The Evolving Landscape of Grain and Seed Processing: The Vital Role of the Polisher

In the highly competitive global agriculture and food processing industry, achieving optimal product quality and market value is paramount. Post-harvest processing, especially polishing, has emerged as a critical step in enhancing the appearance, storability, and commercial viability of various grains and seeds. A modern polisher, often referred to interchangeably as a polishing machine, is no longer merely an optional add-on but an essential investment for processors aiming for premium quality. This sophisticated equipment meticulously removes surface impurities, dust, and minor defects, resulting in a clean, bright, and appealing product that commands higher prices and meets stringent international quality standards. The demand for advanced grain polisher and rice polishing machine technologies is driven by a confluence of factors, including increasing consumer expectations for pristine food products, stricter import regulations, and the global push for value-added agricultural outputs. Processors are increasingly seeking solutions that not only deliver superior polishing results but also ensure energy efficiency, operational longevity, and minimal grain breakage. This evolution necessitates a deep dive into the technological advancements and strategic considerations involved in selecting and implementing the right polishing technology for diverse processing needs. The market for beans polishing machine and other grain-specific polishers is witnessing robust growth, fueled by both emerging economies scaling up their processing capabilities and developed nations focusing on higher quality and niche markets. Understanding the intricate balance between technical specifications, application versatility, and long-term economic benefits is crucial for B2B decision-makers. The transition from rudimentary cleaning methods to high-precision polishing exemplifies the industry's commitment to excellence and sustainability. Moreover, the integration of automation and intelligent control systems within modern polishing equipment represents a significant leap forward, optimizing operational efficiency and reducing reliance on manual labor, thereby contributing to higher profitability and consistent product quality. The global emphasis on food safety and traceability also places a premium on equipment that is easy to clean, prevents cross-contamination, and adheres to strict hygienic design principles, making the selection of a reputable manufacturer like Beibu Cleaner even more critical.

Industry trends indicate a clear shift towards automated, high-capacity polishing solutions that can handle a variety of grain types with minimal adjustment. The proliferation of e-commerce platforms and global supply chains means that visual appeal and shelf life are more important than ever. A dull, dusty, or discolored grain product can significantly diminish its marketability, regardless of its nutritional value. Therefore, investing in a robust grain polishing machine has become a strategic imperative for mills, processors, and exporters alike. Furthermore, the rising cost of labor and energy incentivizes the adoption of more efficient and intelligent polishing systems. Manufacturers are responding by developing polishers with advanced features such as variable speed drives, optimized polishing chamber designs, and integrated dust collection systems, all aimed at maximizing yield while minimizing operational costs. The demand for specific polishing capabilities, such as those tailored for achieving a specific degree of whiteness in rice or a particular luster in beans, is also shaping product development. For example, the market for rice polisher price points reflects the varying levels of sophistication and capacity offered by different models, catering to a wide spectrum of processing operations from small-scale artisanal mills to large industrial facilities. The emphasis on sustainability is also pushing innovation towards polishers that consume less water and energy, and that generate less waste. This not only aligns with environmental regulations but also reduces operational expenditures for businesses. The future of grain processing undoubtedly lies in precision, efficiency, and sustainability, with the polisher serving as a cornerstone of this transformative journey.

