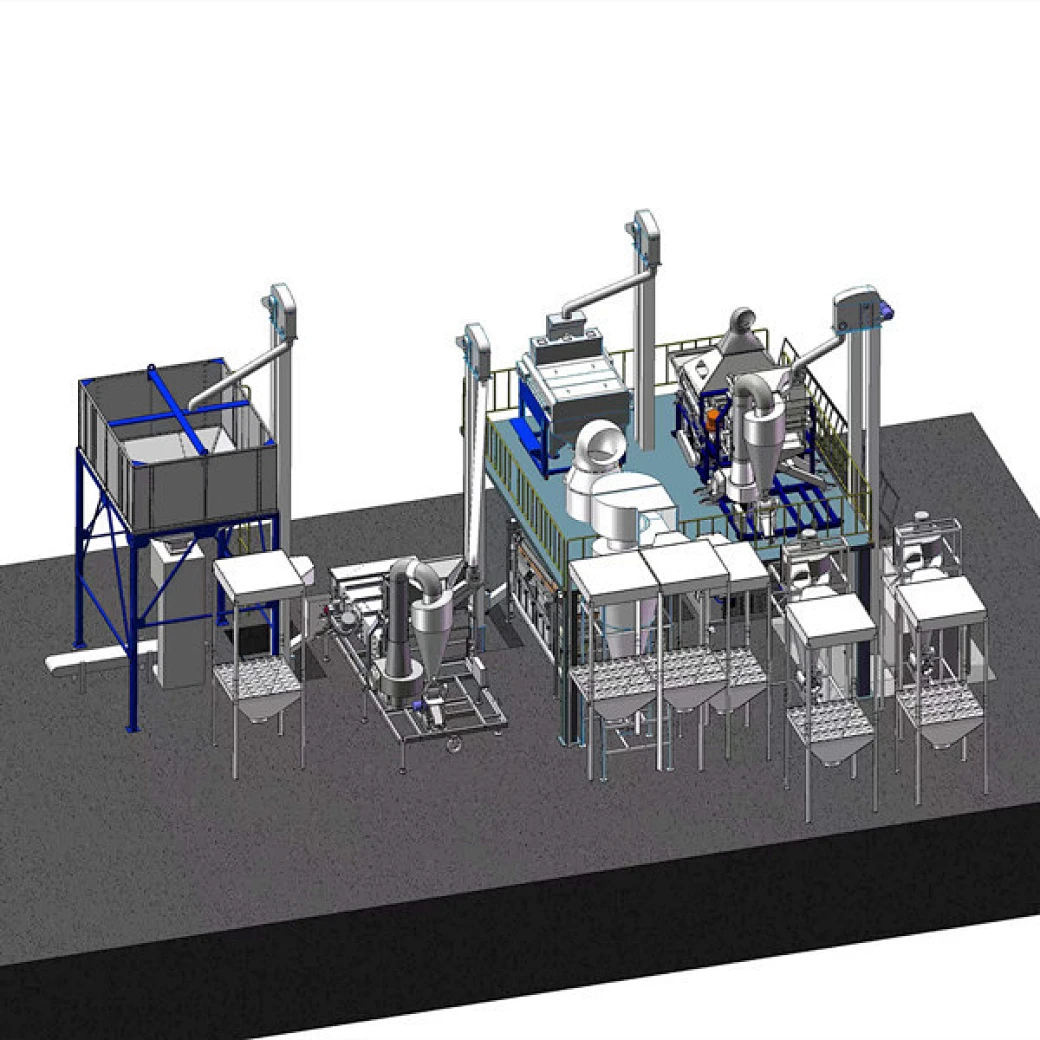

- Overview of Rice Destoner Price and Industry Trends

- Understanding the Technology and Benefits of Rice Destoner Machines

- Comparative Manufacturer Analysis: Rice Destoner Price Table

- Key Factors Affecting Rice Destoner Machine Price

- Customization Options to Optimize Cost and Performance

- Application Case Studies: Operational Efficiency and ROI

- Conclusion: Making an Informed Rice Destoner Price Decision

(rice destoner price)

Rice Destoner Price and Industry Trends

The rice destoner price

landscape is evolving rapidly as global demand for high-quality milled rice intensifies. According to recent market research, the destoning equipment sector is projected to grow by 7.1% CAGR over the next five years, driven by modernization in rice processing facilities and increasing food safety regulations. Average market prices for rice destoner machines currently range from $1,500 to $9,000 depending on capacity, technology, and origin. In Southeast Asia, price sensitivity is particularly notable, as small and medium mills account for over 65% of new rice destoner purchases annually.