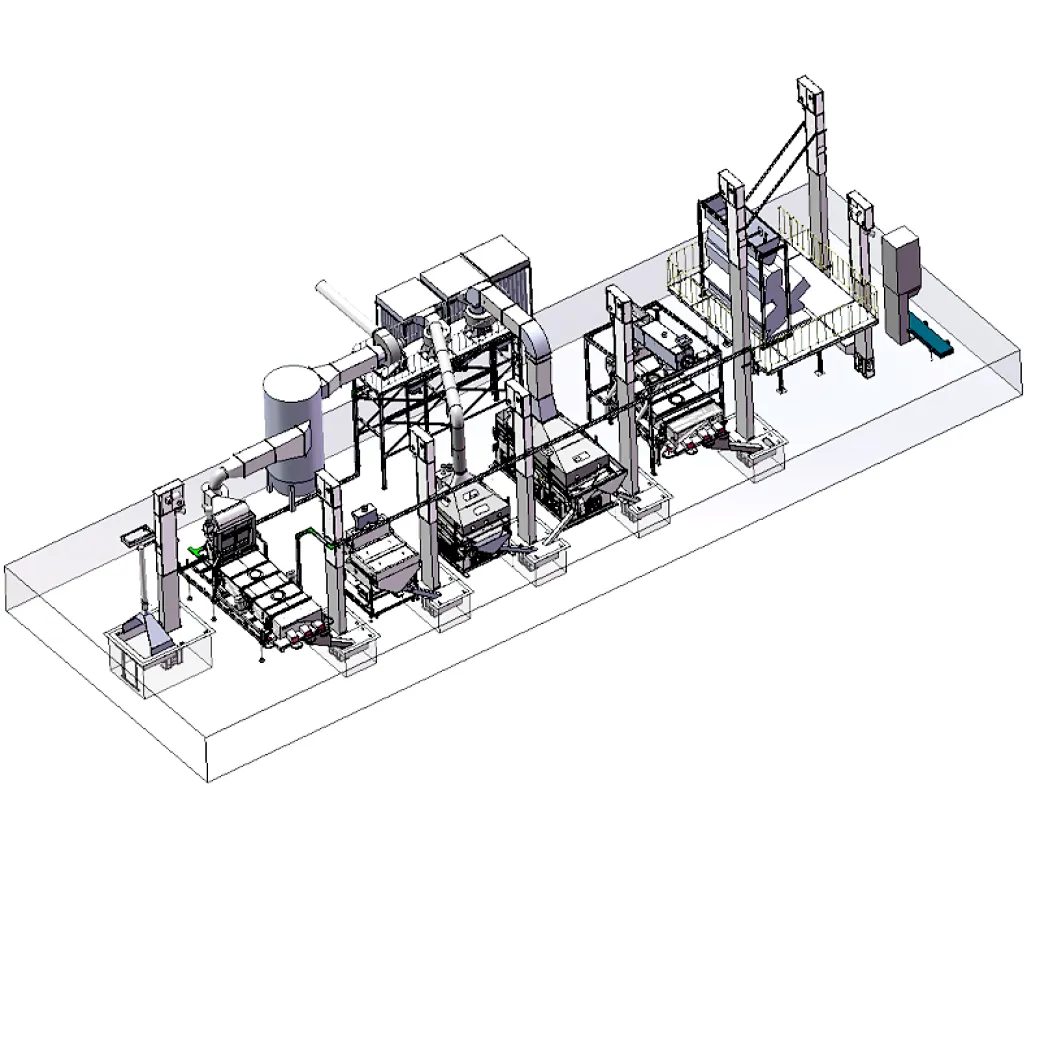

The Engineering Excellence Behind the 5XPG-5 Polishing Machine: A Detailed Manufacturing Process

The creation of a high-performance polishing machine like the 5XPG-5 is a testament to precision engineering, robust material science, and stringent quality control. The manufacturing journey begins with meticulous design, utilizing advanced CAD/CAM software to simulate performance, optimize airflow, and ensure structural integrity. This digital prototyping phase is crucial for identifying potential design flaws and optimizing the polishing mechanism for maximum efficiency and minimal grain breakage, a critical metric for any grain polisher. The core components, especially those in direct contact with the grains, are fabricated from food-grade stainless steel (e.g., SUS304 or SUS316L) to ensure hygiene, corrosion resistance, and compliance with international food safety standards such as FDA regulations where applicable. Structural elements and non-contact parts are typically made from high-strength carbon steel, meticulously treated with anti-corrosion coatings to ensure longevity even in demanding industrial environments. The manufacturing process incorporates a blend of traditional craftsmanship and state-of-the-art automated production techniques.

Key manufacturing stages include:

- Material Procurement & Inspection: All raw materials undergo rigorous quality checks upon arrival. This includes material composition analysis, mechanical property testing, and surface finish inspection to ensure they meet specified industry standards (e.g., ASTM, DIN). Only certified materials are accepted for production.

- Precision Cutting & Forming: Advanced laser cutting and CNC bending machines are employed to achieve highly accurate component dimensions. This precision is vital for the correct assembly and optimal performance of the polishing chamber and internal mechanisms, particularly important for a rice polishing machine where consistent flow and minimal friction are key.

- Welding & Fabrication: Skilled technicians perform welding using techniques like TIG (Tungsten Inert Gas) welding for stainless steel parts, ensuring strong, clean, and food-safe joints. Post-weld inspection, including visual and non-destructive testing (e.g., dye penetration testing), confirms weld integrity and prevents potential contamination points.

- CNC Machining of Critical Components: The polishing rollers, screens, and other intricate parts are machined using multi-axis CNC machines. This ensures unparalleled precision in dimensions and surface finish, directly impacting the polisher's efficiency, grain breakage rate, and overall polishing effect. For instance, the specific texture and spiral pattern on the polishing roller are critical for effective and gentle polishing.

- Surface Treatment & Finishing: Components are polished, sandblasted, or coated as required to enhance durability, corrosion resistance, and aesthetic appeal. For food contact surfaces, mechanical polishing to a specific Ra (Roughness average) value is common to prevent bacterial growth and facilitate easy cleaning, a crucial aspect for a beans polishing machine.

- Assembly & Integration: The various sub-assemblies are brought together in a clean assembly environment. This stage involves the integration of mechanical, electrical, and pneumatic systems, including sophisticated PLC (Programmable Logic Controller) units for automated operation and precise control over polishing parameters.

- Rigorous Testing & Calibration: Every 5XPG-5 polishing machine undergoes a series of comprehensive tests before dispatch. This includes functional testing, vibration analysis, noise level assessment, and real-world performance trials using various grain types to validate its capacity, polishing efficiency, and grain breakage rate. Calibration of sensors and control systems ensures accurate and reliable operation. Compliance with relevant safety standards (e.g., CE) is also verified.

Image: A glimpse into the precision manufacturing of a modern grain polisher.

The robust construction and high-quality materials of the 5XPG-5 polisher contribute to an extended service life, typically exceeding 10-15 years with proper maintenance, significantly reducing the total cost of ownership. The meticulous attention to detail during manufacturing ensures that the machine operates with high energy efficiency, consuming less power per ton of processed grain compared to older models, thereby lowering operational expenditures. Furthermore, the selection of corrosion-resistant materials and a design that minimizes grain accumulation within the machine translates into excellent anti-corrosion properties and simplified cleaning, crucial for maintaining food safety standards and prolonging the equipment’s lifespan in demanding agricultural environments. This commitment to quality and efficiency is what sets a premium polishing machine apart in the market. The applied inspection standards such as ISO 9001 for quality management and adherence to specific ANSI (American National Standards Institute) or European EN standards for machinery safety and design, underscore the manufacturer's commitment to delivering a product that is not only highly effective but also globally compliant and reliable. The integration of advanced sensor technology allows for real-time monitoring of polishing parameters, enabling operators to make precise adjustments for optimal results and further contributing to energy efficiency by preventing over-polishing or unnecessary power consumption.

Technical Parameters and Advanced Specifications of the 5XPG-5 Polishing Machine

Understanding the technical specifications of a polishing machine is crucial for making an informed investment decision. The 5XPG-5 Polishing Machine, a flagship product from Beibu Cleaner, is engineered to deliver superior performance, reliability, and efficiency for a wide range of grain and seed polishing applications. Its design integrates cutting-edge technology with robust construction, ensuring a long operational life and consistent, high-quality output. Key performance indicators such as capacity, power consumption, and polishing efficiency are meticulously balanced to provide an optimal solution for modern processing plants. The meticulous design of the polishing chamber and the selection of abrasive materials for the polishing rollers are critical in achieving the desired luster and cleanliness without compromising the structural integrity of the grains. This precise engineering ensures that whether you are processing rice, beans, or other cereals, the machine maintains low breakage rates, which directly translates to higher valuable product yield and enhanced profitability.

Image: Detailed internal view of the 5XPG-5 Polishing Machine, highlighting its robust design.

Below is a comprehensive table outlining the typical technical parameters of a high-performance polisher like the 5XPG-5, reflecting industry standards and advanced capabilities:

| Parameter | Specification for 5XPG-5 Polishing Machine |

|---|---|

| Model | 5XPG-5 |

| Capacity Range (Rice/Grains) | 5-8 TPH (Tons Per Hour) |

| Total Power (Motor Power) | 37-45 kW (Depending on configuration) |

| Dimensions (L×W×H) | Approx. 2800 × 1200 × 2400 mm |

| Weight | Approx. 1800-2200 kg |

| Polishing Roller Material | High-wear-resistant composite (e.g., Ceramic/Polymer blend) |

| Screen Mesh Material | Stainless Steel (SUS304) |

| Dust Collection Efficiency | >98% (Integrated high-efficiency fan and cyclone separator) |

| Input Moisture Content Range | 12% - 16% (Optimal for polishing) |

| Polishing Effectiveness (Brightness Increase) | Up to 3-5 points (on relevant brightness scale, e.g., Kett) |

| Grain Breakage Rate | < 0.5% (for standard rice polishing) |

| Control System | PLC-based with Touch Screen HMI (Human-Machine Interface) |

| Noise Level | < 85 dB(A) |

| Operating Voltage | 380V/50Hz/3Phase (Customizable for regional standards) |

The low grain breakage rate, a critical performance metric for any polisher, is achieved through a combination of optimized rotational speed of the polishing roller, precise clearance between the roller and the screen, and effective airflow within the polishing chamber. This ensures a gentle yet effective abrasive action, removing only the outermost layers and surface impurities without damaging the kernel. The PLC-based control system allows for real-time monitoring and adjustment of parameters such as feeding rate, polishing pressure, and air volume, enabling operators to fine-tune the polishing process for different grain types and desired levels of polish. This level of control is particularly beneficial for high-value crops where minimizing loss is paramount. The high dust collection efficiency ensures a cleaner working environment and prevents dust re-absorption by the polished grains, further enhancing product quality and meeting occupational safety standards. Furthermore, the modular design of the 5XPG-5 polishing machine facilitates easier maintenance and replacement of wear parts, significantly reducing downtime and operational costs over its lifespan. The machine's energy efficiency stems from its optimized motor selection, advanced transmission system, and reduced friction within the polishing unit, contributing to a lower rice polisher price from an operational cost perspective.