Key drivers affecting rice destoner machine price include raw material costs, import tariffs, and advances in automation technologies. Notably, the adoption of sensor-driven and intelligent separation systems has not only enhanced output quality but also impacted final pricing significantly. With strict international standards for stone and foreign material limits—such as the 0.02% tolerance set by the Codex Alimentarius—choosing the right rice destoner is both an operational and regulatory necessity for millers worldwide.

Advanced Technology and Advantages of Rice Destoner Machines

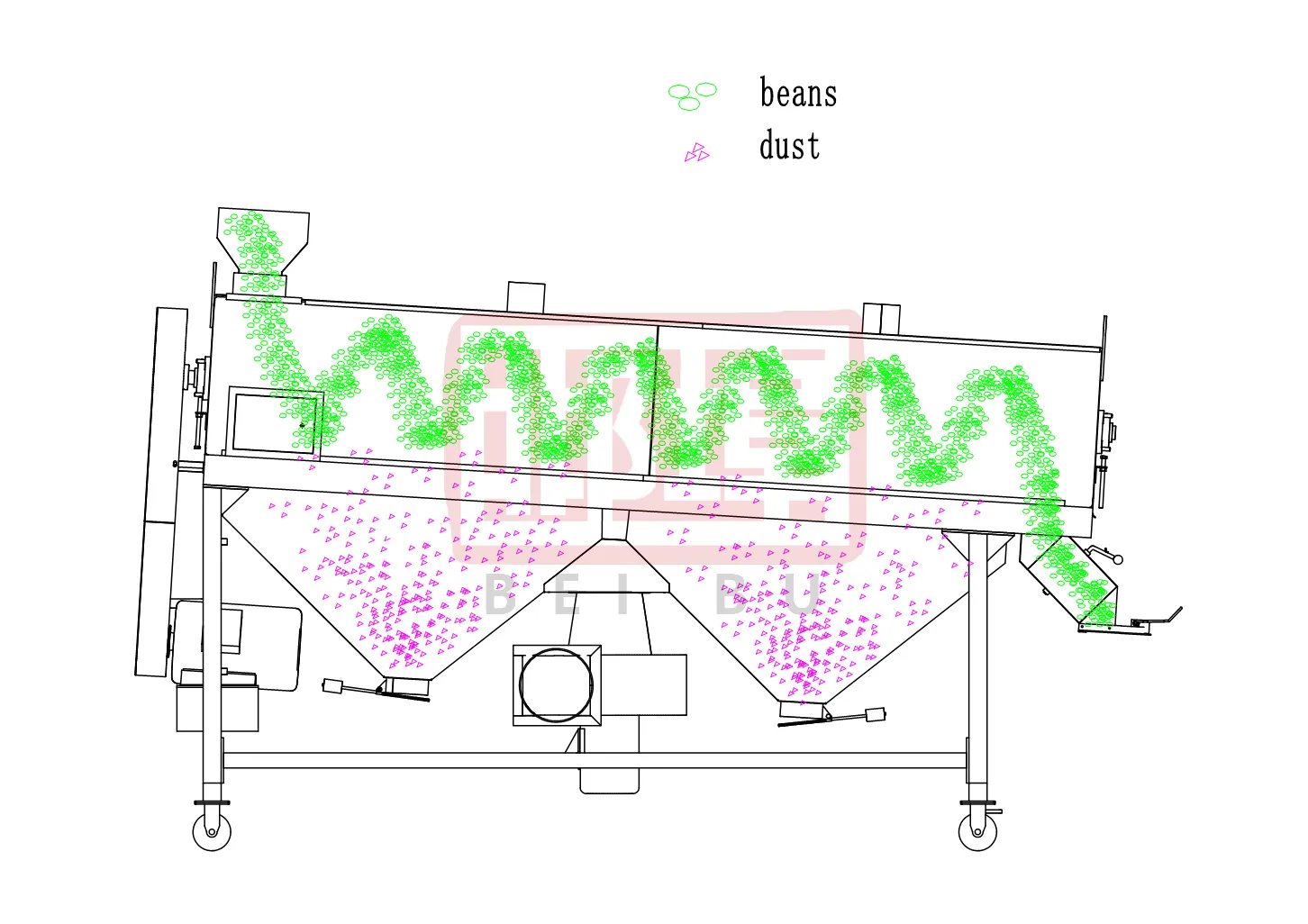

Modern rice destoners stand out for their ability to dramatically reduce contaminants, delivering cleaner product output and boosting consumer trust. Most contemporary systems use air-suction technology combined with oscillating sieves, efficiently removing stones and heavy impurities from brown, white, or parboiled rice grains. An average high-speed rice destoner can process up to 5 tons/hour with over 98% stone removal efficiency.

New advancements include variable frequency drives (VFDs) for optimized grain flow and PLC-based automation to minimize human error. By integrating digital controls, leading brands offer machines that self-adjust based on incoming grain density and contamination load—a critical advantage for millers handling variable crop qualities. Secondary benefits go beyond safety, extending to longer mill equipment lifespans by preventing downstream abrasion from unwanted grit. Additionally, energy-efficient motors are now standard, reducing annual operational costs by up to 15% compared to early models.

Comparative Manufacturer Analysis: Rice Destoner Price Table

Selecting a rice destoner is as much about the manufacturer as it is about the specification. Below, a comparative table highlights price points, core technical features, and after-sales support from prominent industry vendors. This at-a-glance data underscores the spectrum of choices available in the global market.

| Manufacturer | Model / Capacity | Destoner Technology | Processing Capacity (T/hr) | Average Price (USD) | Warranty (Years) | Energy Consumption (kW) | Support / Parts Availability |