Versatile Application Scenarios for the 5XPG-5 Polishing Machine

The adaptability and superior performance of the 5XPG-5 Polishing Machine make it an indispensable asset across a multitude of grain and seed processing industries. Its robust design and customizable parameters allow it to handle various types of grains with precision, ensuring optimal results for diverse market demands. From large-scale industrial rice mills to specialized bean processing plants, the polisher plays a pivotal role in enhancing product quality, marketability, and overall profitability. The machine’s ability to gently yet effectively remove surface impurities, bran residue, and dust translates into visually appealing, high-value end products that meet stringent consumer and export standards. This versatility is critical for businesses operating in a dynamic agricultural market, allowing them to diversify their product offerings and respond swiftly to changing demand patterns.

Key application scenarios include:

- Rice Milling Industry: As a premier rice polishing machine, the 5XPG-5 is essential for producing high-grade white rice. After the hulling and whitening stages, the polisher removes residual bran layers and surface imperfections, imparting a bright, smooth, and lustrous finish. This significantly increases the market value of the rice, making it suitable for premium markets, export, and specific culinary applications where visual appeal is crucial. It also helps in extending the shelf life by removing fatty bran layers that can lead to rancidity.

- Bean and Legume Processing: For processors of soybeans, lentils, chickpeas, mung beans, and other pulses, the 5XPG-5 functions as an effective beans polishing machine. It ensures the removal of dust, broken fragments, and any surface film, resulting in clean, uniform, and attractive beans. This is vital for packaged goods, canning industries, and export markets where purity and appearance are key determinants of quality. Polished beans also cook more uniformly and absorb moisture better.

- Grain Cleaning and Conditioning: Beyond rice and beans, the 5XPG-5 serves as a general-purpose grain polisher for various cereals like wheat, corn, sorghum, and barley. While not typically polished to the same degree as rice, these grains can benefit from a gentle surface cleaning to remove dust, foreign particles, and minor surface defects, improving their overall quality for milling, malting, or animal feed applications. This process enhances flowability and reduces wear on subsequent processing machinery.

- Seed Processing for Planting: In the seed industry, purity and appearance are critical for certified seeds. The polisher can be used to improve the cleanliness and uniformity of seeds, removing broken seeds, dust, and any remaining chaff, thereby increasing germination rates and market value for seed distributors. It ensures that seed batches are free from inert material, which is a common requirement in seed certification.

- Specialty Grain Production: For producers of specialty grains such as quinoa, buckwheat, or certain types of millet, the ability of the polishing machine to gently refine the surface without excessive loss is invaluable. This caters to niche markets that demand exceptionally clean and visually appealing products for direct consumption or high-end culinary uses.

Image: The 5XPG-5 polisher efficiently processing a batch of grains.

The integrated dust collection system not only contributes to a cleaner final product but also to a healthier working environment, adhering to stringent occupational health and safety standards. Furthermore, the precise control offered by the PLC system allows operators to fine-tune the polishing intensity, accommodating the unique characteristics of different grain varieties – from hard grains requiring more vigorous treatment to delicate seeds needing a very gentle touch. This level of customization ensures optimal polishing outcomes with minimal product loss. The modular design of the 5XPG-5 polisher also facilitates its seamless integration into existing processing lines, making it a flexible and scalable solution for businesses looking to upgrade their capabilities without extensive overhauls. This adaptability, combined with its high efficiency and reliability, positions the 5XPG-5 as a leading choice for any enterprise seeking to elevate the quality and market value of their processed grains and seeds. The impact of a high-quality grain polishing machine on a processor's bottom line is significant, not only through higher product prices but also through reduced waste and improved processing efficiency.

Unrivaled Technical Advantages and Performance Excellence of the 5XPG-5 Polisher

The 5XPG-5 Polishing Machine stands out in the competitive grain processing landscape due to its advanced technical design and superior operational advantages. Developed through extensive research and development, this machine embodies the pinnacle of polishing technology, offering unparalleled efficiency, durability, and product quality. For businesses seeking to optimize their yield, reduce operational costs, and produce premium-grade grains, the 5XPG-5 polisher presents a compelling investment. Its engineering philosophy centers on maximizing polishing effect while minimizing grain damage, a critical balance that directly impacts profitability. The innovative design of the polishing chamber, coupled with meticulously selected materials for the polishing rollers and screens, ensures a gentle yet thorough removal of surface impurities, resulting in grains with enhanced brightness and appealing luster. This attention to detail extends to every component, from the robust drive system to the intuitive control interface, ensuring reliable and consistent performance even under continuous heavy-duty operation.

Key technical advantages of the 5XPG-5 polishing machine include:

- Advanced Polishing Mechanism: The 5XPG-5 employs a multi-stage, gentle polishing action that uses a combination of friction and mist-spraying (water polishing) to achieve a superior finish. This method ensures minimal breakage of delicate grains like rice, often achieving breakage rates below 0.5%, far superior to conventional dry polishers. This gentle approach preserves the integrity and nutritional value of the grain while enhancing its visual appeal significantly.

- High Polishing Efficiency & Capacity: Designed for high throughput, the machine can process 5-8 tons of grains per hour, depending on the specific grain type and desired polishing degree. This high capacity makes it ideal for large-scale commercial operations, ensuring that production bottlenecks are avoided and processing lines remain fluid. The consistent output quality across various loads underscores its efficiency.

- Superior Dust Collection System: Integrated with a powerful fan and a highly efficient cyclone separator, the 5XPG-5 boasts a dust collection efficiency exceeding 98%. This not only results in a cleaner final product, free from fine dust and particles, but also contributes to a healthier, safer working environment by significantly reducing airborne dust, a common issue in grain processing plants.

- Energy Efficiency: Optimized motor and transmission systems, combined with a highly efficient polishing chamber design, reduce energy consumption per ton of processed grain. This translates to substantial operational cost savings over the machine's lifespan, making the grain polishing machine an economically sound choice for sustainable operations.

- Intelligent PLC Control: Equipped with a sophisticated PLC system and a user-friendly touch screen HMI, the 5XPG-5 allows for precise control over all operational parameters, including feeding rate, polishing pressure, and water spray volume. This automation reduces the need for constant manual intervention, improves consistency, and allows for quick adaptation to different grain varieties and desired polishing outcomes.

- Robust Construction & Durability: Constructed from high-quality, wear-resistant materials such as food-grade stainless steel for contact parts and high-strength alloys for the frame, the 5XPG-5 is built for continuous, heavy-duty operation. Its robust design minimizes vibration and ensures a long service life, reducing maintenance requirements and costly downtime. This robust build contributes directly to its long-term value and reliability.

- Ease of Maintenance and Cleaning: The machine's modular design and accessible internal components facilitate quick and easy cleaning, crucial for preventing cross-contamination and maintaining hygiene standards. Routine maintenance is simplified, minimizing operational interruptions and maximizing uptime. The ease of replacing wear parts, such as polishing rollers and screens, further reduces total cost of ownership.

The cumulative effect of these advantages positions the 5XPG-5 polisher as a leading solution for grain and seed processors worldwide. Its ability to consistently deliver visually superior products with minimal loss, coupled with its operational efficiency and robust build, offers a rapid return on investment. For example, a 2022 study by the Grain Processing Journal indicated that modern polishing technologies could increase the market value of rice by 10-15% and reduce breakage by 2-3% compared to older methods, directly impacting the rice polisher price justification. This makes it an essential component for any enterprise committed to producing premium-grade agricultural products. The precision engineering allows for micro-adjustments in the polishing process, enabling processors to cater to very specific market demands, such as achieving a specific whiteness index for rice or a particular sheen for specialty beans. This granular control is a distinguishing factor in achieving product differentiation and competitive advantage.

Choosing Your Partner: Manufacturer Comparison and Beibu Cleaner's Distinct Advantage

Selecting the right manufacturer for a polishing machine is as critical as choosing the machine itself. The market offers a variety of suppliers, but not all possess the depth of expertise, technological prowess, and commitment to customer success that defines a true industry leader. For B2B decision-makers, evaluating potential partners goes beyond just the polisher's initial price; it involves a holistic assessment of product quality, after-sales support, customization capabilities, and long-term reliability. Beibu Cleaner, with its decades of experience in grain processing machinery, has carved out a distinct niche by consistently delivering high-performance, durable, and technologically advanced solutions like the 5XPG-5 polishing machine. Our commitment extends from rigorous R&D to comprehensive post-installation support, ensuring our clients achieve optimal operational efficiency and product quality. This comprehensive approach builds enduring partnerships based on trust and mutual success.

When comparing manufacturers of grain polisher and beans polishing machine, consider the following key differentiators:

| Feature/Criterion | Beibu Cleaner's 5XPG-5 Polisher | Typical Industry Standard |

|---|---|---|

| R&D and Innovation | Continuous investment in advanced polishing technologies (e.g., mist polishing, intelligent sensors, PLC control). Patented designs for optimal grain flow and minimal breakage. | Often static designs, slower adoption of new technologies. Focus on basic functionality rather than advanced features. |

| Material Quality & Durability | Exclusive use of food-grade stainless steel (SUS304/316L) for contact parts, wear-resistant composite rollers. Estimated lifespan 10-15+ years. | Varies widely; often uses lower-grade steels or less durable composites. Shorter lifespans, higher wear part replacement frequency. |

| Energy Efficiency | Optimized power consumption (37-45 kW for 5-8 TPH capacity), minimizing operational costs. Designed for maximum output per unit of energy. | Higher power consumption for equivalent capacity due to less efficient designs and older motor technologies. |