|---|---|---|---|---|---|---|---|

| Buhler | DSGA-101 / 5 | Vibratory + Air Suction | 5 | 7,850 | 2 | 2.3 | Global, 48h delivery |

| SATAKE | FGXS45A / 4 | Pneumatic Precision | 4 | 6,995 | 3 | 2.1 | Asia/Europe, 72h delivery |

| China National (CNMEC) | DT-5 / 5 | Oscillating Screen + Suction | 5 | 2,450 | 1 | 2.5 | Asia/Africa, 5d delivery |

| Agro Processing | APD350 / 3.5 | Vibratory + Manual Adjust | 3.5 | 1,850 | 1 | 2.0 | Local, On-request |

| Yongxiang Machinery | YXS-5A / 5 | Gravity Table + Suction | 5 | 2,100 | 2 | 1.8 | Asia, 3d delivery |

This data emphasizes how rice destoner price variations correlate tightly with technology types, service reliability, and production scale.

Main Factors Influencing Rice Destoner Machine Price

Understanding the factors that drive rice destoner price is essential for making a cost-effective investment. Key elements affecting machine cost include:

- Technology Integration: The inclusion of features like automatic grain sensing, digital controls, or multiple separation stages often increases price but also enhances accuracy.

- Capacity Requirements: Machines designed for high-throughput industrial plants (5-8 T/hr) command higher premiums compared to compact semi-automatic models.

- Material and Build Quality: Stainless steel construction for food contact parts and robust frame design contributes to durability and impacts long-term cost efficiency.

- Brand Reputation and After-sales Service: Leading manufacturers justify higher prices with strong warranties and global service networks, crucial for minimizing downtime.

- Local Taxes, Tariffs, and Logistics: Import fees and shipping costs, together with government incentives for agricultural modernization in some countries, also affect final machine price.

Custom Configuration Solutions for Cost and Performance Optimization

To maximize the return on investment, many manufacturers and integrators offer custom solutions tailored to unique mill requirements. Options typically include:

- Variable Processing Widths: Customized infeed and screen dimensions to match both small-farm and large-scale plant layouts.