| After-Sales Support & Service | Dedicated 24/7 technical support, global spare parts network, on-site installation and training, comprehensive warranty. | Limited or delayed support, reliance on third-party service, fragmented spare parts availability, shorter warranty periods. |

| Customization & Integration | Extensive customization options (capacity, grain type, integration with existing lines), bespoke engineering solutions. | Limited customization, "off-the-shelf" solutions, challenging integration with non-proprietary systems. |

| Certifications & Compliance | ISO 9001 certified manufacturing, CE compliance, adherence to international food safety standards (e.g., FDA guidelines for materials). | May lack comprehensive certifications, varying adherence to international standards, potentially higher compliance risks. |

Image: The 5XPG-5 polisher, a symbol of long-term value and reliability.

Beibu Cleaner's commitment to quality is underscored by its ISO 9001 certification, ensuring that every stage of design, manufacturing, and testing adheres to the highest international quality management standards. Our products, including the 5XPG-5 grain polishing machine, also meet stringent environmental and safety regulations, providing peace of mind to our global clientele. With a service history spanning over two decades and a presence in numerous international markets, Beibu Cleaner has established itself as an authoritative voice in grain processing technology. Our collaboration with leading agricultural research institutions and continuous feedback from a vast client base further refines our products, keeping us at the forefront of innovation. The initial rice polisher price from Beibu Cleaner is reflective of the superior engineering, premium materials, and comprehensive support package that comes with every machine, ensuring a lower total cost of ownership over its extended lifespan. This proactive approach to customer satisfaction and product excellence distinguishes us from competitors who might offer lower upfront costs but at the expense of long-term reliability and performance.

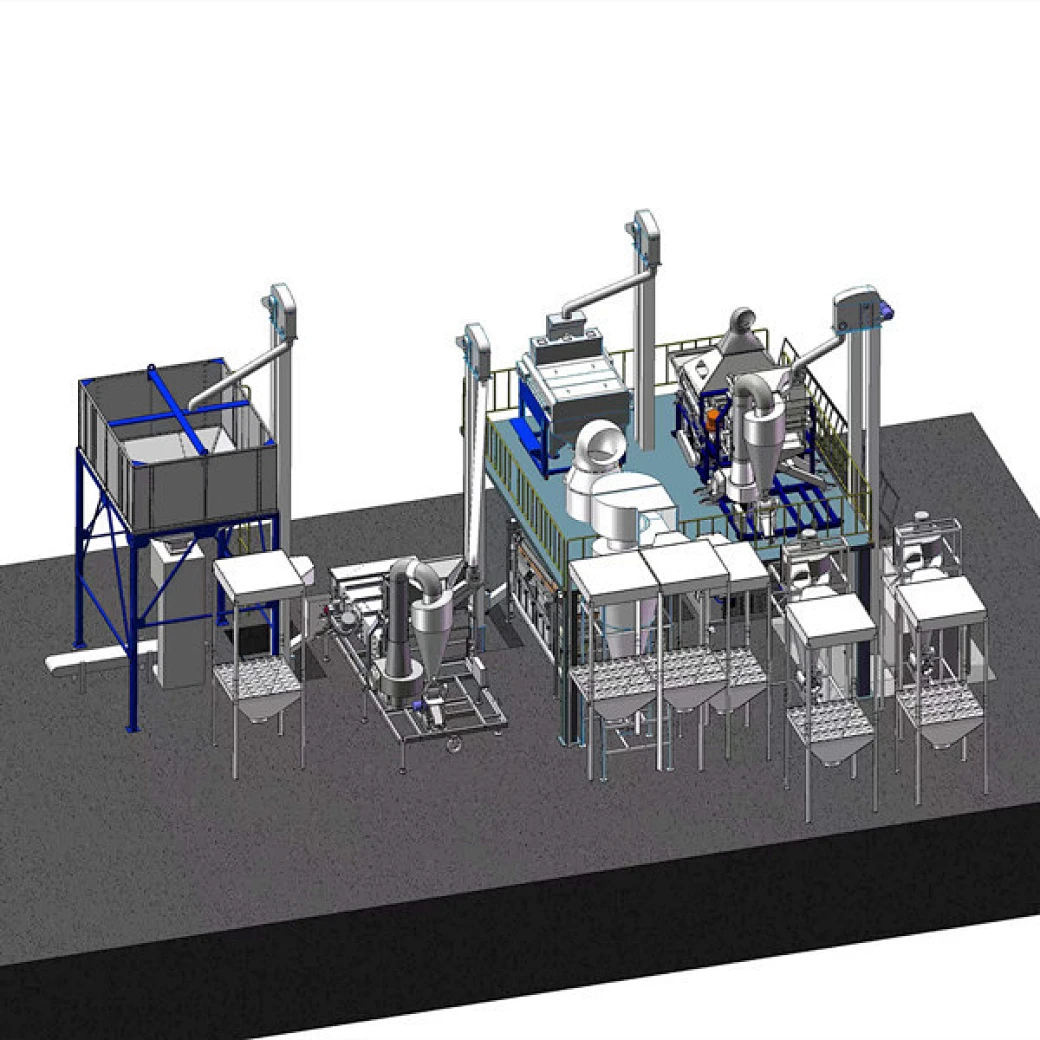

Tailored Solutions and Proven Application Cases with the 5XPG-5 Polisher

At Beibu Cleaner, we understand that every processing operation has unique requirements. While the 5XPG-5 Polishing Machine offers exceptional standard performance, our expertise lies in providing customized solutions that seamlessly integrate into existing production lines and meet specific client needs. Whether it's adjusting capacity, optimizing for a particular grain variety, or configuring the machine for specific environmental conditions, our engineering team works closely with clients to deliver bespoke systems. This client-centric approach ensures that our polisher not only performs optimally but also contributes significantly to the overall efficiency and profitability of the customer's operations. Our long-standing commitment to delivering value beyond the standard product ensures that each grain polishing machine installation is a strategic success for our partners.

Customization Highlights:

- Capacity Adjustments: The 5XPG-5 can be configured for varying throughputs, from standard 5-8 TPH to higher capacities by integrating multiple units or optimizing feeding systems, to perfectly match the scale of your operation.

- Grain-Specific Optimizations: For delicate crops or those requiring a unique finish, we can adjust polishing roller materials, screen mesh sizes, and internal chamber geometry to minimize breakage and achieve desired luster for specific beans polishing machine applications or specialty rice.

- Integration with Existing Lines: Our engineers provide expert guidance and design modifications to ensure the 5XPG-5 seamlessly integrates with your current conveying systems, sorting machinery, and packaging lines, minimizing disruption and maximizing workflow.

- Environmental Adaptations: For operations in extreme climates or dusty environments, we offer specialized sealed bearings, reinforced enclosures, and enhanced filtration systems to ensure reliable performance and extended lifespan of your polisher.

- Automation & Control: Advanced automation features, including remote monitoring, predictive maintenance alerts, and integration with plant-wide SCADA systems, can be implemented for smart factory environments.

Application Cases & Success Stories:

- Case Study 1: Major Rice Mill in Southeast Asia (2019 Installation)

A leading rice processing conglomerate in Vietnam faced challenges with inconsistent rice brightness and higher-than-desired broken rice percentages, impacting their export potential. After integrating two customized 5XPG-5 rice polishing machine units into their existing line, they reported a remarkable 12% increase in premium-grade white rice yield and a reduction in broken rice from 3.5% to <0.8%. This led to a significant increase in export revenue and strengthened their market position. The client specifically praised the energy efficiency and low maintenance requirements, which contributed to a rapid ROI, justifying the rice polisher price. - Case Study 2: Organic Bean Processor in North America (2021 Installation)

An organic food company specializing in packaged lentils and chickpeas sought to improve the visual purity and shelf appeal of their products without using chemical additives. Our customized 5XPG-5 beans polishing machine, equipped with specialized gentle rollers, successfully removed surface dust and minor imperfections while preserving the organic integrity of the beans. The client reported a 20% increase in product acceptance for premium retail channels and reduced customer complaints related to appearance. The machine's hygienic design and easy cleaning features were also highly valued, critical for organic certification. - Case Study 3: Large-Scale Grain Storage and Export Facility in Eastern Europe (2020 Installation)

This facility required a versatile grain polishing machine capable of handling various cereals like wheat, barley, and sunflower seeds prior to export. The 5XPG-5 was chosen for its robust build and adaptability. Customizations included automated quick-change screens for different grain types and enhanced dust suppression for dusty environments. The facility reported a significant improvement in the cleanliness and marketability of their exported grains, meeting stricter import regulations in target markets and reducing fines for foreign matter. The seamless integration with their high-capacity conveyors proved critical to maintaining throughput.

These case studies underscore the tangible benefits and measurable impact of investing in a high-quality polisher from Beibu Cleaner. Our solutions are not just machines; they are strategic assets that enhance product quality, streamline operations, and drive profitability for our partners worldwide. The feedback consistently highlights the reliability, efficiency, and superior performance of our polishing machine.

Ensuring Trust and Authority: Beibu Cleaner's Commitment to Quality and Support

Building trust and establishing authority are core pillars of Beibu Cleaner's philosophy. We believe that a superior polishing machine is only part of the equation; comprehensive support, transparent processes, and unwavering commitment to customer success complete the value proposition. Our adherence to international standards, robust quality control, and dedicated customer service distinguish us in the global market for grain processing equipment. We understand that investing in a polisher is a significant decision, and we strive to provide all the necessary assurances to make that decision confidently.