- Flexible Power Supply: Machines engineered to operate efficiently under 220V or 380V systems, vital for deployment in both rural and urban zones.

- Hybrid Control Panels: Either manual/analog for cost-sensitive buyers or fully automated (PLC/Touchscreen) for high-precision operations.

- Modular Component Upgrades: Swappable sieves, aspirators, or blower units that can be easily replaced as processing needs grow—minimizing initial capital outlay.

- Integrated Stone and Husk Separation: Advanced designs handling simultaneous stone and husk removal in a single pass, further increasing efficiency.

Application Case Studies: Productivity and ROI in Action

Practical deployment of rice destoner machines provides clear evidence of their operational value. Consider these industry examples:

Case 1: Mid-size Rice Mill in Vietnam

A 5-ton/hour PLC-controlled destoner by Buhler enabled this processor to cut manual quality control labor by 53%. Stone contamination in final product dropped to under 0.008%, resulting in a 32% increase in export orders within 18 months.

Case 2: Cooperative in Nigeria

By deploying a CNMEC DT-5 model, a rural mill cooperative reduced annual equipment downtime from 95 hours to 24 hours, and increased throughput by 19%. The unit’s price of $2,450 was recouped in under six months through labor savings and higher market prices for cleaner rice.

Case 3: Japanese Premium Rice Brand

Upgrading to a fully automated SATAKE model, this customer achieved near-zero breakage rates and 99.6% purity, winning new contracts with leading supermarkets and improving net profit margins by 4.2% year-on-year.

Across applications, typical ROI periods for rice destoners range between 6 and 20 months, influenced by machine choice, local wage rates, and value-added product premiums.

Conclusion: Making an Informed Rice Destoner Price Selection

Carefully researching rice destoner price and matching machine capabilities to operational needs is fundamental for any rice processor seeking quality assurance and cost efficiency. To summarize, technology sophistication and reliable after-sales support justify certain price premiums, while scaling production capacity or customizing configurations can unlock considerable savings.

Whether through global leaders or specialized regional suppliers, today’s rice destoner market offers solutions for every budget and application. With data-led evaluation and attention to long-term performance metrics, buyers can achieve rapid ROI while ensuring compliance with stringent global food safety benchmarks. The right rice destoner investment underpins not just product safety, but the competitive future of any rice business.

(rice destoner price)

FAQS on rice destoner price

Q: What is the current rice destoner price?

A: The rice destoner price varies depending on the model and capacity. Generally, prices range from $500 to $5,000. It's best to check with local suppliers for precise quotes.Q: How much does a rice destoner machine cost?

A: The rice destoner machine price depends on its features, size, and brand. Basic models start at around $500, while advanced machines can exceed $4,000. Bulk purchases may also offer discounts.Q: What factors affect the rice destoner price?

A: Factors include machine capacity, material quality, automation level, and brand reputation. Additional features like dust collectors or energy efficiency also influence the price. Always compare specifications before purchasing.Q: Where can I find reliable rice destoner suppliers?

A: Reliable rice destoner suppliers can be found online through platforms like Alibaba and Made-in-China, or local agricultural equipment stores. Check customer reviews and certifications before buying. Direct contact with manufacturers often leads to better deals.Q: Are used rice destoners cheaper than new ones?

A: Yes, used rice destoners are generally more affordable than new ones. However, ensure they are in good working condition and have spare parts availability. A thorough inspection before purchase is recommended.Jul. 03, 2024

Apr. 24, 2024

Welcome Thaillan Clients Visit Our Company-Hebei Beibu Machinery Technology CO.,LTD

Aug. 13, 2024

Beibu Machinery-Sesame cleaning machine and related farm equipment delivery!

Feb. 27, 2025

How to choose a sunflower seed cleaning machine? Beibu Machinery gives you a perfect answer

Mar. 15, 2024

Hot Selling New Designed Big Capacity Cleaning Machine-Hebei Beibu Machinery Technology Co.,LTD

Jun. 28, 2024

Multi Functions Soybean Cleaning Machine-Hebei Beibu Machinery Technology Co.,LTD

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.