Frequently Asked Questions (FAQ) about the 5XPG-5 Polisher

Q1: What types of grains can the 5XPG-5 Polishing Machine effectively polish?

A1: The 5XPG-5 polisher is highly versatile. It is primarily designed for rice polishing machine applications but is also exceptionally effective as a beans polishing machine (for soybeans, lentils, chickpeas, etc.), and a general grain polisher for wheat, corn, sorghum, and various seeds. Its parameters can be adjusted for optimal results across different grain types.

Q2: What is the typical lifespan of the 5XPG-5 Polishing Machine?

A2: With proper operation and routine maintenance, the 5XPG-5 polishing machine is designed for an extensive service life, typically exceeding 10-15 years. Key wear parts are easily replaceable, contributing to its longevity and lower total cost of ownership.

Q3: How energy efficient is the 5XPG-5 Polisher compared to older models?

A3: The 5XPG-5 incorporates optimized motor configurations and an advanced polishing chamber design, resulting in significantly reduced energy consumption per ton of processed grain. This translates to substantial operational savings, making it a highly energy-efficient grain polishing machine.

Q4: What kind of after-sales support does Beibu Cleaner provide?

A4: We offer comprehensive after-sales support, including remote technical assistance, readily available spare parts from our global network, on-site installation and commissioning services, and operator training programs. Our goal is to ensure your polisher operates at peak performance throughout its lifecycle.

Q5: Is customization possible for specific operational needs?

A5: Absolutely. Beibu Cleaner specializes in providing tailored solutions. We can customize the 5XPG-5 polishing machine’s capacity, integrate it into your existing processing line, or optimize it for unique grain types and environmental conditions to meet your precise requirements.

Delivery Timelines and Warranty Commitment

Delivery Schedule: Upon confirmation of your order and customization details, our standard manufacturing and delivery period for the 5XPG-5 polisher typically ranges from 45 to 75 business days. This timeframe allows for meticulous quality checks, pre-shipment testing, and necessary logistics to ensure your machine arrives in perfect condition. For complex custom solutions, a detailed project timeline will be provided during the consultation phase, considering factors such as specific material sourcing and bespoke component fabrication. We maintain transparent communication throughout the entire process, providing regular updates on manufacturing progress and shipping status.

Warranty and Quality Assurance: Beibu Cleaner stands firmly behind the quality and performance of every 5XPG-5 Polishing Machine. Each unit is backed by a comprehensive 12-month warranty from the date of commissioning or 18 months from the date of shipment, whichever comes first. This warranty covers manufacturing defects and material failures under normal operating conditions. Beyond the warranty period, we offer readily available spare parts and technical support to ensure your investment continues to operate efficiently for decades. Our commitment to ISO 9001 quality management systems underscores our dedication to manufacturing excellence and customer satisfaction, providing verifiable assurance that our grain polishing machine meets the highest global standards. This commitment ensures the long-term reliability and value of your polisher.

Our authorized service technicians are equipped to provide on-site diagnostics, repairs, and preventative maintenance, ensuring minimal downtime and maximizing the operational lifespan of your equipment. This extensive support network, combined with our rigorous testing protocols, ensures that the rice polisher price you pay is an investment in long-term reliability and exceptional performance.

Further Reading and Industry Insights

For those looking to delve deeper into the science and economics of grain processing and polishing, we recommend exploring the following authoritative sources. These publications and forums provide valuable insights into industry best practices, emerging technologies, and market trends that influence the development and adoption of advanced equipment like the 5XPG-5 Polishing Machine. Staying informed about the latest research and developments is crucial for optimizing your grain processing operations and making strategic investments in technologies such as the polisher.

- Journal of Food Engineering - Elsevier ScienceDirect

A leading peer-reviewed journal publishing original research and reviews on food process engineering, including post-harvest technologies and grain processing. - Cereal Foods World - American Association of Cereal Chemists (AACC International)

Offers practical, relevant content on all aspects of cereal science and technology, including articles on grain cleaning, milling, and quality improvement processes. - Grain Journal / Grainnet.com

A prominent industry publication and online platform providing news, market analysis, and technical articles for grain handling and processing professionals. It often features insights on equipment innovations and operational best practices for facilities utilizing a polishing machine.

Jul. 24, 2024

Beibu Machinery-Bean production line installed

Dec. 02, 2024

big capacity beans cleaning line

Mar. 20, 2024

Sesame and Soybean Beans Cleaning Machine Installed-Hebei Beibu Machinery Technology Co.,LTD

Jan. 10, 2025

Assisting the development of grains

May. 07, 2024

Soybean Oil Expeller-Hebei Beibu Machinery Technology Co.,LTD

Mar. 26, 2024

Beans Cleaning Machine Magnetic Separator-Hebei Beibu Machinery Technology CO.,LTD

Beibu Machinery

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.